Virtual Sensors for Estimating District Heating Energy Consumption under Sensor Absences in a Residential Building

Abstract

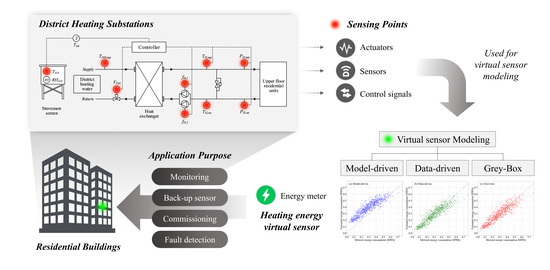

:1. Introduction

1.1. District Heating Systems in a Building

1.2. Virtual Sensing Technologies in Building Energy Systems

1.3. Literature Review and Limitations

- The estimation models for the DH states and variables were usually proposed for the DH networks or primary sides without the relationships with the demand side of a terminal building (such as a multiunit building).

- Limited studies have been conducted on virtual sensors regarding the DH energy consumption.

- Previous studies typically involved laboratory experimental setups (because it is difficult to obtain various operational datasets in a real DH substation or to perform sensing in actual buildings).

- Key sensors for system control are usually installed or managed in real systems. The absence of sensors makes it difficult (or impossible) to develop virtual sensors.

- The previous methods were usually evaluated under testing conditions that are similar to the training datasets used or under representative operative conditions. This is because it is difficult to obtain various testing datasets in the development of building-level virtual sensors. In this situation, the way to define the different operation patterns or several testing conditions should be proposed to determine the better virtual sensor under the limited data and sensing environments.

1.4. Purpose and Contributions

2. Methods

2.1. System Description

2.2. Gathering Operational Datasets under the Sensor Absences of DHS

2.3. Virtual Sensor Development Process under Sensor Absences

2.4. Virtual Sensor Modeling

2.5. Determining Testing Conditions Using a Clustering Method

3. Results and Discussion

3.1. Clustering Results

3.2. Results of Training for the Virtual Sensors

3.3. Comparison between Data-Driven and Grey-Box Virtual Sensors (Test Condition 1)

3.4. Data-Driven Virtual Sensor vs. Grey-Box Virtual Sensor under Different Testing Conditions (Test Conditions 2 and 3)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| BAS | build automation system |

| DHS | district heating system |

| DPV | differential pressure valve |

| FDD | fault detection and diagnosis |

| LPM | liter per minute |

| MAE | mean absolute error |

| MLP | multi-layer perceptron |

| RAE | relative absolute error |

| RMSE | root mean square error |

| RPM | revolutions per minute |

| TCV | temperature control valve |

| VRF | variable refrigerant flow |

| Greek Symbols | |

| regressed coefficient of polynomial | |

| centroid of cluster | |

| Symbols | |

| a | actual (true) value |

| mean of actual value | |

| Cp | specific heat |

| e | estimated value |

| f | pump control signal (frequency) |

| k | number of clusters |

| M | mass flow rate |

| n | general counter |

| P | pressure |

| Q | Energy consumption |

| RH | relative humidity |

| Si | ith cluster |

| T | temperature |

| t | time step |

| V | TCV opening rate in the primary side |

| Subscripts | |

| Data | data-driven |

| meter | metered heating consumption from heat demand side |

| design | design information |

| DH | secondary section |

| env | environmental information |

| Grey | grey-box |

| H | primary section |

| Meter | meter measurement |

| Model | model-driven |

| OA | outdoor air |

| ret | return side |

| sup | supply side |

| sys | system information |

| VS | virtual sensor model |

References

- Zhang, Q.; Tian, Z.; Ma, Z.; Li, G.; Lu, Y.; Niu, J. Development of the heating load prediction model for the residential building of district heating based on model calibration. Energy 2020, 205, 117949. [Google Scholar] [CrossRef]

- Gao, L.; Cui, X.; Ni, J.; Lei, W.; Huang, T.; Bai, C.; Yang, J. Technologies in smart district heating system. Energy Procedia 2017, 142, 1829–1834. [Google Scholar] [CrossRef]

- Li, H.; Yu, D.; Braun, J.E. A review of virtual sensing technology and application in building systems. HVAC R Res. 2011, 17, 619–645. [Google Scholar]

- Choi, Y.; Yoon, S. Virtual sensor-assisted in situ sensor calibration in operational HVAC systems. Build. Environ. 2020, 181, 107079. [Google Scholar] [CrossRef]

- Sun, J.; Dong, J.; Shen, B.; Li, W. Virtual pressure sensor for electronic expansion valve control in a vapor compression refrigeration system. Energies 2020, 13, 4917. [Google Scholar] [CrossRef]

- Qian, M.; Yan, D.; Liu, H.; Berardi, U.; Liu, Y. Power consumption and energy efficiency of VRF system based on large scale monitoring virtual sensors. Build. Simul. 2020, 13, 1145–1156. [Google Scholar] [CrossRef]

- Cheung, H.; Braun, J.E. Virtual power consumption and cooling capacity virtual sensors for rooftop units. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 9–12 July 2014. [Google Scholar]

- Fang, T.; Lahdelma, R. State estimation of district heating network based on customer measurements. Appl. Therm. Eng. 2014, 73, 1211–1221. [Google Scholar] [CrossRef]

- Sajjadi, S.; Shamshirband, S.; Alizamir, M.; Yee, P.L.; Mansor, Z.; Manaf, A.A.; Altameem, T.A.; Mostafaeipour, A. Extreme learning machine for prediction of heat load in district heating systems. Energy Build. 2016, 122, 222–227. [Google Scholar] [CrossRef]

- Guo, Y.; Li, G.; Chen, H.; Hu, Y.; Shen, L.; Li, H.; Hu, M.; Li, J. Development of a virtual variable-speed compressor power sensor for variable refrigerant flow air conditioning system. Int. J. Refrig. 2017, 74, 73–85. [Google Scholar] [CrossRef]

- Ploennigs, J.; Ahmed, A.; Hensel, B.; Stack, P.; Menzel, K. Virtual sensors for estimation of energy consumption and thermal comfort in buildings with underfloor heating. Adv. Eng. Inform. 2011, 25, 688–698. [Google Scholar] [CrossRef]

- Zhang, Z.L. Temperature Control Strategies for Radiant Floor Heating Systems. Master’s Thesis, Concordia University, Montreal, QC, Canada, 2001. [Google Scholar]

- Almeida, L.B. Handbook of Neural Computation; Oxford University Press: Oxford, UK, 1997. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Delving deep into rectifiers: Surpassing human-level performance on imagenet classification. In Proceedings of the International Conference on Computer Vision, ICCV, Santiago, Chile, 7–13 December 2015; pp. 1026–1034. [Google Scholar]

- Kingma, D.P.; Ba, J.L. Adam: A method for stochastic optimization. In Proceedings of the 3rd International Conference or Learning Representations, San Diego, CA, USA, 22 December 2015; pp. 1–15. [Google Scholar]

- Xue, P.; Zhou, Z.; Fang, X.; Chen, X.; Liu, L.; Liu, Y.; Liu, J. Fault detection and operation optimization in district heating substations based on data mining techniques. Appl. Energy 2017, 205, 926–940. [Google Scholar] [CrossRef]

- An, J.; Yan, D.; Hong, T. Clustering and statistical analyses of air-conditioning intensity and use patterns in residential buildings. Energy Build. 2018, 174, 214–227. [Google Scholar] [CrossRef]

- Bholowalia, P.; Kumar, A. EBK-Means: A clustering technique based on elbow method and k-means in WSN. Int. J. Comput. Appl. 2014, 105, 17–24. [Google Scholar]

| Training Parameters | Settings |

|---|---|

| Batch size/Epochs | 4/200 |

| Training/validation ratio | 85%/15% |

| Early stopping | Applied with 10 epochs patience rule |

| Bias neurons | Applied at an input layer and all hidden layers |

| Bias/kernal initialization | Zero/Kaiming [14] |

| Number of neurons | 14 (input layer)-64-64-64-1 (output layer) |

| Loss function | Mean squared error |

| Optimizer | Adam [15] |

| Training period | 01/01–01/31 (Hourly time step) |

| Regression Parameters | Settings |

|---|---|

| Function | Second-degree polynomial function |

| Number of coefficient | 3 |

| Domain/Range | Qmodel/Qmetered |

| Regression method | Least squares |

| Training period | 01/01–01/31 (Hourly time step) |

| Virtual Sensor | RMSE | MAE | RAE | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cluster ID | Cluster ID | Cluster ID | |||||||

| Severe | Moderate | Light | Severe | Moderate | Light | Severe | Moderate | Light | |

| Model-driven | 0.1043 | 0.11674 | 0.10023 | 0.09385 | 0.10778 | 0.9377 | 0.78595 | 1.33724 | 1.57397 |

| Data-driven | 0.058 | 0.05039 | 0.0397 | 0.04479 | 0.03823 | 0.03194 | 0.37509 | 0.47436 | 0.53615 |

| Grey-box | 0.05464 | 0.0463 | 0.03555 | 0.04164 | 0.03648 | 0.02681 | 0.34873 | 0.45261 | 0.44994 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, S.; Choi, Y.; Koo, J.; Hong, Y.; Kim, R.; Kim, J. Virtual Sensors for Estimating District Heating Energy Consumption under Sensor Absences in a Residential Building. Energies 2020, 13, 6013. https://doi.org/10.3390/en13226013

Yoon S, Choi Y, Koo J, Hong Y, Kim R, Kim J. Virtual Sensors for Estimating District Heating Energy Consumption under Sensor Absences in a Residential Building. Energies. 2020; 13(22):6013. https://doi.org/10.3390/en13226013

Chicago/Turabian StyleYoon, Sungmin, Youngwoong Choi, Jabeom Koo, Yejin Hong, Ryunhee Kim, and Joowook Kim. 2020. "Virtual Sensors for Estimating District Heating Energy Consumption under Sensor Absences in a Residential Building" Energies 13, no. 22: 6013. https://doi.org/10.3390/en13226013

APA StyleYoon, S., Choi, Y., Koo, J., Hong, Y., Kim, R., & Kim, J. (2020). Virtual Sensors for Estimating District Heating Energy Consumption under Sensor Absences in a Residential Building. Energies, 13(22), 6013. https://doi.org/10.3390/en13226013