Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects

Abstract

:1. Introduction

1.1. Methane as a Greenhouse Gas

1.2. Dairy Production as Important Source of Methane Emission

1.3. Opportunities in Biogas Production

1.4. Manure and Wheat Straw as Biogas Plant Feedstock

2. Materials and Methods

2.1. Biogas Production Efficiency from Substrates

2.2. Energetic and Economic Calculations

3. Results

3.1. Basic Characterization of Analyzed Dairy Farm

3.2. Methane Productivity Analysis

3.3. Energetic and Economic Calculations

4. Discussion

5. Conclusions

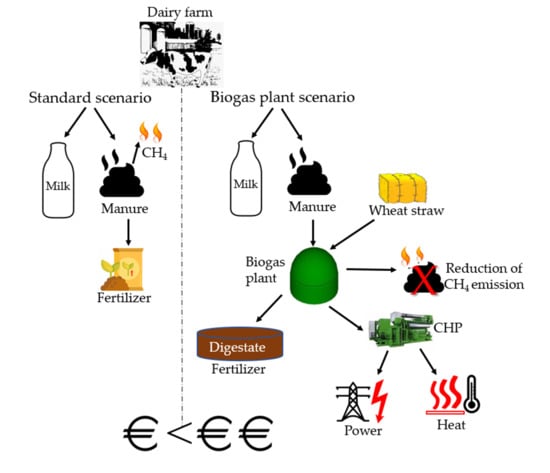

- Investment in a biogas plant operating at a dairy farm and using cow manure as one of the main substrates is a more profitable scenario than traditional dairy farming.

- Currently, in Polish conditions, a scenario with a biogas plant operating with a capacity of 500 kW brings 332,000 €/a more profit than a conventional scenario (only milk production), even when taking into account additional costs, including the purchase of straw to ensure the continuous operation of the installation (manure from 600 cows will not provide substrate coverage).

- In the analyzed case, the cost of building a biogas plant will pay off in less than six years. However, it is important to underline that this concerns the biogas plant with a power of 500 kW working with cow manure and wheat straw. Smaller-scale installations, as well as other substrates, can change this revenue time.

- The economic advantage of the dairy farm scenario with a biogas plant over the conventional variant will be even more significant if the European Commission introduces charges for methane emissions from agriculture (which will affect particular dairy farms that store manure in piles).

- It should be necessary to develop and conduct energetic and economic analyses for scenarios based on smaller size installations and alternative substrates (dairy waste, food-industry waste, etc.).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IPCC. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; p. 1535. Available online: https://www.ipcc.ch/report/ar5/wg1/ (accessed on 1 October 2020).

- IEA. World Energy Outlook. 2013. Available online: https://edgar.jrc.ec.europa.eu/overview.php?v=50_GHG (accessed on 1 October 2020).

- EEA. EEA Greenhouse Gas—Data Viewer. 2013. Available online: https://www.eea.europa.eu/ds_resolveuid/f4269fac-662f-4ba0-a416-c25373823292 (accessed on 1 October 2020).

- Cole, N.A.; Meyer, B.E.; Parker, D.B.; Neel, J.; Turner, K.E.; Northup, B.K.; Jennings, T.; Jennings, J.S. Effects of diet quality on energy metabolism and methane production by beef steers fed a warm-season grass-based hay diet. Appl. Anim. Sci. 2020, 36, 652–667. [Google Scholar] [CrossRef]

- EU 2030 Climate Target Plan Impact Assessment, Commission Staff Working Document Impact Assessment: Accompanying the Document Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions Stepping up Europe’s 2030 Climate Ambition Investing in a Climate-neutral Future for the Benefit of our People. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020SC0176 (accessed on 2 October 2020).

- EGD. Communication on The European Green Deal. 2016. Available online: https://ec.europa.eu/info/publications/communication-european-green-deal_en (accessed on 2 October 2020).

- Matthews, C.; Crispie, F.; Lewis, E.; Reid, M.; O’Toole, P.W.; Cotter, P.D. The rumen microbiome: A crucial consideration when optimising milk and meat production and nitrogen utilisation efficiency. Gut Microbes 2019, 10, 115–132. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Downing, M.M.; Nejadhashemi, A.P.; Harrigan, T.; Woznicki, S.A. Climate change and livestock: Impacts, adaptation, and mitigation. Clim. Risk Manag. 2017, 16, 145–163. [Google Scholar] [CrossRef]

- Leytem, A.B.; Dungan, R.S.; Bjorneberg, D.L.; Koehn, A.C. Emissions of Ammonia, Methane, Carbon Dioxide, and Nitrous Oxide from Dairy Cattle Housing and Manure Management Systems. J. Environ. Qual. 2011, 40, 1383–1394. [Google Scholar] [CrossRef] [Green Version]

- Bryszak, M.; Szumacher-Strabel, M.; Huang, H.; Pawlak, P.; Lechniak, D.; Kołodziejski, P.; Yanza, Y.R.; Patra, A.K.; Váradyová, Z.; Cieslak, A. Lupinus angustifolius seed meal supplemented to dairy cow diet improves fatty acid composition in milk and mitigates methane production. Anim. Feed Sci. Technol. 2020, 267, 114590. [Google Scholar] [CrossRef]

- Benchaar, C.; Hassanat, F. Methane emissions of stored manure from dairy cows fed conventional or brown midrib corn silage. J. Dairy Sci. 2019, 102, 10632–10638. [Google Scholar] [CrossRef]

- Kolling, G.J.; Stivanin, S.C.B.; Gabbi, A.M.; Machado, F.S.; Ferreira, A.L.; Campos, M.M.; Tomich, T.R.; Cunha, C.S.; Dill, S.W.; Pereira, L.G.R.; et al. Performance and methane emissions in dairy cows fed oregano and green tea extracts as feed additives. J. Dairy Sci. 2018, 101, 4221–4234. [Google Scholar] [CrossRef]

- Lee, M.A.; Todd, A.; Sutton, M.A.; Chagunda, M.G.G.; Roberts, D.J.; Rees, R.M. A time-series of methane and carbon dioxide production from dairy cows during a period of dietary transition. Cogent Environ. Sci. 2017, 3, 1385693. [Google Scholar] [CrossRef]

- Aemiro, A.; Hanada, M.; Umetsu, K.; Nishida, T. The effect of Sunphenon 30S-O on methane emission, nutrient intake, digestibility and rumen fermentation. Anim. Feed Sci. Technol. 2016, 214, 34–43. [Google Scholar] [CrossRef]

- Gislon, G.; Colombini, S.; Borreani, G.; Crovetto, G.M.; Sandrucci, A.; Galassi, G.; Tabacco, E.; Rapetti, L. Milk production, methane emissions, nitrogen, and energy balance of cows fed diets based on different forage systems. J. Dairy Sci. 2020, 103, 8048–8061. [Google Scholar] [CrossRef]

- Wanapat, M.; Cherdthong, A.; Phesatcha, K.; Kang, S. Dietary sources and their effects on animal production and environmental sustainability. Anim. Nutr. 2015, 1, 96–103. [Google Scholar] [CrossRef] [PubMed]

- Knapp, J.R.; Laur, G.L.; Vadas, P.A.; Weiss, W.P.; Tricarico, J.M. Invited review: Enteric methane in dairy cattle production: Quantifying the opportunities and impact of reducing emissions. J. Dairy Sci. 2014, 97, 3231–3261. [Google Scholar] [CrossRef] [Green Version]

- Benchaar, C.; Hassanat, F. Frequency of diet delivery to dairy cows: Effect on nutrient digestion, rumen fermentation, methane production, nitrogen utilization, and milk production. J. Dairy Sci. 2020, 103, 7094–7109. [Google Scholar] [CrossRef] [PubMed]

- Bell, M.J.; Saunders, N.; Wilcox, R.H.; Homer, E.M.; Goodman, J.R.; Craigon, J.; Garnsworthy, P.C. Methane emissions among individual dairy cows during milking quantified by eructation peaks or ratio with carbon dioxide. J. Dairy Sci. 2014, 97, 6536–6546. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, T.; Mayne, C.S.; Gordon, F.G.; Porter, M.G.; Agnew, R.E.; Patterson, D.C.; Ferris, C.P.; Kilpatrick, D.J. Mitigation of enteric methane emissions through improving efficiency of energy utilization and productivity in lactating dairy cows. J. Dairy Sci. 2010, 93, 2630–2638. [Google Scholar] [CrossRef] [PubMed]

- Uddin, M.E.; Larson, R.A.; Wattiaux, M.A. Effects of dairy cow breed and dietary forage on greenhouse gas emissions from manure during storage and after field application. J. Clean. Prod. 2020, 270, 122461. [Google Scholar] [CrossRef]

- Wattiaux, M.A.; Uddin, M.E.; Letelier, P.; Jackson, R.D.; Larson, R.A. INVITED REVIEW: Emission and mitigation of greenhouse gases from dairy farms: The cow, the manure, and the field. Appl. Anim. Sci. 2019, 35, 238–254. [Google Scholar] [CrossRef]

- Xue, B.; Wang, L.Z.; Yan, T. Methane emission inventories for enteric fermentation and manure management of yak, buffalo and dairy and beef cattle in China from 1988 to 2009. Agric. Ecosyst. Environ. 2014, 195, 202–210. [Google Scholar] [CrossRef]

- Kozłowski, K.; Dach, J.; Lewicki, A.; Malińska, K.; Do Carmo, I.E.P.; Czekała, W. Potential of biogas production from animal manure in Poland. Arch. Environ. Prot. 2019, 45, 99–108. [Google Scholar] [CrossRef]

- Thiruvenkatachari, R.R.; Carranza, V.; Ahangar, F.; Marklein, A.; Hopkins, F.; Venkatram, A. Uncertainty in using dispersion models to estimate methane emissions from manure lagoons in dairies. Agric. For. Meteorol. 2020, 290, 108011. [Google Scholar] [CrossRef]

- VanderZaag, A.C.; Flesch, T.K.; Desjardins, R.L.; Baldé, H.; Wright, T. Measuring methane emissions from two dairy farms: Seasonal and manure-management effects. Agric. For. Meteorol. 2014, 194, 259–267. [Google Scholar] [CrossRef]

- Ma, G.; Ndegwa, P.; Harrison, J.H.; Chen, Y. Methane yields during anaerobic co-digestion of animal manure with other feedstocks: A meta-analysis. Sci. Total Environ. 2020, 728, 138224. [Google Scholar] [CrossRef] [PubMed]

- Jafari-Sejahrood, A.; Najafi, B.; Faizollahzadeh Ardabili, S.; Shamshirband, S.; Mosavi, A.; Chau, K. wing Limiting factors for biogas production from cow manure: Energo-environmental approach. Eng. Appl. Comput. Fluid Mech. 2019, 13, 954–966. [Google Scholar] [CrossRef] [Green Version]

- Ding, L.; Lu, Q.; Xie, L.; Liu, J.; Cao, W.; Shi, Z.; Li, B.; Wang, C.; Zhang, G.; Ren, S. Greenhouse gas emissions from dairy open lot and manure stockpile in northern China: A case study. J. Air Waste Manag. Assoc. 2016, 66, 267–279. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, J.; Duan, C.; Ji, Y.; Sun, Y. Methane emissions during storage of different treatments from cattle manure in Tianjin. J. Environ. Sci. 2010, 22, 1564–1569. [Google Scholar] [CrossRef]

- Zhang, N.; Bai, Z.; Ledgard, S.; Luo, J.; Ma, L. Ammonia mitigation effects from the cow housing and manure storage chain on the nitrogen and carbon footprints of a typical dairy farm system on the North China Plain. J. Clean. Prod. 2021, 280, 124465. [Google Scholar] [CrossRef]

- Flesch, T.K.; Desjardins, R.L.; Worth, D. Fugitive methane emissions from an agricultural biodigester. Biomass Bioenergy 2011, 35, 3927–3935. [Google Scholar] [CrossRef]

- Díaz-Vázquez, D.; Alvarado-Cummings, S.C.; Meza-Rodríguez, D.; Senés-Guerrero, C.; de Anda, J.; Gradilla-Hernández, M.S. Evaluation of biogas potential from livestock manures and multicriteria site selection for centralized anaerobic digester systems: The case of Jalisco, Mexico. Sustainability 2020, 12, 3527. [Google Scholar] [CrossRef]

- Feng, L.; Ward, A.J.; Moset, V.; Møller, H.B. Methane emission during on-site pre-storage of animal manure prior to anaerobic digestion at biogas plant: Effect of storage temperature and addition of food waste. J. Environ. Manag. 2018, 225, 272–279. [Google Scholar] [CrossRef]

- Wang, Q.; Thompson, E.; Parsons, R.; Rogers, G.; Dunn, D. Economic feasibility of converting cow manure to electricity: A case study of the CVPS Cow Power program in Vermont. J. Dairy Sci. 2011, 94, 4937–4949. [Google Scholar] [CrossRef] [Green Version]

- Massé, D.I.; Jarret, G.; Hassanat, F.; Benchaar, C.; Saady, N.M.C. Effect of increasing levels of corn silage in an alfalfa-based dairy cow diet and of manure management practices on manure fugitive methane emissions. Agric. Ecosyst. Environ. 2016, 221, 109–114. [Google Scholar] [CrossRef]

- Sommer, S.G.; Petersen, S.O.; Søgaard, H.T. Greenhouse Gas Emission from Stored Livestock Slurry. J. Environ. Qual. 2000, 29, 744–751. [Google Scholar] [CrossRef]

- VanderZaag, A.; Amon, B.; Bittman, S.; Kuczyński, T. Ammonia Abatement with Manure Storage and Processing Techniques. In Costs of Ammonia Abatement and the Climate Co-Benefits; Springer: Berlin/Heidelberg, Germany; Dordrecht, The Netherlands, 2015; pp. 75–112. [Google Scholar] [CrossRef]

- Hindrichsen, I.K.; Wettstein, H.R.; Machmüller, A.; Kreuzer, M. Methane emission, nutrient degradation and nitrogen turnover in dairy cows and their slurry at different milk production scenarios with and without concentrate supplementation. Agric. Ecosyst. Environ. 2006, 113, 150–161. [Google Scholar] [CrossRef]

- Kupper, T.; Häni, C.; Neftel, A.; Kincaid, C.; Bühler, M.; Amon, B.; VanderZaag, A. Ammonia and greenhouse gas emissions from slurry storage—A review. Agric. Ecosyst. Environ. 2020, 300, 106963. [Google Scholar] [CrossRef]

- Browne, J.D.; Gilkinson, S.R.; Frost, J.P. The effects of storage time and temperature on biogas production from dairy cow slurry. Biosyst. Eng. 2015, 129, 48–56. [Google Scholar] [CrossRef]

- Luo, T.; Khoshnevisan, B.; Huang, R.; Chen, Q.; Mei, Z.; Pan, J.; Liu, H. Analysis of revolution in decentralized biogas facilities caused by transition in Chinese rural areas. Renew. Sustain. Energy Rev. 2020, 133, 110133. [Google Scholar] [CrossRef]

- Garcia, N.H.; Mattioli, A.; Gil, A.; Frison, N.; Battista, F.; Bolzonella, D. Evaluation of the methane potential of different agricultural and food processing substrates for improved biogas production in rural areas. Renew. Sustain. Energy Rev. 2019, 112, 1–10. [Google Scholar] [CrossRef]

- Zemo, K.H.; Panduro, T.E.; Termansen, M. Impact of biogas plants on rural residential property values and implications for local acceptance. Energy Policy 2019, 129, 1121–1131. [Google Scholar] [CrossRef]

- Korberg, A.D.; Skov, I.R.; Mathiesen, B.V. The role of biogas and biogas-derived fuels in a 100% renewable energy system in Denmark. Energy 2020, 199, 117426. [Google Scholar] [CrossRef]

- Rosa, A.P.; Chernicharo, C.A.L.; Lobato, L.C.S.; Silva, R.V.; Padilha, R.F.; Borges, J.M. Assessing the potential of renewable energy sources (biogas and sludge) in a full-scale UASB-based treatment plant. Renew. Energy 2018, 124, 21–26. [Google Scholar] [CrossRef]

- RED I. Renewable Energy—Recast to 2030 (RED II) EU Science Hub. 2013. Available online: https://ec.europa.eu/jrc/en/jec/renewable-energy-recast-2030-red-ii (accessed on 10 October 2020).

- Kozłowski, K.; Pietrzykowski, M.; Czekała, W.; Dach, J.; Kowalczyk-Juśko, A.; Jóźwiakowski, K.; Brzoski, M. Energetic and economic analysis of biogas plant with using the dairy industry waste. Energy 2019, 183, 1023–1031. [Google Scholar] [CrossRef]

- Lauer, M.; Hansen, J.K.; Lamers, P.; Thrän, D. Making money from waste: The economic viability of producing biogas and biomethane in the Idaho dairy industry. Appl. Energy 2018, 222, 621–636. [Google Scholar] [CrossRef]

- McVoitte, W.P.A.; Clark, O.G. The effects of temperature and duration of thermal pretreatment on the solid-state anaerobic digestion of dairy cow manure. Heliyon 2019, 5, e02140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Klavon, K.H.; Lansing, S.A.; Mulbry, W.; Moss, A.R.; Felton, G. Economic analysis of small-scale agricultural digesters in the United States. Biomass Bioenergy 2013, 54, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Klootwijk, C.W.; Van Middelaar, C.E.; Berentsen, P.B.M.; de Boer, I.J.M. Dutch dairy farms after milk quota abolition: Economic and environmental consequences of a new manure policy. J. Dairy Sci. 2016, 99, 8384–8396. [Google Scholar] [CrossRef] [Green Version]

- Vergote, T.L.I.; Bodé, S.; De Dobbelaere, A.E.J.; Buysse, J.; Meers, E.; Volcke, E.I.P. Monitoring methane and nitrous oxide emissions from digestate storage following manure mono-digestion. Biosyst. Eng. 2020, 196, 159–171. [Google Scholar] [CrossRef]

- Khayum, N.; Anbarasu, S.; Murugan, S. Biogas potential from spent tea waste: A laboratory scale investigation of co-digestion with cow manure. Energy 2018, 165, 760–768. [Google Scholar] [CrossRef]

- Vanden Nest, T.; Amery, F.; Fryda, L.; Boogaerts, C.; Bilbao, J.; Vandecasteele, B. Renewable P sources: P use efficiency of digestate, processed animal manure, compost, biochar and struvite. Sci. Total Environ. 2021, 750, 141699. [Google Scholar] [CrossRef]

- Iocoli, G.A.; Zabaloy, M.C.; Pasdevicelli, G.; Gómez, M.A. Use of biogas digestates obtained by anaerobic digestion and co-digestion as fertilizers: Characterization, soil biological activity and growth dynamic of Lactuca sativa L. Sci. Total Environ. 2019, 647, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Ehmann, A.; Bach, I.M.; Bilbao, J.; Lewandowski, I.; Müller, T. Phosphates recycled from semi-liquid manure and digestate are suitable alternative fertilizers for ornamentals. Sci. Hortic. 2019, 243, 440–450. [Google Scholar] [CrossRef]

- Czekała, W.; Bartnikowska, S.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kozłowski, K.; Bugała, A.; Lewicki, A.; Cieślik, M.; Typańska, D.; et al. The energy value and economic efficiency of solid biofuels produced from digestate and sawdust. Energy 2018, 159, 1118–1122. [Google Scholar] [CrossRef]

- Czekała, W.; Lewicki, A.; Pochwatka, P.; Czekała, A.; Wojcieszak, D.; Jóźwiakowski, K.; Waliszewska, H. Digestate management in polish farms as an element of the nutrient cycle. J. Clean. Prod. 2020, 242, 118454. [Google Scholar] [CrossRef]

- Hung, C.Y.; Tsai, W.T.; Chen, J.W.; Lin, Y.Q.; Chang, Y.M. Characterization of biochar prepared from biogas digestate. Waste Manag. 2017, 66, 53–60. [Google Scholar] [CrossRef] [PubMed]

- Törnwall, E.; Pettersson, H.; Thorin, E.; Schwede, S. Post-treatment of biogas digestate-An evaluation of ammonium recovery, energy use and sanitation. In Proceedings of the Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 142, pp. 957–963. [Google Scholar] [CrossRef]

- Baral, K.R.; Labouriau, R.; Olesen, J.E.; Petersen, S.O. Nitrous oxide emissions and nitrogen use efficiency of manure and digestates applied to spring barley. Agric. Ecosyst. Environ. 2017, 239, 188–198. [Google Scholar] [CrossRef]

- Castro, L.; Escalante, H.; Jaimes-Estévez, J.; Díaz, L.J.; Vecino, K.; Rojas, G.; Mantilla, L. Low cost digester monitoring under realistic conditions: Rural use of biogas and digestate quality. Bioresour. Technol. 2017, 239, 311–317. [Google Scholar] [CrossRef] [PubMed]

- Maldaner, L.; Wagner-Riddle, C.; VanderZaag, A.C.; Gordon, R.; Duke, C. Methane emissions from storage of digestate at a dairy manure biogas facility. Agric. For. Meteorol. 2018, 258, 96–107. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, L.; Feng, L.; Sun, D.; Dang, Y. Comparison of varying operating parameters on heavy metals ecological risk during anaerobic co-digestion of chicken manure and corn stover. Bioresour. Technol. 2018, 247, 660–668. [Google Scholar] [CrossRef]

- Dahlin, J.; Herbes, C.; Nelles, M. Biogas digestate marketing: Qualitative insights into the supply side. Resour. Conserv. Recycl. 2015, 104, 152–161. [Google Scholar] [CrossRef]

- Marin-Batista, J.D.; Villamil, J.A.; Qaramaleki, S.V.; Coronella, C.J.; Mohedano, A.F.; de la Rubia, M.A. Energy valorization of cow manure by hydrothermal carbonization and anaerobic digestion. Renew. Energy 2020, 160, 623–632. [Google Scholar] [CrossRef]

- Møller, H.B.; Moset, V.; Brask, M.; Weisbjerg, M.R.; Lund, P. Feces composition and manure derived methane yield from dairy cows: Influence of diet with focus on fat supplement and roughage type. Atmos. Environ. 2014, 94, 36–43. [Google Scholar] [CrossRef]

- Li, Y.; Achinas, S.; Zhao, J.; Geurkink, B.; Krooneman, J.; Willem Euverink, G.J. Co-digestion of cow and sheep manure: Performance evaluation and relative microbial activity. Renew. Energy 2020, 153, 553–563. [Google Scholar] [CrossRef]

- Duan, N.; Khoshnevisan, B.; Lin, C.; Liu, Z.; Liu, H. Life cycle assessment of anaerobic digestion of pig manure coupled with different digestate treatment technologies. Environ. Int. 2020, 137, 105522. [Google Scholar] [CrossRef] [PubMed]

- Valentinuzzi, F.; Cavani, L.; Porfido, C.; Terzano, R.; Pii, Y.; Cesco, S.; Marzadori, C.; Mimmo, T. The fertilising potential of manure-based biogas fermentation residues: Pelleted vs. liquid digestate. Heliyon 2020, 6, e03325. [Google Scholar] [CrossRef] [PubMed]

- Igliński, B.; Buczkowski, R.; Iglińska, A.; Cichosz, M.; Piechota, G.; Kujawski, W. Agricultural biogas plants in Poland: Investment process, economical and environmental aspects, biogas potential. Renew. Sustain. Energy Rev. 2012, 16, 4890–4900. [Google Scholar] [CrossRef]

- Singh, P.; Singh, N. Political economy of bioenergy transitions in developing countries: A case study of Punjab, India. World Dev. 2019, 124, 104630. [Google Scholar] [CrossRef]

- Stürmer, B.; Leiers, D.; Anspach, V.; Brügging, E.; Scharfy, D.; Wissel, T. Agricultural biogas production: A regional comparison of technical parameters. Renew. Energy 2021, 164, 171–182. [Google Scholar] [CrossRef]

- Piwowar, A.; Dzikuć, M.; Adamczyk, J. Agricultural biogas plants in Poland-Selected technological, market and environmental aspects. Renew. Sustain. Energy Rev. 2016, 58, 69–74. [Google Scholar] [CrossRef]

- Gieseke, D.; Lambertz, C.; Gauly, M. Relationship between herd size and measures of animal welfare on dairy cattle farms with freestall housing in Germany. J. Dairy Sci. 2018, 101, 7397–7411. [Google Scholar] [CrossRef]

- Mazurkiewicz, J.; Marczuk, A.; Pochwatka, P.; Kujawa, S. Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding. Materials 2019, 12, 3848. [Google Scholar] [CrossRef] [Green Version]

- Kowalczyk-Juśko, A.; Pochwatka, P.; Zaborowicz, M.; Czekała, W.; Mazurkiewicz, J.; Mazur, A.; Janczak, D.; Marczuk, A.; Dach, J. Energy value estimation of silages for substrate in biogas plants using an artificial neural network. Energy 2020, 202, 117729. [Google Scholar] [CrossRef]

- Cieślik, M.; Dach, J.; Lewicki, A.; Smurzyńska, A.; Janczak, D.; Pawlicka-Kaczorowska, J.; Boniecki, P.; Cyplik, P.; Czekała, W.; Jóźwiakowski, K. Methane fermentation of the maize straw silage under meso- and thermophilic conditions. Energy 2016, 115, 1495–1502. [Google Scholar] [CrossRef]

- Dach, J.; Boniecki, P.; Przybył, J.; Janczak, D.; Lewicki, A.; Czekała, W.; Witaszek, K.; Rodríguez Carmona, P.C.; Cieślik, M. Energetic efficiency analysis of the agricultural biogas plant in 250 kWe experimental installation. Energy 2014, 69, 34–38. [Google Scholar] [CrossRef]

- Wandera, S.M.; Qiao, W.; Algapani, D.E.; Bi, S.; Yin, D.; Qi, X.; Liu, Y.; Dach, J.; Dong, R. Searching for possibilities to improve the performance of full scale agricultural biogas plants. Renew. Energy 2018, 116, 720–727. [Google Scholar] [CrossRef]

- Abraham, A.; Mathew, A.K.; Park, H.; Choi, O.; Sindhu, R.; Parameswaran, B.; Pandey, A.; Park, J.H.; Sang, B.I. Pretreatment strategies for enhanced biogas production from lignocellulosic biomass. Bioresour. Technol. 2020, 301, 122725. [Google Scholar] [CrossRef] [PubMed]

- Ramos-Suárez, J.L.; Gómez, D.; Regueiro, L.; Baeza, A.; Hansen, F. Alkaline and oxidative pretreatments for the anaerobic digestion of cow manure and maize straw: Factors influencing the process and preliminary economic viability of an industrial application. Bioresour. Technol. 2017, 241, 10–20. [Google Scholar] [CrossRef]

- Li, P.; He, C.; Li, G.; Ding, P.; Lan, M.; Gao, Z.; Jiao, Y. Biological pretreatment of corn straw for enhancing degradation efficiency and biogas production. Bioengineered 2020, 11, 251–260. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Victorin, M.; Davidsson, Å.; Wallberg, O. Characterization of Mechanically Pretreated Wheat Straw for Biogas Production. Bioenergy Res. 2020, 13, 833–844. [Google Scholar] [CrossRef] [Green Version]

- Yu, Q.; Liu, R.; Li, K.; Ma, R. A review of crop straw pretreatment methods for biogas production by anaerobic digestion in China. Renew. Sustain. Energy Rev. 2019, 107, 51–58. [Google Scholar] [CrossRef]

- Gallegos, D.; Wedwitschka, H.; Moeller, L.; Zehnsdorf, A.; Stinner, W. Effect of particle size reduction and ensiling fermentation on biogas formation and silage quality of wheat straw. Bioresour. Technol. 2017, 245, 216–224. [Google Scholar] [CrossRef]

- Feng, Y.; Zhao, X.; Guo, Y.; Yang, G.; Xi, J.; Ren, G. Changes in the material characteristics of maize straw during the pretreatment process of methanation. J. Biomed. Biotechnol. 2012, 2012. [Google Scholar] [CrossRef] [Green Version]

- Khoshnevisan, B.; Shafiei, M.; Rajaeifar, M.A.; Tabatabaei, M. Biogas and bioethanol production from pinewood pre-treated with steam explosion and N-methylmorpholine-N-oxide (NMMO): A comparative life cycle assessment approach. Energy 2016, 114, 935–950. [Google Scholar] [CrossRef]

- Marks, S.; Dach, J.; Morales, F.J.F.; Mazurkiewicz, J.; Pochwatka, P.; Gierz, Ł. New trends in substrates and biogas systems in Poland. J. Ecol. Eng. 2020, 21, 19–25. [Google Scholar] [CrossRef]

- Mainardis, M.; Flaibani, S.; Trigatti, M.; Goi, D. Techno-economic feasibility of anaerobic digestion of cheese whey in small Italian dairies and effect of ultrasound pre-treatment on methane yield. J. Environ. Manag. 2019, 246, 557–563. [Google Scholar] [CrossRef] [PubMed]

- DIN 38 414/S8. German Standard Methods for the Examination of Water, Waste Water and Sludge; Sludge and Sediments (Group S); Determination of the Amenability to Anaerobic Digestion (S 8); DIN Deutches Institut für Normung e. V.: Berlin, Germany, 2012. [Google Scholar]

- VDI 4630. Fermentation of Organic Materials. Characterization of the Substrate, Sampling, Collection of Material Data, Fermentation Tests; Verein Deutscher Ingenieure e.V.: Düsseldorf, Germany, 2016. [Google Scholar]

- Malik, W.; Mohan, C.; Annachhatre, A.P. Community based biogas plant utilizing food waste and cow dung. Mater. Today-Proc. 2020, 28, 1910–1915. [Google Scholar] [CrossRef]

- Fjørtoft, K.; Morken, J.; Hanssen, J.F.; Briseid, T. Methane production and energy evaluation of a farm scaled biogas plant in cold climate area. Bioresour. Technol. 2014, 169, 72–79. [Google Scholar] [CrossRef] [PubMed]

- Pham, C.H.; Vu, C.C.; Sommer, S.G.; Bruun, S. Factors affecting process temperature and biogas production in small-scale rural biogas digesters in winter in northern Vietnam. Asian-Australas. J. Anim. Sci. 2014, 27, 1050–1056. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Igliński, B.; Piechota, G.; Iwański, P.; Skarzatek, M.; Pilarski, G. 15 Years of the Polish agricultural biogas plants: Their history, current status, biogas potential and perspectives. Clean Technol. Environ. Policy 2020, 22, 281–307. [Google Scholar] [CrossRef]

- Chasnyk, O.; Sołowski, G.; Shkarupa, O. Historical, technical and economic aspects of biogas development: Case of Poland and Ukraine. Renew. Sustain. Energy Rev. 2015, 52, 227–239. [Google Scholar] [CrossRef]

- Achinas, S.; Willem Euverink, G.J. Rambling facets of manure-based biogas production in Europe: A briefing. Renew. Sustain. Energy Rev. 2020, 119, 109566. [Google Scholar] [CrossRef]

- Zareei, S. Evaluation of biogas potential from livestock manures and rural wastes using GIS in Iran. Renew. Energy 2018, 118, 351–356. [Google Scholar] [CrossRef]

- Hosseini Taleghani, A.; Lim, T.-T.; Lin, C.-H.; Ericsson, A.C.; Vo, P.H. Degradation of Veterinary Antibiotics in Swine Manure via Anaerobic Digestion. Bioengineering 2020, 7, 123. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, J.; Achinas, S.; Zhang, Z.; Krooneman, J.; Euverink, G.J.W. The biomethanation of cow manure in a continuous anaerobic digester can be boosted via a bioaugmentation culture containing Bathyarchaeota. Sci. Total Environ. 2020, 745, 141042. [Google Scholar] [CrossRef]

- Ahmed, S.; Einfalt, D.; Kazda, M. Co-Digestion of Sugar Beet Silage Increases Biogas Yield from Fibrous Substrates. Biomed Res. Int. 2016, 2016. [Google Scholar] [CrossRef] [Green Version]

- Koryś, K.A.; Latawiec, A.E.; Grotkiewicz, K.; Kuboń, M. The Review of Biomass Potential for Agricultural Biogas Production in Poland. Sustainability 2019, 11, 6515. [Google Scholar] [CrossRef] [Green Version]

- Zbytek, Z.; Dach, J.; Pawłowski, T.; Smurzyńska, A.; Czekała, W.; Janczak, D. Energy and economic potential of maize straw used for biofuels production. In MATEC Web of Conferences; EDP Sciences: Ullis, France, 2016; Volume 60, p. 4008. [Google Scholar] [CrossRef] [Green Version]

- Sieborg, M.U.; Jønson, B.D.; Larsen, S.U.; Vazifehkhoran, A.H.; Triolo, J.M. Co-Ensiling of Wheat Straw as an Alternative Pre-Treatment to Chemical, Hydrothermal and Mechanical Methods for Methane Production. Energies 2020, 13, 4047. [Google Scholar] [CrossRef]

- Ai, P.; Chen, M.; Ran, Y.; Jin, K.; Peng, J.; Abomohra, A.E.F. Digestate recirculation through co-digestion with rice straw: Towards high biogas production and efficient waste recycling. J. Clean. Prod. 2020, 263, 121441. [Google Scholar] [CrossRef]

- Siddique, M.N.I.; Wahid, Z.A. Achievements and perspectives of anaerobic co-digestion: A review. J. Clean. Prod. 2018, 194, 359–371. [Google Scholar] [CrossRef]

- Misson, G.; Mainardis, M.; Incerti, G.; Goi, D.; Peressotti, A. Preliminary evaluation of potential methane production from anaerobic digestion of beach-cast seagrass wrack: The case study of high-adriatic coast. J. Clean. Prod. 2020, 254, 120131. [Google Scholar] [CrossRef]

- Mainardis, M.; Flaibani, S.; Mazzolini, F.; Peressotti, A.; Goi, D. Techno-economic analysis of anaerobic digestion implementation in small Italian breweries and evaluation of biochar and granular activated carbon addition effect on methane yield. J. Environ. Chem. Eng. 2019, 7, 103184. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Price of milk | €/L | 0.29 |

| Milk production | L/LSU/a | 11,000 |

| Number of cows | LSU | 600 |

| Income from the sale of milk | €1000/a | 1925 |

| Manure weight | Mg/a | 9855 |

| Substrate | TS | VS | C:N Ratio | Biogas | CH4 Content | CH4 |

|---|---|---|---|---|---|---|

| [% FM] | [% TS] | [m3/Mg FM] | [%] | [m3/Mg FM] | ||

| Cow manure | 21.56 | 85.62 | 21:1 | 79.90 | 56.37 | 45.04 |

| Wheat straw | 92.67 | 96.96 | 95:1 | 468.49 | 56.72 | 265.72 |

| Parameter | Unit | Value |

|---|---|---|

| CH4 yield of manure | m3/Mg | 45.04 |

| Amount of methane | m3/a | 443,869 |

| Electric energy | MWh/a | 1770 |

| Electric power of the installation | MWe | 0.211 |

| Additional substrate: wheat straw | ||

| The mass of straw | Mg/a | 2300 |

| CH4 yield of straw | m3/Mg | 265.72 |

| Amount of methane | m3/a | 611,156 |

| Electric energy | MWh/a | 2437 |

| Electric power of the installation | MWe | 0.289 |

| Total amount of methane | m3/a | 1,055,025 |

| Total electric energy | MWh/a | 4207 |

| Total electric power | MWe | 0.500 |

| Electricity price | EUR/MWh | 158.3 |

| Electricity value | EUR/a | 666,044 |

| Amount of heat | MWh/a | 4732 |

| Amount of heat | GJ/a | 17,037 |

| Heat power | MW | 0.563 |

| Price for heat | EUR/GJ | 8.77 |

| Heat value | EUR/a | 134,500 |

| Parameter | Standard Scenario | Biogas Plant Scenario |

|---|---|---|

| Profits [kEUR/a] | ||

| Sold milk | 1925 | 1925 |

| Manure as fertilizer | 259 | |

| Digestate as fertilizer | 74 | |

| Electricity production | 666 | |

| Heat | 135 | |

| Costs [kEUR/a] | ||

| Straw cost | −76 | |

| Depreciation | −132 | |

| Service costs and others | −77 | |

| Balance | 2184 | 2516 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pochwatka, P.; Kowalczyk-Juśko, A.; Sołowiej, P.; Wawrzyniak, A.; Dach, J. Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects. Energies 2020, 13, 6058. https://doi.org/10.3390/en13226058

Pochwatka P, Kowalczyk-Juśko A, Sołowiej P, Wawrzyniak A, Dach J. Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects. Energies. 2020; 13(22):6058. https://doi.org/10.3390/en13226058

Chicago/Turabian StylePochwatka, Patrycja, Alina Kowalczyk-Juśko, Piotr Sołowiej, Agnieszka Wawrzyniak, and Jacek Dach. 2020. "Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects" Energies 13, no. 22: 6058. https://doi.org/10.3390/en13226058

APA StylePochwatka, P., Kowalczyk-Juśko, A., Sołowiej, P., Wawrzyniak, A., & Dach, J. (2020). Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects. Energies, 13(22), 6058. https://doi.org/10.3390/en13226058