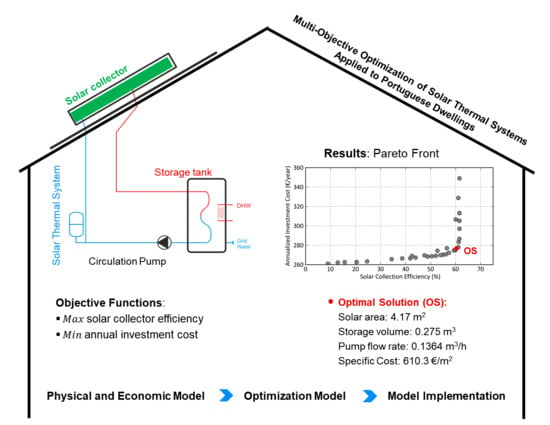

Multi-Objective Optimization of Solar Thermal Systems Applied to Portuguese Dwellings

Abstract

:1. Introduction

1.1. Technology Background

1.2. Brief Literature Review

2. Materials and Methods

2.1. Solar Radiation in Portugal

2.2. Typical DHW Consumption Profile of Portuguese Dwellings

2.3. Solar Thermal System Description and Physical Model

2.4. Economic Model Definition

2.4.1. Solar Collector Cost Equation

2.4.2. Circulation Pump Cost Equation

2.4.3. Storage Tank Cost Equation

3. Optimization Model

3.1. Definition of Objective Function, Decision Variables and Constraints

3.2. Optimization Algorithm

4. Results and Discussion

4.1. Main Results

4.2. Sensitivity Analysis

5. Main Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Visa, I.; Duta, A.; Moldovan, M.; Burduhos, B.; Neagoe, M. Solar Energy Conversion Systems in the Built Environment; Green Energy and Technology; Springer International Publishing: Cham, Germany, 2020; pp. 327–339. [Google Scholar]

- Lebeña, E.P.; Costa, J.C. Instaladores de Equipamentos Solares térmicos. In Conversão Térmica da Energia Solar; Sociedade Portuguesa de Energia Solar: Lisbon, Portugal, 2008; pp. 1–89. [Google Scholar]

- Paulescu, M.; Paulescu, E.; Gravila, P.; Badescu, V. Weather Modeling and Forecasting of PV Systems Operation; Springer: London, UK, 2013; Volume 103, pp. 127–179. [Google Scholar]

- Tsalikis, G.; Martinopoulos, G. Solar energy systems potential for nearly net zero energy residential buildings. Sol. Energy 2015, 115, 743–756. [Google Scholar] [CrossRef]

- Islam, M.; Morimoto, T. Advances in low to medium temperature non-concentrating solar thermal technology. Renew. Sustain. Energy Rev. 2018, 82, 2066–2093. [Google Scholar] [CrossRef]

- Karki, S.; Haapala, K.R.; Fronk, B.M. Technical and economic feasibility of solar flat-plate collector thermal energy systems for small and medium manufacturers. Appl. Energy 2019, 254, 113649. [Google Scholar] [CrossRef]

- Ramos, A.; Guarracino, I.; Mellor, A.; Alonso-álvarez, D.; Childs, P.; Ekins-daukes, N.J.; Markides, C.N. Solar-Thermal and Hybrid Photovoltaic-Thermal Systems for Renewable Heating; Imperial College: London, UK, 2017. [Google Scholar]

- Antoniadis, C.N.; Martinopoulos, G. Optimization of a building integrated solar thermal system with seasonal storage using TRNSYS. Renew. Energy 2019, 137, 56–66. [Google Scholar] [CrossRef]

- Araújo, A.; Silva, R.; Pereira, V. Solar thermal modeling for rapid estimation of auxiliary energy requirements in domestic hot water production: On-off versus proportional flow rate control. Sol. Energy 2019, 177, 68–79. [Google Scholar] [CrossRef]

- Martinopoulos, G.; Tsalikis, G. Diffusion and adoption of solar energy conversion systems—The case of Greece. Energy 2018, 144, 800–807. [Google Scholar] [CrossRef]

- Klein, S.; Beckman, W. A general design method for closed-loop solar energy systems. Sol. Energy 1979, 22, 269–282. [Google Scholar] [CrossRef]

- Chen, C.; Diao, Y.; Zhao, Y.; Wang, Z.; Liang, L.; Wang, T.; Zhu, T.; Ma, C. Thermal performance of a closed collector–storage solar air heating system with latent thermal storage: An experimental study. Energy 2020, 202, 117764. [Google Scholar] [CrossRef]

- Xiao, Q.; Cao, J.; Zhang, Y.; Li, L.; Xu, T.; Yuan, W. The application of solar-to-thermal conversion phase change material in novel solar water heating system. Sol. Energy 2020, 199, 484–490. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Designing and Modeling Solar Energy Systems. In Solar Energy Engineering; Elsevier BV: Amsterdam, The Netherlands, 2014; pp. 583–699. [Google Scholar]

- Kalogirou, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- Zeng, R.; Zhang, X.; Deng, Y.; Li, H.; Zhang, G. Optimization and performance comparison of combined cooling, heating and power/ground source heat pump/photovoltaic/solar thermal system under different load ratio for two operation strategies. Energy Convers. Manag. 2020, 208, 112579. [Google Scholar] [CrossRef]

- Assaf, J.; Shabani, B. Multi-objective sizing optimisation of a solar-thermal system integrated with a solar-hydrogen combined heat and power system, using genetic algorithm. Energy Convers. Manag. 2018, 164, 518–532. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, C. A review of solar collectors and thermal energy storage in solar thermal applications. Appl. Energy 2013, 104, 538–553. [Google Scholar] [CrossRef] [Green Version]

- Lin, W.; Ma, Z.; Ren, H.; Gschwander, S.; Wang, S. Multi-objective optimisation of thermal energy storage using phase change materials for solar air systems. Renew. Energy 2019, 130, 1116–1129. [Google Scholar] [CrossRef]

- Ong, K.S.; Tong, W.L. System Performance of U-Tube and Heat Pipe Solar Water Heaters. J. Appl. Sci. Eng. 2012, 15, 105–110. [Google Scholar]

- Marion, M.; Voicu, I.; Tiffonnet, A.-L. Study and optimization of a solar subcritical organic Rankine cycle. Renew. Energy 2012, 48, 100–109. [Google Scholar] [CrossRef]

- Yongga, A.; Li, N.; Long, J.; He, Y. Thermal performance of a novel solar thermal facade system in a hot-summer and cold-winter zone. Sol. Energy 2020, 204, 106–114. [Google Scholar] [CrossRef]

- Frattolillo, A.; Canale, L.; Ficco, G.; Mastino, C.C.; Dell’Isola, M. Potential for Building Façade-Integrated Solar Thermal Collectors in a Highly Urbanized Context. Energies 2020, 13, 5801. [Google Scholar] [CrossRef]

- Katsaprakakis, D.A.; Zidianakis, G.; Yiannakoudakis, Y.; Manioudakis, E.; Dakanali, I.; Kanouras, S. Working on Buildings’ Energy Performance Upgrade in Mediterranean Climate. Energies 2020, 13, 2159. [Google Scholar] [CrossRef]

- Artur, C.; Neves, D.; Cuamba, B.C.; Leão, A.J. Domestic hot water technology transition for solar thermal systems: An assessment for the urban areas of Maputo city, Mozambique. J. Clean. Prod. 2020, 260, 121043. [Google Scholar] [CrossRef]

- Košičan, J.; Picazo, M.; Ángel, P.; Vilcekova, S. A Multicriteria Methodology to Select the Best Installation of Solar Thermal Power in a Family House. Energies 2020, 13, 1047. [Google Scholar] [CrossRef] [Green Version]

- Sami, S.; Semmar, D.; Hamid, A.; Mecheri, R.; Yaiche, M. Viability of integrating Solar Water Heating systems into High Energy Performance housing in Algeria. Energy 2018, 149, 354–363. [Google Scholar] [CrossRef]

- Louvet, Y.; Fischer, S.; Furbo, S.; Giovannetti, F.; Helbig, S.; Köhl, M.; Mugnier, D.; Philippen, D.; Veynandt, F.; Vajen, K. Economic comparison of reference solar thermal systems for households in five European countries. Sol. Energy 2019, 193, 85–94. [Google Scholar] [CrossRef]

- Gautam, A.; Chamoli, S.; Kumar, A.; Singh, S. A review on technical improvements, economic feasibility and world scenario of solar water heating system. Renew. Sustain. Energy Rev. 2017, 68, 541–562. [Google Scholar] [CrossRef]

- Tschopp, D.; Tian, Z.; Berberich, M.; Fan, J.; Perers, B.; Furbo, S. Large-scale solar thermal systems in leading countries: A review and comparative study of Denmark, China, Germany and Austria. Appl. Energy 2020, 270, 114997. [Google Scholar] [CrossRef]

- Tsilingiridis, G.; Martinopoulos, G. Thirty years of domestic solar hot water systems use in Greece—Energy and environmental benefits—Future perspectives. Renew. Energy 2010, 35, 490–497. [Google Scholar] [CrossRef]

- Ferreira, A.C.; Nunes, M.; Teixeira, S.F.C.F.; Leão, C.P.; Silva, Â.M.; Teixeira, J.C.F.; Martins, L. An economic perspective on the optimisation of a small-scale cogeneration system for the Portuguese scenario. Energy 2012, 45, 436–444. [Google Scholar] [CrossRef]

- Ferreira, A.C.; Nunes, M.; Martins, L.; Teixeira, S.F.C.F. Maximum Profit of a Cogeneration System Based on Stirling Thermodynamic Cycle. In Proceedings of the 2014 14th International Conference on Computational Science and Its Applications, Guimaraes, Portugal, 30 June–3 July 2014; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2014; pp. 156–160. [Google Scholar]

- Cruz-Peragón, F.; Palomar, J.M.; Casanova, P.; Dorado, M.; Manzano-Agugliaro, F. Characterization of solar flat plate collectors. Renew. Sustain. Energy Rev. 2012, 16, 1709–1720. [Google Scholar] [CrossRef]

- Sharma, N.; Diaz, G. Performance model of a novel evacuated-tube solar collector based on minichannels. Sol. Energy 2011, 85, 881–890. [Google Scholar] [CrossRef]

- Mansour, M.K. Thermal analysis of novel minichannel-based solar flat-plate collector. Energy 2013, 60, 333–343. [Google Scholar] [CrossRef]

- Sahin, B.; Kodal, A. Performance analysis of an endoreversible heat engine based on a new thermoeconomic optimization criterion. Energy Convers. Manag. 2001, 42, 1085–1093. [Google Scholar] [CrossRef]

- Bejan, A.; Tsatsaronis, G.; Moran, M. Thermal Design and Optimization; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Yılmaz, I.H. Residential use of solar water heating in Turkey: A novel thermo-economic optimization for energy savings, cost benefit and ecology. J. Clean. Prod. 2018, 204, 511–524. [Google Scholar] [CrossRef]

- Asadi, J.; Amani, P.; Amani, M.; Kasaeian, A.; Bahiraei, M. Thermo-economic analysis and multi-objective optimization of absorption cooling system driven by various solar collectors. Energy Convers. Manag. 2018, 173, 715–727. [Google Scholar] [CrossRef]

- Cavaco, A.; Silva, H.; Canhoto, P.; Neves, S.; Neto, J.; Collares Pereira, M. Global Solar Radiation in Portugal and Its Variability, Monthly and Yearly; Institute of Earth Sciences: Evora, Portugal, 2016. [Google Scholar]

- Desempenho Energético dos Edifícios; DL 118/2013 Decreto-Lei n.o 118/2013; Diário da República: Portugal, 2013; Volume 159, pp. 4988–5005.

- Kumar, L.; Hasanuzzaman, M.; Rahim, N. Global advancement of solar thermal energy technologies for industrial process heat and its future prospects: A review. Energy Convers. Manag. 2019, 195, 885–908. [Google Scholar] [CrossRef]

- El Mkadmi, C.; Wahed, M.A. Optimization of a solar thermal system for low temperature industrial heating process. In Proceedings of the 2016 International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 14–17 November 2016; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2016; pp. 313–319. [Google Scholar]

- Menke, C.; Gebauer, M.; Jonas, D. Optimization of Large-scale Solar Thermal Systems for Student Dormitories in Germany. In Proceedings of the 49th Annual Conference of the Australian Solar Energy Society, Sydney, Australia, 1 December 2011. [Google Scholar]

- Belyakov, N. Solar energy. Sustainable Power Generation, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 417–438. [Google Scholar]

- Rao, P.; Francis, J.; Love, J.T. Two dimensional analysis of a flat-plate solar collector. In Proceedings of the 11th Thermophysics Conference, Atlanta, GA, USA, 16–20 June 2014; American Institute of Aeronautics and Astronautics (AIAA): Reston, VA, USA, 1976; pp. 1–4. [Google Scholar]

- Islam, M.; Morimoto, T. Performance Prediction of Solar Collector Adsorber Tube Temperature using a Nonlinear Autoregressive Model with eXogenous Input. Int. J. Comput. Appl. 2015, 114, 24–32. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, A.C.; Silva, A. Application of a costing methodology to estimate capital costs of solar thermal systems in residential Portuguese context. Int. J. Sustain. Energy Plan. Manag. 2020, 26, 33–46. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Tsatsaronis, G. SPECO: A systematic and general methodology for calculating efficiencies and costs in thermal systems. Energy 2006, 31, 1257–1289. [Google Scholar] [CrossRef]

- Tronchin, L.; Tommasino, M.C.; Fabbri, K. On the cost-optimal levels of energy-performance requirements for buildings: A case study with economic evaluation in Italy. Int. J. Sustain. Energy Plan. Manag. 2014, 3, 49–62. [Google Scholar] [CrossRef]

- Biegler, L.T.; Grossmann, I.E.; Westerberg, A.W. The Factorial Method of Cost Estimation; Physical and Chemical Engineering Sciences; Prentice Hall International: Upper Saddle River, NJ, USA, 1997. [Google Scholar]

- Ferreira, A.C.; Silva, A.M. Development of a costing methodology for solar thermal systems: Application to Portuguese scenario. In Proceedings of the 4th International Conference on Energy & Environment: Bringing together Engineering and Economics, Guimarães, Portugal, 16 May 2019; Paula Ferreira, U., Isabel Soares, F., Eds.; University of Minho: Guimarães, Portugal, 2019; pp. 64–70. [Google Scholar]

- Hachem, H.; Gheith, R.; Aloui, F.; Ben Nasrallah, S. Technological challenges and optimization efforts of the Stirling machine: A review. Energy Convers. Manag. 2018, 171, 1365–1387. [Google Scholar] [CrossRef]

- Attonaty, K.; Pouvreau, J.; Deydier, A.; Oriol, J.; Stouffs, P. Thermodynamic and economic evaluation of an innovative electricity storage system based on thermal energy storage. Renew. Energy 2020, 150, 1030–1036. [Google Scholar] [CrossRef]

- Rao, R.V.; Patel, V. Multi-objective optimization of heat exchangers using a modified teaching-learning-based optimization algorithm. Appl. Math. Model. 2013, 37, 1147–1162. [Google Scholar] [CrossRef]

- Ferreira, A.C.; Vaz, A.I.F.; Teixeira, S.F.; Teixeira, J.C. Thermal-economic design of a micro-gas turbine CHP system using a multi-objective optimization approach. In Proceedings of the PANACM 2015—1st Pan-American Congress on Computational Mechanics, in Conjunction with the 11th Argentine Congress on Computational Mechanics, MECOM 2015, Buenos Aires, Argentina, 27–29 April 2015. [Google Scholar]

- Ferreira, A.C.; Rocha, A.M.A.C.; Teixeira, S.F.C.F.; Nunes, M.; Martins, L. On Solving the Profit Maximization of Small Cogeneration Systems. In Proceedings of the Computer Vision—ECCV 2020; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2012; Volume 7335, pp. 147–158. [Google Scholar]

- Ferreira, A.C.; Silva, Â.M.; Teixeira, S.F.C.F. Multi-objective Optimization of Solar Thermal Systems Applied to Residential Building in Portugal. In Proceedings of the Computer Vision—ECCV 2020; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019; pp. 26–39. [Google Scholar]

- Valdés, M.; Durán, M.D.; Rovira, A. Thermoeconomic optimization of combined cycle gas turbine power plants using genetic algorithms. Appl. Therm. Eng. 2003, 23, 2169–2182. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Sayyaadi, H.; Mohammadi, A.H.; Barranco-Jimenez, M.A. Thermo-economic multi-objective optimization of solar dish-Stirling engine by implementing evolutionary algorithm. Energy Convers. Manag. 2013, 73, 370–380. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evolut. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef] [Green Version]

- MathWorks. Create genetic algorithm options structure 2018, 2014a edition. Available online: https://www.mathworks.com/help/gads/gaoptimset.html (accessed on 12 September 2018).

- Greenstream Publishing, Solar Electricity Handbook. Available online: http://www.solarelectricityhandbook.com/solar-irradiance.html (accessed on 1 January 2019).

- Vulcano Thermal Solar Systems Catalog Prices—Vulcano. 2017. Available online: www.vulcano.pt (accessed on 1 February 2017).

| Locations | GHI | GHI Variability |

|---|---|---|

| Guimarães (North) | 1600 kWh/m2 | 3% |

| Lisbon (Centre) | 1890 kWh/m2 | 4% |

| Faro (South) | 1950 kWh/m2 | 2% |

| Component | Parameter | Value |

|---|---|---|

| Solar collector | Reference cost coefficient, Cref, solar | 298.5 €/m2 |

| Reference collector area, A ref, solar | 2.50 m2 | |

| Sizing factor, bsolar | 0.5 | |

| Circulation Pump | Reference cost coefficient, Cref, pump | 322.5 €/(m3.h) |

| Reference flow rate, ref, pump | 0.98 m3/h | |

| Sizing factor, bpump | 0.3 | |

| Storage tank | Reference cost coefficient, Cref, storage | 3647.5 €/m3 |

| Reference storage volume, Vref, storage | 0.32 m3 | |

| Sizing factor, bstorage | 0.3 | |

| Thermal insulation correction factor, | 0.985 |

| Decision Variable | Minimum Value | Maximum Value |

|---|---|---|

| Solar collector linear coefficient loss, a1 | 3.684 W/m2.K | 3.692 W/m2.K |

| Solar collector area, Asolar | 4.00 m2 | 6.25 m2 |

| Storage tank volume, Vstorage | 0.203 m3 | 0.439 m3 |

| Physical Parameter | Value |

|---|---|

| Solar collector linear coefficient loss, a1 | 3.684 W/m2.K |

| Solar collector area, Asolar | 4.17 m2 |

| Storage tank volume, Vstorage | 0.275 m3 |

| Pump flow rate,pump | 0.1364 m3/h |

| Component | Purchase Cost | Relative Cost |

|---|---|---|

| Csolar | 1059.6 € |  |

| Cstorage | 1098.6 € | |

| Cpump | 174.9 € | |

| Cinstallation | 211.9 € | |

| Total purchasing cost | 2545.0 € |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, A.C.; Silva, A.; Teixeira, J.C.; Teixeira, S. Multi-Objective Optimization of Solar Thermal Systems Applied to Portuguese Dwellings. Energies 2020, 13, 6739. https://doi.org/10.3390/en13246739

Ferreira AC, Silva A, Teixeira JC, Teixeira S. Multi-Objective Optimization of Solar Thermal Systems Applied to Portuguese Dwellings. Energies. 2020; 13(24):6739. https://doi.org/10.3390/en13246739

Chicago/Turabian StyleFerreira, Ana Cristina, Angela Silva, José Carlos Teixeira, and Senhorinha Teixeira. 2020. "Multi-Objective Optimization of Solar Thermal Systems Applied to Portuguese Dwellings" Energies 13, no. 24: 6739. https://doi.org/10.3390/en13246739

APA StyleFerreira, A. C., Silva, A., Teixeira, J. C., & Teixeira, S. (2020). Multi-Objective Optimization of Solar Thermal Systems Applied to Portuguese Dwellings. Energies, 13(24), 6739. https://doi.org/10.3390/en13246739