Model Based IAS Analysis for Fault Detection and Diagnosis of IC Engine Powertrains

Abstract

:1. Introduction

- High signal to noise ratio (SNR);

- Being directly related to machine dynamics;

- Inexpensive transducers;

- Easy installation.

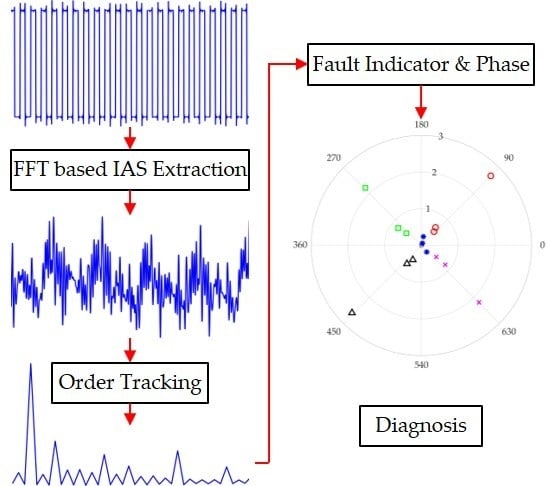

2. Torsional Vibration Measurements and Processing

2.1. Test Facilities of the Engine Powertrain

2.2. IAS Extraction

3. Torsional Model Development of the Powertrain

3.1. Torsional Model

3.2. Torque Simulation

3.3. Verification of the Torsional Model

4. Model Based Investigation

4.1. Simulation of Misfire Faults

4.2. Fault Detection and Diagnosis

5. Experimental Verification

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sharma, A.; Sugumaran, V.; Babu Devasenapati, S. Misfire detection in an IC engine using vibration signal and decision tree algorithms. Measurement 2014, 50, 370–380. [Google Scholar] [CrossRef]

- Tao, J.; Qin, C.; Li, W.; Liu, C. Intelligent Fault Diagnosis of Diesel Engines via Extreme Gradient Boosting and High-Accuracy Time–Frequency Information of Vibration Signals. Sensors 2019, 19, 3280. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, T.R.; Tan, A.C.; Ma, L.; Mathew, J. Condition monitoring and fault diagnosis of diesel engines using instantaneous angular speed analysis. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 304–315. [Google Scholar] [CrossRef] [Green Version]

- Charchalis, A.; Dereszewski, M.; Charchalis, A.; Dereszewski, M. Processing of Instantaneous Angular Speed Signal for Detection of a Diesel Engine Failure. Math. Probl. Eng. 2013, 2013, e659243. [Google Scholar] [CrossRef]

- Xie, J.; Chen, J.; Peng, Y.; Zi, Y. A New Concept of Instantaneous Whirling Speed for Cracked Rotor’s Axis Orbit. Appl. Sci. 2019, 9, 4120. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Gu, F.; Harris, G.; Ball, A.; Bennett, N.; Travis, K. The Measurement of Instantaneous Angular Speed. Mech. Syst. Signal Process. 2005, 19, 786–805. [Google Scholar] [CrossRef]

- Remond, D. Practical performances of high-speed measurement of gear transmission error or torsional vibrations with optical encoders. Meas. Sci. Technol. 1998, 9, 347. [Google Scholar] [CrossRef]

- Gu, F.; Yesilyurt, I.; Li, Y.; Harris, G.; Ball, A. An Investigation of the Effects of Measurement Noise in the Use of Instantaneous Angular Speed for Machine Diagnosis. Mech. Syst. Signal Process. 2006, 20, 1444–1460. [Google Scholar] [CrossRef]

- Jung, D.; Frisk, E.; Krysander, M. A flywheel error compensation algorithm for engine misfire detection. Control Eng. Pract. 2016, 47, 37–47. [Google Scholar] [CrossRef]

- Diamond, D.H.; Heyns, P.S.; Oberholster, A.J. Online shaft encoder geometry compensation for arbitrary shaft speed profiles using Bayesian regression. Mech. Syst. Signal Process. 2016, 81, 402–418. [Google Scholar] [CrossRef] [Green Version]

- Gubran, A.A.; Sinha, J.K. Shaft Instantaneous Angular Speed for Blade Vibration in Rotating Machine. Mech. Syst. Signal Process. 2014, 44, 47–59. [Google Scholar] [CrossRef]

- Gu, F.; Jacob, P.J.; Ball, A.D. Non-parametric models in the monitoring of engine performance and condition: Part 2: Non-intrusive estimation of diesel engine cylinder pressure and its use in fault detection. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 1999, 213, 135–143. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Bond Randall, R. Improved automated diagnosis of misfire in internal combustion engines based on simulation models. Mech. Syst. Signal Process. 2015, 64–65, 58–83. [Google Scholar] [CrossRef] [Green Version]

- Feldman, M.; Seibold, S. Damage Diagnosis of Rotors: Application of Hilbert Transform and Multihypothesis Testing. J. Vib. Control 1999, 5, 421–442. [Google Scholar] [CrossRef] [Green Version]

- Charles, P.; Sinha, J.K.; Gu, F.; Lidstone, L.; Ball, A.D. Detecting the Crankshaft Torsional Vibration of Diesel Engines for Combustion Related Diagnosis. J. Sound Vib. 2009, 321, 1171–1185. [Google Scholar] [CrossRef]

- Eriksson, D.; Eriksson, L.; Frisk, E.; Krysander, M. Flywheel angular velocity model for misfire and driveline disturbance simulation. IFAC Proc. Vol. 2013, 46, 570–575. [Google Scholar] [CrossRef]

- Boysal, A.; Rahnejat, H. Torsional vibration analysis of a multi-body single cylinder internal combustion engine model. Appl. Math. Model. 1997, 21, 481–493. [Google Scholar] [CrossRef]

- Mendes, A.S.; Meirelles, P.S.; Zampieri, D.E. Analysis of torsional vibration in internal combustion engines: Modelling and experimental validation. Proc. Inst. Mech. Eng. Part K J. Multi Body Dyn. 2008, 222, 155–178. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, K.; Ding, Q.; Gu, J.X. Engine Misfire Diagnosis Based on the Torsional Vibration of the Flexible Coupling in a Diesel Generator Set: Simulation and Experiment. J. Vib. Eng. Technol. 2019. [Google Scholar] [CrossRef]

| Technical Parameters | Key Specifications |

|---|---|

| Engine type | Diesel engine |

| Number of Cylinders | 4 |

| Firing order | 1-3-4-2 |

| Maximum torque | 425 Nm @ 1300 rpm |

| Maximum power | 74.2 kW @ 2200 rpm |

| Compression ratio | 18.3:1 |

| Equipment | Model | Key Specifications |

|---|---|---|

| Optical switch | OPB900W55Z | 70 ns |

| Magnetic pickup | IME12-02 BPSZ | 2 kHz |

| Cylinder pressure | Kistler 6125A | 15.8 pC/bar |

| DAQ device | YE6323 | 4 CH, 750 kHz |

| Test Cases | Speeds | Loads |

|---|---|---|

| Health condition | 1000 rpm 1300 rpm 1600 rpm | 0 Nm 105 Nm 201 Nm 315 Nm |

| Cylinder 1 misfire | 1200 rpm 1800 rpm | 0 Nm 105 Nm |

| Cylinder 1 misfire | 1200 rpm 1800 rpm | 0 Nm 105 Nm |

| - | - |

| Modal Order | Natural Frequency (Hz) |

|---|---|

| 1st | 25 |

| 2nd | 69.1 |

| 3rd | 275.2 |

| 4th | 511.7 |

| 5th | 1229.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Huang, B.; Yun, Y.; Cattley, R.; Gu, F.; Ball, A.D. Model Based IAS Analysis for Fault Detection and Diagnosis of IC Engine Powertrains. Energies 2020, 13, 565. https://doi.org/10.3390/en13030565

Xu Y, Huang B, Yun Y, Cattley R, Gu F, Ball AD. Model Based IAS Analysis for Fault Detection and Diagnosis of IC Engine Powertrains. Energies. 2020; 13(3):565. https://doi.org/10.3390/en13030565

Chicago/Turabian StyleXu, Yuandong, Baoshan Huang, Yuliang Yun, Robert Cattley, Fengshou Gu, and Andrew D. Ball. 2020. "Model Based IAS Analysis for Fault Detection and Diagnosis of IC Engine Powertrains" Energies 13, no. 3: 565. https://doi.org/10.3390/en13030565

APA StyleXu, Y., Huang, B., Yun, Y., Cattley, R., Gu, F., & Ball, A. D. (2020). Model Based IAS Analysis for Fault Detection and Diagnosis of IC Engine Powertrains. Energies, 13(3), 565. https://doi.org/10.3390/en13030565