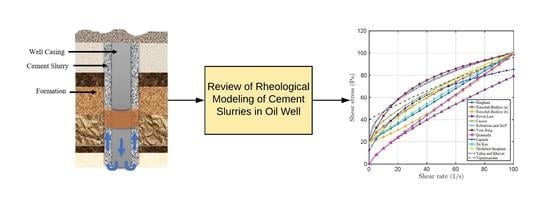

A Review of Rheological Modeling of Cement Slurry in Oil Well Applications

Abstract

:1. Introduction

2. Constitutive Modeling of Cement Slurries

- Physical factors, such as water-to-cement ratio, geometry of the cement grain (specific surface of cement particles) [38];

- Chemical and mineralogical factors, such as the cement type, its chemical composition, additive types, cement particle concentration in the mix, structural modifications after hydration [41];

- Mixing conditions, such as the type of blender/grinding condition, hydration time, storage/transport condition, curing temperature, stirrer rate, and time [38];

- Measurement conditions (experimental equipment and procedures).

2.1. Models for the Total Stress Tensor

2.2. The Importance of Yield Stress and Viscosity

2.2.1. Yield Stress Models

Effect of Concentration on the Yield Stress

Effect of Water-to-Cement Ratio on the Yield Stress

Effect of Additives/Admixtures on the Yield Stress

Effect of Damage on the Yield Stress

2.2.2. Viscosity Relationships

- Shear rate

- Volume Fraction

- Temperature

- Pressure P

- Thixotropic behavior (structural parameter )

- Water-to-cement ratio w/c

- Additives (Superplasticiser)

- Mixing method

- Electric field

- Magnetic field

- ….

Effect of Shear Rate on the Viscosity

Effect of Volume Fraction on the Viscosity

Effects of Temperature and Pressure on the Viscosity

Effect of Additives/Admixtures on the Viscosity

Effect of Water-to-Cement Ratio on the Viscosity

Effect of Mixing Method and the Wall Slip on the Viscosity

2.2.3. Thixotropic Nature of Cement

2.2.4. A New Model for Cement Slurry

3. Concluding Remarks

Supplementary Materials

Supplementary File 1Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Disclaimer

Appendix A. Cement Chemistry

Appendix B. Governing Equations of Motion and Heat Transfer

Appendix B.1. Single Component Approach

- Conservation of masswhere is the partial derivative with respect to time, is the divergence operator, and is the velocity vector, is the density of the slurry.

- Conservation of linear momentumwhere b is the body force vector, T is the Cauchy stress tensor, and is the total time derivative, given by .

- Conservation of angular momentumThis equation indicates that in the absence of couple stresses the stress tensor is symmetric.

- Convection-diffusion equation for the particleswhere is the particle flux, and is the particle volume fraction function or volume distribution (related to concentration), which is a continuous function of position, and time, where . In reality, at a particle and at a void space (fluid).

- Conservation of energywhere is the specific internal energy, is the gradient of velocity, is the heat flux vector, and r is the specific radiant energy. For complete thermodynamical considerations, the application of the second law of thermodynamics (or the entropy inequality), is also needed [264,265]:where is the specific entropy density, is the entropy flux, and s is the entropy supply density from external sources, and means the material time derivative of . If we assume that , and , where is the absolute temperature, Equation (A6) reduces to the more familiar form of the Clausius–Duhem inequality:

Appendix B.2. Multi-Phase (Component) Flow Approach

- Conservation of mass:where = 1, 2.

- Conservation of linear momentum

- Conservation of angular momentum

- Conservation of energy

- Entropywherefor any scalar , andfor any vector w, whereThe entropy inequality becomes:wherewhere is the density of the component, is the velocity vector, is the symmetric part of the velocity gradient, T is the stress tensor, represents the interaction forces, is the temperature, is the internal energy, r is the radiant heating, is the Helmholtz free energy , is the entropy per unit mass, q is the heat flux vector, and , and are the supply terms. is the symmetric part of the partial stress tensor , and is an anti-symmetric second-order tensor. The entropy inequality is used to impose certain restrictions on the types of motions and processes. Constitutive relations are required for , , , , and .

Appendix C. Computational Fluid Dynamics Studies

References

- Sabins, F.; Wiggins, M.L. Parametric study of gas entry into cemented wellbores. Oceanogr. Lit. Rev. 1998, 1, 182. [Google Scholar]

- Lootens, D.; Hébraud, P.; Lécolier, E.; Van Damme, H. Gelation, Shear-Thinning and Shear-Thickening in Cement Slurries. Oil Gas Sci. Technol. 2004, 59, 31–40. [Google Scholar] [CrossRef]

- Banfill, P.F. The rheology of fresh cement and concrete-a review. In Proceedings of the 11th International Cement Chemistry Congress, Durban, South Africa, 11–16 May 2003; Volume 1, pp. 50–62. [Google Scholar]

- Velayati, A.; Tokhmechi, B.; Soltanian, H.; Kazemzadeh, E. Cement slurry optimization and assessment of additives according to a proposed plan. J. Nat. Gas Sci. Eng. 2015, 23, 165–170. [Google Scholar] [CrossRef]

- Hodne, H.; Saasen, A.; O’Hagan, A.B.; Wick, S.O. Effects of time and shear energy on the rheological behaviour of oilwell cement slurries. Cem. Concr. Res. 2000, 30, 1759–1766. [Google Scholar] [CrossRef]

- Sabins, F.; Childs, J.D. Method of Using Thixotropic Cements for Combating Gas Migration Problems. U.S. Patent 4524828, 25 June 1985. [Google Scholar]

- Shahin, G.T., Jr. Method for Monitoring Well Cementing Operations. U.S. Patents 6125935, 3 October 2000. [Google Scholar]

- Vuk, T.; LjubicÏ-Mlakar, T.; GabrovsÏek, R.; KaucÏicÏ, V. Tertiary gelation of oilwell cement. Cem. Concr. Res. 2000, 30, 1709–1713. [Google Scholar] [CrossRef]

- Li, Z.; Vandenbossche, J.; Iannacchione, A.; Brigham, J.; Kutchko, B. Theory-Based Review of Limitations with Static Gel Strength in Cement/Matrix Characterization. SPE Drill. Complet. 2016, 31, 145–158. [Google Scholar] [CrossRef]

- Prohaska, M.; Ogbe, D.O.; Economides, M.J. Determining wellbore pressures in cement slurry columns. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 26–28 May 1993. [Google Scholar]

- Tao, C.; Kutchko, B.G.; Rosenbaum, E.; Wu, W.-T.; Massoudi, M. Steady Flow of a Cement Slurry. Energies 2019, 12, 2604. [Google Scholar] [CrossRef] [Green Version]

- Taylor, H.F. Cement Chemistry; Thomas Telford: London, UK, 1997; ISBN 0-7277-2592-0. [Google Scholar]

- Brothers, L.E.; Palmer, A.V. Cementing in Deep Water Offshore Wells. U.S. Patents 6835243, 28 December 2004. [Google Scholar]

- Scherer, G.W.; Funkhouser, G.P.; Peethamparan, S. Effect of pressure on early hydration of class H and white cement. Cem. Concr. Res. 2010, 40, 845–850. [Google Scholar] [CrossRef]

- American Petroleum Institute (API). 10B Recommended Practice for Testing Oil Well Cements and Cement Additives; American Petroleum Institute: Washington, DC, USA, 1997. [Google Scholar]

- Kumar, S.; Singh, C.J.; Singh, R.P.; Kachari, J. Microfine cement: Special superfine Portland cement. In Proceedings of the 7th NCB International Seminar, New Delhi, India, 30 April 2002. [Google Scholar]

- Saasen, A.; Rafoss, E.; Behzadi, A. Experimental investigation of rheology and thickening time of class G oil well cement slurries containing glycerin. Cem. Concr. Res. 1991, 21, 911–916. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F. Concrete; Prentice Hall: Englewood, NJ, USA, 1981. [Google Scholar]

- Vlachou, P.-V.; Piau, J.-M. Physicochemical study of the hydration process of an oil well cement slurry before setting. Cem. Concr. Res. 1999, 29, 27–36. [Google Scholar] [CrossRef]

- Frigaard, I.A.; Paso, K.G.; de Souza Mendes, P.R. Bingham’s model in the oil and gas industry. Rheol. Acta 2017, 56, 259–282. [Google Scholar] [CrossRef] [Green Version]

- Banfill, P.F.G. Rheology of fresh cement paste. In Annual Transactions of The Nordic Rheology Society; 1997; Available online: https://researchportal.hw.ac.uk/en/publications/rheology-of-fresh-cement-paste (accessed on 23 January 2020).

- Shahriar, A. Investigation on Rheology of Oil Well Cement Slurries. Ph.D. Dissertation, University of Western Ontario, London, ON, Canada, 2011. [Google Scholar]

- Rice, J.A.; Gu, C.; Li, C.; Guan, S. A radar-based sensor network for bridge displacement measurements. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2012, San Diego, CA, USA, 11–15 March 2012; Volume 8345, p. 83450I. [Google Scholar]

- Guan, S.; Rice, J.A.; Li, C.; Gu, C. Automated DC offset calibration strategy for structural health monitoring based on portable CW radar sensor. IEEE Trans. Instrum. Meas. 2014, 63, 3111–3118. [Google Scholar] [CrossRef]

- Guan, S.; Rice, J.A.; Li, C.; Li, Y.; Wang, G. Dynamic and static structural displacement measurement using backscattering DC coupled radar. Smart Struct. Syst. 2015, 16, 521–535. [Google Scholar] [CrossRef]

- Guan, S.; Rice, J.A.; Li, C.; Li, Y.; Wang, G. Structural displacement measurements using DC coupled radar with active transponder. Struct. Control Health Monit. 2017, 24, e1909. [Google Scholar] [CrossRef]

- Helsel, M.A.; Ferraris, C.F.; Bentz, D. Comparative study of methods to measure the density of Cementitious powders. J. Test. Eval. 2015, 44, 2147–2154. [Google Scholar] [CrossRef]

- Bentz, D.P.; Garboczi, E.J.; Haecker, C.J.; Jensen, O.M. Effects of cement particle size distribution on performance properties of Portland cement-based materials. Cem. Concr. Res. 1999, 29, 1663–1671. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar] [CrossRef]

- Schowalter, W.R. Mechanics of Non-Newtonian Fluids; Pergamon Press: Oxford, UK, 1978; ISBN 0-08-021778-8. [Google Scholar]

- Macosko, C.W.; Larson, R.G. Rheology: Principles, Measurements, and Applications; Wiley: Hoboken, NJ, USA, 1994. [Google Scholar]

- Bird, R.B.; Armstrong, R.C.; Hassager, O. Dynamics of Polymeric Liquids. Volume 1: Fluid Mechanics. 1987. Available online: https://inis.iaea.org/search/search.aspx?orig_q=RN:18088690 (accessed on 23 January 2020).

- Carreau, P.J.; De Kee, D.C.R.; Chhabra, R.P. Rheology of Polymeric Systems: Principles and Applications; Hanser Publishers: New York, NY, USA, 1997. [Google Scholar]

- Marchesini, F.H.; Oliveira, R.M.; Althoff, H.; de Souza Mendes, P.R. Irreversible time-dependent rheological behavior of cement slurries: Constitutive model and experiments. J. Rheol. 2019, 63, 247–262. [Google Scholar] [CrossRef]

- Shaughnessy, R.; Clark, P.E. The rheological behavior of fresh cement pastes. Cem. Concr. Res. 1988, 18, 327–341. [Google Scholar] [CrossRef]

- Wallevik, J.E. Thixotropic investigation on cement paste: Experimental and numerical approach. J. Non-Newton. Fluid Mech. 2005, 132, 86–99. [Google Scholar] [CrossRef]

- Rubio-Hernández, F.-J. Rheological Behavior of Fresh Cement Pastes. Fluids 2018, 3, 106. [Google Scholar] [CrossRef] [Green Version]

- Lapasin, R.; Papo, A.; Rajgelj, S. Flow behavior of fresh cement pastes. A comparison of different rheological instruments and techniques. Cem. Concr. Res. 1983, 13, 349–356. [Google Scholar] [CrossRef]

- Asaga, K.; Roy, D.M. Rheological properties of cement mixes: IV. Effects of superplasticizers on viscosity and yield stress. Cem. Concr. Res. 1980, 10, 287–295. [Google Scholar] [CrossRef]

- Barbic, L.; Tinta, V.; Lozar, B.; Marinkovic, V. Effect of Storage Time on the Rheological Behavior of Oil Well Cement Slurries. J. Am. Ceram. Soc. 1991, 74, 945–949. [Google Scholar] [CrossRef]

- Moore, F. The rheology of ceramic slip and bodies. Trans. Brit. Ceram. Soc. 1959, 58, 470–492. [Google Scholar]

- Ish-Shalom, M.; Greenberg, S.A. The Rheology of Fresh Portland Cement Pastes. 1960. Available online: https://trid.trb.org/view/102102 (accessed on 23 January 2020).

- Odler, I. Hydration, setting and hardening of Portland cement. LEA’s Chem. Cem. Concr. 1998, 4, 241–297. [Google Scholar]

- Bingham, E.C. Fluidity and Plasticity; McGraw-Hill: New York City, NY, USA, 1922; Volume 2. [Google Scholar]

- Atzeni, C.; Massidda, L.; Sanna, U. Comparison between rheological models for portland cement pastes. Cem. Concr. Res. 1985, 15, 511–519. [Google Scholar] [CrossRef]

- Robertson, R.E.; Stiff, H.A., Jr. An improved mathematical model for relating shear stress to shear rate in drilling fluids and cement slurries. Soc. Pet. Eng. J. 1976, 16, 31–36. [Google Scholar] [CrossRef]

- Macosko, C.W.; Krieger, I.M. Rheology: Principles, Measurements, and Applications. J. Colloid Interface Sci. 1996, 178, 382. [Google Scholar]

- Lootens, D.; Jousset, P.; Martinie, L.; Roussel, N.; Flatt, R.J. Yield stress during setting of cement pastes from penetration tests. Cem. Concr. Res. 2009, 39, 401–408. [Google Scholar] [CrossRef]

- Denn, M.M. Polymer Melt Processing: Foundations in Fluid Mechanics and Heat Transfer; Cambridge University Press: Cambridge, UK, 2008; ISBN 1-316-58314-7. [Google Scholar]

- White, J.L. Approximate constitutive equations for slow flow of rigid plastic viscoelastic fluids. J. Non-Newton. Fluid Mech. 1981, 8, 195–202. [Google Scholar] [CrossRef]

- Lipscomb, G.G.; Denn, M.M. Flow of Bingham fluids in complex geometries. J. Non-Newton. Fluid Mech. 1984, 14, 337–346. [Google Scholar] [CrossRef]

- Mendes, P.R.S.; Dutra, E.S. Viscosity function for yield-stress liquids. Appl. Rheol. 2004, 14, 296–302. [Google Scholar] [CrossRef]

- Herschel, W.H.; Bulkley, R. Measurement of consistency as applied to rubber-benzene solutions. Am. Soc. Test. Mater. 1926, 26, 621–633. [Google Scholar]

- Jones, T.E.R.; Taylor, S. A mathematical model relating the flow curve of a cement paste to its water/cement ratio. Mag. Concr. Res. 1977, 29, 207–212. [Google Scholar] [CrossRef]

- Choi, M.; Prud’homme, R.K.; Scherer, G. Rheological evaluation of compatibility in oil well cementing. Appl. Rheol. 2017, 27, 43354. [Google Scholar]

- Ostwald, W. Ueber die rechnerische Darstellung des Strukturgebietes der Viskosität. Colloid Polym. Sci. 1929, 47, 176–187. [Google Scholar] [CrossRef]

- Williamson, R.V. The flow of pseudoplastic materials. Ind. Eng. Chem. 1929, 21, 1108–1111. [Google Scholar] [CrossRef]

- Lapasin, R.; Papo, A.; Rajgelj, S. The phenomenological description of the thixotropic behaviour of fresh cement pastes. Rheol. Acta 1983, 22, 410–416. [Google Scholar] [CrossRef]

- Eyring, H. Viscosity, plasticity, and diffusion as examples of absolute reaction rates. J. Chem. Phys. 1936, 4, 283–291. [Google Scholar] [CrossRef]

- Sisko, A.W. The flow of lubricating greases. Ind. Eng. Chem. 1958, 50, 1789–1792. [Google Scholar] [CrossRef]

- Papo, A. Rheological models for cement pastes. Mater. Struct. 1988, 21, 41–46. [Google Scholar] [CrossRef]

- Casson, N. Rheology of disperse systems. In Proceedings of a Conference Organized by the British Society of Rheology; Perga-mon Press: New York, NY, USA, 1959. [Google Scholar]

- Kok, M.V.; Karakaya, G. Fluid migration and rheological properties of different origin G-class cements in oil well drilling applications. Int. J. Oil Gas Coal Technol. 2018, 19, 449–457. [Google Scholar] [CrossRef]

- Shangraw, R.; Grim, W.; Mattocks, A.M. An Equation for Non-Newtonian Flow. Trans. Soc. Rheol. 1961, 5, 247–260. [Google Scholar] [CrossRef]

- Beirute, R.M.; Flumerfelt, R.W. An Evaluation of the Robertson-Stiff Model Describing Rheological Properties of Drilling Fluids and Cement Slurries. Soc. Pet. Eng. J. 1977, 17, 97–100. [Google Scholar] [CrossRef]

- Batra, R.L.; Parthasarathy, H. Flow of a Robertson-Stiff Fluid Between Two Approaching Disks. Polym. Plast. Technol. Eng. 1996, 35, 497–516. [Google Scholar] [CrossRef]

- Vom Berg, W. Influence of specific surface and concentration of solids upon the flow behaviour of cement pastes. Mag. Concr. Res. 1979, 31, 211–216. [Google Scholar] [CrossRef]

- Lapasin, R.; Longo, V.; Rajgelj, S. Thixotropic behaviour of cement pastes. Cem. Concr. Res. 1979, 9, 309–318. [Google Scholar] [CrossRef]

- Billberg, P. Development of SCC static yield stress at rest and its effect on thelateral form pressure. In SCC 2005, Combining the Second North American Conference on the Design and Use of Self-Consolidating Concrete and the Fourth International RILEM Symposium on Self-Compacting Concrete; 2005; pp. 583–589. Available online: http://www.diva-portal.org/smash/record.jsf?pid=diva2%3A343052&dswid=4012 (accessed on 23 January 2020).

- Quemada, D. Models for rheological behavior of concentrated disperse media under shear. Adv. Rheol. 1984, 2, 571–582. [Google Scholar]

- De Kee, D.; Chan Man Fong, C.F. Rheological properties of structured fluids. Polym. Eng. Sci. 1994, 34, 438–445. [Google Scholar] [CrossRef]

- Yahia, A.; Khayat, K.H. Applicability of rheological models to high-performance grouts containing supplementary cementitious materials and viscosity enhancing admixture. Mater. Struct. 2003, 36, 402–412. [Google Scholar] [CrossRef]

- Yahia, A.; Khayat, K. Analytical models for estimating yield stress of high-performance pseudoplastic grout. Cem. Concr.Res. 2001, 31, 731–738. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Heidari, M.; Qu, Q.; Farzam, H.; Pappas, J.M. Behavior of piezoresistive smart cement contaminated with oil based drilling mud. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014. [Google Scholar]

- Yuan, B.; Yang, Y.; Tang, X.; Xie, Y. A starting pressure prediction of thixotropic cement slurry: Theory, model and example. J. Pet. Sci. Eng. 2015, 133, 108–113. [Google Scholar] [CrossRef]

- Tattersall, G.H.; Banfill, P.F. The Rheology of Fresh Concrete; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 1983; ISBN 0-273-08558-1. Available online: https://trid.trb.org/view/199391 (accessed on 23 January 2020).

- Barnes, H.A.; Walters, K. The yield stress myth? Rheol. acta 1985, 24, 323–326. [Google Scholar] [CrossRef]

- Barnes, H.A. The ‘yield stress myth’? paper–21 years on. Appl. Rheol. 2007, 17, 43110-1–43110-5. [Google Scholar] [CrossRef]

- Barnes, H.A. The yield stress—A review or ‘παντα ρει’—Everything flows? J. Non-Newton. Fluid Mech. 1999, 81, 133–178. [Google Scholar] [CrossRef]

- Hartnett, J.P.; Hu, R.Y. The yield stress—An engineering reality. J. Rheol. 1989, 33, 671–679. [Google Scholar] [CrossRef]

- Astarita, G. Letter to the Editor: The engineering reality of the yield stress. J. Rheol. 1990, 34, 275–277. [Google Scholar] [CrossRef]

- Evans, I.D. Letter to the editor: On the nature of the yield stress. J. Rheol. 1992, 36, 1313–1318. [Google Scholar] [CrossRef]

- Papanastasiou, T.C. Flows of materials with yield. J. Rheol. 1987, 31, 385–404. [Google Scholar] [CrossRef]

- Bonn, D.; Denn, M.M. Yield stress fluids slowly yield to analysis. Science 2009, 324, 1401–1402. [Google Scholar] [CrossRef]

- Denn, M.M.; Bonn, D. Issues in the flow of yield-stress liquids. Rheol. acta 2011, 50, 307–315. [Google Scholar] [CrossRef] [Green Version]

- Moller, P.; Fall, A.; Chikkadi, V.; Derks, D.; Bonn, D. An attempt to categorize yield stress fluid behaviour. Philos. Trans. Royal Soc. A Math. Phys. Eng. Sci. 2009, 367, 5139–5155. [Google Scholar] [CrossRef] [PubMed]

- Bird, R.B.; Dai, G.C.; Yarusso, B.J. The rheology and flow of viscoplastic materials. Rev. Chem. Eng. 1983, 1, 1–70. [Google Scholar] [CrossRef]

- Møller, P.C.; Mewis, J.; Bonn, D. Yield stress and thixotropy: On the difficulty of measuring yield stresses in practice. Soft Matter 2006, 2, 274–283. [Google Scholar] [CrossRef]

- Dinkgreve, M.; Paredes, J.; Denn, M.M.; Bonn, D. On different ways of measuring “the” yield stress. J. Non-Newton. Fluid Mech. 2016, 238, 233–241. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Boger, D.V. Measuring the flow properties of yield stress fluids. Annu. Rev. Fluid Mech. 1992, 24, 47–88. [Google Scholar] [CrossRef]

- Coussot, P. Yield stress fluid flows: A review of experimental data. J. Non-Newton. Fluid Mech. 2014, 211, 31–49. [Google Scholar] [CrossRef]

- Coussot, P.; Nguyen, Q.D.; Huynh, H.T.; Bonn, D. Viscosity bifurcation in thixotropic, yielding fluids. J. Rheol. 2002, 46, 573–589. [Google Scholar] [CrossRef] [Green Version]

- Jarny, S.; Roussel, N.; Rodts, S.; Bertrand, F.; Le Roy, R.; Coussot, P. Rheological behavior of cement pastes from MRI velocimetry. Cem. Concr. Res. 2005, 35, 1873–1881. [Google Scholar] [CrossRef]

- Roussel, N.; Ovarlez, G.; Garrault, S.; Brumaud, C. The origins of thixotropy of fresh cement pastes. Cem. Concr. Res. 2012, 42, 148–157. [Google Scholar] [CrossRef]

- Mahaut, F.; Mokéddem, S.; Chateau, X.; Roussel, N.; Ovarlez, G. Effect of coarse particle volume fraction on the yield stress and thixotropy of cementitious materials. Cem. Concr.Res. 2008, 38, 1276–1285. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, G.; Schlegel, E. Rheological characterization of CSH phases–water suspensions. Cem. Concr. Res. 2002, 32, 593–599. [Google Scholar] [CrossRef]

- Nachbaur, L.; Mutin, J.C.; Nonat, A.; Choplin, L. Dynamic mode rheology of cement and tricalcium silicate pastes from mixing to setting. Cem. Concr. Res. 2001, 31, 183–192. [Google Scholar] [CrossRef]

- Schultz, M.A.; Struble, L.J. Use of oscillatory shear to study flow behavior of fresh cement paste. Cem. Concr. Res. 1993, 23, 273–282. [Google Scholar] [CrossRef]

- Perrot, A.; Lecompte, T.; Khelifi, H.; Brumaud, C.; Hot, J.; Roussel, N. Yield stress and bleeding of fresh cement pastes. Cem. Concr. Res. 2012, 42, 937–944. [Google Scholar] [CrossRef]

- Assaad, J.J.; Harb, J.; Maalouf, Y. Effect of vane configuration on yield stress measurements of cement pastes. J. Non-Newton. Fluid Mech. 2016, 230, 31–42. [Google Scholar] [CrossRef]

- Qian, Y.; Kawashima, S. Distinguishing dynamic and static yield stress of fresh cement mortars through thixotropy. Cem. Concr. Res. 2018, 86, 288–296. [Google Scholar] [CrossRef]

- Michaux, M.; Defosse, C. Oil well cement slurries I. Microstructural approach of their rheology. Cem. Concr. Res. 1986, 16, 23–30. [Google Scholar] [CrossRef]

- Vance, K.; Kumar, A.; Sant, G.; Neithalath, N. The rheological properties of ternary binders containing Portland cement, limestone, and metakaolin or fly ash. Cem. Concr. Res. 2013, 52, 196–207. [Google Scholar] [CrossRef]

- Struble, L.; Sun, G.-K. Viscosity of Portland cement paste as a function of concentration. Adv. Cem. Based Mater. 1995, 2, 62–69. [Google Scholar] [CrossRef]

- Legrand, C. Rheologie Des Melanges De Ciment Ou De Sable et d’eau. Rev. Mater Constr. Trav. Publics Cim. Beton 1970. [Google Scholar]

- Kurdowski, W. Cement and Concrete Chemistry; Springer Science & Business: Berlin/Heidelberg, Germany, 2014; ISBN 94-007-7945-3. [Google Scholar]

- Sybertz, F.; Reick, P. Effect of fly as on the rheological properties of cement paste. Rheol. Fresh Cem. Concr. 1991, 13–22. [Google Scholar]

- Zhou, Z.; Solomon, M.J.; Scales, P.J.; Boger, D.V. The yield stress of concentrated flocculated suspensions of size distributed particles. J. Rheol. 1999, 43, 651–671. [Google Scholar] [CrossRef]

- Flatt, R.J.; Bowen, P. Yield Stress of Multimodal Powder Suspensions: An Extension of the YODEL (Yield Stress mODEL). J. Am. Ceram. Soc. 2007, 90, 1038–1044. [Google Scholar] [CrossRef]

- Hamaker, H.C. The London—van der Waals attraction between spherical particles. Physica 1937, 4, 1058–1072. [Google Scholar] [CrossRef]

- Flatt, R.J.; Bowen, P. Yodel: A Yield Stress Model for Suspensions. J. Am. Ceram. Soc. 2006, 89, 1244–1256. [Google Scholar] [CrossRef]

- Ma, S.; Kawashima, S. A rheological approach to study the early-age hydration of oil well cement: Effect of temperature, pressure and nanoclay. Constr. Build. Mater. 2019, 215, 119–127. [Google Scholar] [CrossRef]

- Chateau, X.; Ovarlez, G.; Trung, K.L. Homogenization approach to the behavior of suspensions of noncolloidal particles in yield stress fluids. J. Rheol. 2008, 52, 489–506. [Google Scholar] [CrossRef] [Green Version]

- Chougnet, A.; Palermo, T.; Audibert, A.; Moan, M. Rheological behaviour of cement and silica suspensions: Particle aggregation modelling. Cem. Concr. Res. 2008, 38, 1297–1301. [Google Scholar] [CrossRef]

- Ivanov, Y.P.; Roshavelov, T.T. The effect of condensed silica fume on the rheological behaviour of cement pastes. In Rheology of Fresh Cement and Concrete: Proceedings of an International Conference, Liverpool, 1990; CRC Press: Boca Raton, FL, USA, 1990; pp. 23–26. [Google Scholar]

- Rosquoët, F.; Alexis, A.; Khelidj, A.; Phelipot, A. Experimental study of cement grout. Cem. Concr. Res. 2003, 33, 713–722. [Google Scholar] [CrossRef] [Green Version]

- Lobanov, V.P. The visco-plastic properties of building mortars. Kolloidn. Zhurnal 1950, 12, 352–358. [Google Scholar]

- Bombled, J.P. Influence of sulphates on the rheological behaviour of cement pastes and their evolution. In Proceedings of the 7th International Congress on the Chemistry of Cement: Paris; Cement Research Institute of India: New Delhi, India, 1980; pp. 164–169. [Google Scholar]

- Roy, D.M.; Asaga, K. Rheological properties of cement mixes: V. The effects of time on viscometric properties of mixes containing superplasticizers; conclusions. Cem. Concr. Res. 1980, 10, 387–394. [Google Scholar] [CrossRef]

- Ivanov, Y.; Stanoeva, E. Influence of cement composition and other factors on the rheological behavior of cement pastes. Silic. Ind. 1979, 44, 199–203. [Google Scholar]

- Ivanov, Y.; Zacharieva, S. Influence of fly ash on the rheology of cement pastes. In Proceedings of the 7th International Congress on the Chemistry of Cement: Paris; Cement Research Institute of India: New Delhi, India, 1980; pp. 103–107. [Google Scholar]

- Chen, X.; Wu, S.; Zhou, J. Experimental and modeling study of dynamic mechanical properties of cement paste, mortar and concrete. Constr. Build. Mater. 2013, 47, 419–430. [Google Scholar] [CrossRef]

- Massoudi, M.; Wang, P. Slag behavior in gasifiers. Part II: Constitutive modeling of slag. Energies 2013, 6, 807–838. [Google Scholar] [CrossRef] [Green Version]

- Fredrickson, A.G. Principles and Applications of Rheology; Prentice-Hall: Upper Saddle River, NJ, USA, 1964. [Google Scholar]

- White, F.M. Fluid Mechanics fourth edition; McGraw and Hill: Singapore, 1994. [Google Scholar]

- Einstein, A. Eine neue bestimmung der moleküldimensionen. Ann. Der Phys. 1906, 324, 289–306. [Google Scholar] [CrossRef] [Green Version]

- Roussel, N.; Lemaître, A.; Flatt, R.J.; Coussot, P. Steady state flow of cement suspensions: A micromechanical state of the art. Cem. Concr. Res. 2010, 40, 77–84. [Google Scholar] [CrossRef]

- Roscoe, R. The viscosity of suspensions of rigid spheres. Br. J. Appl. Phys. 1952, 3, 267. [Google Scholar] [CrossRef]

- Mooney, M. The viscosity of a concentrated suspension of spherical particles. J. Colloid Sci. 1951, 6, 162–170. [Google Scholar] [CrossRef]

- Krieger, I.M.; Dougherty, T.J. A mechanism for non-Newtonian flow in suspensions of rigid spheres. Trans. Soc. Rheol. 1959, 3, 137–152. [Google Scholar] [CrossRef]

- Struble, L.; Szecsy, R.; Lei, W.-G.; Sun, G.-K. Rheology of cement paste and concrete. Cem. Concr. Aggreg. 1998, 20, 269–277. [Google Scholar]

- Mansoutre, S.; Colombet, P.; Damme, H.V. Water retention and granular rheological behavior of fresh C3S paste as a function of concentration. Cem. Concr. Res. 1999, 29, 1441–1453. [Google Scholar]

- Justnes, H.; Vikan, H. Viscosity of cement slurries as a function of solids content. Ann. Trans. Nordic Rheol. Soc. 2005, 13, 75–82. [Google Scholar]

- Bonen, D.; Shah, S.P. Fresh and hardened properties of self-consolidating concrete. Prog. Struct. Eng. Mater. 2005, 7, 14–26. [Google Scholar] [CrossRef]

- Hendrickx, R.; Rezeau, M.; Van Balen, K.; Van Gemert, D. Mortar and paste rheology: Concentration, polydispersity and air entrapment at high solid fraction. Appl. Rheol. 2009, 19. [Google Scholar] [CrossRef]

- Tregger, N.A.; Pakula, M.E.; Shah, S.P. Influence of clays on the rheology of cement pastes. Cem. Concr. Res. 2010, 40, 384–391. [Google Scholar] [CrossRef]

- Bentz, D.P.; Ferraris, C.F.; Galler, M.A.; Hansen, A.S.; Guynn, J.M. Influence of particle size distributions on yield stress and viscosity of cement–fly ash pastes. Cem. Concr. Res. 2012, 42, 404–409. [Google Scholar] [CrossRef]

- Ouyang, J.; Tan, Y. Rheology of fresh cement asphalt emulsion pastes. Constr. Build. Mater. 2015, 80, 236–243. [Google Scholar] [CrossRef]

- O’Neill, R.; McCarthy, H.O.; Montufar, E.B.; Ginebra, M.-P.; Wilson, D.I.; Lennon, A.; Dunne, N. Critical review: Injectability of calcium phosphate pastes and cements. Acta Biomater. 2017, 50, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.-T.; Lin, C.-W. Stiffening Behaviors of Cement Pastes Measured by a Vibrational Viscometer. Adv. Civ. Eng. Mater. 2017, 6, 20160061. [Google Scholar] [CrossRef]

- Murata, J.; Kikukawa, H. Studies on rheological analysis of fresh concrete. In Proceedings of the RILEM Seminar: Fresh Concrete; RILEM: Paris, France, 1973. [Google Scholar]

- Mills, P. Non-Newtonian behaviour of flocculated suspensions. J. De Phys. Lett. 1985, 46, 301–309. [Google Scholar] [CrossRef]

- Liu, D.-M. Particle packing and rheological property of highly-concentrated ceramic suspensions: φm determination and viscosity prediction. J. Mater. Sci. 2000, 35, 5503–5507. [Google Scholar] [CrossRef]

- Chong, J.S.; Christiansen, E.B.; Baer, A.D. Rheology of concentrated suspensions. J. Appl. Polym. Sci. 1971, 15, 2007–2021. [Google Scholar] [CrossRef]

- Aiad, I.; El-Sabbagh, A.M.; Adawy, A.I.; Shafek, S.H.; Abo-EL-Enein, S.A. Effect of some prepared superplasticizers on the rheological properties of oil well cement slurries. Egypt. J. Pet. 2018, 27, 1061–1066. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Mohammed, A. Smart cement rheological and piezoresistive behavior for oil well applications. J. Pet. Sci. Eng. 2015, 135, 50–58. [Google Scholar] [CrossRef]

- Kim, J.H.; Kwon, S.H.; Kawashima, S.; Yim, H.J. Rheology of cement paste under high pressure. Cem. Concr. Compos. 2017, 77, 60–67. [Google Scholar] [CrossRef]

- Ravi, K.M.; Sutton, D.L. New rheological correlation for cement slurries as a function of temperature. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 23–26 September 1990. [Google Scholar]

- Sercombe, J.; Hellmich, C.; Ulm, F.-J.; Mang, H. Modeling of Early-Age Creep of Shotcrete. I: Model and Model Parameters. J. Eng. Mech. 2000, 126, 284–291. [Google Scholar] [CrossRef]

- Bazant, Z.P. Creep and damage in concrete. Mater. Sci. Concr. IV 1995, 355–389. Available online: http://cee.northwestern.edu/people/bazant/PDFs/Papers%20-%20Backup%202_20_2013/331.pdf (accessed on 23 January 2020).

- Ulm, F.-J.; Coussy, O. Strength growth as chemo-plastic hardening in early age concrete. J. Eng. Mech. 1996, 122, 1123–1132. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of phase change. I General theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Pang, X.; Meyer, C.; Darbe, R.; Funkhouser, G.P. Modeling the effect of curing temperature and pressure on cement hydration kinetics. ACI Mater. J. 2013, 110, 137. [Google Scholar]

- Wu, D.; Cai, S.; Huang, G. Coupled effect of cement hydration and temperature on rheological properties of fresh cemented tailings backfill slurry. Trans. Nonferrous Metals Soc. China 2014, 24, 2954–2963. [Google Scholar] [CrossRef]

- Wu, D.; Fall, M.; Cai, S.J. Coupling temperature, cement hydration and rheological behaviour of fresh cemented paste backfill. Miner. Eng. 2013, 42, 76–87. [Google Scholar] [CrossRef]

- Papo, A.; Caufin, B. A study of the hydration process of cement pastes by means of oscillatory rheological techniques. Cem. Concr. Res. 1991, 21, 1111–1117. [Google Scholar] [CrossRef]

- Aïtcin, P.-C. Cements of yesterday and today: Concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Jayasree, C.; Murali Krishnan, J.; Gettu, R. Influence of superplasticizer on the non-Newtonian characteristics of cement paste. Mater. Struct. 2011, 44, 929–942. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L. A critical review of preparation design and workability measurement of concrete material for largescale 3D printing. Front. Struct. Civ. Eng. 2018, 12, 382–400. [Google Scholar] [CrossRef]

- Bellotto, M. Cement paste prior to setting: A rheological approach. Cem. Concr. Res. 2013, 52, 161–168. [Google Scholar] [CrossRef]

- Mikanovic, N.; Jolicoeur, C. Influence of superplasticizers on the rheology and stability of limestone and cement pastes. Cem. Concr. Res. 2008, 38, 907–919. [Google Scholar] [CrossRef]

- Daukšys, M.; Skripkiūnas, G.; Janavičius, E. Complex influence of plasticizing admixtures and sodium silicate solution on rheological properties of Portland cement paste. Mater. Sci. 2009, 15, 349–355. [Google Scholar]

- Rehman, S.K.U.; Ibrahim, Z.; Jameel, M.; Memon, S.A.; Javed, M.F.; Aslam, M.; Mehmood, K.; Nazar, S. Assessment of Rheological and Piezoresistive Properties of Graphene based Cement Composites. Int. J. Concr. Struct. Mater. 2018, 12, 64. [Google Scholar] [CrossRef]

- Sanfelix, S.G.; Santacruz, I.; Szczotok, A.M.; Belloc, L.M.O.; De la Torre, A.G.; Kjøniksen, A.-L. Effect of microencapsulated phase change materials on the flow behavior of cement composites. Constr. Build. Mater. 2019, 202, 353–362. [Google Scholar] [CrossRef]

- Khayat, K.H.; Yahia, A. Effect of welan gum-high-range water reducer combinations on rheology of cement grout. Mater. J. 1997, 94, 365–372. [Google Scholar]

- Cyr, M.; Legrand, C.; Mouret, M. Study of the shear thickening effect of superplasticizers on the rheological behaviour of cement pastes containing or not mineral additives. Cem. Concr. Res. 2000, 30, 1477–1483. [Google Scholar] [CrossRef]

- Nehdi, M.; Mindess, S.; Aıtcin, P.-C. Rheology of High-Performance Concrete: Effect of Ultrafine Particles. Cem. Concr. Res. 1998, 28, 687–697. [Google Scholar] [CrossRef]

- Gołaszewski, J.; Szwabowski, J. Influence of superplasticizers on rheological behaviour of fresh cement mortars. Cem. Concr. Res. 2004, 34, 235–248. [Google Scholar] [CrossRef]

- Aiad, I. Influence of time addition of superplasticizers on the rheological properties of fresh cement pastes. Cem. Concr. Res. 2003, 33, 1229–1234. [Google Scholar] [CrossRef]

- Puertas, F.; Santos, H.; Palacios, M.; Martınez-Ramırez, S. Polycarboxylate superplasticiser admixtures: Effect on hydration, microstructure and rheological behaviour in cement pastes. Adv. Cem. Res. 2005, 17, 77–89. [Google Scholar] [CrossRef]

- Zingg, A.; Winnefeld, F.; Holzer, L.; Pakusch, J.; Becker, S.; Gauckler, L. Adsorption of polyelectrolytes and its influence on the rheology, zeta potential, and microstructure of various cement and hydrate phases. J. Colloid Interface Sci. 2008, 323, 301–312. [Google Scholar] [CrossRef]

- Wong, H.H.C.; Kwan, A.K.H. Rheology of Cement Paste: Role of Excess Water to Solid Surface Area Ratio. J. Mater. Civ. Eng. 2008, 20, 189–197. [Google Scholar] [CrossRef]

- Abbas, G.; Irawan, S.; Kumar, S.; Memon, R.K.; Khalwar, S.A. Characteristics of Oil Well Cement Slurry using Hydroxypropylmethylcellulose. J. Appl. Sci. 2014, 14, 1154–1160. [Google Scholar] [CrossRef]

- Zhang, X.; Han, J. The effect of ultra-fine admixture on the rheological property of cement paste. Cem. Concr. Res. 2000, 30, 827–830. [Google Scholar] [CrossRef]

- Park, C.K.; Noh, M.H.; Park, T.H. Rheological properties of cementitious materials containing mineral admixtures. Cem. Concr. Res. 2005, 35, 842–849. [Google Scholar] [CrossRef]

- Vikan, H.; Justnes, H. Rheology of cementitious paste with silica fume or limestone. Cem. Concr. Res. 2007, 37, 1512–1517. [Google Scholar] [CrossRef]

- Stryczek, S.; Brylicki, W.; Małolepszy, J.; Gonet, A.; Wiśniowski, R.; Kotwica, Ł. Potential use of fly ash from fluidal combustion of brown coal in cementing slurries for drilling and geotechnical works. Arch. Min. Sci. 2009, 54, 775–786. [Google Scholar]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Seta, L.; Zinno, R. Rheological behaviour of fresh cement pastes: Influence of synthetic zeolites, limestone and silica fume. Cem. Concr. Res. 2014, 63, 38–45. [Google Scholar] [CrossRef]

- Li, D.; Wang, D.; Ren, C.; Rui, Y. Investigation of rheological properties of fresh cement paste containing ultrafine circulating fluidized bed fly ash. Constr. Build. Mater. 2018, 188, 1007–1013. [Google Scholar] [CrossRef]

- Burroughs, J.F.; Weiss, J.; Haddock, J.E. Influence of high volumes of silica fume on the rheological behavior of oil well cement pastes. Constr. Build. Mater. 2019, 203, 401–407. [Google Scholar] [CrossRef]

- Laskar, A.I.; Talukdar, S. Rheological behavior of high performance concrete with mineral admixtures and their blending. Constr. Build. Mater. 2008, 22, 2345–2354. [Google Scholar] [CrossRef]

- Provis, J.L.; Duxson, P.; van Deventer, J.S.J. The role of particle technology in developing sustainable construction materials. Adv. Powder Technol. 2010, 21, 2–7. [Google Scholar] [CrossRef]

- Hou, J.; Liu, Z. Synthesizing Dispersant for MTC Design and Its Effect on Slurry Rheology. SPE Drill. Complet. 2000, 15, 31–36. [Google Scholar] [CrossRef]

- Nehdi, M. Why some carbonate fillers cause rapid increases of viscosity in dispersed cement-based materials. Cem. Concr. Res. 2000, 30, 1663–1669. [Google Scholar] [CrossRef]

- Hodne, H.; Saasen, A.; Strand, S. Rheological properties of high temperature oil well cement slurries. Annu. Trans. Nordi. Rheol. Soc. 2001, 8, 31–38. [Google Scholar]

- Kaufmann, J.; Winnefeld, F.; Hesselbarth, D. Effect of the addition of ultrafine cement and short fiber reinforcement on shrinkage, rheological and mechanical properties of Portland cement pastes. Cem. Concr. Compos. 2004, 26, 541–549. [Google Scholar] [CrossRef]

- Sonebi, M.; Svermova, L.; Bartos, P.J.M. Factorial Design of Cement Slurries Containing Limestone Powder for Self-Consolidating Slurry-Infiltrated Fiber Concrete. ACI Mater. J. 2004, 101, 136–145. [Google Scholar]

- Senff, L.; Hotza, D.; Lucas, S.; Ferreira, V.M.; Labrincha, J.A. Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars. Mater. Sci. Eng. A 2012, 532, 354–361. [Google Scholar] [CrossRef]

- Soltanian, H.; Khalokakaie, R.; Ataei, M.; Kazemzadeh, E. Fe2O3 nanoparticles improve the physical properties of heavy-weight wellbore cements: A laboratory study. J. Nat. Gas Sci. Eng. 2015, 26, 695–701. [Google Scholar] [CrossRef]

- Sun, X.; Wu, Q.; Lee, S.; Qing, Y.; Wu, Y. Cellulose Nanofibers as a Modifier for Rheology, Curing and Mechanical Performance of Oil Well Cement. Sci. Rep. 2016, 6, 31654. [Google Scholar] [CrossRef] [Green Version]

- Tang, Z.; Huang, R.; Mei, C.; Sun, X.; Zhou, D.; Zhang, X.; Wu, Q. Influence of Cellulose Nanoparticles on Rheological Behavior of Oil Well Cement-Water Slurries. Materials 2019, 12, 291. [Google Scholar] [CrossRef] [Green Version]

- Colombo, A.; Geiker, M.R.; Justnes, H.; Lauten, R.A.; De Weerdt, K. On the effect of calcium lignosulfonate on the rheology and setting time of cement paste. Cem. Concr. Res. 2017, 100, 435–444. [Google Scholar] [CrossRef]

- Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Hotza, D.; Repette, W.L. Effect of nano-silica on rheology and fresh properties of cement pastes and mortars. Constr. Build. Mater. 2009, 23, 2487–2491. [Google Scholar] [CrossRef]

- Quercia, G.; Brouwers, H.J.H.; Garnier, A.; Luke, K. Influence of olivine nano-silica on hydration and performance of oil-well cement slurries. Mater. Des. 2016, 96, 162–170. [Google Scholar] [CrossRef]

- Wang, W.; Taleghani, A.D. Three-dimensional analysis of cement sheath integrity around Wellbores. J. Pet. Sci. Eng. 2014, 121, 38–51. [Google Scholar] [CrossRef]

- Phan, T.H.; Chaouche, M.; Moranville, M. Influence of organic admixtures on the rheological behaviour of cement pastes. Cem. Concr. Res. 2006, 36, 1807–1813. [Google Scholar] [CrossRef]

- Emoto, T.; Bier, T.A. Rheological behavior as influenced by plasticizers and hydration kinetics. Cem. Concr. Res. 2007, 37, 647–654. [Google Scholar] [CrossRef]

- Lu, H.; Xie, C.; Gao, Y.; Li, L.; Zhu, H. Cement Slurries with Rheological Properties Unaffected by Temperature. SPE Drill. Complet. 2016, 30, 316–321. [Google Scholar] [CrossRef]

- Velayati, A.; Soltanian, H.; Pourmazaheri, Y.; Aghajafari, A.H.; Kazemzadeh, E.; Barati, P. Investigation of Cassia fistula fruit dry extract effect on the oil and gas well cement properties. J. Nat. Gas Sci. Eng. 2016, 36, 298–304. [Google Scholar] [CrossRef]

- Wang, C.; Chen, X.; Wang, R. Do chlorides qualify as accelerators for the cement of deepwater oil wells at low temperature? Constr. Build. Mater. 2017, 133, 482–494. [Google Scholar] [CrossRef]

- Tao, C.; Watts, B.; Ferraro, C.C.; Masters, F.J. A Multivariate Computational Framework to Characterize and Rate Virtual Portland Cements. Comput. Aided Civ. Infrastruct. Eng. 2019, 34, 266–278. [Google Scholar] [CrossRef]

- Tao, C. Optimization of Cement Production and Hydration for Improved Performance, Energy Conservation, and Cost. Ph.D. Dissertation, University of Florida, Gainesville, FL, USA, 2017. [Google Scholar]

- Stryczek, S.; Wiśniowski, R.; Gonet, A.; Złotkowski, A.; Ziaja, J. Influence of Polycarboxylate Superplasticizers on Rheological Properties of Cement Slurries Used in Drilling Technologies/Wpływ Superplastyfikatorów Z Grupy Polikarboksylanów Na Właściwości Reologiczne Zaczynów Cementowych Stosowanych W Technologiach Wiertniczych. Arch. Min. Sci. 2013, 58, 719–728. [Google Scholar]

- Massidda, L.; Sanna, U. Rheological Behaviour of Portland Cement Pastes Containing Fly Ash; Il Cemento: Milano, Roma, 1982. [Google Scholar]

- Yang, M.; Jennings, H.M. Influences of mixing methods on the microstructure and rheological behavior of cement paste. Adv. Cem. Based Mater. 1995, 2, 70–78. [Google Scholar] [CrossRef]

- Williams, D.A.; Saak, A.W.; Jennings, H.M. The influence of mixing on the rheology of fresh cement paste. Cem. Concr. Res. 1999, 29, 1491–1496. [Google Scholar] [CrossRef]

- Orban, J.; Parcevaux, P.; Guillot, D. Influence of shear history on the rheological properties of oil well cement slurries. In Proceedings of the 8th International Congress on the Chemistry of Cement, Rio de Janeiro, Brazi, 22–27 September 1986; Volume 6, pp. 243–247. [Google Scholar]

- Saleh, F.K.; Salehi, S.; Teodoriu, C. Experimental investigation of mixing energy of well cements: The gap between laboratory and field mixing. J. Nat. Gas Sci. Eng. 2019, 63, 47–57. [Google Scholar] [CrossRef]

- Han, D.; Ferron, R.D. Effect of mixing method on microstructure and rheology of cement paste. Constr. Build. Mater. 2015, 93, 278–288. [Google Scholar] [CrossRef] [Green Version]

- Saleh, F.K.; Teodoriu, C. The mechanism of mixing and mixing energy for oil and gas wells cement slurries: A literature review and benchmarking of the findings. J. Nat. Gas Sci. Eng. 2017, 38, 388–401. [Google Scholar] [CrossRef]

- Mannheimer, R.J. Laminar and turbulent flow of cement slurries in large diameter pipe: A comparison with laboratory viscometers. J. Rheol. 1991, 35, 113–133. [Google Scholar] [CrossRef]

- Saak, A.W.; Jennings, H.M.; Shah, S.P. The influence of wall slip on yield stress and viscoelastic measurements of cement paste. Cem. Concr. Res. 2001, 31, 205–212. [Google Scholar] [CrossRef]

- Bannister, C.E. Rheological evaluation of cement slurries: Methods and models. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 21–24 September 1980. [Google Scholar]

- Roussel, N. Steady and transient flow behaviour of fresh cement pastes. Cem. Concr. Res. 2005, 35, 1656–1664. [Google Scholar] [CrossRef]

- Mewis, J. Thixotropy-a general review. J. Non-Newton. Fluid Mech. 1979, 6, 1–20. [Google Scholar] [CrossRef]

- Barnes, H.A. Thixotropy—A review. J. Non-Newton. Fluid Mech. 1997, 70, 1–33. [Google Scholar] [CrossRef]

- Freundlich, H. Thixotropy; Hermann & Cie: Paris, France, 1935; Volume 1. [Google Scholar]

- Barnes, H.A.; Hutton, J.F.; Walters, K. An Introduction to Rheology; Elsevier: Edinburgh, London, UK, 1989; ISBN 0-08-093369-6. [Google Scholar]

- Hartley, G.S. Negative thixotropy. Nature 1938, 142, 161. [Google Scholar] [CrossRef]

- Renardy, M.; Wang, X. Boundary layers for the upper convected Maxwell fluid. J. Non-Newton. Fluid Mech. 2012, 189, 14–18. [Google Scholar] [CrossRef]

- Renardy, M.; Renardy, Y. Thixotropy in yield stress fluids as a limit of viscoelasticity. IMA J. Appl. Math. 2016, 81, 522–537. [Google Scholar] [CrossRef]

- Larson, R.G. A constitutive equation for polymer melts based on partially extending strand convection. J. Rheol. 1984, 28, 545–571. [Google Scholar] [CrossRef]

- Fredrickson, A.G. A model for the thixotropy of suspensions. AIChe J. 1970, 16, 436–441. [Google Scholar] [CrossRef]

- Renardy, M. The mathematics of myth: Yield stress behavior as a limit of non-monotone constitutive theories. J. Non-Newton. Fluid Mech. 2010, 165, 519–526. [Google Scholar] [CrossRef]

- de Souza Mendes, P.R.; Thompson, R.L. A unified approach to model elasto-viscoplastic thixotropic yield-stress materials and apparent yield-stress fluids. Rheol. Acta 2013, 52, 673–694. [Google Scholar] [CrossRef]

- de Souza Mendes, P.R. Thixotropic elasto-viscoplastic model for structured fluids. Soft Matter 2011, 7, 2471–2483. [Google Scholar] [CrossRef]

- Chappuis, J. Rheological measurements with cement pastes in viscometers: A comprehensive approach. In Proceedings of Fresh Cement and Concrete; Taylor & Francis: London, UK, 1990; pp. 3–12. [Google Scholar]

- Al Ghanami, R.C.; Saunders, B.R.; Bosquillon, C.; Shakesheff, K.M.; Alexander, C. Responsive particulate dispersions for reversible building and deconstruction of 3D cell environments. Soft Matter 2010, 6, 5037–5044. [Google Scholar] [CrossRef]

- Sant, G.; Ferraris, C.F.; Weiss, J. Rheological properties of cement pastes: A discussion of structure formation and mechanical property development. Cem. Concr. Res. 2008, 38, 1286–1296. [Google Scholar] [CrossRef]

- Tsenoglou, C. Scaling concepts in suspension rheology. J. Rheol. 1990, 34, 15–24. [Google Scholar] [CrossRef]

- Usui, H. A thixotropy model for coal-water mixtures. J. Non-Newton. Fluid Mech. 1995, 60, 259–275. [Google Scholar] [CrossRef]

- Potanin, A.A.; De Rooij, R.; Van den Ende, D.; Mellema, J. Microrheological modeling of weakly aggregated dispersions. J. Chem. Phys. 1995, 102, 5845–5853. [Google Scholar] [CrossRef]

- Quemada, D. Rheological modelling of complex fluids: IV: Thixotropic and “thixoelastic” behaviour. Start-up and stress relaxation, creep tests and hysteresis cycles. Eur. Phys. J. Appl. Phys. 1999, 5, 191–207. [Google Scholar] [CrossRef]

- Feys, D.; Asghari, A. Influence of maximum applied shear rate on the measured rheological properties of flowable cement pastes. Cem. Concr. Res. 2019, 117, 69–81. [Google Scholar] [CrossRef]

- Cheng, D.C.; Evans, F. Phenomenological characterization of the rheological behaviour of inelastic reversible thixotropic and antithixotropic fluids. B. J. Appl. Phys. 1965, 16, 1599. [Google Scholar] [CrossRef]

- Legrand, C. Contribution à l’étude de la rhéologie du béton frais. Mater. Constr. 1972, 5, 275–295. [Google Scholar] [CrossRef]

- Hattori, K.; Izumi, K. A rheological expression of coagulation rate theory. J. Dispers. Sci. Technol. 1982, 3, 129–145. [Google Scholar] [CrossRef]

- Roussel, N. A thixotropy model for fresh fluid concretes: Theory, validation and applications. Cem. Concr. Res. 2006, 36, 1797–1806. [Google Scholar] [CrossRef]

- Roussel, N. Rheology of fresh concrete: From measurements to predictions of casting processes. Mater. Struct. 2007, 40, 1001–1012. [Google Scholar] [CrossRef]

- Mewis, J.; Wagner, N.J. Colloidal Suspension Rheology; Cambridge University Press: Cambridge, UK, 2012; ISBN 0-521-51599-8. [Google Scholar]

- de Souza Mendes, P.R. Modeling the thixotropic behavior of structured fluids. J. Non-Newton. Fluid Mech. 2009, 164, 66–75. [Google Scholar] [CrossRef]

- Truesdell, C.; Noll, W. The Non-linear Field Theories of Mechanics; Springer: Berlin, Germany, 1992. [Google Scholar]

- Reynolds, O. LVII. On the dilatancy of media composed of rigid particles in contact. With experimental illustrations. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1885, 20, 469–481. [Google Scholar] [CrossRef] [Green Version]

- Reynolds, O. IV. On the theory of lubrication and its application to Mr. Beauchamp tower’s experiments, including an experimental determination of the viscosity of olive oil. Philos. Trans. Royal Soc. Lond. 1886, 1, 157–234. [Google Scholar]

- Massoudi, M.; Mehrabadi, M.M. A continuum model for granular materials: Considering dilatancy and the Mohr-Coulomb criterion. Acta Mech. 2001, 152, 121–138. [Google Scholar] [CrossRef]

- Reiner, M. A mathematical theory of dilatancy. Am. J. Math. 1945, 67, 350–362. [Google Scholar] [CrossRef]

- Massoudi, M. A generalization of Reiner’s mathematical model for wet sand. Mech. Res. Commun. 2011, 38, 378–381. [Google Scholar] [CrossRef] [Green Version]

- Man, C.-S. Nonsteady channel flow of ice as a modified second-order fluid with power-law viscosity. Arch. Ration. Mech. Anal. 1992, 119, 35–57. [Google Scholar] [CrossRef]

- Man, C.-S.; Sun, Q.-X. On the significance of normal stress effects in the flow of glaciers. J. Glaciol. 1987, 33, 268–273. [Google Scholar] [CrossRef] [Green Version]

- Gupta, G.; Massoudi, M. Flow of a generalized second grade fluid between heated plates. Acta Mech. 1993, 99, 21–33. [Google Scholar] [CrossRef]

- Massoudi, M. Heat transfer in complex fluids. In Two Phase Flow, Phase Change and Numerical Modeling; No. NETL-PUB-234; National Energy Technology Lab (NETL): Pittsburgh, PA, USA; In-house ResearchIn-house Research: Morgantown, WV, USA, 2012. [Google Scholar]

- Wu, W.-T.; Aubry, N.; Massoudi, M.; Kim, J.; Antaki, J.F. A numerical study of blood flow using mixture theory. Int. J. Eng. Sci. 2014, 76, 56–72. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miao, L.; Massoudi, M. Heat transfer analysis and flow of a slag-type fluid: Effects of variable thermal conductivity and viscosity. Int. J. Non-Linear Mech. 2015, 76, 8–19. [Google Scholar] [CrossRef]

- Wu, W.-T.; Aubry, N.; Antaki, J.F.; Massoudi, M. Normal stress effects in the gravity driven flow of granular materials. Int. J. Non-Linear Mech. 2017, 92, 84–91. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.-T.; Aubry, N.; Antaki, J.; Massoudi, M. Flow of a Dense Suspension Modeled as a Modified Second Grade Fluid. Fluids 2018, 3, 55. [Google Scholar] [CrossRef] [Green Version]

- Dunn, J.E.; Fosdick, R.L. Thermodynamics, stability, and boundedness of fluids of complexity 2 and fluids of second grade. Arch. Ration. Mech. Anal. 1974, 56, 191–252. [Google Scholar] [CrossRef]

- Tao, C.; Rosenbaum, E.; Kutchko, B.G.; Massoudi, M. Effects of Shear-rate Dependent Viscosity on the Flow of A Cement Slurry; NETL-PUB-22169; National Energy Technology Lab (NETL): Pittsburgh, PA, USA, 2018. [Google Scholar]

- Hanehara, S.; Yamada, K. Interaction between cement and chemical admixture from the point of cement hydration, absorption behaviour of admixture, and paste rheology. Cem. Concr. Res. 1999, 29, 1159–1165. [Google Scholar] [CrossRef]

- Stutzman, P. Scanning electron microscopy imaging of hydraulic cement microstructure. Cem. Concr. Compos. 2004, 26, 957–966. [Google Scholar] [CrossRef]

- Gebauer, J.; Kristmann, M. The influence of the composition of industrial clinker on cement and concrete properties. World Cem. Technol. 1979, 10, 46–51. [Google Scholar]

- Powers, T.C. Structure and physical properties of hardened Portland cement paste. J. Am. Ceram. Soc. 1958, 41, 1–6. [Google Scholar] [CrossRef]

- Slattery, J.C. Advanced Transport Phenomena; Cambridge University Press: Cambridge, UK, 1999; ISBN 1-316-58390-2. [Google Scholar]

- Probstein, R.F. Physicochemical Hydrodynamics: An Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2005; ISBN 0-471-72512-9. [Google Scholar]

- Liu, I.-S. Continuum Mechanics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 3-662-05056-0. [Google Scholar]

- Ziegler, H. An introduction to Thermomechanics; Elsevier: Amsterdam, The Netherlands, 2012; Volume 21, ISBN 0-444-59893-6. [Google Scholar]

- Malekmohammadi, S.; Naccache, M.F.; Frigaard, I.A.; Martinez, D.M. Buoyancy driven slump flows of non-Newtonian fluids in pipes. J. Pet. Sci. Eng. 2010, 72, 236–243. [Google Scholar] [CrossRef]

- Aranha, P.E.; Miranda, C.R.; Magalhães, J.V.M.; Campos, G.; Martins, A.L. Dynamic Aspects Governing Cement-Plug Placement in Deepwater Wells. SPE Drill. Complet. 2011, 26, 341–351. [Google Scholar] [CrossRef]

- Atkin, R.J.; Craine, R.E. Continuum theories of mixtures: Applications. IMA J. Appl. Math. 1976, 17, 153–207. [Google Scholar] [CrossRef]

- Atkin, R.J.; Craine, R.E. Continuum theories of mixtures: Basic theory and historical development. Q. J. Mech. Appl. Math. 1976, 29, 209–244. [Google Scholar] [CrossRef]

- Bowen, R.M. Theory of mixtures in continuum physics. In Mixtures and Electromagnetic Field Theories; Academic Press: New York, NY, USA, 1976. [Google Scholar]

- Truesdell, C. Thermodynamics of diffusion. In Rational Thermodynamics; Springer: Berlin/Heidelberg, Germany, 1984; pp. 219–236. [Google Scholar]

- Rajagopal, K.R.; Tao, L. Mechanics of mixtures. J. Fluid Mech. 1996, 323, 410. [Google Scholar]

- Liu, L.; Fang, Z.; Qi, C.; Zhang, B.; Guo, L.; Song, K.I.-I.L. Numerical study on the pipe flow characteristics of the cemented paste backfill slurry considering hydration effects. Powder Technol. 2019, 343, 454–464. [Google Scholar] [CrossRef]

- Rohani, B.; Wahid, M.A.; Sies, M.M.; Saqr, K.M. Comparison of Eddy Dissipation Model and Presumed Probability Density Function Model for Temperature Prediction in a Non-Premixed Turbulent Methane Flame. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2012; Volume 1440, pp. 384–391. Available online: https://doi.org/10.1063/1.4704240 (accessed on 23 January 2020).

- Wang, P. The model constant A of the eddy dissipation model. Prog. Comput. Fluid Dyn. Int. J. 2016, 16, 118–125. [Google Scholar] [CrossRef]

- Wallevik, J.E. Rheology of Particle Suspensions: Fresh Concrete, Mortar and Cement Paste with Various Types of Lignosulfonates; Fakultet for Ingeniørvitenskap og Teknologi: Trondheim, Norway, 2003; ISBN 82-471-5566-4. Available online: http://hdl.handle.net/11250/236410 (accessed on 23 January 2020).

- Moyers-Gonzalez, M.A.; Frigaard, I.A. Kinematic instabilities in two-layer eccentric annular flows, part 2: Shear-thinning and yield-stress effects. J. Eng. Math. 2009, 65, 25–52. [Google Scholar] [CrossRef]

- Manzar, M.A.; Shah, S.N. Particle Distribution and Erosion During the Flow of Newtonian and Non-Newtonian Slurries in Straight and Coiled Pipes. Eng. Appl. Comput. Fluid Mech. 2009, 3, 296–320. [Google Scholar] [CrossRef] [Green Version]

- Lootens, D. Ciments et Suspensions concentrées Modèles. ÉCoulement, Encombrement et Flocculation. Ph.D. Dissertation, Université Pierre et Marie Curie-Paris VI, Paris, France, 2004. Available online: https://pastel.archives-ouvertes.fr/tel-00007217/ (accessed on 23 January 2020).

- Patankar, S. Numerical Heat Transfer and Fluid Flow; CRC Press: Boca Raton, FL, USA, 1980; ISBN 1-4822-3421-1. [Google Scholar]

- Cremonesi, M.; Ferrara, L.; Frangi, A.; Perego, U. Simulation of the flow of fresh cement suspensions by a Lagrangian finite element approach. J. Non-Newton. Fluid Mech. 2010, 165, 1555–1563. [Google Scholar] [CrossRef]

- Aranha, P.E.; Miranda, C.; Cardoso, W.; Campos, G.; Martins, A.; Gomes, F.C.; de Araujo, S.B.; Carvalho, M. A comprehensive theoretical and experimental study on fluid displacement for oilwell-cementing operations. SPE Drill. Complet. 2012, 27, 596–603. [Google Scholar] [CrossRef]

- Bu, Y.; Li, Z.; Wan, C.; Li, H.A. Determination of optimal density difference for improving cement displacement efficiency in deviated wells. J. Nat. Gas Sci. Eng. 2016, 31, 119–128. [Google Scholar] [CrossRef]

- Zulqarnain, M.; Tyagi, M. Development of simulations based correlations to predict the cement volume fraction in annular geometries after fluid displacements during primary cementing. J. Pet. Sci. Eng. 2016, 145, 1–10. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Z.; Zeng, Q.; Li, J.; Guo, X. Lattice Boltzmann simulation for steady displacement interface in cementing horizontal wells with eccentric annuli. J. Pet. Sci. Eng. 2016, 145, 213–221. [Google Scholar] [CrossRef]

- Anglade, C.; Papon, A.; Mouret, M. Constitutive parameter identification: An application of inverse analysis to the flow of cement-based suspensions in the fresh state from synthetic data. J. Non-Newton. Fluid Mech. 2017, 241, 14–25. [Google Scholar]

- Wu, W.; Huang, X.; Li, Y.; Fang, C.; Jiang, X. A modified LBM for non-Newtonian effect of cement paste flow in 3D printing. Rapid Prototyp. J. 2019, 25, 22–29. [Google Scholar] [CrossRef]

- Bao, K.; Lavrov, A.; Nilsen, H.M. Numerical modeling of non-Newtonian fluid flow in fractures and porous media. Comput. Geosci. 2017, 21, 1313–1324. [Google Scholar] [CrossRef]

- Tardy, P.M.J. A 3D model for annular displacements of wellbore completion fluids with casing movement. J. Pet. Sci. Eng. 2018, 162, 114–136. [Google Scholar] [CrossRef]

- Tardy, P.M.J.; Bittleston, S.H. A model for annular displacements of wellbore completion fluids involving casing movement. J. Pet. Sci. Eng. 2015, 126, 105–123. [Google Scholar] [CrossRef]

- Zhou, Y.; Wojtanowicz, A.K.; Li, X.; Miao, Y. Analysis of gas migration in Sustained-Casing-Pressure annulus by employing improved numerical model. J. Pet. Sci. Eng. 2018, 169, 58–68. [Google Scholar] [CrossRef]

- Naccache, M.F.; Pinto, H.A.M.; Abdu, A. Flow displacement in eroded regions inside annular ducts. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 420. [Google Scholar] [CrossRef]

- Foroushan, H.K.; Ozbayoglu, E.M.; Miska, S.Z.; Yu, M.; Gomes, P.J. On the Instability of the Cement/Fluid Interface and Fluid Mixing (includes associated erratum). SPE Drill. Complet. 2018, 33, 063–076. [Google Scholar] [CrossRef]

- Skadsem, H.J.; Kragset, S.; Lund, B.; Ytrehus, J.D.; Taghipour, A. Annular displacement in a highly inclined irregular wellbore: Experimental and three-dimensional numerical simulations. J. Pet. Sci. Eng. 2019, 172, 998–1013. [Google Scholar] [CrossRef]

- Murphy, E.; Lomboy, G.; Wang, K.; Sundararajan, S.; Subramaniam, S. The rheology of slurries of athermal cohesive micro-particles immersed in fluid: A computational and experimental comparison. Chem. Eng. Sci. 2019, 193, 411–420. [Google Scholar] [CrossRef]

- Rosenbaum, E.; Massoudi, M.; Dayal, K. The Influence of Bubbles on Foamed Cement Viscosity Using an Extended Stokesian Dynamics Approach. Fluids 2019, 4, 166. [Google Scholar] [CrossRef] [Green Version]

- Ohen, H.A.; Blick, E.F. Golden section search method for determining parameters in Robertson-Stiff non-Newtonian fluid model. J. Pet. Sci. Eng. 1990, 4, 309–316. [Google Scholar] [CrossRef]

- Shahriar, A.; Nehdi, M.L. Artificial intelligence model for rheological properties of oil well cement slurries incorporating SCMs. Adv. Cem. Res. 2012, 24, 173–185. [Google Scholar] [CrossRef]

- Shahriar, A.; Nehdi, M. Modeling Rheological Properties of Oil Well Cement Slurries Using Multiple Regression Analysis and Artificial Neural Networks. Int. J. Mater. Sci. 2013, 3, 13. [Google Scholar]

- Shahriar, A.; Nehdi, M.L. Optimization of rheological properties of oil well cement slurries using experimental design. Mater. Struct. 2012, 45, 1403–1423. [Google Scholar] [CrossRef]

- Bassioni, G.; Ali, M.M.; Almansoori, A.; Raudaschl-Sieber, G.; Kühn, F.E. Rapid determination of complex oil well cement properties using mathematical models. RSC Adv. 2017, 7, 5148–5157. [Google Scholar] [CrossRef] [Green Version]

- el Mahdi Safhi, A.; Benzerzour, M.; Rivard, P.; Abriak, N.-E. Feasibility of using marine sediments in SCC pastes as supplementary cementitious materials. Powder Technol. 2019, 344, 730–740. [Google Scholar] [CrossRef]

- Watts, B.; Tao, C.; Ferraro, C.; Masters, F. Proficiency analysis of VCCTL results for heat of hydration and mortar cube strength. Constr. Build. Mater. 2018, 161, 606–617. [Google Scholar] [CrossRef]

- Ferraro, C.C.; Watts, B.; Tao, C.; Masters, F. Advanced Analysis, Validation and Optimization of Virtual Cement and Concrete Testing; Florida Department of Transportation: Tallahassee, FL, USA, 2017; Available online: https://trid.trb.org/view/1569681 (accessed on 23 January 2020).

| Cement Properties | Value |

|---|---|

| Cement Powder Density | 3.15 g/cm3 |

| Cement Slurry Density | 1.38 g/cm3–2.28 g/cm3 |

| Cement Particle Size | 0.1 to 100 |

| Compressive Strength | 20–40 Mpa |

| Maximum Solid Concentration Packing | 0.65 (spherical particles) |

| in the Krieger and Dougherty’s relation | 1.5–2 |

| Viscosity of the Continuous Phase (Base Fluid) | 1 cP for water at 20 °C |

| Reynolds Number | 2716–3971 |

| Author(s) | Model | Equation No. |

|---|---|---|

| Bingham (1922) | (2) | |

| Bingham (tensor form) | (4) | |

| Herschel–Bulkley (1926) | (9) | |

| Power-Law (1929) | (10) | |

| Williamson (1929) | (11) | |

| Eyring (1936) | (12) | |

| Sisko (1958) | (13) | |

| Casson (1959) | (14) | |

| Shangraw–Grim–Mattocks | (15) | |

| Ellis (1965) | (16) | |

| Robertson and Stiff (1976) | (17) | |

| Robertson and Stiff (tensor form) | (18) | |

| Vom Berg (1979) | (19) | |

| Lapasin (1979) | (20) | |

| Quemada (1984) | (22) | |

| Modified Casson (1985) | (23) | |

| Atzeni (1985) | (24) | |

| Lapasin (1983) | (25) | |

| De Kee (1994) | (29) | |

| Modified Bingham (2001) | (30) | |

| Yahia and Khayat (2001) | (31) | |

| Vipulanandan (2014) | (32) | |

| Yuan (2015) | (33) |

| Equation | K | n | a | b | c | ||||

|---|---|---|---|---|---|---|---|---|---|

| Bingham (1922) | 20 | 0.8 | - | - | - | - | - | ||

| Herschel–Bulkley (1926) | 20 | - | 2.5 0.25 | 0.75 1.25 | - | - | - | - | - |

| Power-Law (1929) | - | - | 2.5 | 0.75 | - | - | - | - | - |

| Casson (1959) | 20 | 0.31 | - | - | - | - | - | - | - |

| Robertson and Stiff (1976) | - | - | - | - | 20 | 1.5 | 0.35 | - | - |

| Vom Berg (1979) | 20 | - | - | - | 26.5 | 0.1 | - | - | - |

| Quemada (1984) | - | - | - | - | 0.14 | 10−4 | 0.14 | - | - |

| Lapasin (1983) | 12.1 | - | - | - | 2100 | 9.45 | 56.1 | 43.6 | 87.6 |

| De Kee (1994) | 20 | 0.89 | - | - | 10−3 | - | - | - | - |

| Modified Bingham (2001) | 20 | 1.15 | - | - | - | - | −0.0035 | - | - |

| Yahia and Khayat (2001) | 20 | 0.9 | - | - | 10−3 | - | - | - | - |

| Vipulanandan (2014) | 40 | - | - | - | 1.38 | 0.004 | - | - | - |

| Effect | Author(s) | Model | Equation No. |

|---|---|---|---|

| Effect of concentration | Legrand (1970) | (34) | |

| Sybertz and Reick (1991) | (35) | ||

| Zhou et al. (1999) | (36) | ||

| Zhou et al. (1999) | (37) | ||

| Flatt and Bowen (2006) | (38) | ||

| Ma and Kawashima (2019) | (40) | ||

| Chateau–Ovarlez–Trung (2008) | (41) | ||

| Chougnet (2008) | (42) | ||

| Lapasin et al. (1983) | (43) | ||

| Effect of water-to-cement ratio | Rosquoët et al. (2003) | (44) | |

| Lapasin et al. (1979) | (45) | ||

| Effect of additives/admixtures | Ivanov and Roshavelov (1990) | (46) | |

| Sybertz and Reick (1991) | (47) | ||

| Effect of damage | Chen et al. (2013) | (48) |

| Cement Type | Strain Rate (1/s) | ||

|---|---|---|---|

| Type I, dispersed | 25 | 0.64 | 5.1 |

| 500 | 0.76 | 6.2 | |

| Type I, flocculated | 500 | 0.64 | 6.3 |

| White cement, dispersed | 25 | 0.67 | 5.7 |

| 500 | 0.80 | 6.8 | |

| Type V, dispersed | 25 | 0.68 | 4.5 |

| 500 | 0.75 | 5.2 |

| Effect | Author(s) | Model | Equation No. |

|---|---|---|---|

| Effect of shear rate | Ostwald-de Waele (1929) | (49) | |

| Robertson and Stiff (1976) | (50) | ||

| Casson (1959) | (51) | ||

| Carreau–Yasuda (1997) | (52) | ||

| Effect of volume fraction | Einstein (1906) | (53) | |

| Roscoe (1952) | (54) | ||

| Mooney (1951) | (55) | ||

| Roscoe (1952) | (56) | ||

| Krieger and Dougherty (1959) | (57) | ||

| Chen and Lin (2017) | (58) | ||

| Murata and Kikukawa (1973) | (59) | ||

| Sybertz and Reick (1991) | (60) | ||

| Mills (1985) | (61) | ||

| Liu (2000) | (62) | ||

| Chong et al. (1971) | (63) | ||

| Effects of temperature and pressure | Sercombe et al. (2000) | (64) | |

| (65) | |||

| Scherer et al. (2010) | (66) | ||

| (67) | |||

| (68) | |||

| Pang et al. (2013) | (69) | ||

| (70) | |||

| Wu et al. (2014) | (71) | ||

| (72) | |||

| (73) | |||

| Effect of additives/admixtures | Ivanov and Roshavelov (1990) | (75) | |

| Sybertz and Reick (1991) | (76) | ||

| Effect of measurements (slip) | Bannister (1980) | (77) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, C.; Kutchko, B.G.; Rosenbaum, E.; Massoudi, M. A Review of Rheological Modeling of Cement Slurry in Oil Well Applications. Energies 2020, 13, 570. https://doi.org/10.3390/en13030570

Tao C, Kutchko BG, Rosenbaum E, Massoudi M. A Review of Rheological Modeling of Cement Slurry in Oil Well Applications. Energies. 2020; 13(3):570. https://doi.org/10.3390/en13030570

Chicago/Turabian StyleTao, Chengcheng, Barbara G. Kutchko, Eilis Rosenbaum, and Mehrdad Massoudi. 2020. "A Review of Rheological Modeling of Cement Slurry in Oil Well Applications" Energies 13, no. 3: 570. https://doi.org/10.3390/en13030570

APA StyleTao, C., Kutchko, B. G., Rosenbaum, E., & Massoudi, M. (2020). A Review of Rheological Modeling of Cement Slurry in Oil Well Applications. Energies, 13(3), 570. https://doi.org/10.3390/en13030570