1. Introduction

Energy security has become a concern in Japan since the accident of the Fukushima nuclear power plant. Furthermore, the global trend toward non-fossil fuels by the sustainable development goals (SDGs) is accelerating renewable energies. Hence, the microalgae biofuel production system is highly promising, but the challenge is its competitiveness with existing energy supply systems. Research has been conducted after the incident of the nuclear power plant to increase renewable energy production.

Microalgae is referred to as one of the best candidates for biofuel production, a source of renewable energy. Fuel production from microalgae in the Minamisoma pilot plant measuring 0.1 ha has been reported, which can facilitate 50 m

3/day in an open raceway pond (ORP) [

1]. Simulation was conducted based on experimental results that considered profitability, energy balance, and emission of environmental load (GHG). Major species of microalgae that had been cultivated were

Desmodesmus sp.,

Dictyosphaerium sp.,

Klebsormidium sp.,

Micractinium sp., and

Scenedesmus sp. [

2].

The bottlenecks in profitability were nutrients and freshwater for algae growth. However, if wastewater were used for microalgae cultivation, costs could be reduced from 1605.9 JPY (14.1 USD: the exchange in

Table A1 in

Appendix A was used)/kg-biocrude-wet to 160.6 JPY (1.4 USD:

Table A1)/kg-biocrude-wet [

1]. Moreover, to fulfill energy demand, a bottleneck in energy balance was the energy requirement for circulating water in the ORP, the hydrothermal-liquefaction (HTL) process, and the centrifugation process.

A previous study showed that the use of wastewater with the addition of CO

2 gas was effective for microalgal growth and reduced CO

2 [

3]. However, in that study, the introduction and the total system’s emissions of wastewater treatment by microalgae were not explained because the details of the oil-production system from algae were unknown. The experiment at the Minamisoma plant showed that wastewater was a potential source from households that could be used after filtration in the ORP for microalgae production [

4]. Wastewater could serve as a nutrient source for culturing microalgae, which could additionally reduce energy and CO

2. Theoretical calculations of microalgae oil production have been reported [

5]; however, the theoretical and practical values calculated differed vastly. Hence, an accurate estimation of CO

2 emissions is highly required. A simulation is required based on the life cycle assessment (LCA) approach to project oil production potentiality from microalgae at the Minamisoma pilot plant.

Therefore, the purpose of this research is to evaluate the potential of microalgae oil production integrated with wastewater treatment including microalgae cultivation. Wastewater treatment and microalgae production could reduce the required energy and CO2 emission, which could improve microalgae systems. This research differs from previous studies in the following two ways. First, the reproducibility in commercial plants is high because the parameters are set by experimental values from Minamisoma and not theoretical values. Secondly, the comparison is being made with the existing systems that are replaceable because of their superiority, with a thorough assessment of the applicability of the technology.

2. Methodology

The authors conducted repeated laboratory experiments, and field experiments using outdoor culture ponds of 33 m

2 which located in Kurihara (Ibaraki Prefecture), and culture pond of 1000 m

2 in Minamisoma. From the cultivation phase up to biocrude production phase, many issues were raised and a detailed procedure for full-scale plant design was obtained [

4]. Based on these results, this study simulation was performed. The main reconstruction was emphasized based on five aspects: use of wastewater, reducing commercial nutrients, energy of circulation equipment, energy requirements for HTL, and centrifugation processes. These five aspects have been considered in a previous study regarding microalgae oil-production systems [

5].

The suitable combination between an algae system and wastewater treatment plant (WWTP) was investigated; subsequently, an oxidation ditch (OD) method for WWTPs [

6] was discovered. Regarding wastewater use, semi-continuous cultivation with overflowing wastewater (primary treatment water) and sodium acetate (0.3 g/L) in the first sedimentation basin was performed at the Tobu purification center (standard activated sludge method) located in the Ibaraki prefecture. Consequently, an algae biomass productivity of 0.037 to 0.049 g/L/day has been reported [

4].

Algal production from primary treatment water has been confirmed. However, the possibility of raw sewage from the OD method can be used instead of overflowing wastewater from the standard activated sludge method (Tobu purification center). The auxiliary experiment, which was performed using raw sewage from the university’s sewage pit, indicated a possibility. The result of algae productivity was 16.8 g/m

2/day with a hydraulic retention time (HRT) of 4 days and add 5% CO

2 (1 L/min/10 L-wastewater) [

7]. Therefore, algal production using raw sewage in the OD method was assumed, where wastewater can be used to reduce freshwater load. However, further research is required on algae productivity values.

Regarding the reduction of commercial nutrients, the waste from the HTL process could be recycled as nutrients [

4]. The additional use of waste organic acids from the HTL process at a high algae concentration is effective for promoting growth. In that experiment, waste organic acids from the HTL process were treated by activated carbon. Half of the nutrients were recycled from the waste and the other half of the nutrients were provided by sodium acetate from commercial nutrients that were used in the initial stage of culture with low algae concentrations.

The energy requirement, such as circulation in an ORP, was calculated from existing facilities in Minamisoma [

4,

5]. However, in this study, the equipment size and number were optimized for the usage time and maximum daily processing capacity, of which the values were calculated using a function (

Appendix A) that reflected the reality better. Also, energy consumption was reduced by changing the centrifugation to condensed sedimentation with flocculants. Furthermore, for the HTL energy, waste heat from power plants or other facilities was used for heat treatment, instead of electricity.

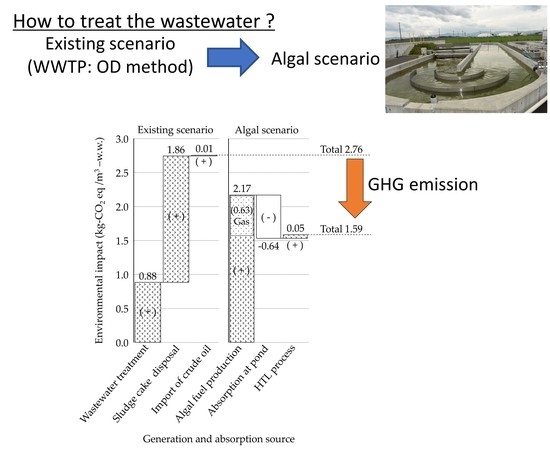

In terms of environmental impact, it was assumed that the exhaust gas and exhaust heat from the power plant could be used without any cost or environmental impact. Also, algae absorption in the culture pond was considered, as well as the emissions related to sludge cake treatment from the OD method. Therefore, two scenarios are proposed in this study: “existing wastewater treatment scenario (existing scenario)” and “algae integrated wastewater treatment scenario (algal scenario)”.

In the wastewater treatment system, the existing scenario begins with aeration and the algal scenario with cultivation (

Figure 1). For comparison, both scenarios treat the same 1 m

3 of wastewater and produce or import oil of 2.17 MJ. Furthermore, each process’ mass of 50-m

3-based experiment was divided into 1 m

3 (

Table 1). Biocrude-wet was assumed as the final product in the algal scenario to compare with crude oil in the existing scenario. After the HTL process, the microalgae are converted to biocrude-wet and the aqueous phase. Subsequently, the substance that dries the biocrude-wet at a temperature of 105 °C until the weight change within 30 seconds is less than 0.01% is called biocrude-dry. The approximate value of two-third of the biocrude-wet to biocrude-dry (0.66) was obtained from the open raceway pond at Minamisoma (Dominant species:

Desmodesmus sp.), under the university of Tsukuba [

8]. One example, the ratio was 0.76, which calculated from below. The 798.8 g at 19.9% biomass suspended solid (SS) of biocrude-wet yielded 611.0 g of biocrude-dry. Under the experimental temperature of 350 °C and a pressure of 19.4 MPa in the HTL process. In another example, using a ratio of 0.69, a 669.7 g at 18.9% SS of biocrude-wet yielded 458.8 g of biocrude-dry. Under the experimental conditions of 350 °C and 19.5 MPa in the HTL process.

Therefore, 113 g of biocrude-wet was purified to 74.7 g (113.2 g × 0.66) of biocrude-dry. Moreover, 74.7 g of biocrude-dry was equal to 48.4 g of crude oil, based on the same higher heating value (HHV) equivalent to 2.17 MJ (0.0747 kg × 29.1 MJ/kg ≈ 0.0484 kg × 44.9 MJ/kg). The processes within the dotted lines represent the system boundary. However, input and output processes such as (O2) and (CO2) were not calculated.

2.1. Existing Wastewater Treatment Scenario (Existing Scenario)

The direct energy and materials for the existing scenario were calculated to estimate the environmental effect; 1 m3 of wastewater treatment was included in 690 g of the disposal sludge cake and 48.4 g of the imported crude oil. The construction energy and materials were not involved in this calculation because the constructed WWTP’s ditch and equipment were likely to be used for algae production. All data to calculate the existing scenario were from a related study.

The existing scenario included CO2 equivalent (eq) emissions for three operational units: emissions from the WWTP by the OD method, from the sludge cake disposal treatment, and from the imported crude oil. The OD method was selected so that the WWTP could be used as a competitor in the algal scenario. The treatment tank of the OD method was similar to the ORP for microalgae cultivation except for the water depth. The general water depth in the OD method was 2.5 m.

2.2. Algae Integrated Wastewater Treatment Scenario (Algal Scenario)

In the algal scenario, 1 m

3 of wastewater can be treated by generating 113 g of biocrude-wet by cultivating the microalgae. The flocculation tank was set in this scenario because using a polymer flocculant and flocculation tank was more efficient than using centrifuges, which were used at Minamisoma (

Table 2). If the centrifugal separator is used for dewatering, the energy usage will be 3–5 kWh/kg-dry-microalgae. Therefore, approximately 30 MJ/L-biocrude was required, which is comparable to the amount of heat generated by biocrude itself. Also, the flocculation system was already used in the OD method’s WWTP in Japan. In addition, a technical methodology for wastewater treatment had been established and optimized.

The environmental impact values were converted to CO2 eq using the global warming potential in 100 years’ time horizon (GWP 100) with SimaPro® v8.0.4. The SimaPro® is the name of LCA software developed by PRé Sustainability company located in the Netherlands.

Relevant data were collected from previous studies. Wastewater was introduced from a sewage facility as a nutrient for the microalgae. The production of microalgae was calculated based on the results obtained from the pilot plant of microalgae biofuel production in Minamisoma [

4]. Subsequently, sufficient exhausted CO

2 and waste heat were assumed for algae fuel production.

The feasibility of wastewater treatment was integrated with microalgae growth culture [

4]. In that experiment, the algal system successfully treated wastewater collected from the Kokaigawa Tobu WWTP in Ibaraki prefecture in December 2018. Before the treatment, the water exhibited a 5-day biochemical oxygen demand (BOD

5) of 52 mg/L, suspended solids (SS) of 140 mg/L, total nitrogen (TN) of 23 mg/L, and total phosphorus (TP) of 4.5 mg/L. Subsequently, after being treated by the algal system, the water exhibited a BOD

5 of 17 mg/L, SS of 18 mg/L, TN of 7.3 mg/L, and TP of 0.19 mg/L. Meanwhile, the water treated by the WWTP exhibited a BOD

5 of 11 mg/L, SS of 15 mg/L, TN of 9.1 mg/L, and TP of 1.4 mg/L. Both systems cleared the standard limit, which was a BOD

5 of less than 40 mg/L and an SS of less than 40 mg/L.

Moreover, the required amounts measured from the conventionally used artificial medium [

7] were TN of 14.0 mg/L and TP of 1.2 mg/L. Compared with before the treatment, the BOD

5 was 52 mg/L, SS 140 mg/L, TN 23 mg/L, and TP 4.5 mg/L, and the TN and TP were sufficient for the inflow wastewater.

The algal scenario included emissions from wastewater treatment as a nutrient for the microalgae, CO2 absorption at the ORP, and CO2 emission in the HTL. Furthermore, the algal scenario included the use of CO2 containing exhaust gas in the ORP and the use of discharged heat in the HTL process from power plants.

The water depth of the ORP for producing microalgae was 0.2 m. Furthermore, experiments in the Minamisoma plant revealed that it could grow even at a depth of 0.8 m. A difference in distance exists between the OD method (2.5 m) and algae ORP (0.8 m). However, the processing capacity of a WWTP using the OD method is generally half that of Tochigi prefecture. Some WWTPs using the OD method used only 3% of its capacity. WWTPs using the OD method are in a rural area. Therefore, if the system capacity is reduced to one third, and assuming that both HRTs are the same, the algal system can be introduced by reducing the depth of the OD from 2.5 to 0.8 m.

From the experimental analysis, it was discovered that the primary overflow water at a standard activated sludge method can be used for algal cultivation. However, in this scenario, the nonprimary treated water at the OD method was set instead of the primary overflow water. Consequently, the effect of algae growth may not be the same throughout the process.

2.2.1. Datasets for Simulation

To calculate the CO2 emission and energy profit ratio (EPR) in the algal scenario, the following data were used in the simulation process. The data were based on the experiment at Minamisoma, from the input of 50 m3-wastewater (m3-w.w.) per day produced by 5.66 kg biocrude-wet. First, the calculation was done based on 50 m3-w.w./day and then divided the result by 50 to adapt to the 1 m3-w.w. of the algal scenario.

More than one hundred parameters had to be calculated in the algal scenario. For convenience, the parameters were categorized into independent, dependent, and fixed. The independent parameters imply that the parameters can be adjusted based on the situation. The dependent parameters change dynamically based on the independent and fixed parameters. The fixed parameter is fixed by experience and literature data (

Table A1). The independent and dependent parameters are explained below, and part of the dependent parameters used in the functions (

Table A2 and

Table A3).

2.2.2. Use of Previous Research Results

The calculation of the algal scenario’s process in this study is a continuation of the theoretical energy analysis of algae fuel production [

5]. The theoretical data was revised to experimental data using new experimental datasets (

Table 3). The expanded calculation was performed to estimate the environmental effect.

In the algal scenario, cultivation, filtration, and extraction were used similarly as in the previous study. However, for the centrifugation process, the centrifuge equipment was replaced with a flocculation tank to reduce the energy input.

Moreover, a purification process was introduced. In a previous study [

5], the HHV of biocrude-wet was set as 34.2 MJ/kg-biocrude-wet. However, in [

4], the HHV of biocrude-dry was 29.1 MJ/kg-biocrude-dry for the microalgae purification in Minamisoma. Biocrude-wet was set as the final product for the flexibility of use for purifications that depend on the use purpose. Furthermore, the price is determined in the biocrude-wet condition, with consideration of moisture content.

2.2.3. Design Parameter of Raceway Pond

The basic parameters were set to calculate the CO

2 emissions and EPR (

Table 4). As mentioned previously, the independent parameters (

Table A1) based on the situation (

Figure 2) at Minamisoma, and the dependent parameters (

Table A2 and

Table A3) were read from the independent parameters automatically. For example, the pump capacity (83 L/min) was calculated by the daily handling volume (50 m

3) divided by the working hours C (pump)(10 h/d), and divided by 60 min, in which the daily handling volume (50 m

3) was obtained from the pond volume (200 m

3) divided by the HRT (4 d). All calculations were based on the handling of 50 m

3-w.w. per day.

2.2.4. Cultivation

In this section, the details of the parameters set and the mass balance for cultivation (ORP) in the algal scenario are provided (

Table 5 and

Figure 3). The wastewater was used as the liquid medium and nutrient, based on [

4], which refers to the possibility of wastewater as a water and nutrient supplier for the algae. As mentioned above, the additional CO

2 (concentration 15%) was recycled from exhausted CO

2 by a power plant or garbage incinerator. CO

2 eq emissions were not observed. However, 55% (0.325 kg/m

3-w.w.) of input CO

2 generated an output to the atmosphere without absorption. Therefore, a direct emission in the scenario was calculated.

In the dependent parameters, the brackets are marked “(e4), (e1), and (n4).” These brackets implied that they were determined by the formulated function. For example, the electricity for the paddlewheel value of 36 MJ/day was calculated from (e4), {2.75 × 0.2 m (Depth)} kW × 18 h/day × 3.6 MJ/kWh = 36 MJ/day. Subsequently, electricity was added for a pump (

Figure 4), and the total electricity was 72.7 MJ/day. The electricity of 72.7 MJ/day was calculated based on a one-day handling volume of 50 m

3 in Minamisoma. The calculation standard of the algal scenario is 1 m

3. To divide by 50 m

3 for adopting 1 m

3, the electricity consumption was observed 1.45 MJ/m

3.

As mentioned in the Methodology, the exhausting nutrient from the HTL process was set in algal cultivation, because the exhausted nutrient could be used as a substitution of acetic acid [

4]. Half of the acetic acid was replaced in this scenario. The total mass of acetic acid input was set at 0.3 g/L. Other masses of input, output, and waste were the same of those of a previous study [

5]. The microalgae proceeded to the sedimentation process after cultivation.

2.2.5. Sedimentation

The flocculant sub-unit is a sedimentation process, described in the next sections of the cultivation system (

Figure 1). In this unit, input is first received from the cultivation sub-unit and is concentrated in the flocculant tank. Subsequently, the output is passed on to the filtration sub-unit (

Figure 5).

The centrifuge equipment (

Figure 6) was replaced with a flocculation tank to reduce the energy input. A polymer coagulant (3 g/m

3-w.w.) for harvest (Sedimentation A) and a polymer coagulant (0.5 g/m

3-w.w.) with Polytec solution (0.25 kg/m

3-w.w.) can be used for treating the waste (Sedimentation B); additionally, electricity (0.04 kWh/m

3-w.w.) instead of centrifuge (1 kWh/m

3-w.w.) can be used in the same microalgae recovery rate [

4] (

Table 6). The surplus material was known as “waste” instead of the term “sludge” used in [

5], but their contents were the same.

2.2.6. Filtration

In the drum filtration sub-unit, algae were concentrated by the pressure of the drum filter (

Figure 7). In this unit, the input from the flocculant sub-unit was passed to the HTL sub-unit (

Figure 8). The biomass microalgae (MA) passing rate was set at 98.02%, while it was set as 100% in the flocculant sub-unit because some biomass remained in the filter and were beyond the system boundary (

Table 7).

2.2.7. Extraction (HTL)

In this HTL sub-unit (

Figure 9), the input from the drum filtration sub-unit produces the biocrude-wet (

Figure 10). The number of HTL units was set as three by the daily handling mass of microalgae and the working hours (

Table 8). In the HTL process, the waste heat energy was used, which required more than 350 °C (8.59 MJ/m

3-w.w.). The CO

2 emissions of 0.053 kg implied a direct CO

2 emission in the HTL process, which differed from the calculated total CO

2 eq. The direct CO

2 emission was calculated from biomass stoichiometry. After the HTL sub-unit, 113 g of biocrude-wet was produced. The biocrude-wet contained H

2O. After drying the H

2O by purification, 74.7 g of biocrude-dry (HHV: 2.17 MJ/kg) was produced. However, this purification method and output ratio were different by purpose to use the biocrude. For example, in the desalter process before the distillation process in the petroleum refining industry, water is added to crude oil for desalting. Hence, the calculation was set based on biocrude-wet, which is before the purification.

4. Conclusions

This study concludes that the microalgae’s realistic scenario using the discharged heat could be effective in treating general wastewater and emitted CO2, in terms of EPR and CO2 emissions. The EPR was 0.41 in the algal scenario as compared with the existing scenario’s 0.21. In addition, the environmental impact could be reduced from 2.76 to 1.59 kg-CO2 eq/m3-w.w. This is combined with 1 m3 of wastewater treatment, waste heat use from power plants, and CO2 absorption in algae production. The waste heat use in the HTL process was 21.5 MJ/m3-w.w. A comprehensive and realistic whole scenario from the cultivation process to biocrude purification was proposed for the first time in terms of environmental impact and energy balance as presented by this study.

Moreover, in the HTL process, experimental data from the Minamisoma plant showed that 113 g of biocrude-wet was produced from 1.42 kg of 20% microalgae (280 g dry weight). Meanwhile, based on stoichiometry, 213 g of biocrude-wet could be produced from 280 g of dry weight of microalgae. This indicated that the experimental value was only half the theoretical value. If the HTL process yielded the theoretical value, then the operating EPR would increase from 0.4 to 0.8 including wastewater treatment. Hence, the EPR could reach 1.0 by improving the efficiency of cultivation, sedimentation, filtration, HTL extraction of microalgae, and scale-up of ORP from 50 m3/day, as well as changing the production area to a warm place where algae could grow easily.

In this study, the algal scenario exhibited some limitations to scale up the pilot plant to the commercialization scale. In general, a system with low energy consumption and low GHG emissions tend to have lower costs. Therefore, it can be assumed that the algal scenario is more economical than the existing scenario. Further studies are required not only the environment but also the economical optimization together, to push up the commercialization stage of the algae scenario.