1. Introduction

Monitoring the degradation of photovoltaic (PV) modules during accelerated stress testing is crucial for understanding the degradation kinetics of the PV modules. Moreover, accurate module power loss data with high temporal resolution is necessary for developing accelerated PV degradation models for predicting PV module lifetime in the field. However, often times, the accelerated tests have to be interrupted, for the PV modules to be characterized on Sun simulators and their power loss measured [

1]. This limits the number of intermediate module power degradation measurements that can be acquired in practice, and is a time-consuming process in itself. Therefore, in-situ (semi) continuous module degradation monitoring methods are necessary.

In-situ module monitoring methods have been developed for different types of accelerated stress tests, stress factors and degradation parameters. Module moisture monitoring during accelerated aging tests for PV module encapsulants, was proposed by Carlsson et al. [

2], by integrating a moisture sensor inside thin-film modules. Tanahashi et al. [

3] proposed in-situ monitoring of AC impedance parameters of PV modules undergoing rapid thermal cycling stress tests, for detecting solder bond failures after prolonged test cycles. A method for monitoring module degradation during dynamic mechanical load testing, was proposed by Bosco et al. [

4], by forward biasing the PV module with a small sinusoidal voltage signal and measuring the differential conductance, and was used to determine the occurrence of ribbon failure and the cycle/time-to-failure. More advanced PV characterization methods, such as electroluminescence (EL) imaging were also implemented for in-situ monitoring of PV module degradation during mechanical load stress testing [

5], as well as integrated into the environmental test chamber, for monitoring of modules undergoing combined accelerated stress testing [

6].

Monitoring the module’s maximum power (

) at Standard Test Conditions (STC: 1000 W/m

2, 25 °C, AM 1.5) during stress testing, is especially important for accelerated stress testing, as it is the reference condition for reporting PV module efficiency and performance parameters. Such a method was previously developed by Hacke et al. [

7], for in-situ monitoring the STC

degradation of crystalline silicon (c-Si) PV modules undergoing voltage stress testing and experiencing shunting type potential-induced degradation (PID-s). The method is based on translating dark current-voltage (I-V) curves acquired in-situ, at 25 °C, from the first to the fourth I-V quadrant. This was achieved by superposition of the dark I-Vs with the module’s short circuit current (

), determined at the beginning of the test. Later, a method was developed for estimating STC

degradation, due to PID-s, from the dark I-V curves measured in-situ at the stress temperature (typically 60 °C or 85 °C), without the need to ramp down the test chamber temperature to 25 °C [

8,

9].

Estimation of the PV module’s STC

degradation from dark I-V measurements was possible because the PID-s mechanism in c-Si modules largely manifests by fill-factor loss due to increasing junction recombination (2nd diode pre-exponential,

) and decreasing shunt resistance (

) [

7], which impact both the dark I-V and light I-V characteristics in similar proportions. However, STC

estimation by dark I-V superposition is limited [

10] if delamination, increased series resistance (

) or photo-current degradation occurs, which affect the light I-V characteristic primarily. Other degradation mechanisms impact the dark and light I-V characteristics of the PV module differently, therefore the dark I-V based STC power estimation method, needs to be to account for degradation of the other solar cell parameters associated with the degradation mode.

Modules undergoing thermo-mechanical stress and cell breakage may undergo

increases due to increased unpassivated surface area at fracture surfaces,

losses due to metallization breaks and solder bond failure [

11,

12],

and junction ideality factor increases, and shunt resistance decreases due to increased physical defects penetrating the junction [

13]. Additionally, some fraction of the cell circuit may be removed when the cell and its metallization become electrically disconnected [

14].

To study these compound degradation modes and develop an in-situ power loss estimation method, modules underwent mechanical loading, thermal cycling and humidity-freeze cycles to impart mechanical damage, during which dark I-V curves and STC flash tests were obtained, and used in equivalent solar cell diode model analysis of the degradation. Thereafter a method is developed for estimating STC power loss in three steps: (i) estimate the effects of shunting and recombination losses by superposition of the dark I-V curves with the initial STC to the first quadrant, and rough estimation of the STC (ii) estimate and losses from the dark I-V slope at high current, and correct the rough STC estimation; and (iii), correct the STC power estimates obtained during the course of degradation, based on module flash testing at the end of the stress test - to include effects of additional series resistance losses observed with illumination, recombination losses, and current mismatch losses. This is achieved by matching the final dark I-V curve-determined to the final flash-test-determined STC , and adjusting the intermediate power loss estimates accordingly.

2. Experiment and Module Degradation Analysis

Four new conventional 60-cell multi-crystalline silicon (mc-Si) PV modules of the same design were subjected to five rounds of stress consisting of 2400 Pa static mechanical loading,

°C to 85 °C thermal cycling (TC), and

°C to 85 °C at 85% RH humidity freeze (HF) cycling stress to various extents. The initial (new) state of the modules, along with the five subsequent stages of stress applied to the modules are designated with roman numerals (I-VI) and further detailed in

Table 1. The number of stress cycles were determined primarily through trial and error and repeatedly stressing and characterization of the modules, with the goal of inducing a progressive degradation of the modules, as well as noticeable power loss.

The degradation of module #1 can be observed in the EL images of the module shown in

Figure 1, where the new state of the module is shown in

Figure 1a, whereas the subsequent mechanical degradation of the module’s cells is shown in

Figure 1b–f. EL images showing the degradation of modules #2–#4 are shown in

Appendix A.1, in

Figure A1,

Figure A2,

Figure A3 respectively.

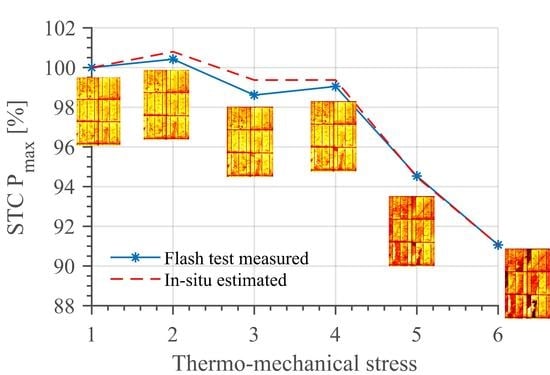

After each stress-test stage, the modules were flash tested under STC and low irradiance conditions (LIC, 200 W/m

2, 25 °C). The STC and low light

degradation is summarized in

Figure 2. Here we observe a final STC power degradation between 8% and 10.4 %, and between 5.5 % to 7 % LIC power loss.

The corresponding light I-V curves for module #1 are shown in

Figure 3a, where we can observe fill factor and short-circuit current losses to a lower extent. Whereas, the dark I-V characteristics of module #1, shown in

Figure 3b, show changes in both the high and low current regions of the dark I-V curve, associated with increased series resistance [

15] and shunt and recombination losses [

16], respectively. The electrical characteristics and power loss of modules #2–#4 are shown in

Appendix A.2,

Figure A4,

Figure A5,

Figure A6 respectively.

By examining the STC I-V curve parameters, we observe that the STC

, summarized in

Figure 4 for all four modules, contributes the most to the module performance degradation, which can be attributed primarily to the partial solar cell cracks, that increase the cells series resistance. Whereas a small decrease in

can be observed for module #1, and to a lesser extent in modules #2 and #3, which can be attributed to a reduced photo-current generating cell area, due to fully disconnected cell cracks.

In addition, the modules show

voltage losses in the later stages of the experiment (V and VI), shown in

Figure 5, whereas the

does not change significantly. Considering that the

ratio decreases in these stages as well, we can deduce that these losses are caused (at least in part) by an increase in series resistance [

17].

To further understand the modes of degradation associated with this type of stress, we analyze the equivalent solar cell parameters of the modules during degradation [

18]. To achieve this we fit the dark I-V curves (

) of the modules taken after each experiment stage to the two-diode solar cell model (

1), often used for dark I-V based solar cell diagnostics [

15]:

where

J is the current density;

V is the terminal voltage;

and

are the diode ideality factors;

and

are area-specific series and shunt resistance parameters, respectively, of the solar cell;

T is the cell temperature;

k is the Boltzmann constant; and

q is the elementary charge.

The effect of the module degradation on the equivalent solar cell model parameters is summarized in

Figure 6. From these results, we can confirm a substantial increase in module series resistance

, previously observed in the I-V parameters and caused by partial solar cell cracks and metallization breaks [

14]. Moreover, from

Figure 6 we can observe a significant increase in the

and

diode model parameters, suggesting solar cell junction degradation and recombination losses occurring in the junction. Lastly, the

and

diode model parameters increase to a lesser extent. This increase can be attributed here to increasing defects and unpassivated surfaces at the cell cracks, causing increased surface and bulk recombination losses.

Concluding on the analysis of the diode model parameters, we can group the power loss mechanisms into three categories: (i) shunting and recombination losses, (ii) series resistance losses, (iii) other losses including recombination losses, current mismatch losses, and a decrease in photo-current generation due to cell fracturing. In the next section we aim to estimate these failure modes’ effect on the module STC power loss separately.

4. Results and Discussion

We experimentally evaluate the accuracy and limits of the in-situ power loss estimation procedure, by comparing the PV module power losses determined in the three steps of the proposed method, with measured module power loss.

First we determine the extent of power loss due to shunting and

losses, by calculating

from (

2), using the

measured at at 1000, 600, and 200 W/m

2 irradiance, and 25 °C. The relative change in

of module #1 is shown in

Figure 7, versus the Sun simulator measured power of the module, denoted as

, under the same irradiance conditions. We can observe that the dark I-V superposition-based power loss estimation is poor, especially under high irradiance conditions and extensive degradation (up to 6% difference in relative power loss). This can be explained by the increased series losses that are not captured by the superposition method.

Similar trends can be observed by comparing STC

of the other module samples with their measured

shown in

Figure 8. As the modules degrade more by cell cracking, the estimation error increases. We can surmise that the shunting and

losses amount to up to 2% of the absolute power loss, explaining up to 30% of the power loss exhibited.

Next, to evaluate the extent of increased series resistance losses, we determine the increase in

from 25 °C dark I-V measurements and use it to estimate the relative module power loss (

), according to (

5) and (

7).

Figure 9 shows the estimated power loss

for module #1. It can be observed that the estimation has improved only slightly, however at 5% STC

degradation (stage V),

underestimates the module #1 degradation by 3% (absolute error), whereas at 10% module degradation (stage VI), the difference between the dark vs. light measured module power degradation can be as much as 5% (absolute error). This is explained by the limited capability of

to characterize the light series resistance, as well as the impact of

losses on the module STC power.

Similar estimation errors are observed for the other modules shown in

Figure 10, with the exception of module #3, which is closest to the ideal estimation line. One possible explanation is that module #3 had the least

losses among the four modules tested, as can be observed from

Figure 4.

The module power loss estimation must be improved by the final STC

adjustment, as in (

7) and (

8), which will compensate for most of the current mismatch, decrease in

and photocurrent-generation, and other losses such as

recombination losses, which are difficult to characterize from the dark I-V curve alone. These findings are consistent with previous research on methods for estimating PV module series resistance [

24], that have concluded that dark series resistance underestimated the light determined series resistance by more than 50%, in most cases [

24].

To exemplify the adjustment procedure, we used the initial and final STC flash test

to calculate the correction factor

from (

7), and use it to adjust the dark I-V-determined series resistance (

) as in (

8). The resulting

as well as

are compared in

Figure 11, with the STC flash test determined resistance of module #1, calculated after each stress stage. As can be observed, stages V and VI show a significant increase in the module’s series resistance that is not captured by

, but can be compensated for, by the final STC flash test, and thus included in

.

Finally,

is calculated by substituting

in (

6), and is compared with the STC measured

in

Figure 12. As can be observed, this approach leads to a more successful estimation of the module degradation, especially in the later stages of the experiment.

The errors between the

and STC

in the early stages of degradation result from the approximation that

scales linearly with the light series resistance, assumed in (

8). Second, flash test and dark I-V measurement errors are compounded, such that individual points in

Figure 12 may be affected. Despite these limitations, if we compare the root-mean-square error (RMSE) between the STC measured

, and the dark I-V estimated

, as in

Table 2 we can observe the final adjustments of the series resistance based on flash testing, and reduce the total estimation error by 3–6 times.

5. Conclusions

Tools and methods for monitoring PV module degradation, in-situ, during accelerated stress testing, are important for understanding the degradation kinetics and developing reliability and accelerated degradation modules, as well as for reducing the cost, duration and effort of accelerated stress tests.

In this regard, in-situ acquired dark I-V curves have previously been used to successfully monitor PID-s during voltage stress testing of c-Si PV modules, and were the basis of the in-situ monitoring method proposed in this work. However monitoring thermo-mechanical induced degradation of PV modules by dark I-V measurements is more challenging, due to the complex nature of the induced degradation modes. Namely, thermo-mechanical stress can compound several failure modes: micro-cracking, partial or complete cell cracking and disconnection, cell interconnect failure, and even delamination. These will affect cells in the modules to different extents, and are sometimes difficult to deconvolute from module level I-V characteristics or by equivalent solar cell model parameters, as the basic assumption of identical cells in the module is broken.

Part of the power loss caused by cell cracking—corresponding to shunting and junction recombination, can be estimated by superposition of the dark I-V with initial module short-circuit current, similar to the in-situ PID power loss estimation method. However, the majority of power loss caused by cell cracking is caused by an increase in the module’s distributed series resistance, which is not well captured by the dark I-V curve superposition method.

As was shown, part of the module’s increased series resistance can be estimated from the dark I-V characteristic, however, not completely. A final STC IV measurement, at the end of the stress test, is necessary to correct the dark I-V power loss estimation. However, module delamination and short-circuit current degradation, occurring during the stress test, will reduce the estimation accuracy of the in-situ method, for intermediate points of degradation. Therefore, for longer thermo-mechanical stress tests, intermediate flash tests would be necessary to correct the power loss estimation in these cases, or another in-situ measurement that is able to characterize degradation of the module’s photo-current generation properties.