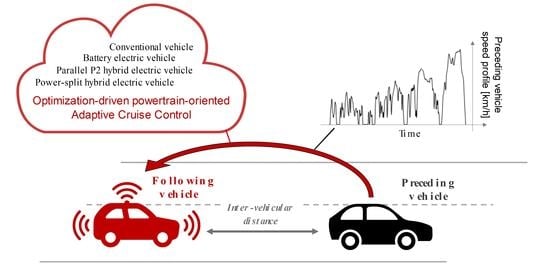

Optimization-Driven Powertrain-Oriented Adaptive Cruise Control to Improve Energy Saving and Passenger Comfort

Abstract

:1. Introduction

2. Vehicle Powertrains

2.1. CV Powertrain

2.2. BEV Powertrain

2.3. P2 HEV Powertrain

2.4. Power-Split HEV Powertrain

3. Multiobjective Optimal Car-Following Driving Problem

3.1. Constraints on the IVD

3.2. Constraints on the Following Vehicle Powertrain

4. Solving the Optimal Car-Following Driving Problem

4.1. CV Powertrain

4.2. BEV Powertrain

4.3. P2 HEV and PS HEV Powertrains

5. Results

6. Conclusions

Funding

Conflicts of Interest

Abbreviations

| ACC | Adaptive cruise control |

| AMT | Automated manual transmission |

| BEV | Battery electric vehicle |

| CACC | Cooperative adaptive cruise control |

| CC | Cruise control |

| CV | Conventional vehicle |

| DP | Dynamic programming |

| EFC | Equivalent fuel consumption |

| EM | Electric motor |

| eVT | Electrically variable transmission |

| HEV | Hybrid electric vehicle |

| HWFET | Highway federal test procedure |

| ICE | Internal combustion engine |

| IVD | Inter-vehicular distance |

| LIDAR | Light Detection and Ranging |

| OOL | Optimal operating line |

| P2 HEV | Parallel P2 hybrid electric vehicle |

| PG | Planetary gearset |

| PS HEV | Power-split hybrid electric vehicle |

| SOC | State-of-charge |

| UDDS | Urban dynamometer driving schedule |

| US06 | US06 supplemental procedure |

| V2V | Vehicle-to-vehicle |

| WLTP | Worldwide harmonized light-vehicle test procedure |

Appendix A. Optimal V2V Driving Pareto Fronts

Appendix B. Time-Series of Suboptimal Control Solutions in WLTP

References

- Iclodean, C.; Cordos, N.; Varga, B.O. Autonomous Shuttle Bus for Public Transportation: A Review. Energies 2020, 13, 2917. [Google Scholar] [CrossRef]

- Lim, H.S.M.; Taeihagh, A. Autonomous Vehicles for Smart and Sustainable Cities: An In-Depth Exploration of Privacy and Cybersecurity Implications. Energies 2018, 11, 1062. [Google Scholar] [CrossRef] [Green Version]

- Bonfitto, A.; Feraco, S.; Amati, N.; Tonoli, A. Virtual Sensing in High-Performance Vehicles with Artificial Intelligence. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019; Volume 59216. [Google Scholar]

- Rios-Torres, J.; Malikopoulos, A.A. Impact of Partial Penetrations of Connected and Automated Vehicles on Fuel Consumption and Traffic Flow. IEEE Trans. Intell. Veh. 2018, 3, 453–462. [Google Scholar] [CrossRef]

- Smith, S.W.; Kim, Y.; Guanetti, J.; Li, R.; Firoozi, R.; Wootton, B.; Kurzhanskiy, A.A.; Borrelli, F.; Horowitz, R.; Arcak, M. Improving Urban Traffic Throughput With Vehicle Platooning: Theory and Experiments. IEEE Access 2020, 8, 141208–141223. [Google Scholar] [CrossRef]

- Ozatay, E.; Ozguner, U.; Onori, S.; Rizzoni, G. Analytical Solution to the Minimum Fuel Consumption Optimization Problem with the Existence of a Traffic Light. In Proceedings of the ASME 2012 5th Annual Dynamic Systems and Control Conference joint with the JSME 2012 11th Motion and Vibration Conference; ASME: Fairfield, CT, USA, 2012; pp. 837–846. [Google Scholar]

- Wang, P.; Gao, S.; Li, L.; Sun, B.; Cheng, S. Obstacle Avoidance Path Planning Design for Autonomous Driving Vehicles Based on an Improved Artificial Potential Field Algorithm. Energies 2019, 12, 2342. [Google Scholar] [CrossRef] [Green Version]

- Rizzoni, G.; Özgüner, U.; Onori, S.; Wollaeger, J.; Kumar, A.; Khayyer, P.; Ozatay, E. Big Data in Automotive Applications: Cloud Computing Based Velocity Profile Generation for Minimum Fuel Consumption. 2016. Available online: https://pdfs.semanticscholar.org/68c6/39425c042ffd2e213b5a172270aa6eb6c6fe.pdf (accessed on 22 January 2021).

- Feraco, S.; Bonfitto, A.; Amati, N.; Tonoli, A. Combined Lane Keeping and Longitudinal Speed Control for Autonomous Driving. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019; Volume 59216. [Google Scholar]

- Feraco, S.; Luciani, S.; Bonfitto, A.; Amati, N.; Tonoli, A. A local trajectory planning and control method for autonomous vehicles based on the RRT algorithm. In Proceedings of the 2020 AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Torino, Italy, 18–20 November 2020; pp. 1–6. [Google Scholar]

- Anselma, P.G.; Belingardi, G. Next Generation HEV Powertrain Design Tools: Roadmap and Challenges; SAE Technical Paper 2019-01-2602; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Makridis, M.; Mattas, K.; Ciuffo, B. Response Time and Time Headway of an Adaptive Cruise Control. An Empirical Characterization and Potential Impacts on Road Capacity. IEEE Trans. Intell. Transp. Syst. 2019, 21, 1677–1686. [Google Scholar] [CrossRef]

- Makridis, M.; Mattas, K.; Ciuffo, B.; Re, F.; Kriston, A.; Minarini, F.; Rognelund, G. Empirical study on the properties of adaptive cruise control systems and their impact on traffic flow and string stability. Transp. Res. Rec. 2020, 2674, 471–484. [Google Scholar] [CrossRef] [Green Version]

- Mahdinia, I.; Arvin, R.; Khattak, J.A.; Ghiasi, A. Safety, energy, and emissions impacts of adaptive cruise control and cooperative adaptive cruise control. Transp. Res. Rec. 2020, 2674, 253–267. [Google Scholar] [CrossRef]

- He, Y.; Makridis, M.; Fontaras, G.; Mattas, K.; Xu, H.; Ciuffo, B. The energy impact of adaptive cruise control in real-world highway multiple-car-following scenarios. Eur. Transp. Res. Rev. 2020, 12, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Lang, D.; Stanger, T.; Del Re, L. Opportunities on Fuel Economy Utilizing V2V Based Drive Systems; SAE Technical Paper 2013-01-0985; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- He, C.R.; Orosz, G. Saving fuel using wireless vehicle-to-vehicle communication. In Proceedings of the 2017 American Control Conference (ACC), Seattle, WA, USA, 24–26 May 2017; pp. 4946–4951. [Google Scholar]

- He, C.R.; Ge, J.I.; Orosz, G. Fuel Efficient Connected Cruise Control for Heavy-Duty Trucks in Real Traffic. IEEE Trans. Control Syst. Technol. 2019, 28, 2474–2481. [Google Scholar] [CrossRef]

- Tunnell, J.A.; Asher, Z.D.; Pasricha, S.; Bradley, T.H. Towards Improving Vehicle Fuel Economy with ADAS. SAE Int. J. CAV 2018, 1, 81–92. [Google Scholar] [CrossRef]

- Olin, P.; Aggoune, K.; Tang, L.; Confer, K.; Kirwan, J.; Deshpande, S.R.; Gupta, S.; Tulpule, P.; Canova, M.; Rizzoni, G. Reducing Fuel Consumption by Using Information from Connected and Automated Vehicle Modules to Optimize Propulsion System Control; SAE Technical Paper 2019-01-1213; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Zhang, F.; Xi, J.; Langari, R. Real-Time Energy Management Strategy Based on Velocity Forecasts Using V2V and V2I Communications. IEEE Trans. Intell. Transp. Syst. 2016, 18, 416–430. [Google Scholar] [CrossRef]

- Plianos, A.; Jokela, T.; Hancock, M. Predictive Energy Optimization for Connected and Automated HEVs; SAE Technical Paper 2018-01-1179; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Anselma, P.G.; Belingardi, G. Enhancing Energy Saving Opportunities through Rightsizing of a Battery Electric Vehicle Powertrain for Optimal Cooperative Driving. SAE Int. J. CAV 2020, 3, 71–83. [Google Scholar] [CrossRef]

- Koch, A.; Teichert, O.; Kalt, S.; Ongel, A.; Lienkamp, M. Powertrain Optimization for Electric Buses under Optimal Energy-Efficient Driving. Energies 2020, 13, 6451. [Google Scholar] [CrossRef]

- Koch, A.; Bürchner, T.; Herrmann, T.; Lienkamp, M. Eco-Driving for Different Electric Powertrain Topologies Considering Motor Efficiency. World Electr. Veh. J. 2021, 12, 6. [Google Scholar] [CrossRef]

- Tate, L.; Hochgreb, S.; Hall, J.; Bassett, M. Energy Efficiency of Autonomous Car Powertrain; SAE Technical Paper 2018-01-1092; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Plum, T.; Wegener, M.; Eisenbarth, M.; Ye, Z.; Etzold, K.; Pischinger, S.; Andert, J. A simulation-based case study for powertrain efficiency improvement by automated driving functions. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 1320–1330. [Google Scholar] [CrossRef]

- Spano, M.; del Vescovo, D.; Sangeorzan, B.; Misul, D.; Belingardi, G. Optimizing engine downsizing and driving behaviour in conventional and hybrid powertrains for autonomous driving applications. Int. J. Mech. Control 2020, 21, 1–12. [Google Scholar]

- Belingardi, G.; Anselma, P.G.; Demic, M. Optimization-Based Controllers for Hybrid Electric Vehicles. Mobil. Veh. Mech. 2018, 44, 53–67. [Google Scholar] [CrossRef]

- Rizzoni, G.; Guzzella, L.; Baumann, B. Unified modeling of hybrid electric vehicle drivetrains. IEEE/ASME Trans. Mechatronics 1999, 4, 246–257. [Google Scholar] [CrossRef]

- Anselma, P.G.; Huo, Y.; Roeleveld, J.; Emadi, A.; Belingardi, G. Rapid optimal design of a multimode power split hybrid electric vehicle transmission. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 740–762. [Google Scholar] [CrossRef]

- Anselma, P.G.; Biswas, A.; Belingardi, G.; Emadi, A. Rapid assessment of the fuel economy capability of parallel and series-parallel hybrid electric vehicles. Appl. Energy 2020, 275, 115319. [Google Scholar] [CrossRef]

- Ayman, M.; Kim, N.; Rousseau, A. Vehicle Modeling for Use in the CAFE Model: Process Description and Modeling Assumptions; Argonne National Lab: Argonne, IL, USA, 2016. [Google Scholar]

- Anselma, P.G.; Kollmeyer, P.; Belingardi, G.; Emadi, A. Multi-Objective Hybrid Electric Vehicle Control for Maximizing Fuel Economy and Battery Lifetime. In Proceedings of the 2020 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 24–26 June 2020; pp. 1–6. [Google Scholar]

- Anselma, P.G.; Belingardi, G.; Falai, A.; Maino, C.; Miretti, F.; Misul, D.; Spessa, E. Comparing Parallel Hybrid Electric Vehicle Powertrains for Real-world Driving. In Proceedings of the 2019 AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Torino, Italy, 2–4 July 2019; pp. 1–6. [Google Scholar]

- Bianchi, D.; Rolando, L.; Serrao, L.; Onori, S.; Rizzoni, G.; Al-Khayat, N.; Hsieh, T.-M.; Kang, P. A Rule-Based Strategy for a Series/Parallel Hybrid Electric Vehicle: An Approach Based on Dynamic Programming. In Proceedings of the ASME 2010 Dynamic Systems and Control Conference; ASME International: New York, NY, USA, 2010; Volume 44175, pp. 507–514. [Google Scholar]

- Rizzoni, G.; Onori, S. Energy management of hybrid electric vehicles: 15 years of development at the Ohio State University. Oil Gas Sci. Technol. 2015, 70, 41–54. [Google Scholar] [CrossRef] [Green Version]

- Biswas, A.; Anselma, P.G.; Rathore, A.; Emadi, A. Comparison of Three Real-Time Implementable Energy Management Strategies for Multi-mode Electrified Powertrain. In Proceedings of the 2020 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 23–26 June 2020; pp. 514–519. [Google Scholar]

- Kim, N.; Rousseau, A.; Rask, E. Autonomie Model Validation with Test Data for 2010 Toyota Prius; SAE Technical Paper 2012-01-1040; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Yang, Y.; Schofield, N.; Emadi, A. Integrated Electromechanical Double-Rotor Compound Hybrid Transmissions for Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2016, 65, 4687–4699. [Google Scholar] [CrossRef]

- Kim, N.; Cha, S.; Peng, H. Optimal Control of Hybrid Electric Vehicles Based on Pontryagin’s Minimum Principle. IEEE Trans. Control Syst. Technol. 2011, 19, 1279–1287. [Google Scholar]

- Németh, B. Coordination of Lateral Vehicle Control Systems Using Learning-Based Strategies. Energies 2021, 14, 1291. [Google Scholar] [CrossRef]

- Jin, X.; Yan, Z.; Yin, G.; Li, S.; Wei, C. An Adaptive Motion Planning Technique for On-Road Autonomous Driving. IEEE Access 2021, 9, 2655–2664. [Google Scholar] [CrossRef]

- US Department of Energy. Nhtsa Issues Advance Notice of Proposed Rulemaking and Research Report on Ground-Breaking Crash Avoidance Technology: “Vehicle-To-Vehicle Communications: Readiness of V2V Technology for Application”. Available online: https://www.nhtsa.gov/sites/nhtsa.dot.gov/files/documents/v2v_fact_sheet_101414_v2a.pdf (accessed on 21 January 2021).

- Chen, C.; Lü, N.; Liu, L.; Pei, Q.-Q.; Li, X.-J. Critical safe distance design to improve driving safety based on vehicle-to-vehicle communications. J. Cent. South Univ. 2013, 20, 3334–3344. [Google Scholar] [CrossRef]

- Bellman, R.; Lee, E. History and development of dynamic programming. IEEE Control Syst. Mag. 1984, 4, 24–28. [Google Scholar] [CrossRef]

- Nazari, S.; Siegel, J.; Middleton, R.; Stefanopoulou, A. Power Split Supercharging: A Mild Hybrid Approach to Boost Fuel Economy. Energies 2020, 13, 6580. [Google Scholar] [CrossRef]

- Jiang, Z.; Qiao, Y.; Chen, Y.; Ji, C. A New Reservoir Operation Chart Drawing Method Based on Dynamic Programming. Energies 2018, 11, 3355. [Google Scholar] [CrossRef] [Green Version]

- An, L.N.; Tuan, T.Q. Dynamic Programming for Optimal Energy Management of Hybrid Wind–PV–Diesel–Battery. Energies 2018, 11, 3039. [Google Scholar] [CrossRef] [Green Version]

- Soldo, J.; Škugor, B.; Deur, J. Synthesis of Optimal Battery State-of-Charge Trajectory for Blended Regime of Plug-in Hybrid Electric Vehicles in the Presence of Low-Emission Zones and Varying Road Grades. Energies 2019, 12, 4296. [Google Scholar] [CrossRef] [Green Version]

- Delprat, S.; Lauber, J.; Guerra, T.; Rimaux, J. Control of a Parallel Hybrid Powertrain: Optimal Control. IEEE Trans. Veh. Technol. 2004, 53, 872–881. [Google Scholar] [CrossRef]

- Pan, C.; Liang, Y.; Chen, L.; Chen, L. Optimal Control for Hybrid Energy Storage Electric Vehicle to Achieve Energy Saving Using Dynamic Programming Approach. Energies 2019, 12, 588. [Google Scholar] [CrossRef] [Green Version]

- Qiao, Y.; Song, Y.; Huang, K. A Novel Control Algorithm Design for Hybrid Electric Vehicles Considering Energy Consumption and Emission Performance. Energies 2019, 12, 2698. [Google Scholar] [CrossRef] [Green Version]

- Sundstrom, O.; Guzzella, L. A generic dynamic programming Matlab function. In Proceedings of the 2009 IEEE Control Applications, (CCA) & Intelligent Control, (ISIC), St. Petersburg, Russia, 8–10 July 2009; pp. 1625–1630. [Google Scholar]

- Du, Y.; Liu, C.; Li, Y. Velocity Control Strategies to Improve Automated Vehicle Driving Comfort. IEEE Intell. Transp. Syst. Mag. 2018, 10, 8–18. [Google Scholar] [CrossRef]

- Luciani, S.; Bonfitto, A.; Amati, N.; Tonoli, A. Model predictive control for comfort optimization in assisted and driverless vehicles. Adv. Mech. Eng. 2020, 12, 1–14. [Google Scholar] [CrossRef]

- Anselma, P.; Kollmeyer, P.; Belingardi, G.; Emadi, A. Multitarget Evaluation of Hybrid Electric Vehicle Powertrain Architectures Considering Fuel Economy and Battery Lifetime; SAE Technical Paper 2020-37-0015; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Alix, G.; Dabadie, J.; Font, G. An ICE Map Generation Tool Applied to the Evaluation of the Impact of Downsizing on Hybrid Vehicle Consumption; SAE Technical Paper 2015-24-2385; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Le Berr, F.; Abdelli, A.; Postariu, D.-M.; Benlamine, R. Design and Optimization of Future Hybrid and Electric Propulsion Systems: An Advanced Tool Integrated in a Complete Workflow to Study Electric Devices. Oil Gas Sci. Technol. 2012, 67, 547–562. [Google Scholar] [CrossRef] [Green Version]

- Petit, M.; Marc, N.; Badin, F.; Mingant, R.; Sauvant-Moynot, V. A Tool for Vehicle Electrical Storage System Sizing and Modelling for System Simulation. In Proceedings of the 2014 IEEE Vehicle Power and Propulsion Conference (VPPC), Coimbra, Portugal, 27–30 October 2014; pp. 1–5. [Google Scholar]

- Ligterink, N.E.; van Mensch, P.; Cuelenaere, R.F.A.; Hausberger, S.; Leitner, D.; Silberholz, G. Correction Algorithms for WLTP Chassis Dynamometer and Coast-Down Testing; TNO-Report 2015 R10955; TNO: Delft, The Netherlands, 2015. [Google Scholar]

| Controlled ICE Status: ON | Controlled ICE Status: OFF | |

|---|---|---|

| Current ICE status: ON | (| | | ( && && |

| Current ICE status: OFF | ( | | | ( && && |

| Component | Parameter | CV | BEV | P2 HEV | PS HEV |

|---|---|---|---|---|---|

| Vehicle body | Mass (kg) | 1248 | 1248 | 1248 | 1248 |

| RLA (N) | 143 | 143 | 143 | 143 | |

| RLB (N/(m/s)) | 0.9 | 0.9 | 0.9 | 0.9 | |

| RLC (N/(m/s2)) | 0.44 | 0.44 | 0.44 | 0.44 | |

| Wheel dynamic radius (m) | 0.273 | 0.273 | 0.273 | 0.273 | |

| Transmission | AMT gear ratios (-) | (3.58; 2.06; 1.40; 1; 0.71; 0.58) | - | (3.58; 2.06; 1.40; 1; 0.71; 0.58) | - |

| PG ratio (-) | - | - | - | 2.6 | |

| EM to FD ratio (-) | - | 2.3 | 2 | 1.26 | |

| FD ratio (-) | 4.1 | 3.4 | 4.1 | 3.27 | |

| Efficiency (-) | 0.9 | 0.9 | 0.9 | 0.85 | |

| ICE | Displacement (l) | 1.2 | - | 1.2 | 1.2 |

| Max power | 89 kW @ 4000 rpm | - | 89 kW @ 4000 rpm | 89 kW @ 4000 rpm | |

| Max torque | 230 Nm @ 2000 rpm | - | 230 Nm @ 2000 rpm | 230 Nm @ 2000 rpm | |

| EM1 | Max power | - | 95 kW @ 14,500 rpm | 26 kW @ 9000 rpm | 26 kW @ 9000 rpm |

| Max torque | - | 147 Nm @ (0–4800 rpm) | 118 Nm @ (0–2000 rpm) | 118 Nm @ (0–2000 rpm) | |

| EM2 | Max power | - | - | - | 45 kW @ 9000 rpm |

| Max torque | - | - | - | 204 Nm @ (0–2000 rpm) | |

| Battery pack | Nominal capacity (Ah) | - | 115.5 | 6.5 | 6.5 |

| Voltage (V) | - | 364 | 310 | 310 |

| Drive Cycle | Vehicle | Parameter | CV | BEV | P2 HEV | PS HEV |

|---|---|---|---|---|---|---|

| WLTP | Preceding | Fuel consumption/battery energy consumption/EFC | 4.27 L/100 km | 15.39 kWh/100 km | 4.74 L/100 km | 5.45 L/100 km |

| RMS (acceleration) (m/s2) | 0.53 | 0.53 | 0.53 | 0.53 | ||

| Following– Opt_energy | Fuel consumption/battery energy consumption/EFC | 3.87 L/100 km (−9.2%) | 14.54 kWh/100 km (−5.5%) | 4.27 L/100 km (−9.8%) | 4.70 L/100 km (−13.7%) | |

| RMS (acceleration) (m/s2) | 0.47 (−10.9%) | 0.52 (−2.5%) | 0.51 (−4.5%) | 0.33 (−38.7%) | ||

| Following– Opt_comfort | Fuel consumption/battery energy consumption/EFC | 4.12 L/100 km (−3.5%) | 14.59 kWh/100 km (−5.2%) | 4.35 L/100 km (−8.2%) | 4.71 L/100 km (−13.6%) | |

| RMS (acceleration) (m/s2) | 0.33 (−38.6%) | 0.31 (−41.6%) | 0.38 (−28.7%) | 0.32 (−40.2%) | ||

| UDDS | Preceding | Fuel consumption/battery energy consumption/EFC | 7.50 L/100 km | 10.80 kWh/100 km | 4.65 L/100 km | 4.46 L/100 km |

| RMS (acceleration) (m/s2) | 0.62 | 0.62 | 0.62 | 0.62 | ||

| Following– Opt_energy | Fuel consumption/battery energy consumption/EFC | 6.67 L/100 km (−11.1%) | 9.91 kWh/100 km (−8.2%) | 4.33 L/100 km (−6.8%) | 4.03 L/100 km (−9.6%) | |

| RMS (acceleration) (m/s2) | 0.61 (−2.7%) | 0.58 (−7.9%) | 0.55 (−11.3%) | 0.46 (−27.0%) | ||

| Following– Opt_comfort | Fuel consumption/battery energy consumption/EFC | 7.15 L/100 km (−4.6%) | 9.98 kWh/100 km (−7.6%) | 4.59 L/100 km (−1.2%) | 4.11 L/100 km (−7.8%) | |

| RMS (acceleration) (m/s2) | 0.33 (−47.5%) | 0.32 (−48.2%) | 0.38 (−38.7%) | 0.36 (−43.1%) | ||

| HWFET | Preceding | Fuel consumption/battery energy consumption/EFC | 3.82 L/100 km | 15.22 kWh/100 km | 4.11 L/100 km | 4.55 L/100 km |

| RMS (acceleration) (m/s2) | 0.30 | 0.30 | 0.30 | 0.30 | ||

| Following– Opt_energy | Fuel consumption/battery energy consumption/EFC | 3.71 L/100 km (−3.0%) | 14.95 kWh/100 km (−1.8%) | 3.95 L/100 km (−3.8%) | 4.37 L/100 km (−4.0%) | |

| RMS (acceleration) (m/s2) | 0.28 (−6.2%) | 0.30 (−0.4%) | 0.29 (−2.5%) | 0.29 (−3.2%) | ||

| Following– Opt_comfort | Fuel consumption/battery energy consumption/EFC | 3.76 L/100 km (−1.8%) | 14.95 kWh/100 km (−1.8%) | 3.95 L/100 km (−3.7%) | 4.37 L/100 km (−4.0%) | |

| RMS (acceleration) (m/s2) | 0.27 (−9.5%) | 0.27 (−11.3%) | 0.29 (−3.3%) | 0.28 (−4.8%) | ||

| US06 | Preceding | Fuel consumption/battery energy consumption/EFC | 4.54 L/100 km | 19.23 kWh/100 km | 4.78 L/100 km | 7.30 L/100 km |

| RMS (acceleration) (m/s2) | 0.99 | 0.99 | 0.99 | 0.98 | ||

| Following– Opt_energy | Fuel consumption/battery energy consumption/EFC | 3.97 L/100 km (−12.7%) | 18.26 kWh/100 km (−5.0%) | 4.46 L/100 km (−6.6%) | 5.69 L/100 km (−22.1%) | |

| RMS (acceleration) (m/s2) | 0.84 (−14.4%) | 0.94 (−4.2%) | 0.94 (−4.3%) | 0.58 (−40.4%) | ||

| Following– Opt_comfort | Fuel consumption/battery energy consumption/EFC | 4.08 L/100 km (−10.3%) | 18.30 kWh/100 km (−4.9%) | 4.51 L/100 km (−5.6%) | 5.70 L/100 km (−21.9%) | |

| RMS (acceleration) (m/s2) | 0.60 (−39.3%) | 0.61 (−38.4%) | 0.59 (−40.4%) | 0.58 (−40.7%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anselma, P.G. Optimization-Driven Powertrain-Oriented Adaptive Cruise Control to Improve Energy Saving and Passenger Comfort. Energies 2021, 14, 2897. https://doi.org/10.3390/en14102897

Anselma PG. Optimization-Driven Powertrain-Oriented Adaptive Cruise Control to Improve Energy Saving and Passenger Comfort. Energies. 2021; 14(10):2897. https://doi.org/10.3390/en14102897

Chicago/Turabian StyleAnselma, Pier Giuseppe. 2021. "Optimization-Driven Powertrain-Oriented Adaptive Cruise Control to Improve Energy Saving and Passenger Comfort" Energies 14, no. 10: 2897. https://doi.org/10.3390/en14102897

APA StyleAnselma, P. G. (2021). Optimization-Driven Powertrain-Oriented Adaptive Cruise Control to Improve Energy Saving and Passenger Comfort. Energies, 14(10), 2897. https://doi.org/10.3390/en14102897