Performance Evaluation of Photovoltaic Modules by Combined Damp Heat and Temperature Cycle Test

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Performance Evaluation of PV Module by Damp Heat Test

3.2. Performance Evaluation of PV Module by Temperature Cycle Test

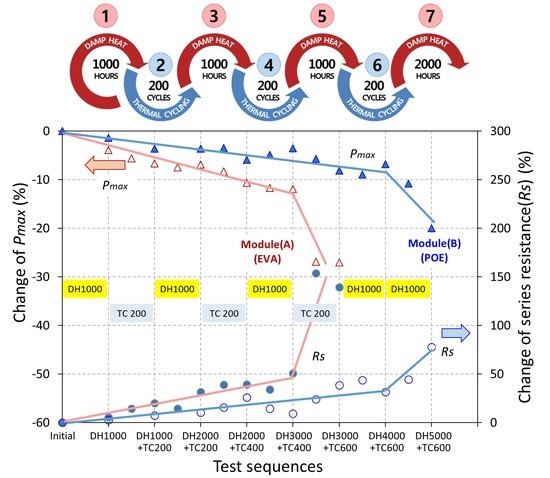

3.3. Performance Evaluation of PV Module by Combined Damp Heat-Temperature Cycle Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kawai, S.; Tanahashi, T.; Fukumoto, Y.; Tamai, F.; Masuda, A.; Kondo, M. Causes of degradation identified by the extended thermal cycling test on commercially available crystalline silicon photovoltaic modules. IEEE J. Photovolt. 2017, 7, 1511–1518. [Google Scholar] [CrossRef]

- Chaturvedi, P.; Hoex, B.; Walsh, T.M. Broken metal fingers in silicon wafer solar cells and PV modules. Sol. Energy Mater. Sol. Cells 2013, 108, 78–81. [Google Scholar] [CrossRef]

- Roy, S.; Kumar, S.; Gupta, R. Investigation and analysis of finger breakages in commercial crystalline silicon photovoltaic modules under standard thermal cycling test. Eng. Fail. Anal. 2019, 101, 309–319. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, R. Investigation and analysis of thermo-mechanical degradation of fingers in a photovoltaic module under thermal cyclic stress conditions. Sol. Energy 2018, 174, 1044–1052. [Google Scholar] [CrossRef]

- Park, H.; Jeong, J.; Shin, E.; Kim, S.; Yi, J. A reliability study of silicon heterojunction photovoltaic modules exposed to damp heat testing. Microelectron. Eng. 2019, 216, 111081. [Google Scholar] [CrossRef]

- Poulek, V.; Šafránková, J.; Černá, L.; Libra, M.; Beránek, V.; Finsterle, T.; Hrzina, P. PV panel and PV inverter damages caused by combination of edge delamination, water penetration, and high string voltage in moderate climate. IEEE J. Photovolt. 2021, 11, 561–565. [Google Scholar] [CrossRef]

- de Olivira, M.C.C.; Diniz, A.S.A.C.; Viana, M.M.; Lins, V.F.C. The causes and effects of degradation of encapsulant ethylene vinyl acetate copolymer (EVA) in crystalline silicon photovoltaic modules: A review. Renew. Sustain. Energy Rev. 2018, 81, 2299–2317. [Google Scholar] [CrossRef]

- Koehl, M.; Hoffmann, S.; Wiesmeier, S. Evaluation of damp-heat testing of photovoltaic modules. Prog. Photovolt. Res. Appl. 2017, 25, 175–183. [Google Scholar] [CrossRef]

- Peike, C.; Hoffmann, S.; Hülsmann, P.; Thaidigsmann, B.; Weiß, K.A.; Koehl, M.; Bentz, P. Origin of damp-heat induced cell degradation. Sol. Energy Mater. Sol. Cells 2013, 116, 49–54. [Google Scholar] [CrossRef]

- Zhu, J.; Koehl, M.; Hoffman, S.; Berger, K.A.; Zamini, S.; Bennett, I.; Gerritsen, E.; Malbranche, P.; Pugliatti, P.; Stefano, A.D.; et al. Changes of solar cell parameters during damp-heat exposure. Prog. Photovolt. Res. Appl. 2016, 24, 1346–1358. [Google Scholar] [CrossRef] [Green Version]

- Masuda, A.; Yamamoto, C.; Uchiyama, N.; Ueno, K.; Yamazaki, T.; Mitsuhashi, K.; Tsutsumida, A.; Watanabe, J.; Shirataki, J.; Matsuda, K. Sequential and combined acceleration tests for crystalline Si photovoltaic modules. Jpn. J. Appl. Phys. 2016, 55, 04ES10. [Google Scholar] [CrossRef]

- Owen-Bellini, M.; Hacke, P.; Miller, D.C.; Kempe, M.D.; Spataru, S.; Tanahashi, T.; Mitterhofer, S.; Jankovec, M.; Topič, M. Advancing reliability assessments of photovoltaic modules and materials using combined-accelerated stress testing. Prog. Photovolt. Res. Appl. 2021, 29, 64–82. [Google Scholar] [CrossRef]

- Spataru, S.; Hacke, P.; Owen-Bellini, M. Combined-accelerated stress testing system for photovoltaic modules. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 3943–3948. [Google Scholar] [CrossRef] [Green Version]

- Pingel, S.; Korth, H.; Winkler, M.; Weiss, P.; Geipel, T. Investigation of damp heat degradation mechanisms and correlation to an Accelerated Test Procedure (HAST). In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition (27th EU-PVSEC), Frankfurt, Germany, 24–28 September 2012; pp. 3137–3141. [Google Scholar] [CrossRef]

- Li, Y.-T.; Lin, W.-Y.; Yang, W.-L.; Hsieh, C.-F. Sequential acceleration tests with Pressure Cooker Test (PCT) and UV for backsheets of PV modules. Energy Procedia 2018, 150, 44–49. [Google Scholar] [CrossRef]

- Schiller, C.H.; Rendler, L.C.; Eberlein, D.; Mülhöfer, G.; Kraft, A.; Neuhaus, D.H. Accelerated TC test in comparison with standard TC test for PV modules with ribbon, wire and shingle interconnection. In Proceedings of the 36th European Photovoltaic Solar Energy Conference and Exhibition (36th EU-PVSEC), Marseille, France, 9–13 September 2019; pp. 995–999. [Google Scholar] [CrossRef]

- Chang, M.; Chen, H.; Chen, C.; Hsueh, C.H. Cocktail sequential test for c-SI PV module: The correlation among accelerated stress factors. In Proceedings of the 31st European Photovoltaic Solar Energy Conference and Exhibition (31st EU-PVSEC), Hamburg, Germany, 14–18 September 2015; pp. 1894–1898. [Google Scholar] [CrossRef]

- Lin, B.; Zheng, C.; Zhu, Q.; Xie, F. A polyolefn encapsulant material designed for photovoltaic modules: From perspectives of peel strength and transmittance. J. Therm. Anal. Calorim. 2020, 140, 2259–2265. [Google Scholar] [CrossRef]

- Oreski, G.; Omazic, A.; Eder, G.C.; Voronko, Y.; Neumaier, L.; Mühleisen, W.; Hirschl, C.; Ujvari, G.; Ebner, R.; Edler, M. Properties and degradation behaviour of polyolefin encapsulants for photovoltaic modules. Prog. Photovolt. Res. Appl. 2020, 28, 1277–1288. [Google Scholar] [CrossRef]

| DH Time (h) | Voc (V) | Isc (A) | FF (%) | Pmax (W) | Rs (Ω) | Rsh (Ω) |

|---|---|---|---|---|---|---|

| 0 | 47.21 | 9.456 | 79.0 | 352.6 | 0.440 | 92.9 |

| 1000 | 46.70 | 9.177 | 79.0 | 338.4 | 0.491 | 68.0 |

| 1500 | 46.82 | 9.138 | 78.9 | 337.7 | 0.508 | 94.1 |

| 2000 | 46.90 | 9.196 | 78.9 | 340.1 | 0.506 | 74.2 |

| 2500 | 46.35 | 9.026 | 79.0 | 330.3 | 0.476 | 67.8 |

| 3000 | 46.61 | 9.072 | 78.2 | 330.8 | 0.519 | 89.2 |

| 3500 | 45.86 | 8.998 | 77.5 | 319.6 | 0.511 | 69.1 |

| 4000 | 45.31 | 8.829 | 77.8 | 311.1 | 0.556 | 68.5 |

| 4500 | 45.36 | 8.761 | 77.5 | 308.1 | 0.543 | 65.8 |

| 5000 | 46.06 | 8.968 | 74.5 | 307.8 | 0.641 | 64.4 |

| 5500 | 45.88 | 8.875 | 66.7 | 271.7 | 0.779 | 58.4 |

| 6000 | 44.87 | 8.467 | 56.6 | 215.1 | 0.962 | 33.1 |

| 6500 | 45.58 | 8.052 | 47.1 | 172.9 | 1.42 | 21.8 |

| 7000 | 45.96 | 6.969 | 44.5 | 142.4 | 1.83 | 17.0 |

| TC Cycle (Cycles) | Voc (V) | Isc (A) | FF (%) | Pmax (W) | Rs (Ω) | Rsh (Ω) |

|---|---|---|---|---|---|---|

| 0 | 47.34 | 9.487 | 78.1 | 350.6 | 0.531 | 125 |

| 200 | 46.91 | 9.400 | 78.0 | 343.8 | 0.465 | 67.3 |

| 300 | 46.89 | 9.365 | 78.1 | 343.0 | 0.457 | 126 |

| 400 | 46.73 | 9.380 | 77.6 | 340.0 | 0.469 | 101 |

| 500 | 46.65 | 9.382 | 76.8 | 336.0 | 0.534 | 62.3 |

| 600 | 46.59 | 9.353 | 76.5 | 333.2 | 0.545 | 95.4 |

| 700 | 46.67 | 9.335 | 76.8 | 334.8 | 0.552 | 95.0 |

| 800 | 46.55 | 9.332 | 76.6 | 332.6 | 0.583 | 102 |

| 900 | 46.55 | 9.357 | 76.6 | 333.6 | 0.566 | 63.3 |

| 1000 | 46.41 | 9.247 | 75.9 | 325.6 | 0.594 | 60.1 |

| 1100 | 47.22 | 9.345 | 76.1 | 335.6 | 0.570 | 69.6 |

| 1200 | 47.34 | 9.403 | 76.3 | 339.5 | 0.556 | 23.6 |

| 1300 | 47.42 | 9.395 | 75.4 | 335.8 | 0.589 | 38.2 |

| 1400 | 47.17 | 9.413 | 75.7 | 336.1 | 0.551 | 82.8 |

| DH/TC (h/Cycles) | Voc (V) | Isc (A) | FF (%) | Pmax (W) | Rs (Ω) | Rsh (Ω) |

|---|---|---|---|---|---|---|

| 0/0 | 47.47 | 9.492 | 78.4 | 353.4 | 0.473 | 75.5 |

| 1000/0 | 46.96 | 9.252 | 78.2 | 339.6 | 0.499 | 50.3 |

| 1000/100 | 46.83 | 9.255 | 77.0 | 333.6 | 0.541 | 56.3 |

| 1000/200 | 46.39 | 9.272 | 76.7 | 330.0 | 0.568 | 52.7 |

| 1500/200 | 46.40 | 9.160 | 76.9 | 326.9 | 0.542 | 42.2 |

| 2000/200 | 46.83 | 9.228 | 76.2 | 329.1 | 0.622 | 51.7 |

| 2000/300 | 46.82 | 9.268 | 74.7 | 324.09 | 0.658 | 47.7 |

| 2000/400 | 46.21 | 9.170 | 74.5 | 315.8 | 0.659 | 57.4 |

| 2500/400 | 46.09 | 9.105 | 74.3 | 312.0 | 0.635 | 48.3 |

| 3000/400 | 46.62 | 9.241 | 72.2 | 311.2 | 0.714 | 59.1 |

| 3000/500 | 46.18 | 9.113 | 61.4 | 258.4 | 1.200 | 36.5 |

| 3000/600 | 45.50 | 8.977 | 63.1 | 257.8 | 1.133 | 55.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.; So, W.; Kim, W.K. Performance Evaluation of Photovoltaic Modules by Combined Damp Heat and Temperature Cycle Test. Energies 2021, 14, 3328. https://doi.org/10.3390/en14113328

Park H, So W, Kim WK. Performance Evaluation of Photovoltaic Modules by Combined Damp Heat and Temperature Cycle Test. Energies. 2021; 14(11):3328. https://doi.org/10.3390/en14113328

Chicago/Turabian StylePark, Hyeonwook, Wonshoup So, and Woo Kyoung Kim. 2021. "Performance Evaluation of Photovoltaic Modules by Combined Damp Heat and Temperature Cycle Test" Energies 14, no. 11: 3328. https://doi.org/10.3390/en14113328

APA StylePark, H., So, W., & Kim, W. K. (2021). Performance Evaluation of Photovoltaic Modules by Combined Damp Heat and Temperature Cycle Test. Energies, 14(11), 3328. https://doi.org/10.3390/en14113328