Heat Transfer with Phase Change in a Multilayer Construction: Simulation versus Experiment

Abstract

:1. Introduction

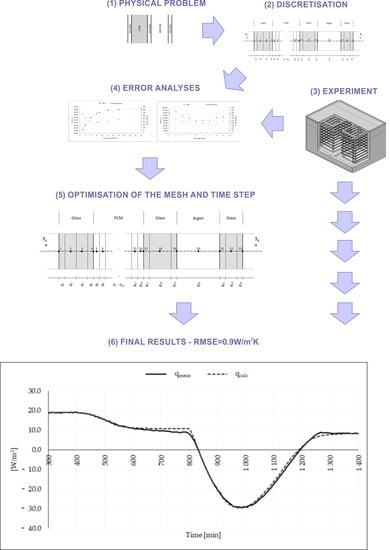

2. Numerical Model of Heat Transfer

3. Experimental Set-Up

4. Model Definition and Boundary Conditions

4.1. Model Definition

- -

- Parameters Tm, ΔT and γ were selected by minimizing Equation (4)

- -

- Integral of effective specific heat ceff(T) was equal to the latent heat declared by Rubitherm LR = 262 kJ/kg

4.2. Boundary Conditions

5. Results

- 300 min < t < ~400 min—stationary heat flow with temperatures in PCM below the phase change range (compare to Figure 14 where all the β ≈ 0)

- ~400 min < t < ~550 min—transient heat flow, the structure heating up but the temperatures in PCM are below the phase change range

- ~550 min < t < ~800 min—temperatures in PCM are in phase change range which causes melting in CVs 5–16 (compare to Figure 14 where 0 < β < 1)

- ~800 min < t < ~900 min—transient heat flow causes the heating up of the structure while PCM temperatures are over the phase change range (compare to Figure 14 where all the β ≈ 1)

- ~900 min < t < ~1200 min—transient heat flow is cooling down the structure, temperatures in PCM are getting close to the phase change range, but material is still fully liquid (compare to Figure 14 where all the β ≈ 1)

- t > ~1200 min—solidifying of the PCM in CV 5–16 begins when temperatures in PCM are entering the phase change range (compare to Figure 14 where 0 < β < 1)

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| T | temperature [°C] |

| t | time [s] |

| dt | time step |

| φ | specific enthalpy [J/kg] |

| c | specific heat [J/kg∙K] |

| ceff | effective specific heat [J/kg∙K] |

| k | thermal conductivity [W/(m∙K)] |

| Q | internal heat source [W/m3] |

| Ωp | analysed region |

| Γp | edge of region |

| Tm | melting temperature [°C] |

| ΔT | phase change temperature range [K] |

| L | latent heat [J/kg] |

| γ | numerical parameter used to fit function to declared parameters |

| HR(T) | partial enthalpy for temperature T declared by the Rubitherm for RT18HC |

| LR | latent heat declared by the Rubitherm for RT18HC |

| Ti | temperature values in nodes representing CVi |

| q | heat flow density |

| qcalc | calculated heat flow density |

| qmeas | measured heat flow density |

| kharm.i−1÷i | mean harmonical value of heat conduction coefficient between nodes i − 1 and i [W/(m∙K)] |

| di−1÷i | distance between nodes i − 1 and i [W/(m∙K)] |

| j | number of time step |

| R | error |

| R(L2) | error calculated according to L2 norm |

| αconv | convective surface coefficient |

| ej | explicit solution in time step j |

| sj | result of simulation in time step j |

References

- Chen, Y.; Xu, P.; Chen, Z.; Wang, H.; Sha, H.; Ji, Y.; Zhang, Y.; Dou, Q.; Wang, S. Experimental investigation of demand response potential of buildings: Combined passive thermal mass and active storage. Appl. Energy 2020, 280, 115956. [Google Scholar] [CrossRef]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Ahmad, D.; Lipinski, T. Latent thermal energy storage technologies and applications: A review. Int. J. Thermofluids 2020, 5–6, 100039. [Google Scholar] [CrossRef]

- Wang, Z.; Qiao, Y.; Liu, Y.; Bao, J.; Gao, Q.; Chen, J.; Yao, H.; Yang, L. Thermal storage performance of building envelopes for nearly-zero energy buildings during cooling season in Western China: An experimental study. Build. Environ. 2021, 194, 107709. [Google Scholar] [CrossRef]

- Heim, D.; Pawłowski, M. The Methodology of Thermal Energy Management for Nearly Zero Energy Buildings. Period. Polytech. Civ. Eng. 2019, 63, 499–517. [Google Scholar] [CrossRef]

- Bamdad, K.; Cholette, M.E.; Omrani, S.; Bell, J. Future energy-optimised buildings—Addressing the impact of climate change on buildings. Energy Build. 2021, 231, 110610. [Google Scholar] [CrossRef]

- Crawley, D.B. Estimating the impacts of climate change and urbanization on building performance. J. Build. Perform. Simul. 2008, 1, 91–115. [Google Scholar] [CrossRef]

- Moazami, A.; Nik, V.M.; Carlucci, S.; Geving, S. Impacts of future weather data typology on building energy performance—Investigating long-term patterns of climate change and extreme weather conditions. Appl. Energy 2019, 238, 696–720. [Google Scholar] [CrossRef]

- Patidar, S.; Jenkins, D.P.; Gibson, G.J.; Banfill, P.F.G. Analysis of probabilistic climate projections: Heat wave, overheating and adaptation. J. Build. Perform. Simul. 2013, 6, 65–77. [Google Scholar] [CrossRef]

- Sailor, D.J. Risks of summertime extreme thermal conditions in buildings as a result of climate change and exacerbation of urban heat islands. Build. Environ. 2014, 78, 81–88. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, S.; Xiao, F.; Gao, D. Peak load shifting control using different cold thermal energy storage facilities in commercial buildings: A review. Energy Convers. Manag. 2013, 71, 101–114. [Google Scholar] [CrossRef]

- Strzałkowski, J.; Sikora, P.; Chung, S.Y.; Abd Elrahman, M. Thermal performance of building envelopes with structural layers of the same density: Lightweight aggregate concrete versus foamed concrete. Build. Environ. 2021, 196, 107799. [Google Scholar] [CrossRef]

- Firlag, S. How to meet the minimum energy performance requirements of Technical Conditions in year 2021? Procedia Eng. 2015, 111, 202–208. [Google Scholar] [CrossRef] [Green Version]

- Heim, D.; Wieprzkowicz, A. Attenuation of Temperature Fluctuations on an External Surface of the Wall by a Phase Change Material-Activated Layer. Appl. Sci. 2017, 8, 11. [Google Scholar] [CrossRef] [Green Version]

- Wieprzkowicz, A.; Heim, D. Energy performance of dynamic thermal insulation built in the experimental façade system. Manag. Environ. Qual. 2016, 27. [Google Scholar] [CrossRef]

- Kośny, J. Chapter 2: Short History of PCM Applications in Building Envelopes. In PCM-Enhanced Building Components; Springer: Berlin/Heidelberg, Germany, 2015; p. 281. ISBN 9783319142852. [Google Scholar]

- Sasic Kalagasidis, A. A multi-level modelling and evaluation of thermal performance of phase-change materials in buildings. J. Build. Perform. Simul. 2014, 7, 289–308. [Google Scholar] [CrossRef] [Green Version]

- Kuznik, F.; Johannes, K.; Lamrani, B. 13—Integrating phase change materials in thermal energy storage systems for buildings. In Advances in Thermal Energy Storage Systems, 2nd ed.; Cabeza, L.F., Ed.; Woodhead Publishing Series in Energy; Woodhead Publishing: Sawston, UK, 2021; pp. 381–422. ISBN 978-0-12-819885-8. [Google Scholar]

- Jurkowska, M.; Szczygieł, I. Review on properties of microencapsulated phase change materials slurries (mPCMS). Appl. Therm. Eng. 2016, 98, 365–373. [Google Scholar] [CrossRef]

- Konuklu, Y.; Ostry, M.; Paksoy, H.O.; Charvat, P. Review on using microencapsulated phase change materials (PCM) in building applications. Energy Build. 2015, 106, 134–155. [Google Scholar] [CrossRef]

- Alehosseini, E.; Jafari, S.M. Nanoencapsulation of phase change materials (PCMs) and their applications in various fields for energy storage and management. Adv. Colloid Interface Sci. 2020, 283, 102226. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Thermal performance assessment of phase change material integrated cementitious composites in buildings: Experimental and numerical approach. Appl. Energy 2017, 207, 654–664. [Google Scholar] [CrossRef]

- Krasoń, J.; Miąsik, P.; Lichołai, L.; Dębska, B.; Starakiewicz, A. Analysis of the Thermal Characteristics of a Composite Ceramic Product Filled with Phase Change Material. Buildings 2019, 9, 217. [Google Scholar] [CrossRef] [Green Version]

- Rathore, P.K.S.; Shukla, S.K. Enhanced thermophysical properties of organic PCM through shape stabilization for thermal energy storage in buildings: A state of the art review. Energy Build. 2021, 236, 110799. [Google Scholar] [CrossRef]

- Kim, H.B.; Mae, M.; Choi, Y.; Heo, J. Applicability of phase change material according to climate zones as defined in ASHRAE standard 169-2013. Build. Environ. 2021, 196, 107771. [Google Scholar] [CrossRef]

- Wijesuriya, S.; Tabares-Velasco, P.C. Empirical validation and comparison of methodologies to simulate micro and macro-encapsulated PCMs in the building envelope. Appl. Therm. Eng. 2021, 188, 116646. [Google Scholar] [CrossRef]

- Zastawna-Rumin, A.; Nowak, K. Experimental thermal performance analysis of building components containing phase change material (PCM). Procedia Eng. 2015, 108, 428–435. [Google Scholar] [CrossRef] [Green Version]

- Shastry, D.M.C.; Arunachala, U.C. Thermal management of photovoltaic module with metal matrix embedded PCM. J. Energy Storage 2020, 28, 101312. [Google Scholar] [CrossRef]

- Huang, S.; Lu, J.; Li, Y.; Xie, L.; Yang, L.; Cheng, Y.; Chen, S.; Zeng, L.; Li, W.; Zhang, Y.; et al. Experimental study on the influence of PCM container height on heat transfer characteristics under constant heat flux condition. Appl. Therm. Eng. 2020, 172, 115159. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Amaral, C.; Figueiredo, A. Thermal performance of a window shutter containing PCM: Numerical validation and experimental analysis. Appl. Energy 2016, 179, 64–84. [Google Scholar] [CrossRef]

- Dellicompagni, P.; Franco, J.; Heim, D.; Wieprzkowicz, A. Numerical modeling of phase change materials using simusol software. Appl. Therm. Eng. 2020, 170, 114772. [Google Scholar] [CrossRef]

- Bianco, L.; Komerska, A.; Cascone, Y.; Serra, V.; Zinzi, M.; Carnielo, E.; Ksionek, D. Thermal and optical characterisation of dynamic shading systems with PCMs through laboratory experimental measurements. Energy Build. 2018, 163, 92–110. [Google Scholar] [CrossRef]

- Goia, F.; Perino, M.; Serra, V. Experimental analysis of the energy performance of a full-scale PCM glazing prototype. Sol. Energy 2014, 100, 217–233. [Google Scholar] [CrossRef]

- Wieprzkowicz, A.; Heim, D. Modelling of thermal processes in a glazing structure with temperature dependent optical properties—An example of PCM-window. Renew. Energy 2020, 160, 653–662. [Google Scholar] [CrossRef]

- Li, D.; Ma, T.; Liu, C.; Zheng, Y.; Wang, Z.; Liu, X. Thermal performance of a PCM-filled double glazing unit with different optical properties of phase change material. Energy Build. 2016, 119, 143–152. [Google Scholar] [CrossRef] [Green Version]

- Goia, F.; Zinzi, M.; Carnielo, E.; Serra, V. Spectral and angular solar properties of a PCM-filled double glazing unit. Energy Build. 2015, 87, 302–312. [Google Scholar] [CrossRef] [Green Version]

- Heim, D.; Krempski-Smejda, M.; Dellicompagni, P.R.; Knera, D.; Wieprzkowicz, A.; Franco, J. Dynamics of Melting Process in Phase Change Material Windows Determined Based on Direct Light Transmission. Energies 2021, 14, 721. [Google Scholar] [CrossRef]

- Zhong, K.; Li, S.; Zhou, Y.; Zhang, X. Dynamic heat transfer characteristics of PCM-filled glass window and hollow glass window. Huagong Xuebao/CIESC J. 2014, 65, 114–123. [Google Scholar] [CrossRef]

- Komerska, A.; Ksionek, D.; Rosinski, M. Determination of the solar transmittance for the translucent shutter with PCM in liquid and solid state. E3S Web Conf. 2017, 22, 84. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Wu, Y.; Li, D.; Ma, T.; Liu, X. Investigations on thermal and optical performances of a glazing roof with PCM layer. Int. J. Energy Res. 2017, 41, 2138–2148. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Li, D.; Ma, T.; Hussein, A.K.; Zhou, Y. Investigation of thermal and optical performance of a phase change material–filled double-glazing unit. J. Build. Phys. 2018, 42, 99–119. [Google Scholar] [CrossRef]

- Recktenwald, G.W. Finite-Difference Approximations to the Heat Equation. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.408.4054&rep=rep1&type=pdf (accessed on 20 May 2021).

- Comini, G.; Del Guidice, S.; Lewis, R.W.; Zienkiewicz, O.C. Finite element solution of non-linear heat conduction problems with special reference to phase change. Int. J. Numer. Methods Eng. 1974. [Google Scholar] [CrossRef]

- Comini, G.; Del Giudice, S.; Saro, O. A conservative algorithm for multidimensional conduction phase change. Int. J. Numer. Methods Eng. 1990. [Google Scholar] [CrossRef]

- Bonacina, C.; Comini, G.; Fasano, A.; Primicerio, M. Numerical solution of phase-change problems. Int. J. Heat Mass Transf. 1973. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Li, D.; Zhou, Y.; Wang, Z.; Liu, X. Effect of PCM thickness and melting temperature on thermal performance of double glazing units. J. Build. Eng. 2017, 11, 87–95. [Google Scholar] [CrossRef] [Green Version]

- Goia, F.; Perino, M.; Haase, M. A numerical model to evaluate the thermal behaviour of PCM glazing system configurations. Energy Build. 2012, 54, 141–153. [Google Scholar] [CrossRef]

- Heim, D. Phase-Change Material Modeling within Whole Building Dynamic Simulation. ASHRAE Trans. 2006, 112, 518–525. [Google Scholar]

- Halimov, A.; Lauster, M.; Müller, D. Energy & Buildings Validation and integration of a latent heat storage model into building envelopes of a high-order building model for Modelica library AixLib. Energy Build. 2019, 202, 109336. [Google Scholar] [CrossRef]

- Al-Saadi, S.N.; Zhai, Z. Modeling phase change materials embedded in building enclosure: A review. Renew. Sustain. Energy Rev. 2013, 21, 659–673. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. Conservation Laws of Fluid Motion and Boundary Conditions. Available online: https://cds.cern.ch/record/1054103/files/9780131274983_TOC.pdf (accessed on 20 May 2021).

- Despres, B. Lax theorem and finite volume schemes. Math. Comput. 2003, 73, 1203–1235. [Google Scholar] [CrossRef] [Green Version]

- Mochnacki, B. Modelowanie i Symulacja Krzepnięcia Odlewów; Wydaw. Nauk. PWN: Warszawa, Poland, 1993; ISBN 8301109467. [Google Scholar]

| Temperature | [°C] | 20 | 0 | −20 | −40 |

|---|---|---|---|---|---|

| Cooling capacity | [kW] (medium: ethanol) | 1.00 | 0.92 | 0.88 | 0.75 |

| Heating capacity | 1.30 | 1.30 | 1.30 | 1.30 | |

| Cooling capacity | [kW] (medium: glycol) | 0.42 | 0.38 | 0.25 | 0.05 |

| Heating capacity | 1.50 | 1.50 | 1.50 | 1.50 |

| Parameter | No | Model | Range | Accuracy |

|---|---|---|---|---|

| Air temperature in chamber | TT (02/5/6) | TP-372 | –40… + 400 °C | ±(0.15 + 0.002·|T|) |

| Surface temperature at glass | TT (01/3) | TP-366 | –40… + 400 °C | ±(0.15 + 0.002·|T|) |

| Heat flow at glass surface | QR (01/2) | gSkin® | ±200 [W/m2] | ±3% |

| Material | d | c | ρ | k |

|---|---|---|---|---|

| [-] | [m] | [J/(kg∙K)] | [kg/m3] | [W/(m∙K)] |

| Glass * | 0.0084 | 840 | 2500 | 1.00 |

| PCM | 0.0120 | 2000 | 880 | 0.20 |

| Glass | 0.0080 | 840 | 2500 | 1.00 |

| Argon | 0.0120 | 520 | 1.80 | 0.025 |

| Glass | 0.0040 | 840 | 2500 | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kułakowski, T.; Krempski-Smejda, M.; Heim, D. Heat Transfer with Phase Change in a Multilayer Construction: Simulation versus Experiment. Energies 2021, 14, 4390. https://doi.org/10.3390/en14154390

Kułakowski T, Krempski-Smejda M, Heim D. Heat Transfer with Phase Change in a Multilayer Construction: Simulation versus Experiment. Energies. 2021; 14(15):4390. https://doi.org/10.3390/en14154390

Chicago/Turabian StyleKułakowski, Tomasz, Michał Krempski-Smejda, and Dariusz Heim. 2021. "Heat Transfer with Phase Change in a Multilayer Construction: Simulation versus Experiment" Energies 14, no. 15: 4390. https://doi.org/10.3390/en14154390

APA StyleKułakowski, T., Krempski-Smejda, M., & Heim, D. (2021). Heat Transfer with Phase Change in a Multilayer Construction: Simulation versus Experiment. Energies, 14(15), 4390. https://doi.org/10.3390/en14154390