Co-Digestion of Kitchen Waste with Grass and Leaves after Hyperthermophilic Pretreatment for Methane and Hydrogen Production

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characteristics of Substrates and Inoculum

2.2. Hyperthermophilic Treatment of Grass and Leaves

2.3. Co-Digestion Second Stage

3. Materials and Methods

3.1. Substrates and Inoculum

3.2. Experiments

3.2.1. Hyperthermophilic Pretreatment of Grass and Leaves

3.2.2. Co-Digestion Second Stage

3.3. Analytical Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Ethical Approval and Consent to Participate

References

- The European Commission. Closing the Loop—An EU Action Plan for the Circular Economy. In Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Sfez, S.; De Meester, S.; Vlaeminck, S.E.; Dewulf, J. Improving the resource footprint evaluation of products recovered from wastewater: A discussion on appropriate allocation in the context of circular economy. Resour. Conserv. Recycl. 2019, 148, 132–144. [Google Scholar] [CrossRef]

- Neczaj, E.; Grosser, A. Circular Economy in Wastewater Treatment Plant—Challenges and Barriers. Proceedings 2018, 2, 614. [Google Scholar] [CrossRef] [Green Version]

- Bianco, M. Circular economy and WWTPs: Water reuse and biogas production. In The Italian Water Industry: Cases of Excellence; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 237–257. ISBN 9783319713366. [Google Scholar]

- Główny Urząd Statystyczny. Ochrona Środowiska 2019. Available online: stat.gov.pl (accessed on 29 November 2019).

- Yun, Y.M.; Lee, M.K.; Im, S.W.; Marone, A.; Trably, E.; Shin, S.R.; Kim, M.G.; Cho, S.K.; Kim, D.H. Biohydrogen production from food waste: Current status, limitations, and future perspectives. Bioresour. Technol. 2018, 248, 79–87. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Braguglia, C.M.; Gallipoli, A.; Gianico, A.; Pagliaccia, P. Anaerobic bioconversion of food waste into energy: A critical review. Bioresour. Technol. 2018, 248, 37–56. [Google Scholar] [CrossRef] [PubMed]

- Urbaniec, K.; Bakker, R.R. Biomass residues as raw material for dark hydrogen fermentation—A review. Int. J. Hydrogen Energy 2015, 40, 3648–3658. [Google Scholar] [CrossRef]

- Sivagurunathan, P.; Kumar, G.; Mudhoo, A.; Rene, E.R.; Saratale, G.D.; Kobayashi, T.; Xu, K.; Kim, S.H.; Kim, D.H. Fermentative hydrogen production using lignocellulose biomass: An overview of pre-treatment methods, inhibitor effects and detoxification experiences. Renew. Sustain. Energy Rev. 2017, 77, 28–42. [Google Scholar] [CrossRef]

- Lo, Y.C.; Lu, W.C.; Chen, C.Y.; Chang, J.S. Dark fermentative hydrogen production from enzymatic hydrolysate of xylan and pretreated rice straw by Clostridium butyricum CGS5. Bioresour. Technol. 2010, 101, 5885–5891. [Google Scholar] [CrossRef]

- Liczbiński, P.; Borowski, S. Effect of hyperthermophilic pretreatment on methane and hydrogen production from garden waste under mesophilic and thermophilic conditions. Bioresour. Technol. 2021, 335, 125264. [Google Scholar] [CrossRef]

- Algapani, D.E.; Qiao, W.; Su, M.; di Pumpo, F.; Wandera, S.M.; Adani, F.; Dong, R. Bio-hydrolysis and bio-hydrogen production from food waste by thermophilic and hyperthermophilic anaerobic process. Bioresour. Technol. 2016, 216, 768–777. [Google Scholar] [CrossRef]

- Lee, M.; Hidaka, T.; Hagiwara, W.; Tsuno, H. Comparative performance and microbial diversity of hyperthermophilic and thermophilic co-digestion of kitchen garbage and excess sludge. Bioresour. Technol. 2009, 100, 578–585. [Google Scholar] [CrossRef]

- Wang, F.; Hidaka, T.; Tsuno, H.; Tsubota, J. Co-digestion of polylactide and kitchen garbage in hyperthermophilic and thermophilic continuous anaerobic process. Bioresour. Technol. 2012, 112, 67–74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, F.; Hidaka, T.; Tsumori, J. Enhancement of anaerobic digestion of shredded grass by co-digestion with sewage sludge and hyperthermophilic pretreatment. Bioresour. Technol. 2014, 169, 299–306. [Google Scholar] [CrossRef] [PubMed]

- Abreu, A.A.; Tavares, F.; Alves, M.M.; Cavaleiro, A.J.; Pereira, M.A. Garden and food waste co-fermentation for biohydrogen and biomethane production in a two-step hyperthermophilic-mesophilic process. Bioresour. Technol. 2019, 278, 180–186. [Google Scholar] [CrossRef] [Green Version]

- Xia, A.; Cheng, J.; Murphy, J.D. Innovation in biological production and upgrading of methane and hydrogen for use as gaseous transport biofuel. Biotechnol. Adv. 2016, 34, 451–472. [Google Scholar] [CrossRef] [PubMed]

- Liczbinski, P.; Borowski, S. Hyperthermophilic treatment of grass and leaves to produce hydrogen, methane and VFA-rich digestate: Preliminary results. Energies 2020, 13, 2814. [Google Scholar] [CrossRef]

- Brown, D.; Li, Y. Solid state anaerobic co-digestion of yard waste and food waste for biogas production. Bioresour. Technol. 2013, 127, 275–280. [Google Scholar] [CrossRef]

- Chen, X.; Yan, W.; Sheng, K.; Sanati, M. Comparison of high-solids to liquid anaerobic co-digestion of food waste and green waste. Bioresour. Technol. 2014, 154, 215–221. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Loh, K.C.; Zhang, J. Food waste enhanced anaerobic digestion of biologically pretreated yard waste: Analysis of cellulose crystallinity and microbial communities. Waste Manag. 2018, 79, 109–119. [Google Scholar] [CrossRef]

- Kouzuma, A.; Kato, S.; Watanabe, K. Microbial interspecies interactions: Recent findings in syntrophic consortia. Front. Microbiol. 2015, 6, 477. [Google Scholar] [CrossRef] [Green Version]

- Braga Nan, L.; Trably, E.; Santa-Catalina, G.; Bernet, N.; Delgenès, J.-P.; Escudié, R. Biomethanation processes: New insights on the effect of a high H2 partial pressure on microbial communities. Biotechnol. Biofuels 2020, 13, 1–17. [Google Scholar] [CrossRef]

- Borowski, S.; Kucner, M.; Czyżowska, A.; Berłowska, J. Co-digestion of poultry manure and residues from enzymatic saccharification and dewatering of sugar beet pulp. Renew. Energy 2016, 99, 492–500. [Google Scholar] [CrossRef]

- Angelidaki, I.; Alves, M.; Bolzonella, D.; Borzacconi, L.; Campos, J.L.; Guwy, A.J.; Kalyuzhnyi, S.; Jenicek, P.; van Lier, J.B. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: A proposed protocol for batch assays. Water Sci. Technol. 2009, 59, 927–934. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- American Public Health Association. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

| Material | Indicator | |||||||

|---|---|---|---|---|---|---|---|---|

| Total Solids (g/kg) | Volatile Solids (g/kg) | Carbon (% TS) | Nitrogen (% TS) | Phosphorus (% TS) | Hydrogen (% TS) | Sulfur (% TS) | C/N | |

| Grass | 133.75 ± 11.20 | 109.57 ± 9.88 | 59.92 ± 3.36 | 2.68 ± 0.09 | 0.96 ± 0.07 | 5.42 ± 0.36 | 0.88 ± 0.02 | 22.36 |

| Leaves | 936.20 ± 5.40 | 821.21 ± 6.25 | 58.80 ± 2.06 | 2.89 ± 0.15 | 0.27 ± 0.02 | 5.41 ± 0.28 | 0.34 ± 0.02 | 20.35 |

| Kitchen waste | 256.34 ± 6.21 | 245.39 ± 5.42 | 54.40 ± 2.18 | 4.16 ± 0.48 | 0.25 ± 0.03 | 5.94 ± 0.28 | 0.31 ± 0.03 | 15.23 |

| Inoculum | 28.25 ± 0.72 | 22.46 ± 0.34 | 62.80 ± 2.80 | 6.49 ± 0.16 | 1.25 ± 0.05 | 5.88 ± 0.26 | 0.60 ± 0.03 | 9.68 |

| Grass 70 °C | Grass 80 °C | Leaves 70 °C | Leaves 80 °C | ||

|---|---|---|---|---|---|

| Duration time (d) | 3 | 3 | 3 | 3 | |

| Mass of water (g) | 250 | 250 | 350 | 350 | |

| Mass of grass (g) | 250 | 250 | 0 | 0 | |

| Mass of leaves (g) | 0 | 0 | 150 | 150 | |

| Initial pH of the mixtures | 7.22 ± 0.05 | 7.17 ± 0.09 | 6.95 ± 0.07 | 6.98 ± 0.03 | |

| Hydrogen yield (NmL/gVS) | 8.00 ± 1.3 | 1.60 ± 0.12 | 2.35 ± 0.30 | 0.42 ± 0.03 | |

| Methane yield (NmL/gVS) | 0.56 ± 0.09 | 2.42 ± 0.08 | 8.47 ± 0.25 | 1.83 ± 0.13 | |

| Digestate quality | pH | 5.49 ± 0.04 | 6.21 ± 0.07 | 5.20 ± 0.02 | 4.89 ± 0.05 |

| sCOD (mg/L) | 24,143 ± 514 | 26,010 ± 410 | 65,167 ± 4250 | 88,866 ± 7688 | |

| TVFA (mg/L) | 12,026 ± 189 | 12,703 ± 320 | 56,473 ± 1217 | 61,060 ± 1324 | |

| Ammonium nitrogen (mg/L) | 152.7 ± 7.2 | 243.3 ± 5.1 | 524.0 ± 16.8 | 322.3 ± 12.0 | |

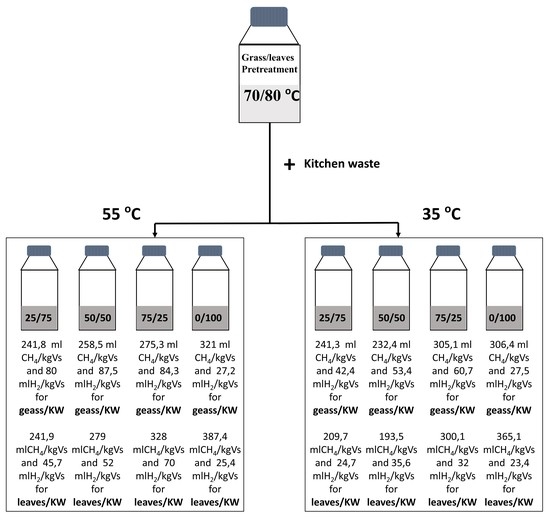

| Substrate | Pretreatment Temperaturę for GW | Co-Digestion Temperature | Methane Yields (NmL/gVS) for GW/KW Proportions | Hydrogen Yields (NmL/gVS) for GW/KW Proportions | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 25/75 | 50/50 | 75/25 | 0/100 | 25/75 | 50/50 | 75/25 | 0/100 | |||

| Grass/KW | 70 °C | 55 °C | 241.8 ± 4.5 | 258.5 ± 3.6 | 305 ± 2.9 | 295.6 ± 8.1 | 80.0 ± 1.8 | 87.5 ± 1.1 | 84.3 ± 0.8 | 27.2 ± 3.3 |

| 35 °C | 182.1 ± 3.8 | 149.0 ± 3.7 | 99.0 ± 3.9 | 244.1 ± 1.7 | 32.7 ± 0.6 | 47.7 ± 0.7 | 49.0 ± 1.1 | 23.5 ± 3.2 | ||

| 80 °C | 55 °C | 122.1 ± 7.6 | 162.7 ± 2.8 | 275.3 ± 6.4 | 321 ± 4.2 | 37.8 ± 2.6 | 54.3 ± 0.8 | 71.2 ± 0.7 | 16.2 ± 0.3 | |

| 35 °C | 241.3 ± 2.8 | 232.4 ± 9.8 | 305.1 ± 8.2 | 306.4 ± 1.4 | 42.4 ± 0.9 | 53.4 ± 1.3 | 60.7 ± 1.2 | 27.5 ± 0.2 | ||

| Leaves/KW | 70 °C | 55 °C | 241.9 ± 5.5 | 272.4 ± 7.7 | 328.0 ± 7.9 | 387.4 ± 2.2 | 45.7 ± 0.9 | 52.0 ± 1.1 | 70.0 ± 1.2 | 25.4 ± 0.2 |

| 35 °C | 209.7 ± 8.8 | 193.5 ± 8.1 | 117.2 ± 6.7 | 365.1 ± 3.6 | 24.7 ± 0.7 | 35.6 ± 1.3 | 32.0 ± 0.8 | 23.4 ± 0.4 | ||

| 80 °C | 55 °C | 234.2 ± 8.3 | 279.0 ± 13.7 | 291.3 ± 11.2 | 235.1 ± 0.8 | 14.9 ± 0.6 | 21.0 ± 1.0 | 25.0 ± 1.0 | 24.1 ± 0.3 | |

| 35 °C | 28.0 ± 2.0 | 126.5 ± 14.9 | 300.1 ± 14.1 | 219.0 ± 0.6 | 1.9 ± 0.1 | 7.9 ± 0.9 | 19.0 ± 0.8 | 5.4 ± 0.2 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liczbiński, P.; Borowski, S. Co-Digestion of Kitchen Waste with Grass and Leaves after Hyperthermophilic Pretreatment for Methane and Hydrogen Production. Energies 2021, 14, 5880. https://doi.org/10.3390/en14185880

Liczbiński P, Borowski S. Co-Digestion of Kitchen Waste with Grass and Leaves after Hyperthermophilic Pretreatment for Methane and Hydrogen Production. Energies. 2021; 14(18):5880. https://doi.org/10.3390/en14185880

Chicago/Turabian StyleLiczbiński, Przemysław, and Sebastian Borowski. 2021. "Co-Digestion of Kitchen Waste with Grass and Leaves after Hyperthermophilic Pretreatment for Methane and Hydrogen Production" Energies 14, no. 18: 5880. https://doi.org/10.3390/en14185880

APA StyleLiczbiński, P., & Borowski, S. (2021). Co-Digestion of Kitchen Waste with Grass and Leaves after Hyperthermophilic Pretreatment for Methane and Hydrogen Production. Energies, 14(18), 5880. https://doi.org/10.3390/en14185880