Effect of Connection Resistance between Cyclones and Backpass on Furnace Solids Suspension Density Profile and Circulation Rates in CFB

Abstract

:1. Introduction

2. Experimental Setup

2.1. Basic Information of the CFB Test Rig

2.2. Measurement Techniques

3. Three Connection Modes and Calculation of Connection Resistance

3.1. Resistance Coefficient of Each Connection Branch of a Connection Mode

3.2. Overall Resistance Coefficient of a Connection Mode

4. Theoretical Analysis

4.1. Solids Recycle Loops and Gas-Flowing Branches

4.2. Pressure Drops from Furnace to Each Connection Branch

4.3. Pressure Drops in a Solids Recycle Loop

4.4. Mass Balance of the Loop in the Whole System

4.5. Solids Suspension Density Distribution in the Furnace

4.6. Solids Circulation Rates

4.7. Solution Procedure

5. Results and Discussion

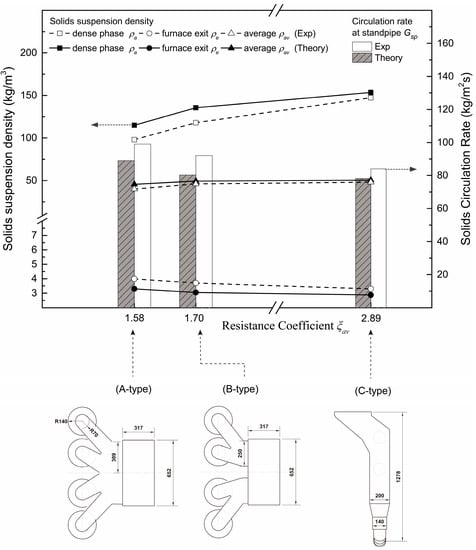

5.1. Effect of Overall Resistance Coefficient on Suspension Density Distribution and Gsp

5.2. Effect of Connection Branch Resistance Distribution on Suspension Density and Gsp,i

5.3. Effect of Superficial Velocity on Suspension Density and Circulation Rate

6. Conclusions

6.1. The Conclusions for the Investigation

- (1)

- The solids suspension density in the furnace and solids circulation rate distributions are influenced by connection resistance. With smaller overall resistance coefficient ξav of a connection, the axial solids suspension density in the furnace distributes more uniform and solids circulation rate becomes larger;

- (2)

- For branch resistances ξb,i (i = 1–4) in a connection, smaller ξb,i leads to higher solids circulation rate in solids recycle loop. Regarding C-type connection mode, the ξb,i is decreasing from connection branch 1~4, resulting in solids suspension density and circulation rates increasing from corresponding recycle loop 1–4. Smaller ξb,i of a connection branch also leads to more evenly axial solids suspension density distribution of corresponding recycle loop;

- (3)

- The effect of connection resistance is enhanced by growing superficial velocity. The variance of lateral solids suspension distribution and solids circulation rates allocation becomes larger with higher superficial velocity. For a connection, non-uniformity of branch resistance ξb,i affects the uneven distribution of solids suspension density and Gsp,i allocation among recycling loops, this effect is strongly intensified by growing velocity.

6.2. Suggestions for the Connection Design of Large Scale CFB Boiler

- (1)

- It is beneficial to design a simple connection structure with a short distance from cyclones to the backpass. A a small value of overall connection resistance coefficient ξav should be chosen, for it leads to less resistance for gas-solid circulation and is helpful for operating flexibly.

- (2)

- For each connection branch in a connection mode, the structure and distance from each cyclone to backpass should be close to each other, ensuring uniformity of branch resistance coefficient ξb,i distribution. It is helpful to diminish uneven solids suspension density distribution and solids circulation rates allocation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Explanation | Unit |

| Ac | Cross-section area of cyclone entrance | m2 |

| Adis | Cross-section area of non-machanical valve | m2 |

| Af | Cross-section area of furnace | m2 |

| Asp | Cross-section area of standpipe | m2 |

| Ar | Archimedes number | |

| D | Width of furnace cross-section | m |

| dc | Diameter of cyclone | m |

| ds | Diameter of standpipe | m |

| dp | Particle diameter | μm |

| Fn | Fluidization number | - |

| g | Gravitational constant | m/s2 |

| Gs | Solids circulation rate | kg/m2·s |

| Gsf | Solids circulation rate at furnace | kg/m2·s |

| Gsp,i | Solids circulation rate at standpipe “i” | kg/m2·s |

| Gsp | Average solids circulation rate among standpipes | kg/m2·s |

| h0 | Height of dense phase | m |

| H | Height of furnace | m |

| H0 | Bed inventory height | m |

| i | No. of theoretical gas branch/solids recycle loop | - |

| L | Length of furnace cross-section | m |

| M | Total solids inventory in CFB system | kg |

| Msp | The mass of solids in standpipe | kg |

| Mf | The mass of solids in furnace | kg |

| Mcyc | The mass of solids in cyclones | kg |

| ΔP | Pressure drop | Pa |

| ΔPAB,i | Pressure drop across furnace of a solids recycle loop | Pa |

| ΔPAB | Pressure drop across furnace, (i = 1–4) | Pa |

| ΔPBE,i | Pressure drop across cyclone of a solids recycle loop | Pa |

| ΔPBE | Pressure drop across cyclones, (i = 1–4) | Pa |

| ΔPEF,i | Pressure drop across a connection branch | Pa |

| ΔPEF | Pressure drop across a connection, (i = 1–4) | Pa |

| ΔPCD,i | Pressure drop across standpipe of a recycle loop | Pa |

| ΔPDA,i | Pressure drop across loop-seal of a recycle loop | Pa |

| Rep | Particle Reynolds number | - |

| Ret | Terminal particle Reynolds number | - |

| ug | Superficial velocity in furnace | m/s |

| ug,i | Superficial velocity in furnace of a gas flowing branch i | m/s |

| umf | Minimum fluidized velocity | m/s |

| ut | Terminal velocity | m/s |

| uvs | Air velocity in supply chamber | m/s |

| uvr | Air velocity in recycle chamber | m/s |

| ξav | Overall resistance coefficient of a connection mode | - |

| ξb,i | Resistance coefficient of connection branch “i” | |

| ξfr,i | Friction resistance coefficient of connection branch “i” | - |

| ξl,i | local resistance coefficient of connection branch “i” | |

| ρi | Solids suspension density of a gas flowing branch | kg/m3 |

| ρa,i | Solids suspension density in dense phase of a gas flowing branch | kg/m3 |

| Average solids suspension density in dense phase | kg/m3 | |

| ρav,i | Average solids suspension density above furnace bottom of a branch | kg/m3 |

| ρav | Average solids suspension density in furnace | kg/m3 |

| ρb | Particle bulk density | kg/m3 |

| ρd,i | Saturated carrying capacity of a gas at certain velocity | kg/m3 |

| ρe,i | Solids suspension density at the furnace exit of a branch | kg/m3 |

| ρe | Average solids suspension density at the furnace exit | kg/m3 |

| ρf | Air density | kg/m3 |

| ρs | Particle density | kg/m3 |

| ρsus | Solids suspension density | kg/m3 |

| ν | Kinetic Viscosity | m2/s |

| εa,i | Voidage at furnace bottom of a branch | − |

| Average voidage at furnace bottom | ||

| εd,i | Saturated solids carrying capacity voidage of a furnace branch | − |

| εmf | Minimum fluidized voidage | − |

| Φ | Sphericity of particle | − |

Appendix A. The Calculation of Terminal Velocity

Appendix B. The Pressure Drop Across Furnace, Cyclones and The Connections

| Type of Connection Modes | ΔPAB | ΔPBE |

|---|---|---|

| A-type | 595.9 | 63.2 |

| B-type | 645.2 | 66.4 |

| C-type | 661.6 | 65.2 |

| Type of Connection Modes | ΔPAB | ΔPBE | ΔPEF |

|---|---|---|---|

| A-type | 604.6 | 57.1 | 32.4 |

| B-type | 653.2 | 57.5 | 38.2 |

| C-type | 667.1 | 58.2 | 49.5 |

References

- Zhou, X.L.; Cheng, L.M.; Zhang, J.; Wang, Q.H.; Luo, Z.Y.; Cen, K.F. Experimental Study on Solids Suspension Density and Solids Circulating Rate in a CFB with Six Circulating Loops. Proc. CSEE 2012, 32, 31–36. [Google Scholar]

- Wang, F.J.; Song, G.L.; Wang, X.F.; Liu, Z.C.; Sun, Y.K.; Lu, Q.G. Cold Experimental Study on a CFB with Four Cyclone Separators on the Same Side. Power Syst. Eng. 2014, 3, 17–19. [Google Scholar]

- Lee, J.M.; Kim, J.S.; Kim, J.J. Characteristics of Solid Hold Up and Circulation Rate in the CFB Reactor with 3-Loops. Korean J. Chem. Eng. 2001, 18, 1000–1004. [Google Scholar] [CrossRef]

- Yang, S.; Yang, H.R.; Liu, Q.; Zhang, H.; Wu, Y.X.; Yue, G.X.; Wang, Y.Z. Research on Flow Non-Uniformity in Main Circulation Loop of a CFB Boiler with Multiple Cyclones. In Proceedings of the 20th International Conference on Fluidized Bed Combustion, Xi’an, China, 18–21 May 2009; Springer: Berlin/Heidelberg, Germany, 2009; Volume 139, pp. 341–344. [Google Scholar]

- Zheng, W.J.; Zhang, M.; Zhang, Y.; Lyu, J.F.; Yang, H.R. The effect of the secondary air injection on the gas-solid flow characteristics in the circulating fluidized bed. Chem. Eng. Res. Des. 2019, 141, 220–228. [Google Scholar] [CrossRef]

- Karlsson, T.; Liu, X.; Pallarès, D.; Johnsson, F. Solids circulation in circulating fluidized beds with low riser aspect ratio and varying total solids inventory. Powder Technol. 2017, 316, 670–676. [Google Scholar] [CrossRef]

- Mo, X.; Cai, R.X.; Huang, X.D.; Zhang, M.; Yang, H.R. The effects of wall friction and solid acceleration on the mal-distribution of gas-solid flow in double identical parallel cyclones. Powder Technol. 2015, 286, 471–477. [Google Scholar] [CrossRef]

- Harris, A.T.; Davidson, J.F.; Thorpe, R.B. Influence of exit geometry in circulating fluidized-bed risers. AIChE J. 2003, 49, 52–64. [Google Scholar] [CrossRef]

- Wang, S.; Luo, K.; Hu, C.S.; Fan, J.R. CFD-DEM study of the effect of cyclone arrangements on the gas-solid flow dynamics in the full-loop circulating fluidized bed. Chem. Eng. Sci. 2017, 172, 199–215. [Google Scholar] [CrossRef]

- Knowlton, T.M. Standpipes and return systems. In Circulating Fluidized Beds; Springer: Dordrecht, The Netherlands, 1997; pp. 214–260. [Google Scholar]

- Sun, X.B.; Li, G.H.; Jiang, M.H. Study on Several Forward Tasks in the Technical Sector of CFB Boilers. Therm. Power Gener. 2005, 34, 1–5. [Google Scholar]

- Song, G.L.; Yang, Z.; Zhou, T.; Lyu, Q.G. Operating technical characteristics on asymmetrical arrangement of six cyclones in a 600 MW supercritical CFB boiler. Appl. Therm. Eng. 2018, 143, 236–247. [Google Scholar] [CrossRef]

- Mo, X.; Cai, R.X.; Lyu, J.F. Analysis of Non-uniform Distribution of Gas-Solid Flow in the 600 MW(e) CFB Boiler Based on the Non-uniform Distribution of Returning Ash Temperature. Proc. CSEE 2016, 36, 153–158. [Google Scholar]

- Glicksman, L.R. Scaling relationships for fluidized beds. Chem. Eng. Sci. 1984, 39, 1373–1379. [Google Scholar] [CrossRef]

- Glicksman, L.R. Scaling relationships for fluidized beds. Chem. Eng. Sci. 1988, 43, 1419–1421. [Google Scholar] [CrossRef]

- Idelcik, I.E.; Ginevskiy, A.S.; Kolesnikov, A.V. Handbook of Hydraulic Resistance; Hemisphere Publishing Corp.: Washington, DC, USA, 1986. [Google Scholar]

- Zheng, Y.; Lu, X.F.; Yang, W.Q.; Fan, L.Y.; Wang, Q.H.; Yan, J. Simulation of Particle Concentration Distribution in a Large-scale Circulating Fluidized Bed Boiler at Different Material-returning Deviations. Proc. CSEE 2020, 40, 848–858. [Google Scholar]

- Bi, H.; Zhu, J.X. Static instability analysis of circulating fluidized beds and concept of high-density risers. AIChE J. 1993, 39, 1272–1280. [Google Scholar] [CrossRef]

- Shepherd, C.B.; Lapple, C.E. Flow Pattern and Pressure Drop. Ind. Eng. Chem. 1939, 31, 972–984. [Google Scholar] [CrossRef]

- Chen, H.Z.; Yang, D.W.; Li, H.Z.; Tan, S.Y. Study on the overall pressure balance of a downflow circulating fluidized bed system. China Particuology 2006, 4, 153–159. [Google Scholar] [CrossRef]

- Rhodes, M.J.; Geldart, D. A model for the circulating fluidized bed. Powder Technol. 1987, 53, 155–162. [Google Scholar] [CrossRef]

- Bai, D.; Issangya, A.S.; Zhu, J.X.; Grace, J.R. Analysis of the Overall Pressure Balance around a High-Density Circulating Fluidized Bed. Ind. Eng. Chem. Res. 1997, 36, 3898–3903. [Google Scholar] [CrossRef]

- Kunii, D.; Levenspiel, O. Entrainment of solids from fluidized beds I. Hold-up of solids in the freeboard II. Operation of fast fluidized beds. Powder Technol. 1990, 61, 193–206. [Google Scholar] [CrossRef]

- Basu, P. Circulating Fluidized Bed Boilers; Springer International Publishing: Cham, Switzerland, 2015; Volume 54, ISBN 978-3-319-06172-6. [Google Scholar]

- Yang, W.C. Criteria for choking in vertical pneumatic conveying lines. Powder Technol. 1983, 35, 143–150. [Google Scholar] [CrossRef]

- Schlichthaerle, P.; Werther, J. Axial pressure profiles and solids concentration distributions in the CFB bottom zone. Chem. Eng. Sci. 1999, 54, 5485–5493. [Google Scholar] [CrossRef]

- Stollhof, M.; Penthor, S.; Mayer, K.; Hofbauer, H. Estimation of the solid circulation rate in circulating fluidized bed systems. Powder Technol. 2018, 336, 1–11. [Google Scholar] [CrossRef]

- Howard, J.R. Fluidized Bed Technology—Principles and Applications; CRC Press: Bristol, UK, 1989. [Google Scholar]

| Items | Symbols | Units | Values in Original Boiler | Values in Test Model | |

|---|---|---|---|---|---|

| Geometric parameters | Height of furnace | H | m | 55.8 | 1.39 |

| Length of furnace | L | m | 39.95 | 0.99 | |

| Width of furnace | D | m | 12.67 | 0.32 | |

| Diameter of cyclone | dc | m | 11.20 | 0.28 | |

| Diamter of standpipe | ds | m | 2.12 | 0.053 | |

| cross-section of the non-mechanical valve | Adis | m2 | 4.84 | 0.0030 | |

| Operating conditions | Temperature | T | °C | 880 | 25 |

| superficial velocity | ug | m/s | 4.37–5.26 | 0.69–0.83 | |

| Air velocity in supply chamber | uvs | m/s | − | 0.063 | |

| Air velocity in recycle chamber | uvr | m/s | − | 0.19–0.38 | |

| Kinematic viscosity | ν | Pa·s | 1.51 × 10−4 | 1.55 × 10−5 | |

| Air density | ρf | kg/m3 | 0.301 | 1.185 | |

| Solids flux at furnace | Gsf | kg/m2s | 16.56 | 3.14 | |

| Solids flux at a standpipe | Gsp | kg/m2s | 678.96 | 128.74 | |

| Bed material properties | Solid diameter | dp | um | 400 | 94 |

| Sphericity | Φ | \ | 0.8 | 0.8 | |

| Minimum fluidized velocity | umf | m/s | 0.052 | 0.0081 | |

| Terminal velocity | ut | m/s | 2.91 | 0.66 | |

| Particle Reynolds number | Rep | \ | 11.13 | 4.02 | |

| Solid density | ρs | kg/m3 | 2000 | 2330 | |

| Dimensionless numbers | ug2/gL | \ | 0.069 | 0.070 | |

| D/L | \ | 0.317 | 0.320 | ||

| ug/umf | \ | 102.08 | 102.11 | ||

| Gsf/ρsug | \ | 1.57 × 10−3 | 1.57 × 10−3 | ||

| Connection Mode | Connection Branch (i) | ξfr,i | ξl,i | Detailed of Local Resistance | ξb,i | ξav |

|---|---|---|---|---|---|---|

| A-type | 1 and 4 | 0.13 | 1.51 | Elbow with right angle, conjunction wye with angle, sudden expansion*2 | 1.64 | 1.58 |

| 2 and 3 | 0.09 | 1.43 | Elbow with right angle, conjunction wye with angle, sudden expansion*2 | 1.52 | ||

| B-type | 1 and 4 | 0.12 | 1.60 | Elbow with right angle, conjunction wye with angle, sudden expansion*2, smooth expansion | 1.82 | 1.70 |

| 2 and 3 | 0.09 | 1.49 | Elbow with right angle, conjunction wye with angle, sudden expansion*2, smooth expansion | 1.58 | ||

| C-type | 1 | 0.16 | 3.10 | elbow, sudden expansion, tee (after junction) *3, smooth expansion, horizontal elbow with sharp corner | 3.26 | 2.89 |

| 2 | 0.12 | 2.98 | Tee before junction, tee after junction*2, smooth expansion, horizontal elbow with sharp corner | 3.10 | ||

| 3 | 0.08 | 2.66 | Tee before junction, tee after junction, smooth expansion, horizontal elbow with sharp corner | 2.74 | ||

| 4 | 0.06 | 1.96 | tees before junction and horizontal elbow with sharp corner | 2.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, G.; Cheng, L.; Li, L.; Wang, J.; Jiang, X.; Zhang, W. Effect of Connection Resistance between Cyclones and Backpass on Furnace Solids Suspension Density Profile and Circulation Rates in CFB. Energies 2021, 14, 6162. https://doi.org/10.3390/en14196162

Luo G, Cheng L, Li L, Wang J, Jiang X, Zhang W. Effect of Connection Resistance between Cyclones and Backpass on Furnace Solids Suspension Density Profile and Circulation Rates in CFB. Energies. 2021; 14(19):6162. https://doi.org/10.3390/en14196162

Chicago/Turabian StyleLuo, Guanwen, Leming Cheng, Liyao Li, Junfeng Wang, Xiaoguo Jiang, and Weiguo Zhang. 2021. "Effect of Connection Resistance between Cyclones and Backpass on Furnace Solids Suspension Density Profile and Circulation Rates in CFB" Energies 14, no. 19: 6162. https://doi.org/10.3390/en14196162

APA StyleLuo, G., Cheng, L., Li, L., Wang, J., Jiang, X., & Zhang, W. (2021). Effect of Connection Resistance between Cyclones and Backpass on Furnace Solids Suspension Density Profile and Circulation Rates in CFB. Energies, 14(19), 6162. https://doi.org/10.3390/en14196162