1. Introduction

A new offshore wind validation campaign was recently conducted within the International Energy Agency (IEA) Wind Task 30, called the Offshore Code Comparison Collaboration, Continued, with Correlation and unCertainty (OC6) project. The aim of the OC6 project (initiated in 2019) is to perform more focused validation projects to investigate critical physical phenomena that drive the inaccuracy in load predictions by engineering-level modeling tools for offshore wind turbines based on potential-flow theory and/or Morison equation. There are four phases in the OC6 project, and Phase I is focused on the underprediction of the loads and resulting motion of floating wind semisubmersibles at their surge and pitch natural frequencies. This issue was identified within the OC5 Phase II project [

1] when validating modeling tools against a scaled-model experiment of the OC5-DeepCwind semisubmersible in a wave tank under combined wind and wave loading. A persistent underprediction of the global loads and motion was identified, which came primarily from the underestimation of the loads/motion of the structure in the low-frequency region where the pitch and surge natural frequencies were located. With semisubmersibles, these frequencies typically lie outside the frequency range of linear wave excitation and are instead excited by nonlinear, low-frequency hydrodynamic loading [

2,

3]. This issue is more pronounced in severe sea states where the second-order difference-frequency wave load surpasses the contribution from wind at low frequencies [

3].

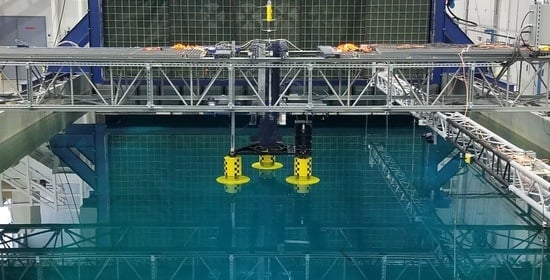

To further investigate the nonlinear hydrodynamic loading, two new wave-tank validation campaigns were performed at the concept basin of the Maritime Research Institute Netherlands (MARIN) in 2017 and 2018 (see

Figure 1) using the OC5-DeepCwind semisubmersible design [

1]. Experiments were performed with a fixed model and a model under forced oscillation to examine the wave diffraction and radiation loadings, respectively. Of course, viscous effects were also present with both configurations, which cannot be removed in wave-basin experiments. Experiments with a floating model were also performed, but with a simplified setup with no aerodynamic loads to focus specifically on the hydrodynamics of the substructure. Phase Ia of the OC6 project aimed to validate engineering-level simulation models against the measurements from these experiments to identify the cause for the underprediction of the nonlinear hydrodynamic response [

4]. The conclusions from this work were that engineering modeling tools underpredict the low-frequency loads in all configurations, including when held fixed, forced to oscillate in surge, and freely floating. Load and motion estimates could be improved for one configuration through model tuning, but the same tuning would worsen the results for another configuration, pointing to the need for improvements to the modeling approach itself.

To examine the limitations of the existing engineering models, the OC6 project is incorporating higher-fidelity tools, such as computational fluid dynamics (CFD), in addition to the experiment and mid-fidelity models to enable a three-way validation that will provide more insight into the physics of the nonlinear hydrodynamic loading for offshore wind systems. However, the validation of the CFD tools themselves is difficult to achieve with the previous datasets examined in OC5 Phase II and OC6 Phase Ia, due to the limited measurements and the reliance on long, 3 h irregular-wave load cases, which are computationally prohibitive for CFD tools to simulate. To address these limitations, a new experimental campaign called OC6 Phase Ib (see

Figure 1 and

Figure 2) was conducted in 2021 at the W2 Harold Alfond Ocean Engineering Laboratory of the University of Maine. This paper provides an overview of this campaign, which had three overarching goals:

test individual components (columns and heave plates) of a semisubmersible (alone and in combination) to better understand how the hydrodynamic loading changes for structures in proximity,

obtain detailed, distributed load information on the structure, and

perform bichromatic-wave cases to facilitate low-frequency load validation.

Component-level tests are not a new concept and are recommended as a step towards the validation of complex systems. In this case, the work has progressed in reverse, starting with a complex full system (for OC5 and OC6 Phase Ia) and moving to component-level experiments once validation issues were identified. Many campaigns have been conducted over the past 50 years to better understand the hydrodynamic loading on components of offshore structures. A large focus has been on heave-plate loading, in particular the effects of the geometry and wave conditions on the resulting loads (see, e.g., [

8,

9,

10,

11]). Further work has been carried out to investigate the loading when heave plates are attached to vertical cylinders, a typical component of offshore semisubmersibles (see, e.g., [

12,

13,

14,

15,

16]).

The primary difference in this campaign is that the geometry of the structural components investigated matches those of the DeepCwind semisubmersible design [

17], which deviates in sizing from oil and gas platforms. The DeepCwind semisubmersible has been widely investigated, serving as a reference for offshore wind research. Secondly, the design complexity was built up across this campaign by examining a cylinder in isolation, then a heave plate attached to that cylinder, and finally the layout of three cylinders with heave plates representative of the DeepCwind design, allowing for examination of how the component loading is directly affected by other members. Thirdly, the components were examined in a neutral position and then in a pitched condition that is representative of the mean orientation of an offshore wind system under operational wind conditions—a configuration that is not typical outside the floating wind area.

Detailed measurements were also integrated into this campaign to enable a better understanding of the components that drive the nonlinear hydrodynamic loading. In the previous OC5 and OC6 experiments, validation was only focused on the hydrodynamic loading across the entire semisubmersible structure, making it difficult to understand the reason for differences between simulations and experiments. The OC6 Phase Ib campaign incorporated load measurements for each of the column/heave plate components of the semisubmersible seen in

Figure 2, as well as pressure measurements on the heave plate and near the still waterline, where it is expected that the nonlinear hydrodynamic loading is the highest. Prior examples of pressure measurement in a wave basin with a surface-piercing structure often focus on water impact problems during extreme wave events (see, e.g., [

18,

19,

20,

21,

22]). In contrast, measurement of pressure on structures in nonbreaking and moderate waves is less common. Some examples are [

23,

24]; the latter considered a horizontal submerged cylinder rather than a vertical, surface-piercing one. While surface-mounted piezoelectric sensors are commonly used for pressure measurements in wave-basin experiments, the pressure measurement in this campaign was carried out using small pressure taps on the surface of the model, which were connected to an array of pressure sensors above the model through tubes. This is a cost-effective setup for achieving the desired sensor spatial density and limiting the impact on the hydrodynamic loading. However, several issues with this experimental setup negatively impacted the reliability of the pressure measurements, and, thus, the data can only be used in a qualitative manner. Nevertheless, the pressure measurements highlight the increased nonlinear, difference/low-frequency pressure oscillation near the calm waterline and provide qualitative references that can be compared to CFD results.

The incorporation of bichromatic waves in this campaign is motivated by two considerations. First, the measured difference-frequency loads from the experiment can be compared directly to the quadratic transfer functions (QTFs) from second-order potential-flow solutions, upon which many mid-fidelity engineering models are based [

4]. Such comparison enables the identification of the limitations of potential-flow theory and provides an understanding of the resulting error. Second, the two frequencies of the bichromatic waves can be carefully chosen to obtain a short repeat period, and the corresponding CFD simulation to be validated only needs to run for several repeat periods (on the order of several hundred seconds full scale) to capture the difference-frequency loads, rather than the typical 3 h time window needed to resolve the low-frequency loads from irregular waves. The computing time is, therefore, significantly shortened.

The advantages of using bichromatic waves to investigate the nonlinear hydrodynamics of floating structures have already been recognized and exploited in the literature. Lopez-Pavon et al. [

25] performed wave-basin experiments of a captive (fixed) offshore wind semisubmersible subjected to bichromatic incident waves, and the surge force on the structure was measured to extract the difference-frequency slow-drift force. It was observed that while second-order potential-flow solution captured the overall trend of second-order wave forces, there was a clear underprediction when compared to the experiment. A follow-up work by Simos et al. [

26] reported an experimental investigation of the slow-drift motion of a freely floating offshore wind semisubmersible in bichromatic waves. The equivalent linear damping ratio estimated from the slow-drift motion was found to be mostly consistent with the values estimated from surge free-decay experiments for large amplitude motion. Do Carmo et al. [

27] also investigated the slow-drift motion of a floating wind semisubmersible excited by bichromatic waves. In this investigation, however, it was observed that the damping estimated from both forced oscillation and free decay in surge led to an underestimation of the slow-drift motion. Li and Bachynski-Polić [

28] performed a series of CFD simulations of a fixed offshore wind semisubmersible in bichromatic waves and successfully used the numerical predictions of the difference-frequency loads to modify the potential-flow QTFs to improve the prediction of nonlinear, low-frequency wave excitation from irregular waves. In contrast to the aforementioned experimental investigations with bichromatic waves, the present experimental campaign also provides measurements of the difference-frequency pitch moment on a fixed offshore wind semisubmersible, which was also underpredicted by engineering models [

4]. Furthermore, the wave loads were also measured with the semisubmersible in a 5°-pitched configuration representative of the operating condition to investigate the effect of a steady pitch angle on wave excitation.

The remainder of this paper provides details about the OC6 Phase Ib experimental campaign so that others may use the dataset for their own purposes. The organization is outlined as follows:

Section 2 and

Section 3 describe the experimental facility and the various configurations of the physical model of the offshore wind semisubmersible substructure. The wave conditions included in this validation campaign are summarized in

Section 4. The suite of measurements taken during the experiment is explained in

Section 5, and the complete Test Matrix and the accessible data from the campaign are tabulated in

Section 6. The uncertainty analysis of the present campaign is briefly summarized in

Section 7, followed by the conclusions in

Section 8.

2. Testing Facility

The validation campaign was performed at the W2 Harold Alfond Ocean Engineering Laboratory of the University of Maine in the United States (

Figure 2), highlighting U.S. capabilities to support the emerging floating wind industry. The W2 facility includes infrastructure to support simultaneous excitation from both wind and waves, but only the wave generation capability was utilized in this project. The basin is 30 m long and 9 m wide, with an adjustable water depth set to 5 m for the present campaign. A flap-type wavemaker with 16 paddles was used to generate the prescribed wave conditions. The wavemaker can generate directional waves

degrees relative to the basin centerline with a maximum wave height of 0.6 m at 1.65-s period and 0.8 m at 2.3-s period. For the present campaign, however, only long-crested waves were generated along the length of the basin (zero-degree wave heading). An elliptical beach at the end of the basin opposite from the wavemaker minimizes wave reflection.

The position of the model during the experiment is shown in

Figure 3. with the basin coordinate system. The origin of the basin coordinate system rests at the intersection of the wavemaker pedal plane at neutral position, the basin center plane, and the still water level (SWL). The +

-direction is along the length of the basin in the direction of wave propagation (0-degree wave heading). The +

-axis points vertically upward, and the +

-axis follows the right-hand convention. The model was installed symmetrically about the basin center plane with the axis of pitch rotation located at

= 8.839 m and

= −0.1506 m model scale. This position was maintained for all model configurations, including both single-column and three-column configurations with and without pitch angle (see

Section 3). The model was fixed in place by rigidly attaching it to the tow carriage.

3. Model Description

A floating wind system can consist of many different components (e.g., multiple columns with attached heave plates in proximity), which violates the assumptions of simplified approaches for representing the hydrodynamic loads, such as the Morison equation originally developed for a single pile without bracing [

29]. This campaign aims to further investigate the effects of the resulting complex hydrodynamic interactions among the structural components on the modeling of hydrodynamic loads in a more generic sense and to enable validation of various modeling approaches for a variety of floater designs.

The model used in this validation campaign is based on the DeepCwind semisubmersible geometry (

Figure 4 and

Figure 5a) examined in the OC4, OC5, and OC6 projects [

1,

4,

17]. A detailed definition of the geometry of the platform was given by Robertson et al. [

17]. For the present experiment, however, the DeepCwind semisubmersible was further simplified to separate the various components of the structure. Only the large members (the three offset columns with heave plates) were retained; the small cross-members (shown in black in

Figure 4) and the central main column were removed as shown in

Figure 5b. Based on previous investigations, the large members provide the most significant contributions to the loads on the overall system. The same model scaling ratio of 1/50 from the previous projects was used in this campaign. For consistency, all dimensional values in the rest of this paper, unless specified otherwise, are presented at full scale following Froude scaling as detailed by Jain et al. [

30].

The remaining three offset columns all have the same dimensions. The surface piercing upper columns have a diameter of 12 m and a draft of 14 m. The heave plates attached to the bottom of the upper columns all have a diameter of 24 m. Two versions of the heave plates with different heights were included in this experiment. The larger Heave Plate 1 (HP1), which is the geometry of the original DeepCwind heave plate design, has a height of 6 m, while the smaller Heave Plate 2 (HP2) has a height of 2.5 m. The thick heave plates used in the present investigation have the additional benefit of avoiding some of the numerical difficulties associated with solving the corresponding second-order potential-flow problem involving thin (zero-thickness) members [

26].

The three upper columns were independently attached to a rigid top-of-column triangular frame to keep their positions fixed relative to each other and to the basin (see

Figure 5b). As with the original DeepCwind semisubmersible, the three offset columns were placed to form an equilateral triangle with a centerline-to-centerline distance of 50 m between columns. Only one set of upper-column and heave-plate (HP1 and HP2) models has small pressure taps on the surface. The pressure taps were connected to an array of pressure sensors through thin tubes, which allowed the instantaneous pressure at the pressure taps to be measured (see

Section 5.3 for details).

To examine the causes of the underprediction by the modeling tools, individual components of this system were first tested in isolation, and then complexity was built up by adding other components. A full list of the model configurations examined in this campaign is provided in

Table 1, with a visual representation in

Figure 6. By focusing on the components, the dataset supports the validation needs beyond just one specific design.

The simplest configuration tested consisted of just a single upper column with no heave plate placed at the upstream-column (UC) position with the two rear columns removed from the triangular frame (see

Figure 6a—Configuration C). The larger HP1 was then attached to the single upper column to form Configuration D, shown in

Figure 6a. Finally, three upper columns with HP1 arranged as they would for a traditional design, as shown in

Figure 5b, were tested. This three-column arrangement corresponds to configurations P and N in

Figure 6b. These two model configurations are geometrically identical; the only difference is that the upper column/heave plate combination instrumented with pressure sensors was placed at the UC position in Configuration P and at the starboard-column (SC) position in Configuration N (see

Figure 7). Switching the position of the column/heave plate combination with the pressure sensors and repeating the experiments allowed us to gather the pressure information on both the UC and the SC. The pressure on the third column on the portside is assumed to be comparable to that on the SC by symmetry.

Additionally, experiments with the smaller HP2 (configurations E and J/K in

Figure 6) were performed to assess the influence of the heave-plate thickness on the hydrodynamic loads. The model was also rotated by 5 degrees about the pitch axis of the structure (configurations F, G, and Q/R in

Figure 6) to an orientation representative of operational wind conditions. These arrangements are unique to offshore wind and provide relevant validation data to the community. As with configurations P/N, configurations J/K and Q/R are identical to each other except for the position of the column/heave plate combination instrumented with the pressure sensors.

4. Wave Conditions

The primary focus of this validation campaign is the hydrodynamic loading at low frequencies near the surge and pitch natural frequencies of the floating wind semisubmersible at approximately 0.01 and 0.032 Hz, respectively [

4]. These frequencies lie outside the linear wave-frequency region, and the hydrodynamic loading, therefore, originates from the nonlinear interaction among the linear wave components. A realistic, irregular wave spectrum can be considered as the superposition of many wave components at different frequencies. These individual waves combine to create the overall spectrum but also interact with each other to create loading at a frequency that is the difference between those of any two individual wave components.

The wave conditions investigated in this validation campaign are listed in

Table 2. A JONSWAP wave spectrum (J1), which is approximately the same wave spectrum examined in the previous validation campaigns run under the OC4, OC5, and OC6 projects [

1,

4,

17], was used to examine the low/difference-frequency loading. Another wave with the same spectrum but a lower significant wave height was also included (J2) to examine how the difference-frequency loading is affected by wave height.

This dataset is intended not just for the validation of engineering models, but also higher-fidelity CFD simulations. The large computational expense of CFD simulations makes it difficult to run full irregular-wave simulations, which typically take 3 h full scale to resolve the low-frequency hydrodynamic loads of concern. Therefore, an additional set of bichromatic waves was developed to focus on the difference-frequency wave-load components more directly and efficiently. Bichromatic waves are simply the addition of two regular waves, allowing one to directly examine the difference-frequency loads from one pair of waves rather than the many pairs that contribute to it in an irregular wave spectrum. If the frequencies are chosen well, bichromatic waves can be made repeatable over a short time window (see [

31] for more information on the development of these bichromatic-wave cases), and the CFD simulations only need to be run for a few repeat periods (on the order of a few hundred seconds full scale) to capture the difference-frequency loads. Five different bichromatic-wave cases were run in this validation campaign (B1–B5). The B1–B3 wave pairs have a difference frequency near the pitch natural frequency of the semisubmersible, around 0.032 Hz. B3 uses the same wave-pair frequencies as B1 but with a reduced wave height. Waves B4 and B5 are wave pairs that have a difference frequency near the surge natural frequency, at approximately 0.01 Hz.

Finally, three regular-wave cases were also performed, R1–R3. The R1 wave frequency matches the peak frequency of the irregular waves, J1 and J2, and the frequency of one of the wave components of B1, B3, and B4. R2 has the same wave frequency as R1, but a lower wave height. Regular wave R3 has a frequency close to that of the other wave component of B1 and B3.

A preliminary characterization of the nature of the wave loading can be obtained based on the nondimensional wave height,

and the diffraction parameter,

, where

,

, and

are the wave height, wavelength, and characteristic body dimension, respectively [

32]. For the present campaign, it is appropriate to take

as the diameter of the upper columns, 12 m.

and

are straightforwardly defined for the regular waves. For the irregular waves, the significant wave height,

, can be used, and

is taken as that corresponding to the peak wave period. Finally, for the bichromatic waves, a conservative characterization can be obtained by taking

as the sum of the wave heights of the two primary wave components and

from the shorter of the two wave components.

Based on the various wave-loading regimes from [

32] (Figure 4.18 on p. 167), all 10 wave conditions in

Table 2 have

, falling in the regime where the wave loads are dominated by inertial effects with small but nonnegligible contributions from viscous drag. Furthermore, all wave conditions have

and fall in the region of negligible wave-diffraction effects. In the absence of wave radiation (the structure was fixed) and weak wave diffraction, it can be conjectured that the side walls of the basin should have little effect on the measured wave loads. Note that, however, this analysis assumes a single column in isolation. If all three columns were present, the hydrodynamic interactions among the columns could potentially result in a larger characteristic body dimension and push some of the wave conditions with shorter waves, such as B2, to the regime with nonnegligible wave-diffraction effects. If this is the case, the basin wall might influence the wave loads. We therefore suggest that the basin walls be included in, for example, CFD simulations if the intent is to validate the numerical simulation with the present dataset.

6. Test Matrix and Data Availability

A test matrix summarizing the experiments performed is presented in

Table 4. As shown in

Table 4, not every possible wave-model combination was tested, but the three-column configurations that resemble the original DeepCwind design were examined with all wave conditions, both in the upright position (configurations P/N with HP1 and configurations J/K with HP2) and in the pitched position (configurations Q/R with HP1). Furthermore, three repetitions were performed for most of the wave-model combinations to help assess the random uncertainties in the measurements.

All data from this validation campaign is open to the public via DOE’s DAP at:

https://a2e.energy.gov/data/oc6/oc6.phase1b (accessed on 24 September 2021). On this main site is a document that describes the format of the dataset [

6] and a Test Report, which summarizes the campaign in more detail [

5]. The repository contains 229 files covering both the experiments with the model present (listed in

Table 4) and the wave-calibration runs without the structure.

The data files for the experiments with the structure are named using a convention that includes identification of the model configuration, wave condition, and repetition number. An example name is “oc6.phase1b.experiment.configQ.waveB1.repeat2.txt,” which indicates the Q configuration with wave B1, and the second repetition of this test. With Configuration Q, the column/heave plate combination instrumented with the pressure sensors was in the UC position (see

Table 1); therefore, the pressure measurements included in this file are for the UC as well.

The file names for wave calibration also identify the wave condition and the repetition. For example, the wave measurements from the first repetition of the calibration of wave B1 are in “oc6.phase1b.experiment.wavecheck.waveB1.repeat1.txt.” All wave conditions were repeated three times during calibration.

This document as well as the data location should be cited in any publication using the dataset. The column headings included in the data files are summarized in

Table 5. Note that not all data columns are present in every file; only the relevant ones are included.

7. Uncertainty Analysis

To make this data applicable to the validation of modeling tools, a thorough assessment of the uncertainty in the load measurements was performed. No uncertainty analysis was performed for the pressure measurements or wave run-up, as these are characterized as reference measurements for qualitative investigations only.

Uncertainty in the load measurements comes from three main sources: uncertainties in the waves, the physical models, and the sensors themselves. Because only fixed tests were performed in this campaign, the uncertainty in the physical model is primarily related to the sizing and orientation of the structures tested. With a low tolerance for model placement (generally within ±2 mm for draft at model scale or 0.5% of total draft and ±0.15° in orientation [

5]) and sizing (all model dimensions verified to be within ±1 mm of specification [

5]), it was determined that the physical model would have minimal contribution to the load uncertainty. Similarly, the systematic uncertainty in the load cells was deemed to be insignificant compared to the other sources based on the available information on sensor calibration [

5], leaving only random uncertainty. An indication of the level of random uncertainty in the load measurements can be seen in

Figure 18, where three repeat measurements of the waves and surge force are show for the irregular wave J1. The excellent comparison exemplifies the low random uncertainty in the experimental campaign.

Therefore, the primary focus of the uncertainty assessment was on the impact of wave uncertainty on the load measurement. This includes the uncertainties in the wave measurements dictated by the performance and installation of the wave probes, but also the contributions from spurious wave components present in the basin.

Wang et al. [

7] performed a thorough assessment of the wave-load uncertainty for the bichromatic-wave cases. The uncertainty level was calculated separately for each bichromatic-wave case for the three-column configurations P/N and for the load magnitudes in surge and pitch at the two primary wave frequencies as well as at the difference frequency, which is the focus of the validation study. At the two primary wave frequencies of the bichromatic waves, the possible presence of small, reflected waves from the downstream elliptical beach simultaneously affected the measurements of the waves and the wave loads. At the difference frequency, small, spurious free waves might also have been present because of imperfect wave generation caused by the mismatch between the wavemaker paddle motion and the exact wave-field velocity of nonlinear bichromatic waves [

33]. The free waves, while small, can lead to nonnegligible contamination of the equally small difference-frequency nonlinear wave loads, an issue first identified in the CFD analysis of OC6 Phase Ib on bichromatic waves [

38,

39]. The errors from these spurious wave components that might have been present in the basin were estimated from a wave-splitting analysis based on the wave measurements taken at multiple locations along the length of the basin during wave calibration, and corresponding uncertainties in the final normalized wave loads were developed. Note that the errors and uncertainties caused by the reflection of the model diffracted waves coming from the side basin walls and the wavemaker were not included in the uncertainty analysis for CFD validation. This is because the exact width of the basin and the distance from the structure to the wavemaker were replicated in the CFD simulations [

7].

The uncertainty levels in the combined wave loads on all three columns (see Table 7 in [

7]) are low for some cases and higher for others, ranging from 5% to 25%. Higher uncertainties in the wave loads (around 20%) were found for bichromatic waves B2 and B5, which involves wave components with periods close to 9.6 s and 7.4 s full scale. Interestingly, higher systematic uncertainties in the wave measurements were also found for these wave components, which might be related to the increased spatial variability of the wave field in the basin. The higher uncertainties in the incident waves contribute to the final uncertainties in the normalized wave loads. The increased uncertainties for these wave components might be related to the wavelengths and the specific dimensions of the basin; however, the exact cause has not been determined definitively. The uncertainty in the normalized wave loads with bichromatic waves B1, B3, and B4 is generally around 10%, except for the difference-frequency surge force for wave B4, which has a higher uncertainty of 20%, partly because of the smallness of the difference-frequency loads in this case. Based on the estimated level of experimental uncertainty, the overall quality of the experimental results is deemed adequate for meaningful validation of numerical predictions.

8. Discussion and Conclusions

This paper summarizes a new validation campaign conducted under the OC6 Phase Ib project, focused on the nonlinear hydrodynamic loading on the components of a generic floating wind semisubmersible platform in a fixed condition. As first identified in the OC5 project, industry tools used to model the behavior of floating semisubmersibles underpredict the loading of these designs, especially at the low frequencies where difference-frequency, nonlinear hydrodynamic loading dominates. The OC6 Phase I project seeks to better understand the cause of this underprediction. In Phase Ia of the project, two experimental campaigns were run to examine whether uncertainty in the experiment contributed significantly to this underprediction, and then to break apart the loading components. Validation work using these experiments was able to identify sources of load underprediction but did not provide the detailed measurements needed to understand the physical phenomena driving the underprediction.

This new OC6 Phase Ib campaign builds on the previous validation campaigns of the OC5 and OC6 projects (see [

1,

4]) in an effort to better understand the physics of the low-frequency load underprediction. The focus is a fixed condition under wave loading examining the wave excitation, which was found to be the source of the largest discrepancies in load predictions in OC6 Phase Ia [

4]. Components of the DeepCwind semisubmersible geometry were used with similar regular and irregular wave conditions, so that measurements from this campaign can be directly compared to past work in the previous projects. Tests were run across a variety of model configurations, building up complexity from simple cylinders to cylinders with heave plates, and then with multiple cylinders with heave plates in proximity. Wave cases were also run with increasing complexity from simple regular-wave cases to bichromatic waves, and finally to irregular wave conditions, with the regular waves matching the peak frequency of the irregular waves and the two main frequencies of the bichromatic waves.

The unique characteristics of this campaign are intended to provide the additional information needed to interrogate the low-frequency behavior of floating semisubmersibles. First, components of the DeepCwind semisubmersible were tested in isolation, and then combined with other members. This approach provides the measurements needed to understand how attached and adjacent members in the semisubmersible affect the loading behavior. Because many engineering models do not directly capture this influence, it is important to understand the impact and the need to address it in the modeling approach. In addition, the semisubmersible design was tested at a neutral position, as well as one offset in the pitch direction, to represent operational wind conditions. These measurements will help elucidate how the wave loading changes as the floating wind platform changes in orientation relative to the waves and improve the ability of models to capture this change.

Previous experiments focused only on the global hydrodynamic loading integrated across the entire structure, which limited more detailed investigations. In this new campaign, load measurements were made for each individual column along with distributed pressure measurements across the heave plate and near the waterline. Additionally, the wave run-up was recorded using a nearby wave probe, and video was taken to capture the behavior as well. These detailed measurements are most valuable for validating CFD models but can also be used to understand how to better tune engineering models. A validated CFD model may then, in turn, be used to perform further investigation into where the engineering models lack accuracy.

Finally, this new experimental campaign employs bichromatic waves in addition to the regular and irregular waves examined in previous projects. Bichromatic waves provide a means for a direct validation of the quadratic transfer functions, which are the main source of the low-frequency loading in the engineering models. They can also be performed over a shorter time frame and can be made repeatable, which makes CFD validation of the low-frequency loading much more feasible. The large computational time for CFD simulations makes irregular wave simulations difficult, especially when trying to ensure a converged solution. Additionally, trying to replicate an irregular wave field in CFD to enable direct validation is much more difficult than a bichromatic wave, which can be more precisely defined.

The end goal is to have this dataset provide the additional information needed to identify and address the inaccuracies in load predictions of floating semisubmersibles. Investigations using this dataset have already been conducted to validate CFD tools within the OC6 project [

7] and to improve the OpenFAST engineering modeling tool [

34]. The open access on the DOE DAP (

https://a2e.energy.gov/data/oc6/oc6.phase1b; accessed on 24 September 2021) will allow other research groups to perform their own investigations with the present dataset. The methodical identification of sources of inaccuracy in high-fidelity CFD tools and mid-fidelity engineering models, enabled by this new dataset, will engender future improvements to the offshore wind design tools. These improvements, in turn, will enable further optimization of floating wind designs, helping to reduce the risk and lower the cost of offshore wind energy.