Energy and Economic Investigation of a Biodiesel-Fired Engine for Micro-Scale Cogeneration

Abstract

:1. Introduction

2. Materials and Methods

2.1. System Description

2.2. Prime Mover

2.3. Mathematical Model of the CHP System

2.3.1. General Equations

2.3.2. Ignition Delay

2.3.3. Combustion and Heat Transfer Rate Model

2.3.4. CHP Performance

2.3.5. Emissions Model

2.3.6. Economic Analysis

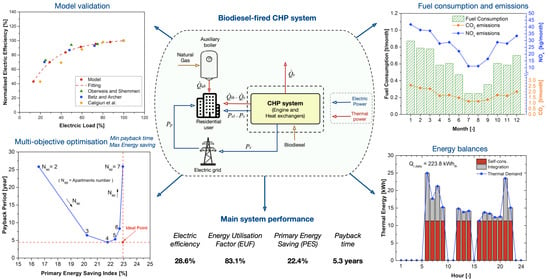

3. Results and Discussion

3.1. Model Validation

3.2. CHP Performance Characterisation

3.3. Case Study: A Domestic Application

3.4. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Area (m2) |

| a | Coefficient (-) |

| B | Bore (m) |

| b | Coefficient (-) |

| bmep | Brake mean effective pressure (bar) |

| Cd | Injector discharge coefficient (-) |

| d | Diameter (mm) |

| E | Electric energy (kWh) |

| Ea | Activation energy (J/mol) |

| fmep | Friction mean effective pressure (bar) |

| Hi | Lower heating value (J/kg) |

| h | Heat transfer coefficient (W/m2 K) |

| k | Thermal conductivity (W/m K) |

| Normalised load factor (%) | |

| m | Mass (kg) |

| Mass flow rate (kg/s) | |

| N | Engine speed (rpm) |

| Nap | Apartments number (-) |

| Nh | Number of injector orifices (-) |

| P | Power (W) |

| p | Pressure (Pa or bar) |

| Q | Thermal energy (kWh) |

| Thermal power (W) | |

| R | Universal gas constant (J/mol K) |

| Re | Reynolds number (-) |

| Sfc | Specific fuel consumption (g/kWh) |

| Normalised fuel consumption (%) | |

| Sp | Mean piston speed (m/s) |

| T | Temperature (K) |

| t | Time (s) |

| U | Internal energy (J) |

| V | Volume (m3) |

| Vd | Displacement (cm3) |

| Greek Characters | |

| α | Wiebe coefficient (-) |

| β | Fuel burned fraction (-) |

| Δ | Difference (-) |

| ϕ | NOx re-entrainment coefficient (-) |

| γ | Specific heat ratio (-) |

| η | Efficiency (-) |

| Normalised efficiency (%) | |

| ρ | Density (kg/m3) |

| σ | Wiebe shape factor (-) |

| τ | Ignition delay (s) |

| υ | Kinematic viscosity (m2/s) |

| Subscripts and Superscripts | |

| ab | Auxiliary boiler |

| ad | Adiabatic |

| b | Brake |

| cool | Cooling system |

| e | Effective |

| el | Electric |

| em | Electro-mechanical |

| exh | Exhaust |

| f | Fuel |

| fr | Friction |

| full | Electric full load |

| h | Generic hour |

| he | Heat exchanger |

| i | Generic configuration |

| in | Indicated |

| inj | Injected |

| max | Maximum |

| min | Minimum |

| misc | Miscellaneous |

| ng | Natural gas |

| oil | Oil |

| p | Purchased |

| r | Request |

| ref | Reference |

| s | Surplus |

| st | Start |

| th | Thermal |

| w | Wall |

| Acronyms | |

| ATDC | After top dead centre |

| CA | Crank angle |

| BSFC | Brake specific fuel consumption |

| BTDC | Before top dead centre |

| BTE | Brake thermal efficiency |

| CHP | Combined heat and power |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| CN | Cetane number |

| EOC | End of combustion |

| EUF | Energy utilisation factor |

| GHG | Greenhouse gas |

| HC | Hydrocarbon |

| HRR | Heat release rate |

| ICE | Internal combustion engine |

| ID | Ignition delay |

| NOx | Nitrogen oxides |

| NPV | Net present value |

| PBT | Payback time |

| PES | Primary energy saving |

| SOC | Start of combustion |

| TDC | Top dead centre |

References

- Kryzia, D.; Kuta, M.; Matuszewska, D.; Olczak, P. Analysis of the Potential for Gas Micro-Cogeneration Development in Poland Using the Monte Carlo Method. Energies 2020, 13, 3140. [Google Scholar] [CrossRef]

- Rosato, A.; Ciervo, A.; Ciampi, G.; Scorpio, M.; Sibilio, S. Integration of Micro-Cogeneration Units and Electric Storages into a Micro-Scale Residential Solar District Heating System Operating with a Seasonal Thermal Storage. Energies 2020, 13, 5456. [Google Scholar] [CrossRef]

- Amber, K.; Day, T.; Ratyal, N.; Kiani, A.; Ahmad, R. Techno, Economic and Environmental Assessment of a Combined Heat and Power (CHP) System—A Case Study for a University Campus. Energies 2018, 11, 1133. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Si, Y.; Liu, C.; Chen, L.; Xue, X.; Guo, Y.; Mei, S. The Value and Optimal Sizes of Energy Storage Units in Solar-Assist Cogeneration Energy Hubs. Appl. Sci. 2020, 10, 4994. [Google Scholar] [CrossRef]

- Li, D.; Xu, X.; Yu, D.; Dong, M.; Liu, H. Rule Based Coordinated Control of Domestic Combined Micro-CHP and Energy Storage System for Optimal Daily Cost. Appl. Sci. 2017, 8, 8. [Google Scholar] [CrossRef] [Green Version]

- Amelio, M.; Morrone, P. Residential cogeneration and trigeneration. In Current Trends and Future Developments on (Bio-) Membranes; Elsevier: Amsterdam, The Netherlands, 2020; pp. 141–175. ISBN 978-0-12-817807-2. [Google Scholar]

- Algieri, A.; Andiloro, S.; Tamburino, V.; Zema, D.A. The Potential of Agricultural Residues for Energy Production in Calabria (Southern Italy). Renew. Sustain. Energy Rev. 2019, 104, 1–14. [Google Scholar] [CrossRef]

- Martinez, S.; Michaux, G.; Salagnac, P.; Bouvier, J.-L. Micro-Combined Heat and Power Systems (Micro-CHP) Based on Renewable Energy Sources. Energy Convers. Manag. 2017, 154, 262–285. [Google Scholar] [CrossRef]

- Kalantzis, N.; Pezouvanis, A.; Ebrahimi, K.M. Internal Combustion Engine Model for Combined Heat and Power (CHP) Systems Design. Energies 2017, 10, 1948. [Google Scholar] [CrossRef] [Green Version]

- Cheekatamarla, P.; Abu-Heiba, A. A Comprehensive Review and Qualitative Analysis of Micro-Combined Heat and Power Modeling Approaches. Energies 2020, 13, 3581. [Google Scholar] [CrossRef]

- Mikalsen, R. Internal combustion and reciprocating engine systems for small and micro combined heat and power (CHP) applications. In Small and Micro Combined Heat and Power (CHP) Systems; Elsevier: Amsterdam, The Netherlands, 2011; pp. 125–146. ISBN 978-1-84569-795-2. [Google Scholar]

- Rodríguez-Fernández, J.; Hernández, J.J.; Calle-Asensio, A.; Ramos, Á; Barba, J. Selection of Blends of Diesel Fuel and Advanced Biofuels Based on Their Physical and Thermochemical Properties. Energies 2019, 12, 2034. [Google Scholar] [CrossRef] [Green Version]

- Algieri, B. The Influence of Biofuels, Economic and Financial Factors on Daily Returns of Commodity Futures Prices. Energy Policy 2014, 69, 227–247. [Google Scholar] [CrossRef] [Green Version]

- Agarwal, A.K. Biofuels (Alcohols and Biodiesel) Applications as Fuels for Internal Combustion Engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Capuano, D.; Costa, M.; Di Fraia, S.; Massarotti, N.; Vanoli, L. Direct Use of Waste Vegetable Oil in Internal Combustion Engines. Renew. Sustain. Energy Rev. 2017, 69, 759–770. [Google Scholar] [CrossRef]

- Basha, S.A.; Gopal, K.R.; Jebaraj, S. A Review on Biodiesel Production, Combustion, Emissions and Performance. Renew. Sustain. Energy Rev. 2009, 13, 1628–1634. [Google Scholar] [CrossRef]

- Raman, L.A.; Deepanraj, B.; Rajakumar, S.; Sivasubramanian, V. Experimental Investigation on Performance, Combustion and Emission Analysis of a Direct Injection Diesel Engine Fuelled with Rapeseed Oil Biodiesel. Fuel 2019, 246, 69–74. [Google Scholar] [CrossRef]

- Saravanan, S.; Nagarajan, G.; Lakshmi Narayana Rao, G.; Sampath, S. Combustion Characteristics of a Stationary Diesel Engine Fuelled with a Blend of Crude Rice Bran Oil Methyl Ester and Diesel. Energy 2010, 35, 94–100. [Google Scholar] [CrossRef]

- Raheman, H.; Ghadge, S.V. Performance of Diesel Engine with Biodiesel at Varying Compression Ratio and Ignition Timing. Fuel 2008, 87, 2659–2666. [Google Scholar] [CrossRef]

- Ge, J.C.; Choi, N.J. Soot Particle Size Distribution, Regulated and Unregulated Emissions of a Diesel Engine Fueled with Palm Oil Biodiesel Blends. Energies 2020, 13, 5736. [Google Scholar] [CrossRef]

- Karami, R.; Rasul, M.G.; Khan, M.M.K. CFD Simulation and a Pragmatic Analysis of Performance and Emissions of Tomato Seed Biodiesel Blends in a 4-Cylinder Diesel Engine. Energies 2020, 13, 3688. [Google Scholar] [CrossRef]

- Paredes Rojas, J.C.; Torres San Miguel, C.R.; Vázquez Medina, R.; Leal Naranjo, J.A.; Ortiz Hernàndez, F.E.; Costa Castelló, R. Pollutant Emissions and Combustion Efficiency Assessment of Engines Using Biodiesel. Appl. Sci. 2020, 10, 8646. [Google Scholar] [CrossRef]

- Scopus Document Search. Available online: https://www.scopus.com (accessed on 16 October 2020).

- McCarthy, P.; Rasul, M.G.; Moazzem, S. Analysis and Comparison of Performance and Emissions of an Internal Combustion Engine Fuelled with Petroleum Diesel and Different Bio-Diesels. Fuel 2011, 90, 2147–2157. [Google Scholar] [CrossRef]

- Lahane, S.; Subramanian, K.A. Effect of Different Percentages of Biodiesel–Diesel Blends on Injection, Spray, Combustion, Performance, and Emission Characteristics of a Diesel Engine. Fuel 2015, 139, 537–545. [Google Scholar] [CrossRef]

- Özener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of Soybean Biodiesel on a DI Diesel Engine Performance, Emission and Combustion Characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Ndayishimiye, P.; Tazerout, M. Use of Palm Oil-Based Biofuel in the Internal Combustion Engines: Performance and Emissions Characteristics. Energy 2011, 36, 1790–1796. [Google Scholar] [CrossRef]

- Rosa, H.A.; Wazilewski, W.T.; Secco, D.; Chaves, L.I.; Veloso, G.; de Souza, S.N.M.; da Silva, M.J.; Santos, R.F. Biodiesel Produced from Crambe Oil in Brazil—A Study of Performance and Emissions in a Diesel Cycle Engine Generator. Renew. Sustain. Energy Rev. 2014, 38, 651–655. [Google Scholar] [CrossRef]

- Öztürk, E. Performance, Emissions, Combustion and Injection Characteristics of a Diesel Engine Fuelled with Canola Oil–Hazelnut Soapstock Biodiesel Mixture. Fuel Process. Technol. 2015, 129, 183–191. [Google Scholar] [CrossRef]

- Khatri, K.K.; Sharma, D.; Soni, S.L.; Tanwar, D. Experimental Investigation of CI Engine Operated Micro-Trigeneration System. Appl. Therm. Eng. 2010, 30, 1505–1509. [Google Scholar] [CrossRef]

- Oberweis, S.; Al-Shemmeri, T.T. Effect of Biodiesel Blending on Emissions and Efficiency in a Stationary Diesel Engine. REPQJ 2010, 1, 304–310. [Google Scholar] [CrossRef]

- Caligiuri, C.; Renzi, M.; Bietresato, M.; Baratieri, M. Experimental Investigation on the Effects of Bioethanol Addition in Diesel-Biodiesel Blends on Emissions and Performances of a Micro-Cogeneration System. Energy Convers. Manag. 2019, 185, 55–65. [Google Scholar] [CrossRef]

- Magno, A.; Mancaruso, E.; Vaglieco, B.M. Effects of a Biodiesel Blend on Energy Distribution and Exhaust Emissions of a Small CI Engine. Energy Convers. Manag. 2015, 96, 72–80. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Singh, T.S.; Verma, T.N. Numerical Investigation of Performance, Combustion and Emission Characteristics of Various Biofuels. Energy Convers. Manag. 2018, 156, 235–252. [Google Scholar] [CrossRef]

- Prabhakaran, P.; Saravanan, C.G.; Vallinayagam, R.; Vikneswaran, M.; Muthukumaran, N.; Ashok, K. Investigation of Swirl Induced Piston on the Engine Characteristics of a Biodiesel Fueled Diesel Engine. Fuel 2020, 279, 118503. [Google Scholar] [CrossRef]

- Hassan, N.M.S.; Rasul, M.G.; Harch, C.A. Modelling and Experimental Investigation of Engine Performance and Emissions Fuelled with Biodiesel Produced from Australian Beauty Leaf Tree. Fuel 2015, 150, 625–635. [Google Scholar] [CrossRef]

- Karami, R.; Rasul, M.G.; Khan, M.M.K.; Mahdi Salahi, M.; Anwar, M. Experimental and Computational Analysis of Combustion Characteristics of a Diesel Engine Fueled with Diesel-Tomato Seed Oil Biodiesel Blends. Fuel 2021, 285, 119243. [Google Scholar] [CrossRef]

- Cho, S.; Park, J.; Song, C.; Oh, S.; Lee, S.; Kim, M.; Min, K. Prediction Modeling and Analysis of Knocking Combustion Using an Improved 0D RGF Model and Supervised Deep Learning. Energies 2019, 12, 844. [Google Scholar] [CrossRef] [Green Version]

- Torres-Jimenez, E.; Dorado, R.; Kegl, B.; Kegl, M. One-Dimensional Modeling and Simulation of Injection Processes of Bioethanol-Biodiesel and Bioethanol-Diesel Fuel Blends. Fuel 2018, 227, 334–344. [Google Scholar] [CrossRef]

- Algieri, A.; Bova, S.; De Bartolo, C.; Nigro, A. Numerical and Experimental Analysis of the Intake Flow in a High Performance Four-Stroke Motorcycle Engine: Influence of the Two-Equation Turbulence Models. J. Eng. Gas. Turbines Power 2007, 129, 1095–1105. [Google Scholar] [CrossRef]

- Gombosuren, N.; Yoshifumi, O.; Hiroyuki, A. A Charge Possibility of an Unfueled Prechamber and Its Fluctuating Phenomenon for the Spark Ignited Engine. Energies 2020, 13, 303. [Google Scholar] [CrossRef] [Green Version]

- Nigro, A.; Algieri, A.; De Bartolo, C.; Bova, S. Fluid Dynamic Investigation of Innovative Intake Strategies for Multivalve Internal Combustion Engines. Int. J. Mech. Sci. 2017, 123, 297–310. [Google Scholar] [CrossRef]

- Ngayihi Abbe, C.V.; Nzengwa, R.; Danwe, R.; Ayissi, Z.M.; Obonou, M. A Study on the 0D Phenomenological Model for Diesel Engine Simulation: Application to Combustion of Neem Methyl Esther Biodiesel. Energy Convers. Manag. 2015, 89, 568–576. [Google Scholar] [CrossRef]

- Gogoi, T.K.; Baruah, D.C. A Cycle Simulation Model for Predicting the Performance of a Diesel Engine Fuelled by Diesel and Biodiesel Blends. Energy 2010, 35, 1317–1323. [Google Scholar] [CrossRef]

- Guardiola, C.; López, J.J.; Martín, J.; García-Sarmiento, D. Semiempirical In-Cylinder Pressure Based Model for NOX Prediction Oriented to Control Applications. Appl. Therm. Eng. 2011, S1359431111003164. [Google Scholar] [CrossRef]

- Ispra. National Inventory Report 2020 - Italian Greenhouse Gas Inventory 1990–2018. Available online: http://www.sinanet.isprambiente.it/it/sia-ispra (accessed on 16 October 2020).

- Ispra. Fattori Di Emissione Atmosferica Di Gas a Effetto Serra Nel Settore Elettrico Nazionale e Nei Principali Paesi Europei. Edizione 2020. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/fattori-di-emissione-atmosferica-di-gas-a-effetto-serra-nel-settore-elettrico-nazionale-e-nei-principali-paesi-europei.-edizione-2020 (accessed on 16 October 2020).

- Qi, D.H.; Chen, H.; Geng, L.M.; Bian, Y.Z. Experimental Studies on the Combustion Characteristics and Performance of a Direct Injection Engine Fueled with Biodiesel/Diesel Blends. Energy Convers. Manag. 2010, 51, 2985–2992. [Google Scholar] [CrossRef]

- Liu, J.; Dumitrescu, C.E. Single and Double Wiebe Function Combustion Model for a Heavy-Duty Diesel Engine Retrofitted to Natural-Gas Spark-Ignition. Appl. Energy 2019, 248, 95–103. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018; ISBN 978-1-260-11610-6. [Google Scholar]

- Klein, M. A Specific Heat Ratio Model and Compression Ratio Estimation; Division of Vehicular Systems, Department of Electrical Engineering, Linköping University: Linköping, Sweden, 2004. [Google Scholar]

- Hardenberg, H.O.; Hase, F.W. An Empirical Formula for Computing the Pressure Rise Delay of a Fuel from Its Cetane Number and from the Relevant Parameters of Direct-Injection Diesel Engines. SAE Trans. 1979, 88, 1823–1834. Available online: www.jstor.org/stable/44658184 (accessed on 10 October 2020).

- Gumus, M. A Comprehensive Experimental Investigation of Combustion and Heat Release Characteristics of a Biodiesel (Hazelnut Kernel Oil Methyl Ester) Fueled Direct Injection Compression Ignition Engine. Fuel 2010, 89, 2802–2814. [Google Scholar] [CrossRef]

- Awad, S.; Varuvel, E.G.; Loubar, K.; Tazerout, M. Single Zone Combustion Modeling of Biodiesel from Wastes in Diesel Engine. Fuel 2013, 106, 558–568. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Giakoumis, E.G.; Kyritsis, D.C. Validation and Sensitivity Analysis of a Two Zone Diesel Engine Model for Combustion and Emissions Prediction. Energy Convers. Manag. 2004, 45, 1471–1495. [Google Scholar] [CrossRef]

- Annand, W.J.D. Heat Transfer in the Cylinders of Reciprocating Internal Combustion Engines. Proc. Inst. Mech. Eng. 1963, 177, 973–996. [Google Scholar] [CrossRef]

- Kaplan, J. Modeling the Spark-Ignition Engine Warm-Up Process to Predict Component Temperatures; Department of Mechanical Engineering, Massachusetts Institute of Technology: Cambridge, MA, USA, 1990. [Google Scholar]

- Wu, J.Y.; Wang, J.L.; Li, S.; Wang, R.Z. Experimental and Simulative Investigation of a Micro-CCHP (Micro Combined Cooling, Heating and Power) System with Thermal Management Controller. Energy 2014, 68, 444–453. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P. Energetic Analysis of Biomass-Fired ORC Systems for Micro-Scale Combined Heat and Power (CHP) Generation. A Possible Application to the Italian Residential Sector. Appl. Therm. Eng. 2014, 71, 751–759. [Google Scholar] [CrossRef]

- European Commission Commission Delegated Regulation (EU) 2015/2402 of 12 October 2015 Reviewing Harmonised Efficiency Reference Values for Separate Production of Electricity and Heat in Application of Directive 2012/27/EU of the European Parliament and of the Council and Repealing Commission Implementing Decision 2011/877/EU. Available online: https://eur-lex.europa.eu/eli/reg_del/2015/2402/oj (accessed on 15 November 2020).

- Algieri, A.; Morrone, P.; Bova, S. Techno-Economic Analysis of Biofuel, Solar and Wind Multi-Source Small-Scale CHP Systems. Energies 2020, 13, 3002. [Google Scholar] [CrossRef]

- Morrone, P.; Algieri, A.; Castiglione, T. Hybridisation of Biomass and Concentrated Solar Power Systems in Transcritical Organic Rankine Cycles: A Micro Combined Heat and Power Application. Energy Convers. Manag. 2019, 180, 757–768. [Google Scholar] [CrossRef]

- The Oxidation of Nitrogen in Combustion and Explosions. In Selected Works of Yakov Borisovich Zeldovich; Barenblatt, G.I.; Sunyaev, R.A. (Eds.) Princeton University Press: Princeton, NJ, USA, 1992; Volume 1, pp. 364–403. ISBN 978-1-4008-6297-9. [Google Scholar]

- Tauzia, X.; Maiboom, A.; Karaky, H. Semi-Physical Models to Assess the Influence of CI Engine Calibration Parameters on NOx and Soot Emissions. Appl. Energy 2017, 208, 1505–1518. [Google Scholar] [CrossRef]

- Saravanan, S.; Nagarajan, G.; Anand, S.; Sampath, S. Correlation for Thermal NOx Formation in Compression Ignition (CI) Engine Fuelled with Diesel and Biodiesel. Energy 2012, 42, 401–410. [Google Scholar] [CrossRef]

- Karaky, H.; Mauviot, G.; Tauzia, X.; Maiboom, A. Development and Validation of a New Zero-Dimensional Semi-Physical NOx Emission Model for a D.I. Diesel Engine Using Simulated Combustion Process. SAE Int. J. Engines 2015, 8, 1924–1937. [Google Scholar] [CrossRef]

- Vellaisamy, R.; Clark, N.; Thompson, G.J.; Atkinson, R.J.; Tissera, C.A.; Swartz, M.M. Assessment of NOx Destruction in Diesel Engines by Injecting NO in the Intake Manifold. Proceedings of SAE 2005 World Congress & Exhibition, Detroit, MI, USA, 11–14 April 2005. SAE Technical Paper 2005-01-0370. [Google Scholar] [CrossRef]

- Riley, D.M.; Tian, J.; Güngör-Demirci, G.; Phelan, P.; Villalobos, J.R.; Milcarek, R.J. Techno-Economic Assessment of CHP Systems in Wastewater Treatment Plants. Environments 2020, 7, 74. [Google Scholar] [CrossRef]

- Hodge, B.K. Alternative Energy Systems and Applications, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2017; ISBN 978-1-119-10921-1. [Google Scholar]

- Neste Market Data. Available online: https://www.neste.com/investors/market-data (accessed on 1 October 2020).

- European Parliament and Council Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC Text with EEA Relevance. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32012L0027&from=EN (accessed on 15 November 2020).

- European Parliament and Council Directive (EU) 2019/944 of the European Parliament and of the Council of 5 June 2019 on Common Rules for the Internal Market for Electricity and Amending Directive 2012/27/EU. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019L0944&from=EN (accessed on 15 November 2020).

- GSE Dispacciamento Rinnovabili. Available online: https://www.gse.it/servizi-per-te/mercati-energetici/dispacciamento-rinnovabili (accessed on 15 November 2020).

- Simpson, M.C.; Chatzopoulou, M.A.; Oyewunmi, O.A.; Le Brun, N.; Sapin, P.; Markides, C.N. Technoeconomic Analysis of Internal Combustion Engine—Organic Rankine Cycle Systems for Combined Heat and Power in Energy-Intensive Buildings. Appl. Energy 2019, 253, 113462. [Google Scholar] [CrossRef]

- Elsner, W.; Wysocki, M.; Niegodajew, P.; Borecki, R. Experimental and Economic Study of Small-Scale CHP Installation Equipped with Downdraft Gasifier and Internal Combustion Engine. Appl. Energy 2017, 202, 213–227. [Google Scholar] [CrossRef]

- Sorknæs, P.; Østergaard, P.A.; Thellufsen, J.Z.; Lund, H.; Nielsen, S.; Djørup, S.; Sperling, K. The Benefits of 4th Generation District Heating in a 100% Renewable Energy System. Energy 2020, 213, 119030. [Google Scholar] [CrossRef]

- Gustafsson, M.S.; Myhren, J.A.; Dotzauer, E.; Gustafsson, M. Life Cycle Cost of Building Energy Renovation Measures, Considering Future Energy Production Scenarios. Energies 2019, 12, 2719. [Google Scholar] [CrossRef] [Green Version]

- Anca-Couce, A.; Hochenauer, C.; Scharler, R. Bioenergy Technologies, Uses, Market and Future Trends with Austria as a Case Study. Renew. Sustain. Energy Rev. 2021, 135, 110237. [Google Scholar] [CrossRef]

- Lyócsa, Š.; Todorova, N.; Výrost, T. Predicting Risk in Energy Markets: Low-Frequency Data Still Matter. Appl. Energy 2021, 282, 116146. [Google Scholar] [CrossRef]

- Algieri, B.; Leccadito, A. Ask CARL: Forecasting Tail Probabilities for Energy Commodities. Energy Econ. 2019, 84, 104497. [Google Scholar] [CrossRef]

- Saravanan, S.; Nagarajan, G.; Narayana Rao, G.L. Feasibility Analysis of Crude Rice Bran Oil Methyl Ester Blend as a Stationary and Automotive Diesel Engine Fuel. Energy Sustain. Dev. 2009, 13, 52–55. [Google Scholar] [CrossRef]

- Cogengreen EcoGEN CHP Units. Available online: www.cogengreen.com (accessed on 10 November 2020).

- Senertec Dachs. Smart Cogeneration. Available online: www.senertec.com (accessed on 10 November 2020).

- Betz, F.; Archer, D. Biodiesel fueled engine generator with heat recovery: Comparing biodiesel to diesel performance. In Proceedings of the ASME 2009 3rd International Conference on Energy Sustainability, San Francisco, CA, USA, 19–23 July 2009; ASMEDC: San Francisco, CA, USA, 2009; Volume 2, pp. 103–108. [Google Scholar]

- Mongibello, L.; Bianco, N.; Caliano, M.; Graditi, G. Influence of Heat Dumping on the Operation of Residential Micro-CHP Systems. Appl. Energy 2015, 160, 206–220. [Google Scholar] [CrossRef]

- Sasso, M.; Roselli, C.; Sibilio, S.; Possidente, R.; Beausoleil-Morrison, I.; Dorer, V. Performance Assessment of Residential Cogeneration Systems in Southern Italy: A Report of Subtask C of FC+COGEN-SIM The Simulation of Building-Integrated Fuel Cell and Other Cogeneration Systems: Annex 42 of the International Energy Agency Energy Conservation in Buildings and Community Systems Programme; Her Majesty the Queen in Right of Canada: Ottawa, ON, Canada, 2008; ISBN 978-0-662-48049-5. [Google Scholar]

- Dinçer, İ.; Rosen, M.; Ahmadi, P. Optimization of Energy Systems; John Wiley & Sons: Chichester, West Sussex, UK, 2018; ISBN 978-1-118-89450-7. [Google Scholar]

- Algieri, A.; Zema, D.A.; Nicotra, A.; Zimbone, S.M. Potential Energy Exploitation in Collective Irrigation Systems Using Pumps as Turbines: A Case Study in Calabria (Southern Italy). J. Clean. Prod. 2020, 257, 120538. [Google Scholar] [CrossRef]

- Morrone, P.; Algieri, A. Integrated Geothermal Energy Systems for Small-Scale Combined Heat and Power Production: Energy and Economic Investigation. Appl. Sci. 2020, 10, 6639. [Google Scholar] [CrossRef]

- Rezaeiha, A.; Montazeri, H.; Blocken, B. A Framework for Preliminary Large-Scale Urban Wind Energy Potential Assessment: Roof-Mounted Wind Turbines. Energy Convers. Manag. 2020, 214, 112770. [Google Scholar] [CrossRef]

| Engine Design | Single Cylinder |

|---|---|

| Operating cycle | Four stroke |

| Ignition | Compression |

| Injection | Direct |

| Cooling | Liquid |

| Bore, B | 105 mm |

| Stroke, L | 115 mm |

| Connecting rod, l | 185 mm |

| Compression ratio, rc | 16.5 |

| Displacement, Vd | 996 cm3 |

| Brake rated power, Pd | 11.0 kW |

| Rated engine speed, Nd | 2000 rpm |

| Parameters | Units | Values |

|---|---|---|

| Reference electric efficiency, ηel,ref | (%) | 44.2 |

| Reference thermal efficiency, ηth,ref | (%) | 85.0 |

| Electro-mechanical efficiency, ηem | (%) | 90.0 |

| Heat exchanger efficiency, ηhe | (%) | 95.0 |

| Biodiesel lower heating value, Hi | (MJ/kg) | 38.8 |

| Biodiesel density, ρf | (kg/m3) | 870 |

| Biodiesel kinematic viscosity at 20 °C, υf | (mm2/s) | 7.8 |

| Biodiesel injection pressure, pf | (bar) | 180 |

| Injector discharge coefficient, CD | (-) | 0.39 |

| Injector orifice number, Nh | (-) | 4 |

| Injector orifice diameter, dinj | (mm) | 0.32 |

| Wiebe constant, α | (-) | 6.9 |

| Parameters | Units | Values |

|---|---|---|

| Interest rate | (%) | 3 |

| Investment period | (years) | 20 |

| Reference cost of electricity withdrawn from the grid | (c€/kWhel) | 20 |

| Reference cost of thermal energy | (c€/kWhth) | 10 |

| Reference revenue of electricity injected into the grid | (c€/kWhel) | 10 |

| Reference cost of biodiesel | (c€/l) | 70 |

| Reference cost of micro-CHP unit | (€/kWel) | 1260 |

| Cost of electricity withdrawn from the grid | (c€/kWhel) | 17–23 |

| Cost of thermal energy | (c€/kWhth) | 7–13 |

| Cost of biodiesel | (c€/l) | 50–80 |

| Cost of micro-CHP unit | (€/kWel) | 1000–2000 |

| Maintenance cost/Investment cost | (%) | 1.2 |

| Parameters | Units | Values |

|---|---|---|

| Electric production | (MWhel/year) | 21.1 |

| Electric self-consumption | (MWhel/year) | 6.8 |

| Electric self-consumption/Electric load | (%) | 50.5 |

| Electric surplus | (MWhel/year) | 14.2 |

| Electric surplus/Electric production | (%) | 67.6 |

| Electric integration | (MWhel/year) | 6.7 |

| Electric integration/Electric load | (%) | 49.5 |

| Thermal production | (MWhth/year) | 40.2 |

| Thermal self-consumption | (MWhth/year) | 37.3 |

| Thermal self-consumption/Thermal load | (%) | 81.3 |

| Thermal surplus | (MWhth/year) | 3.0 |

| Thermal surplus/Thermal production | (%) | 7.4 |

| Thermal integration | (MWhth/year) | 8.6 |

| Thermal integration/Thermal load | (%) | 18.7 |

| Global electric efficiency | (%) | 28.6 |

| Global thermal efficiency | (%) | 54.5 |

| Primary energy saving index | (%) | 22.4 |

| Energy utilization factor | (%) | 83.1 |

| Biodiesel consumption | (t/year) | 6.84 |

| Natural gas consumption | (m3/year) | 958.6 |

| CO2 emissions | (t/year) | 21.0 |

| NOx emissions | (kg/year) | 324.2 |

| GHG emissions | (tCO2,eq/year) | 21.4 |

| Payback period | (years) | 5.3 |

| Net present value at 20 years | (€) | 17,594 |

| Specific net present value at 20 years | (€/kWel) | 2626.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perrone, D.; Algieri, A.; Morrone, P.; Castiglione, T. Energy and Economic Investigation of a Biodiesel-Fired Engine for Micro-Scale Cogeneration. Energies 2021, 14, 496. https://doi.org/10.3390/en14020496

Perrone D, Algieri A, Morrone P, Castiglione T. Energy and Economic Investigation of a Biodiesel-Fired Engine for Micro-Scale Cogeneration. Energies. 2021; 14(2):496. https://doi.org/10.3390/en14020496

Chicago/Turabian StylePerrone, Diego, Angelo Algieri, Pietropaolo Morrone, and Teresa Castiglione. 2021. "Energy and Economic Investigation of a Biodiesel-Fired Engine for Micro-Scale Cogeneration" Energies 14, no. 2: 496. https://doi.org/10.3390/en14020496

APA StylePerrone, D., Algieri, A., Morrone, P., & Castiglione, T. (2021). Energy and Economic Investigation of a Biodiesel-Fired Engine for Micro-Scale Cogeneration. Energies, 14(2), 496. https://doi.org/10.3390/en14020496