1. Introduction

Over the last century, batteries of all types have become an essential aspect of modern life. In general, batteries can be divided into two main categories: primary (single-use) and secondary (rechargeable) [

1]. Due to an increased focus on sustainability in recent years, secondary batteries have seen an increase in development and applications [

2]. From electric vehicles to mobile devices, secondary batteries act as a reliable and rechargeable source of energy for many electronic devices, increasing their overall versatility and portability [

3,

4]. However, recharging these batteries can prove cumbersome, since many modern devices require a charging cable to be plugged into a charging port. To overcome this hurdle, many researchers and companies are implementing wireless power transmission (WPT) to allow for wireless charging of mobile electronics, electric vehicles, toys, and medical implants [

5,

6,

7,

8,

9].

In contrast to modern “high-tech” devices, where rechargeable batteries are permanently integrated within the system, enumerable other devices and products are powered by simple household batteries. Household batteries come in standardized form factors and voltages (e.g., AAA, AA, C, D, 9 V, etc.) and are available as either primary or secondary cells. A major drawback of rechargeable household batteries is that they typically must be removed from the product, placed on a charger for several hours, and then reinstalled in the product. This inconvenience is a major impediment to their utility in household products. But what if a household battery could be wirelessly recharged? What if it could be recharged without removal from the host electronic device? Besides the added convenience from a consumer standpoint, wireless charging capabilities could turn “old-tech” into “high-tech”. Additionally, eliminating the need for an openable and accessible battery compartment could yield better waterproofing of outdoor products, fewer restrictions on product form factors or coverings, and improved safety for toys and devices used by children.

Two prominent forms of near-field WPT are inductive power transmission (IPT) and electrodynamic wireless power transmission (EWPT). IPT involves using a time-varying magnetic field to inductively transfer energy between a transmitter coil and a receiver coil [

10]. The main drawback to this method is the high frequency range (~0.1 MHz to 10 MHz) that most IPT devices require. Operations at these frequencies are severely limited, as higher frequency signals cannot penetrate conductive environments and lower magnetic field strengths must be used in accordance with IEEE health and safety guidelines [

11,

12]. In addition to limited magnetic field amplitudes at higher frequencies, these systems also tend to generate eddy (Foucault) currents within conductive media between the transmitter and the receiver. These eddy currents can lead to uncontrolled and undesired heating of the intervening media [

13]. Due to the limitations of IPT systems, researchers have proposed and designed systems using EWPT that use an electromechanical approach to transfer energy [

14,

15,

16,

17,

18,

19,

20,

21,

22]. In general, EWPT systems use time-varying magnetic fields to oscillate (translational or rotational) a permanent magnet within a receiver system. The motion of the oscillating magnet is converted into electricity via Faraday’s law, using a static coil around the magnet or via piezoelectric elements attached to the suspension structure. Both transduction schemes of EWPT systems operate at lower frequencies (<1 kHz), allowing for higher magnetic fields, better penetration through conductive media, and less parasitic heating [

20].

To demonstrate the utility and opportunities afforded by an EWPT receiver (namely small receiver size and wireless transmission at modest distances through clutter), we report the design, fabrication, and testing of a first-generation, wirelessly rechargeable AA-sized battery prototype that can directly replace a conventional AA battery in a typical household electronic device. This prototype contains a 316 stainless steel EWPT receiver that charges an internal storage element via a power management unit. This EWPT receiver is inspired by a previous design [

20,

21], but has been modified to increase its reliability and power output. The significance of this work is twofold. First, we demonstrate a fully functioning wirelessly chargeable battery in a standard AA-battery form factor. Second, we characterize the AA-sized prototype and its internal components at low, safe magnetic charging fields, rather than absurdly high fields that will never be practical. Herein, we characterize and report the system operation at a point near its minimum operating condition, defined as the lowest magnetic field strength where the EWPT receiver can produce sufficient voltage and power for the power management circuitry to function. Since end use in a consumer setting contains unpredictable operating conditions, characterizing the AA-sized prototype in these low-end conditions is a better representation than the worse-case operating performance in a real-world setting, as opposed to operating at maximal performance conditions in a laboratory/controlled environment.

3. Experimental Results

Several different experiments were performed to characterize the overall AA-sized prototype and the EWPT receiver. For the EWPT receiver, these tests included a resonant frequency sweep, an optimum load sweep, and a power effectiveness calculation (with the effectiveness calculation performed with the EWPT receiver, the PMC board, and a 1000 µF capacitor). The basic functionality of the completed prototype (with the capacitor replaced with the LiPo cell) was qualitatively observed after benchtop characterization by installing the prototype within two electronic devices: an analog clock and a wireless computer mouse. Basic functionality tests confirmed whether the two electronic devices were fully functional and had wireless charging capabilities with the prototype installed.

3.1. Experimental Setup

The experimental setup for each test required a transmitter system to generate a time-varying magnetic field (

Figure 8). This alternating magnetic field was generated using a Helmholtz coil pair (1000906 3B Scientific, Hamburg, Germany; 124 turns per coil; 300 mm outer diameter; 150 mm coil separation). An ac signal was generated by a waveform generator (DG1022A Rigol, Beaverton, OR, USA) and was fed into a power amplifier (K1 Crown, Los Angeles, CA, USA). The amplified ac signal was fed into the Helmholtz coil pair. The amplitude of magnetic field was linearly dependent on the amplitude of the current supplied to the coil. Initially, the magnetic field strength was measured directly with a gaussmeter (475DSP Lake Shore Cryotronics Inc., Westerville, OH, USA) connected to a transverse Hall probe (XHMMA-1482 Lake Shore Cryotronics Inc., Westerville, OH, USA) placed at the center of the Helmholtz coil pair. However, by using a current probe (TCP312A Tektronix, Beaverton, OR, USA) and a current probe amplifier (TCPA300 Tektronix, Beaverton, OR, USA), a calibration curve was generated to estimate the field strengths based on the supplied current amplitude. Lastly, a digital storage oscilloscope (DPO-2004 B Tektronix, Beaverton, OR, USA) was used to measure current and voltage waveforms for various inputs and outputs. Because the overall goal was to determine the low-end performance of the AA-sized prototype and its components, the transmitter system was used only to produce a low magnetic field strength of 50 µT

rms; only slightly stronger than Earth’s magnetic field (on the surface). For magnetic fields with frequencies below 1 kHz, the maximum allowable (IEEE safety regulations) field strengths are 2.71 mT

rms for controlled environments and 0.904 mT

rms for the general public [

12].

3.2. Resonant Frequency

The first test was a frequency sweep of the EWPT receiver to analyze its open circuit response, as well as to experimentally identify its torsional resonant frequency. Because an EWPT system operates by converting the mechanical motion of a resonating magnet into electricity, it was imperative to drive the system near one of its mechanical resonant frequencies (where angular displacement and angular velocities reach a local maxima) to maximize the output voltage and power. The EWPT receiver was designed to have a maximum output at its 1st torsional resonance mode, so this torsional resonant frequency needed to be experimentally determined to serve as the operating frequency for all subsequent experimentation. To generate the resonance curve, the EWPT receiver (disconnected from the PMC board) was placed at the center of the Helmholtz coil pair, and the open-circuit voltage generated by the receiver was measured at various frequencies. Based on the frequency response of the EWPT receiver (

Figure 9), the torsional resonant frequency of the receiver was 238 Hz, which generated an open-circuit voltage of 1.66 V

rms. As shown in the resonant curve, the −3 dB bandwidth was 3.44 Hz, corresponding to a mechanical quality factor of 69.

3.3. Optimum Resistive Load

The next test was an optimum resistive load sweep to determine the theoretical maximum power that can be generated by the EWPT receiver. For this test, the EWPT receiver was connected to a resistance substitution box (RS-500 ELENCO, Wheeling, IL, USA) to apply a variable load resistance to the output of the receiver. The rms voltage (

) across this resistive load (

) was measured, and then the average power (

) dissipated by the load was calculated using:

By plotting the calculated average power versus the load resistance, the maximum power and its corresponding resistive load value were determined (

Figure 10). For the EWPT receiver, the optimum resistive load was 3.8 kΩ, which produced a load voltage of 954 mV

rms and, thus, a maximum power of 240 µW. Although 3.8 kΩ was the optimum resistive load, we observed that the generated power was relatively constant, between 3.0 kΩ and 4.0 kΩ.

3.4. Power Effectiveness

The next characterization parameter of interest was the “effectiveness” of the power management circuitry. The effectiveness was a measure of the total output power from the PMC board compared to the theoretical maximum power the EWPT receiver could produce at its optimum load. The experimental setup required the transmitter system, the EWPT receiver, the PMC board, a 1000 µF capacitor, and a Digilent Analog Discovery 2 (DAD) data acquisition system. The DAD board served as a USB powered oscilloscope for obtaining voltage measurements. The digital storage oscilloscope could not be used in place of the DAD boards, as the digital storage oscilloscope had a common ground across its four channels, which would short-circuit the system if attempting to obtain simultaneous measurements from the EWPT receiver and the PMC. The 1000 µF electrolytic capacitor was connected to the battery terminals of the PMC board. The load terminals of the PMC were connected to the load resistance. Lastly, the EWPT receiver was connected to the input terminals of the PMC board and placed within a time-varying magnetic field to charge the capacitor.

To measure the PMC’s effectiveness, voltage measurements were obtained across the capacitor during its charge cycle, and a numeric approximation for the voltage curve,

, across the capacitor was generated. Using the derivative of this voltage curve and the capacitance,

, then the current,

, within the capacitor was calculated using the capacitor terminal using:

From there, the dc power over the capacitor charge cycle,

, was calculated using:

The voltage across the resistive load was measured and the dc power across the load was calculated by replacing

with

in Equation (1). The power across the resistive load and the power across the capacitor were summed to produce the overall output power from the PMC (

). Lastly, the power effectiveness (

) was calculated using:

where

is the theoretical maximum power output from the EWPT receiver using an optimal/matched resistive load (instead of the power management electronics), which was separately determined to be 240 µW for 50 µT

rms excitation field during the optimum resistive load sweep.

The effectiveness tests were performed with a 50 kΩ load, a 100 kΩ load, and no load (open circuit) connected to the output terminals of the PMC. For each resistive load, a curve fit was performed over the capacitor voltage measurements (

Figure 11). The shape of the voltage curve was dependent on the task the BQ25570 chip was performing. The initial region was a slow-growing polynomial that converged to approximately 1.5 V. After the capacitor reached 1.5 V, the voltage grew much faster, with some fluctuations occurring due to the cold start process of the BQ25570 chip. The next major change occurred once the capacitor reached 3.3 V, as this was the programmed starting point for the PMC board to start outputting 1.5 V to the attached load. The final region occurred after the capacitor reached 4.2 V and began cyclically charging and discharging around 4.2 V. Lastly, the minimum load required for the PMC to charge the capacitor was found to be 23 kΩ. At this load, the capacitor would not charge beyond 3.3 V, as the 1.5 V output terminals were draining the capacitor at the same rate it was being charged.

The current to the capacitor was determined by curve fitting a numerical approximation to the voltage curves and taking their derivative. With the approximated current, the dc power curves for each resistive load were generated (

Figure 12). The power effectiveness for each case was then calculated.

Table 1 summarizes the results. A final power calculation was performed to calculate the power supplied to the transmitter system. This average power was calculated as 19.1 mW, which resulted in an end-to-end power transfer efficiency (PTE) for the overall system that was less than 1%. This efficiency is arguably quite low, but not unexpected, since the system characterization is performed near the minimal operating point of the electronics. Additionally, system efficiency can be significantly improved via further design optimizations of the transmitter, EWPT receiver, and the receiver PMC.

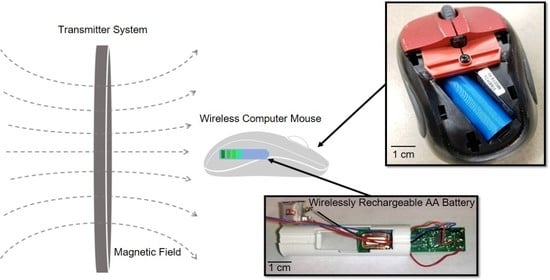

3.5. Prototype System Demonstration

After characterizing the AA-sized prototype in a benchtop setting, the prototype was fully assembled and installed within two common electronic devices to study its basic functionality. These devices were a battery powered clock and a wireless computer mouse (

Figure 13). Both devices were fully functional and exhibited wireless recharging capabilities while the prototype was installed in each host device.

In terms of dimensions, the AA-sized prototype had a final outer diameter of 14.2 mm and an overall length of 51.2 mm. The diameter was well within the desired range of 14 mm ± 0.5 mm, but the length was slightly outside the desired range of 50 mm ± 0.5 mm. This trivial error in length was due to underestimation of the thickness of the metal end caps on the final AA-sized prototype. Fortunately, the top of the internal structure has approximately 3 mm of excess length that can easily be reduced in future design iterations to lower the overall length into the desired range.

4. Conclusions

The overall goal of this series of experimentation was twofold. The first main objective was to demonstrate a fully functioning wirelessly chargeable battery in a standard AA-battery form factor. The completed prototype was able to produce 1.5 V across the metal end caps, which matched the 1.5 V standard potential for Alkaline AA batteries. The size of the prototype was approximately the same as a standard AA battery, with a final outer diameter of 14.2 mm and an overall length of 51.2 mm. Lastly, the prototype was used to power both a battery-powered clock and a wireless computer mouse. While installed in each host device, the prototype enabled each device to have wireless charging capabilities.

The second objective was to characterize the AA-sized prototype and its internal components at low, safe magnetic charging fields. In a very low magnetic field of 50 µTrms (5.5% of the maximum allowable for general public use) and near the minimal operating point of the electronics, the device was able to generate a maximum power output of 118 µW, with a power effectiveness of 49.3%. This power effectiveness showed that the power supplied to both the storage element and attached load was nearly half of the maximum potential power output from the EWPT receiver at this magnetic field strength. The power transfer efficiency for the overall prototype was low (<1%); however, for low-power applications, power efficiency may not be a primary design goal, as user experience, cost, and convenience may take a higher priority.

Regarding the EWPT receiver itself, the 316 stainless steel design was an overall improvement on prior designs. With a torsional resonant frequency of only 238 Hz, the stainless steel EWPT receiver produced a maximum power of 240 µW when connected to a 3.8 kΩ load. The prior design produced an average power of 102 µW and had a power density of 0.32 mW/cm

3 at 50 µT

rms. The 316 stainless steel design produced 235% more power, with a power density of 0.80 mW/cm

3 for the same magnetic field strength. Normalizing these power densities by the magnetic field amplitude squared allows for direct comparison with devices tested at different field strengths. These key parameters for other EWPT receivers are tabulated in

Table 2.