On-Line Optimization of Energy Consumption in Electromagnetic Mill Installation

Abstract

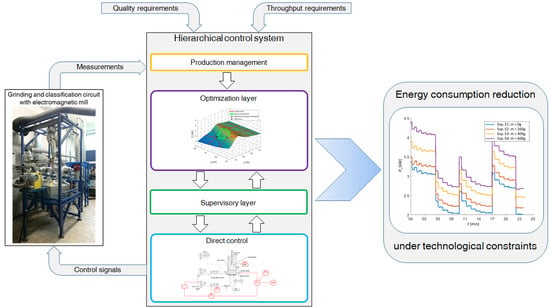

:1. Introduction

2. Electromagnetic Mill

2.1. Construction and Operating Principles of EMM

2.2. Semi-Industrial Grinding and Classification Circuit

3. Power Optimization Problem

3.1. Objective Function

3.2. Constraints

3.2.1. Product Quality Constraints

3.2.2. EMM Voltage Constraint

3.2.3. Magnetic Field Induction Constraints

3.3. Optimization Algorithm

4. Algorithm Validation in Semi-Industrial Tests

4.1. Algorithm Implementation

4.2. Results of Experiments

4.3. Discussion of Results

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wills, B.A.; Napier-Munn, T. Comminution. In Wills’ Mineral Processing Technology; Butterworth-Heinemann: Oxford, UK, 2005; Chapter 5; pp. 108–117. [Google Scholar]

- Fuerstenau, M.C.; Han, K.N. Principles of Mineral Processing; SME: Chicago, IL, USA, 2003. [Google Scholar]

- Mular, A.L.; Doug, N.H.; Derek, J.B. Mineral Processing Plant Design. Practice and Control Proceedings; SME: Chicago, IL, USA, 2002. [Google Scholar]

- Leistner, T.; Peuker, U.A.; Rudolph, M. How Gangue Particle Size Can Affect the Recovery of Ultrafine and Fine Particles During Froth Flotation. Miner. Eng. 2017, 109, 1–9. [Google Scholar] [CrossRef]

- Wang, Y.; Forssberg, E. Enhancement of energy efficiency for mechanical production of fine and ultra-fine particles in comminution. China Particuol. 2007, 5, 193–201. [Google Scholar] [CrossRef]

- Jeswiet, J.; Szekeres, A. Energy consumption in mining comminution. Procedia CIRP 2016, 48, 140–145. [Google Scholar] [CrossRef] [Green Version]

- Fuerstenau, D.; Abouzeid, A.Z. The energy efficiency of ball milling in comminution. Int. J. Miner. Process. 2002, 67, 161–185. [Google Scholar] [CrossRef]

- Walkiewicz, J.; Clark, A.; McGill, S. Microwave-assisted grinding. IEEE Trans. Ind. Appl. 1991, 27, 239–243. [Google Scholar] [CrossRef]

- Musa, F.; Morrison, R. A more sustainable approach to assessing comminution efficiency. Miner. Eng. 2009, 22, 593–601. [Google Scholar] [CrossRef]

- Hesse, M.; Popov, O.; Lieberwirth, H. Increasing efficiency by selective comminution. Miner. Eng. 2017, 103, 112–126. [Google Scholar] [CrossRef]

- Wang, Y.M.; Forssberg, E. New Milling Technology. Technical Report; MinFo: Stockholm, Sweden, 2001. [Google Scholar]

- Grimble, M.J. Industrial Control System Design; Wiley: Hoboken, NJ, USA, 2001. [Google Scholar]

- Hodouin, D. Methods for automatic control, observation, and optimization in mineral processing plants. J. Process Control 2011, 21, 211–225. [Google Scholar] [CrossRef]

- Simon, J.; Guélou, G.; Srinivasan, B.; Berthebaud, D.; Mori, T.; Maignan, A. Exploring the thermoelectric behavior of spark plasma sintered Fe7-xCoxS8 compounds. J. Alloy. Compd. 2020, 819, 152999. [Google Scholar] [CrossRef]

- Lokiec, H.; Lokiec, T. Inductor of Electromagnetic Mill. Polish Patent No. PL 226554 B1, 19 May 2015. (In Polish). [Google Scholar]

- Electromagnetic Mill. Available online: https://globecore.com/products/magnetic-mill/ (accessed on 10 March 2021).

- Styla, S. Laboratory studies of an electromagnetic mill inductor with a power source. Int. Q. J. Econ. Technol. Model. Process. 2017, 6, 109–114. [Google Scholar]

- Styla, S. New Grinding Technology Using an Electromagnetic Mill–Testing the Efficiency of the Process. Int. Q. J. Econ. Technol. Model. Process. 2017, 6, 81–88. [Google Scholar]

- Calus, D.; Makarchuk, O. Analysis of interaction of forces of working elements in electromagnetic mill. Przeglad Elektrotechniczny 2019, 1, 64–69. [Google Scholar] [CrossRef]

- Makarchuk, O.; Calus, D.; Moroz, V. Mathematical model to calculate the trajectories of electromagnetic mill operating elements. Tekhnichna Elektrodynamika 2021, 2, 26–34. [Google Scholar] [CrossRef]

- Ogonowski, S.; Ogonowski, Z.; Swierzy, M.; Pawelczyk, M. Control system of electromagnetic mill load. In Proceedings of the 25th International Conference on Systems Engineering, Las Vegas, NV, USA, 22–24 August 2017; pp. 69–76. [Google Scholar] [CrossRef]

- Ogonowski, S.; Ogonowski, Z.; Pawelczyk, M. Multi-objective and multi-rate control of the grinding and classification circuit with electromagnetic mill. Appl. Sci. 2018, 8, 506. [Google Scholar] [CrossRef] [Green Version]

- Sosinski, R. Opracowanie Metodyki Projektowania Trójfazowych Wzbudników z Biegunami Jawnymi Pola Wirującego do Młynów Elektromagnetycznych (Development of Design Methodology for three-Phase Salient-Pole Exciters of Rotating Field for Electromagnetic Mills—In Polish). Ph.D. Thesis, Czestochowa University of Technology, Czestochowa, Poland, 2006. [Google Scholar]

- Mitsubishi Electric F700 Inverter Instruction Manual. Available online: https://dl.mitsubishielectric.com/dl/fa/document/manual/inv/ib0600177eng/ib0600177engf.pdf (accessed on 10 March 2021).

- Kabzinski, J. Advanced Control of Electrical Drives and Power Electronic Converters; Springer International Publishing AG: Cham, Switzerland, 2017; ISBN 978-3-319-83362-0. [Google Scholar]

- Goralczyk, M.; Krot, P.; Zimroz, R.; Ogonowski, S. Increasing Energy Efficiency and Productivity of the Comminution Process in Tumbling Mills by Indirect Measurements of Internal Dynamics—An Overview. Energies 2020, 13, 6735. [Google Scholar] [CrossRef]

- Pawelczyk, M.; Ogonowski, Z.; Ogonowski, S.; Foszcz, D.; Saramak, D.; Gawenda, T.; Krawczykowski, D. Method for Dry Grinding in Electromagnetic Mill. Polish Patent PL 413041, 6 June 2015. [Google Scholar]

- Wolosiewicz-Glab, M.; Ogonowski, S.; Foszcz, D.; Gawenda, T. Assessment of classification with variable air flow for inertial classifier in dry grinding circuit with electromagnetic mill using partition curves. Physicochem. Probl. Miner. Process. 2018, 54, 440–447. [Google Scholar] [CrossRef]

- SIMATIC S7-300. Available online: https://new.siemens.com/global/en/products/automation/systems/industrial/plc/simatic-s7-300.html (accessed on 10 March 2021).

- SIMATIC S7-1200. Available online: https://new.siemens.com/global/en/products/automation/systems/industrial/plc/s7-1200.html (accessed on 10 March 2021).

- Buchczik, D.; Wegehaupt, J.; Krauze, O. Indirect measurements of milling product quality in the classification system of electromagnetic mill. In Proceedings of the 22nd International Conference on Methods and Models in Automation and Robotics, Miedzyzdroje, Poland, 28–31 August 2017; pp. 1039–1044. [Google Scholar] [CrossRef]

- Budzan, S.; Buchczik, D.; Pawelczyk, M.; Tuma, J. Combining Segmentation and Edge Detection for Efficient Ore Grain Detection in an Electromagnetic Mill Classification System. Sensors 2019, 19, 1805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- LUMEL 1 and 3-Phase Power Network Meter ND20. Available online: https://www.lumel.com.pl/en/catalogue/product/1-and-3-phase-power-network-meter-nd20 (accessed on 10 March 2021).

- SIMATIC IPC 477D Panel PC. Available online: https://mall.industry.siemens.com/mall/en/WW/Catalog/Product/?mlfb=6AV7240-6BD17-0PA2 (accessed on 10 March 2021).

- GE Digital Proficy HMI/SCADA iFIX. Available online: https://www.ge.com/digital/applications/hmi-scada/ifix (accessed on 10 March 2021).

- Tatjewski, P. Advanced Control of Industrial Processes: Structures and Algorithms; Springer: London, UK, 2007. [Google Scholar]

- French, M. Fundamentals of Optimization; Springer International Publishing AG: Cham, Switzerland, 2018; ISBN 978-3-319-76191-6. [Google Scholar]

- Ogonowski, S.; Ogonowski, Z.; Swierzy, M. Power optimizing control of grinding process in electromagnetic mill. In Proceedings of the 21st International Conference on Process Control, Strbske Pleso, Slovakia, 6–9 June 2017; pp. 370–375. [Google Scholar] [CrossRef]

- Braspenning, P.J.; Thuijsman, F.; Weijters, A.J.M.M. Artificial Neural Networks. An Introduction to ANN Theory and Practice; Springer: Berlin/Heidelberg, Germany, 1995; ISBN 978-3-540-59488-8. [Google Scholar]

- Krauze, O.; Buchczik, D.; Budzan, S. Measurement-Based Modelling of Material Moisture and Particle Classification for Control of Copper Ore Dry Grinding Process. Sensors 2021, 21, 667. [Google Scholar] [CrossRef] [PubMed]

- Wolberg, J. Data Analysis Using the Method of Least Squares: Extracting the Most Information from Experiments; Springer: Berlin/Heidelberg, Germany, 2006; ISBN 978-3-540-25674-8. [Google Scholar]

- Kiefer, J. Sequential minimax search for a maximum. Proc. Am. Math. Soc. 1953, 4, 502–506. [Google Scholar] [CrossRef]

| Distance from Pole | Magnetic Induction B [mT] | ||||

|---|---|---|---|---|---|

| Left | Right | fo = 40 Hz | fo = 50 Hz | fo = 60 Hz | fo = 70 Hz |

| x [mm ] | x’ [mm] | Io = 90 A | Io = 68 A | Io = 56 A | Io = 49 A |

| 0 | 120 | 190 | 144 | 136 | 120 |

| 20 | 100 | 148 | 115 | 95 | 86 |

| 40 | 80 | 128 | 102 | 84 | 75 |

| 60 | 60 | 124 | 100 | 84 | 74 |

| 80 | 40 | 128 | 102 | 86 | 75 |

| 100 | 20 | 144 | 110 | 100 | 86 |

| 120 | 0 | 190 | 156 | 137 | 119 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogonowski, S. On-Line Optimization of Energy Consumption in Electromagnetic Mill Installation. Energies 2021, 14, 2380. https://doi.org/10.3390/en14092380

Ogonowski S. On-Line Optimization of Energy Consumption in Electromagnetic Mill Installation. Energies. 2021; 14(9):2380. https://doi.org/10.3390/en14092380

Chicago/Turabian StyleOgonowski, Szymon. 2021. "On-Line Optimization of Energy Consumption in Electromagnetic Mill Installation" Energies 14, no. 9: 2380. https://doi.org/10.3390/en14092380

APA StyleOgonowski, S. (2021). On-Line Optimization of Energy Consumption in Electromagnetic Mill Installation. Energies, 14(9), 2380. https://doi.org/10.3390/en14092380