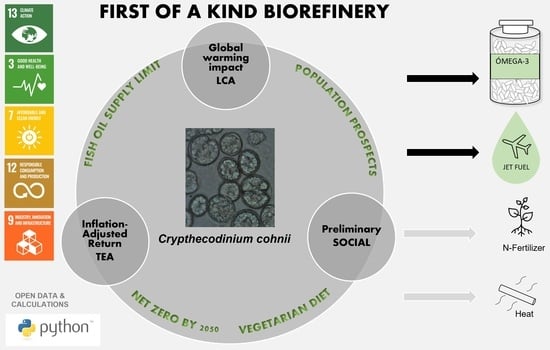

Cascading Crypthecodinium cohnii Biorefinery: Global Warming Potential and Techno-Economic Assessment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bench-Scale Inventory and Scale-Up Considerations

2.2. GHG Analysis

2.2.1. Reference for DHA

2.2.2. Reference for Maritime or Jet Fuel

2.2.3. Reference for N-Fertilizer

2.2.4. Reference for District Heating

2.2.5. Net-Zero Carbon Electricity

2.2.6. Conventional versus Dynamic Inventory

2.3. TEA Analysis

2.4. Social Analysis

3. Results

3.1. C. cohnii Supply Needs

3.2. C. cohnii Biorefinery Global Warming Potential and Benefits

3.3. C. cohnii Biorefinery Products LCA Values

3.4. C. cohnii Biorefinery Techno-Economic Analysis

3.5. C. cohnii Biorefinery Concept from a Social Point of View

4. Discussion

5. Conclusions

- Estimate future biomass feedstock needs (in support of the energy transition);

- Evaluate GHG savings and product GHG emission factors according to both conventional and dynamic LCA, and covering the same boundaries and allocation rules;

- Evaluate TEA based on main units (batch bioreactors, freeze drying, supercritical fluid extraction, CHP, and historically lower and higher commodity cost (prices w/o vat), reference EUR 2018;

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Item | Emission Factor | Reference |

|---|---|---|

| Aviation kerosene | 78.3 gCO2eq/MJ | [46] |

| Fish oil | 1.72 tCO2eq/t | Own study based on [43,80] |

| Fish oil DHA | 8.62 tCO2eq/t | Own study based on [43,80] |

| N-fertilizer | 3886.12 gCO2eq/kg | [46] |

| District heating | 47.3 tCO2eq/TJ | [12] |

| Antibiotics | 6 kgCO2eq/kg | [81] |

| Yeast extract | 0.15 kgCO2eq/kg | Gabi database * |

| CSL | 0.5 kgCO2eq/kg | [82] |

| Glycerol | 0.2358 kgCO2eq/kg | [83] |

| Sea salt | 0.0133 kgCO2eq/kg | [84] |

| Hydrogen | 6.848 tCO2eq/t | [12] |

| Electricity | 0 or 150 gCO2eq/kWh | Own study based on [46] |

Appendix B

| Item | Higher End Cost (EUR) | Lower End Cost (EUR) | Reference |

|---|---|---|---|

| Electricity (EUR/kWh) | 0.17 | 0.01 | [58] |

| Diesel (EUR/L) | 0.95 | 0.33 | [58] |

| Jet fuel (EUR/L) | 0.56 | 0.12 | [59] |

| Demineralized water (EUR/m3) | 0.90 | 0.45 | [61] |

| Yeast extract (EUR/kg) | 5.83 | 0.80 | [26] |

| CSL (corn step liquor) (EUR/kg) | 0.16 | 0.00 | [26] |

| Glycerol (EUR/kg) | 0.40 | 0.08 | [26] |

| Glucose (EUR/kg) | 0.96 | 0.08 | [26] |

| Fish oil (EUR/kg) | 1.63 | 0.20 | [41] |

| DHA/EPA (EUR/kg) | 8.17 | 1.00 | Own estimation based on fish oil and 20% Omega-3 content |

| N-fertilizer (EUR/kg) | 0.52 | 0.08 | [60] |

| Rock salt (EUR/kg) | 0.06 | 0.02 | [86] |

| Hydrogen (EUR/kg) | 3.20 | 0.80 | [63] |

| District heating (EUR/MJ) | 0.02 | 0.01 | [62] |

| Equipment | Cost (EUR) | Reference |

|---|---|---|

| 4 × Batch reactor (2000 L) * | 4 × 28,077 | [87] |

| Freeze dryer (250 L, 4 shelves, 800 10R vials per cycle) | 100,000 | [88] |

| Supercritical fluid extraction (50 L extraction vessel) | 567,000 | [89] |

| HDS (small scale) | 73,000 | [90] |

| CHP | 330,000 | [91,92,93] |

References

- Intergovernmental Panel on Climate Change. The Carbon Cycle and Atmospheric Carbon Dioxide. Chapter 3. IPCC Third Assessment Report; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2001. [Google Scholar]

- Rana, S.; Pichandi, S.; Parveen, S.; Fangueiro, R. Regenerated Cellulosic Fibers and Their Implications on Sustainability. In Textile Science and Clothing Technology; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Baylis, S.A.; Hall, K.; Jumeau, E.J. The analysis of the C1–C5 components of natural gas samples using gas chromatography-combustion-isotope ratio mass spectrometry. Org. Geochem. 1994, 21, 777–785. [Google Scholar] [CrossRef]

- Nasir, Q.; Sabil, K.M.; Nasrifar, K. Measurement and Phase Behavior Modeling (Dew Point + Bubble Point) of CO2 Rich Gas Mixture. J. Appl. Sci. 2014, 14, 1061–1066. [Google Scholar] [CrossRef]

- European Commission. A Study on the Economic Valuation of Environmental Externalities from Landfill Disposal and Incineration of Waste. Final Main Report; European Commission: Brussels, Belgium, 2000. [Google Scholar]

- Cherubini, F.; Gasser, T.; Bright, R.M.; Ciais, P.; Strømman, A.H. Linearity between temperature peak and bioenergy CO2 emission rates. Nat. Clim. Chang. 2014, 4, 983–987. [Google Scholar] [CrossRef]

- UNEP/WMO. Integrated Assessment of Black Carbon and Tropospheric Ozone; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2011. [Google Scholar]

- Rogelj, J.; Shindell, D.; Jiang, K.; Fifita, S.; Forster, P.; Ginzburg, V.; Handa, C.; Kheshgi, H.; Kobayashi, S.; Kriegler, E.; et al. Mitigation Pathways Compatible with 1.5 °C in the Context of Sustainable Development. In Global Warming of 1.5 °C, (IPCC Special Report); Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2018. [Google Scholar]

- Huppmann, D.; Kriegler, E.; Krey, V.; Riahi, K.; Rogelj, J.; Calvin, K.; Humpenoeder, F.; Popp, A.; Rose, S.K.; Weyant, J.; et al. IAMC 1.5 °C Scenario Explorer and Data Hosted by IIASA; (Version release 2.0) [Data set]; Integrated Assessment Modeling Consortium & International Institute for Applied Systems Analysis: Laxenburg, Austria, 2019. [Google Scholar]

- Dahiya, S.; Katakojwala, R.; Ramakrishna, S.; Mohan, S.V. Biobased Products and Life Cycle Assessment in the Context of Circular Economy and Sustainability. Mater. Circ. Econ. 2020, 2, 7. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EU) No 601/2012 on the Monitoring and Reporting of Greenhouse Gas Emissions Pursuant to Directive 2003/87/EC of the European Parliament and of the Council; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- European Union. Directive (EU) 2018/410 of the European Parliament and the Council of 14 March 2018 Amending Directive 2003/87/EC to Enhance Cost-Effective Emission Reductions and Low-Carbon Investments, and Decision (EU) 2015/1814; European Commission: Brussels, Belgium, 2018; Volume 1933. [Google Scholar]

- International Organization for Standardization. ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Cowie, A.L.; Berndes, G.; Bentsen, N.S.; Brandão, M.; Cherubini, F.; Egnell, G.; George, B.; Gustavsson, L.; Hanewinkel, M.; Harris, Z.M.; et al. Applying a science-based systems perspective to dispel misconceptions about climate effects of forest bioenergy. GCB Bioenergy 2021, 13, 1210–1231. [Google Scholar] [CrossRef]

- Prussi, M.; Panoutsou, C.; Chiaramonti, D. Assessment of the Feedstock Availability for Covering EU Alternative Fuels Demand. Appl. Sci. 2022, 12, 740. [Google Scholar] [CrossRef]

- Ding, S.; Parlett, C.M.A.; Fan, X. Recent developments in multifunctional catalysts for fatty acid hydrodeoxygenation as a route towards biofuels. Mol. Catal. 2021, 523, 111492. [Google Scholar] [CrossRef]

- Blair, M.J.; Gagnon, B.; Klain, A.; Kulišić, B. Contribution of Biomass Supply Chains for Bioenergy to Sustainable Development Goals. Land 2021, 10, 181. [Google Scholar] [CrossRef]

- Simonsen, T.; Weiss, N.D.; Dick, S.V.; Thuijl, V.T.; Thomsen, S.T. Progress Towards Biofuels for Marine Shipping. Status and Identification of Barriers for Utilization of Advanced Biofuels in the Marine Sector. 2021. Available online: https://www.ieabioenergy.com/blog/publications/progress-towards-biofuels-for-marine-shipping/ (accessed on 1 March 2022).

- Prussi, M.; Weindorf, W.; Buffi, M.; Sánchez López, J.; Scarlat, N. Are algae ready to take off? GHG emission savings of algae-to-kerosene production. Appl. Energy 2021, 304, 117817. [Google Scholar] [CrossRef]

- Pike, I.H.; Jackson, A. Fish oil: Production and use now and in the future. Lipid Technol. 2010, 22, 59–61. [Google Scholar] [CrossRef]

- International Energy Agency. Ammonia Technology Roadmap. Towards More Sustainable Nitrogen Fertiliser Production; International Energy Agency: Paris, France, 2021. [Google Scholar]

- United Nations. World Population Prospects: The 2015 Revision; United Nations: New York, NY, USA, 2015; Volume XXXIII. [Google Scholar]

- Oliver, L.; Dietrich, T.; Marañón, I.; Villarán, M.C.; Barrio, R.J. Producing Omega-3 Polyunsaturated Fatty Acids: A Review of Sustainable Sources and Future Trends for the EPA and DHA Market. Resources 2020, 9, 148. [Google Scholar] [CrossRef]

- FAO. The State of World Fisheries and Aquaculture 2020. Sustainability in Action; FAO: Rome, Italy, 2020. [Google Scholar]

- International Energy Agency. Database Documentation Oil Information 2021 Edition; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Moniz, P.; Silva, C.; Oliveira, A.C.; Reis, A.; Lopes da Silva, T. Raw Glycerol Based Medium for DHA and Lipids Production, Using the Marine Heterotrophic Microalga Crypthecodinium cohnii. Processes 2021, 9, 2005. [Google Scholar] [CrossRef]

- Lopes da Silva, T.; Moniz, P.; Silva, C.; Reis, A. The dark side of microalgae biotechnology: A heterotrophic biorefinery platform directed to ω-3 rich lipid production. Microorganisms 2019, 7, 670. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khanum, F.; Giwa, A.; Nour, M.; Al-Zuhair, S.; Taher, H. Improving the economic feasibility of biodiesel production from microalgal biomass via high-value products coproduction. Int. J. Energy Res. 2020, 44, 11453–11472. [Google Scholar] [CrossRef]

- Martin, L.; Skinner, C.; Marriott, R.J. Supercritical extraction of oil seed rape: Energetic evaluation of process scale. J. Supercrit. Fluids 2015, 105, 55–59. [Google Scholar] [CrossRef]

- Murphy, J.; McKeogh, E.; Kiely, G. Technical/economic/environmental analysis of biogas utilisation. Appl. Energy 2004, 77, 407–427. [Google Scholar] [CrossRef]

- Johnson, M.; Heggs, P.J.; Mahmud, T. Assessment of Overall Heat Transfer Coefficient Models to Predict the Performance of Laboratory-Scale Jacketed Batch Reactors. Org. Process Res. Dev. 2016, 20, 204–214. [Google Scholar] [CrossRef] [Green Version]

- Paixão, S.M.; Alves, L.; Pacheco, R.; Silva, C.M. Evaluation of Jerusalem artichoke as a sustainable energy crop to bioethanol: Energy and CO2eq emissions modeling for an industrial scenario. Energy 2018, 150, 468–481. [Google Scholar] [CrossRef] [Green Version]

- Ducoste, J.J.; Clark, M.M.; Weetman, R.J. Turbulence in flocculators: Effects of tank size and impeller type. AIChE J. 1997, 43, 328–338. [Google Scholar] [CrossRef]

- Elangovan, S.; Elliott, D.C.; Santosa, D.; Spatari, S.; Karanjikar, M. Novel Electro-Deoxygenation Process for Bio-Oil Upgrading; U.S. Department of Energy: Golden, CO, USA, 2018.

- Hosokai, S.; Matsuoka, K.; Kuramoto, K.; Suzuki, Y. Modification of Dulong’s formula to estimate heating value of gas, liquid and solid fuels. Fuel Process. Technol. 2016, 152, 399–405. [Google Scholar] [CrossRef]

- Energetics Incorporated. Energy and Environmental Profile of the U.S. Chemical Industry; Energetics Incorporated: Columbia, MD, USA, 2000. [Google Scholar]

- Swanson, D.; Block, R.; Mousa, S.A. Omega-3 Fatty Acids EPA and DHA: Health Benefits Throughout Life. Adv. Nutr. 2012, 3, 1–7. [Google Scholar] [CrossRef] [PubMed]

- D’Eliseo, D.; Velotti, F. Omega-3 Fatty Acids and Cancer Cell Cytotoxicity: Implications for Multi-Targeted Cancer Therapy. J. Clin. Med. 2016, 5, 15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Toppe, J. Farmed fish: A major provider or a major consumer of omega-3 oils? Int. News Fats Oils Relat. Mater. 2013, 24, 477–479. [Google Scholar]

- Cashion, T.; Le Manach, F.; Zeller, D.; Pauly, D. Most fish destined for fishmeal production are food-grade fish. Fish Fish. 2017, 18, 837–844. [Google Scholar] [CrossRef]

- OECD; FAO. OECD-FAO Agricultural Outlook 2019–2028; OECD: Paris, France; FAO: Rome, Italy, 2020. [Google Scholar]

- Rincón-Cervera, M.Á.; González-Barriga, V.; Romero, J.; Rojas, R.; López-Arana, S. Quantification and Distribution of Omega-3 Fatty Acids in South Pacific Fish and Shellfish Species. Foods 2020, 9, 233. [Google Scholar] [CrossRef] [Green Version]

- Bartek, L.; Strid, I.; Henryson, K.; Junne, S.; Rasi, S.; Eriksson, M. Life cycle assessment of fish oil substitute produced by microalgae using food waste. Sustain. Prod. Consum. 2021, 27, 2002–2021. [Google Scholar] [CrossRef]

- European Environment Agency. Greenhouse Gas Emission Intensity of Electricity Generation in Europe; European Environment Agency: Copenhagen, Denmark.

- UK DEFRA. 2021 Government Greenhouse Gas Conversion Factors for Company Reporting: Methodology Paper for Conversion Factors Final Report; UK DEFRA: Birmingham, UK, 2021.

- Annex C: Methodology for Calculation of GHG Emission Avoidance. European Comission. 2021. Available online: https://ec.europa.eu/info/funding-tenders/opportunities/docs/2021-2027/innovfund/wp-call/call-annex_c_innovfund-lsc-2020-two-stage_en.pdf (accessed on 1 January 2022).

- Kalogerakis, N.; Politi, M.; Foteinis, S.; Chatzisymeon, E.; Mantzavinos, D. Recovery of antioxidants from olive mill wastewaters: A viable solution that promotes their overall sustainable management. J. Environ. Manag. 2013, 128, 749–758. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Lee, H.; Molburg, J. Allocation of Energy Use in Petroleum Refineries to Petroleum Products: Implications for Life-Cycle Energy Use and Emission Inventory of Petroleum Transportation Fuels. Int. J. Life Cycle Assess. 2004, 9, 34–44. [Google Scholar] [CrossRef]

- Prussi, M.; Yugo, M.; De Prada, L.; Padella, M.; Edwards, R. JEC Well-To-Wheels Report v5; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Pachauri, R.K., Meyer, L.A., Eds.; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- International Energy Agency. Net Zero by 2050: A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Bruckner, T.; Bashmakov, I.A.; Mulugetta, Y.; Chum, H.; de la Navarro, A.V.; Edmonds, J.; Faaij, A.; Fungtammasan, B.; Garg, A.; Hertwich, E.; et al. Energy Systems. In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Clauß, J.; Stinner, S.; Solli, C.; Lindberg, K.B.; Madsen, H.; Georges, L. Evaluation Method for the Hourly Average CO2eq. Intensity of the Electricity Mix and Its Application to the Demand Response of Residential Heating. Energies 2019, 12, 1345. [Google Scholar] [CrossRef] [Green Version]

- Silva, C. Greenhouse Gas Emission Assessment of Simulated Wastewater Biorefinery. Resources 2021, 10, 78. [Google Scholar] [CrossRef]

- Vance, C.; Sweeney, J.; Murphy, F. Space, time, and sustainability: The status and future of life cycle assessment frameworks for novel biorefinery systems. Renew. Sust. Energ. Rev. 2022, 159, 11225. [Google Scholar] [CrossRef]

- Henrich, E.; Dahmen, N.; Dinjus, E. Cost estimate for biosynfuel production via biosyncrude gasification. Biofuels Bioprod. Biorefining 2009, 3, 28–41. [Google Scholar] [CrossRef]

- Jenkins, S. Chemical Engineering Plant Cost Index. Available online: https://www.chemengonline.com/2019-cepci-updates-january-prelim-and-december-2018-final/?printmode=1 (accessed on 1 January 2022).

- Heald, S.; Debrosses, N.; Rademaekers, K. Study on Energy Prices, Costs and Subsidies and Their Impact on Industry and Households: Final Report; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- IndexMundi. Available online: https://www.indexmundi.com/commodities/?commodity=jet-fuel&months=240¤cy=eur (accessed on 1 January 2022).

- OECD; FAO. OECD-FAO Agricultural Outlook 2018–2027; OECD: Paris, France; FAO: Rome, Italy, 2018; Volume 181. [Google Scholar]

- European Commission. Demineralised Water Production from River Water Using Membrane Separation Technology; European Commission: Brussels, Belgium, 2000. [Google Scholar]

- Werner, S. European District Heating Price Series; Report 2016:316; Energiforsk: Stockholm, Sweden, 2016. [Google Scholar]

- Platts. S&P Global Platts Press Release, S&P Global Platts Launches World’s First Hydrogen Price Assessments, 18 December 2019. Available online: https://www.spglobal.com/commodityinsights/en/about-commodityinsights/media-center/press-releases/2019/18-12-2019-hydrogen-launch, (accessed on 1 January 2022).

- Hydrogen Council. Path to Hydrogen Competitiveness: A Cost Perspective; Hydrogen Council: Brussels, Belgium, 2020. [Google Scholar]

- Owen, R.; Macnaghten, P.; Stilgoe, J. Responsible research and innovation: From science in society to science for society, with society. Sci. Public Policy 2012, 39, 751–760. [Google Scholar] [CrossRef] [Green Version]

- Tempels, T.H.; Van den Belt, H. Once the rockets are up, who should care where they come down? The problem of responsibility ascription for the negative consequences of biofuel innovations. Springerplus 2016, 5, 135. [Google Scholar] [CrossRef] [Green Version]

- Parada, M.P.; Asveld, L.; Osseweijer, P.; Posada, J.A. Setting the design space of biorefineries through sustainability values, a practical approach. Biofuels Bioprod. Biorefining 2018, 12, 29–44. [Google Scholar] [CrossRef] [Green Version]

- Asveld, L. Towards including social sustainability in green and sustainable chemistry. Curr. Opin. Green Sustain. Chem. 2019, 19, 61–65. [Google Scholar] [CrossRef]

- ICAO. CORSIA Eligible Fuels—Life Cycle Assessment Methodology; ICAO: Montreal, QC, Canada, 2019. [Google Scholar]

- Pacheco, R.; Silva, C. Global Warming Potential of Biomass-to-Ethanol: Review and Sensitivity Analysis through a Case Study. Energies 2019, 12, 2535. [Google Scholar] [CrossRef] [Green Version]

- Diao, J.; Song, X.; Zhang, X.; Chen, L.; Zhang, W. Genetic Engineering of Crypthecodinium cohnii to Increase Growth and Lipid Accumulation. Front. Microbiol. 2018, 9, 492. [Google Scholar] [CrossRef] [Green Version]

- Didrihsone, E.; Dubencovs, K.; Grube, M.; Shvirksts, K.; Suleiko, A.; Suleiko, A.; Vanags, J. Crypthecodinium cohnii Growth and Omega Fatty Acid Production in Mediums Supplemented with Extract from Recycled Biomass. Mar. Drugs 2022, 20, 68. [Google Scholar] [CrossRef]

- Cannon, D. From Fish Oil to Microalgae Oil…A Win-Win Shift for Humans and Our Habitat. Explore 2009, 5, 299–303. [Google Scholar] [CrossRef]

- Lane, K.; Derbyshire, E.; Li, W.; Brennan, C. Bioavailability and Potential Uses of Vegetarian Sources of Omega-3 Fatty Acids: A Review of the Literature. Crit. Rev. Food Sci. Nutr. 2014, 54, 572–579. [Google Scholar] [CrossRef] [PubMed]

- Van der Voort, M.P.J.; Spruijt, J.; Potters, J.; de Wolf, P.L.; Elissen, H.J.H. Socio-Economic Assessment of Algae-Based PUFA Production. Public Output Report of the PUFAChain Project; PUFAChain: Göttingen, Germany, 2017. [Google Scholar]

- Chauton, M.S.; Reitan, K.I.; Norsker, N.H.; Tveterås, R.; Kleivdal, H.T. A techno-economic analysis of industrial production of marine microalgae as a source of EPA and DHA-rich raw material for aquafeed: Research challenges and possibilities. Aquaculture 2015, 436, 95–103. [Google Scholar] [CrossRef]

- Kleivdal, H.; Chauton, M.S.; Reitan, K.I. ProAlgae. Industrial Production of Marine Microalgae as a Source of EPA and DHA Rich Raw Material in Fish Feed—Basis, Knowledge Status and Possibilities; SINTEF: Trondheim, Norway, 2013. [Google Scholar]

- Mendes, A.; Da Silva, T.L.; Reis, A. DHA concentration and purification from the marine heterotrophic microalga Crypthecodinium cohnii CCMP 316 by winterization and urea complexation. Food Technol. Biotechnol. 2007, 45, 38–44. [Google Scholar]

- Slegers, P.M.; Olivieri, G.; Breitmayer, E.; Sijtsma, L.; Eppink, M.H.M.; Wijffels, R.H.; Reith, J.H. Design of Value Chains for Microalgal Biorefinery at Industrial Scale: Process Integration and Techno-Economic Analysis. Front. Bioeng. Biotechnol. 2020, 8, 550758. [Google Scholar] [CrossRef]

- Fréon, P.; Durand, H.; Avadí, A.; Huaranca, S.; Orozco Moreyra, R. Life cycle assessment of three Peruvian fishmeal plants: Toward a cleaner production. J. Clean. Prod. 2017, 145, 50–63. [Google Scholar] [CrossRef]

- Brunet, R.; Guillén-Gosálbez, G.; Jiménez, L. Combined simulation–optimization methodology to reduce the environmental impact of pharmaceutical processes: Application to the production of Penicillin V. J. Clean. Prod. 2014, 76, 55–63. [Google Scholar] [CrossRef]

- Mu, D.; Seager, T.; Rao, P.S.; Zhao, F. Comparative Life Cycle Assessment of Lignocellulosic Ethanol Production: Biochemical Versus Thermochemical Conversion. Environ. Manag. 2010, 46, 565–578. [Google Scholar] [CrossRef]

- European Comission. Environmental Factsheet: Glycerol; European Comission: Brussels, Belgium, 2014. [Google Scholar]

- Edwards, R.; O’Connell, A.; Padella, M.; Giuntoli, J.; Koeble, R.; Bulgheroni, C.; Marelli, L.; Lonza, L. Definition of Input Data to Assess GHG Default Emissions from Biofuels in EU Legislation; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Numjuncharoen, T.; Papong, S.; Malakul, P.; Mungcharoen, T. Life-Cycle GHG Emissions of Cassava-Based Bioethanol Production. Energy Procedia 2015, 79, 265–271. [Google Scholar] [CrossRef] [Green Version]

- US Statistcis. Producer Price Index by Commodity: Chemicals and Allied Products: Rock Salt [WPU06130271]; Federal Reserve Bank of St. Louis: St. Louis, MO, USA, 2022. [Google Scholar]

- Appendix D: Capital Cost Guidelines. In Rules of Thumb in Engineering Practice; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2007; pp. 376–436.

- Stratta, L.; Capozzi, L.C.; Franzino, S.; Pisano, R. Economic Analysis of a Freeze-Drying Cycle. Processes 2020, 8, 1399. [Google Scholar] [CrossRef]

- Attard, T.; McElroy, C.; Hunt, A. Economic Assessment of Supercritical CO2 Extraction of Waxes as Part of a Maize Stover Biorefinery. Int. J. Mol. Sci. 2015, 16, 17546–17564. [Google Scholar] [CrossRef] [Green Version]

- NREL Equipment Design and Cost Estimation for Small Modular Biomass Systems, Synthesis Gas Cleanup, and Oxygen Separation Equipment; NREL: Golden, CO, USA, 2006.

- ESC. CHP Engineering and Instalation Costs. Available online: https://understandingchp.com/chp-applications-guide/6-8-rules-of-thumb-for-chp-engineering-and-installation-costs/ (accessed on 1 January 2022).

- EPA. Financing CHP Projects at Wastewater Treatment -Facilities with Clean Water State Revolving Funds; EPA: Frankfurt Germany, 2014. [Google Scholar]

- DBEIS. Combined Heat and Power—Finance; DBEIS: London, UK, 2021.

| Unit Process | Inputs | Outputs |

|---|---|---|

| Starter | Wild C. cohnii Medium | C. cohnii starter |

| Inoculum | C. cohnii starter Medium | C. cohnii inoculum |

| Batch (1) | C. cohnii inoculum 0.1 (% v/v) Medium 0.9 (% v/v) Incubator (168 h, 50% capacity, 33.6 kWh) Centrifugation (0.5 h, 100% capacity, 0.4 kWh) | C. cohnii (77% moisture) |

| Freeze drying | Vacuum + freezing + heating + condenser 2 kWh/kgH2O [28] Removed water 0.72 kgH2O/kgdry algae | 70.6 g C. cohnii (5% moisture) 0.06 g/L/h (e.g., 3 L 168 h, 70.6 g dry) 27% fatty acids (31% DHA) |

| Supercritical fluid extraction | Cooling + pumping + heating + extraction + separation 10 kWh/kgbio-oil [29] | 13 g Oil w/o DHA 6 g DHA |

| In | Out |

|---|---|

| 70.6 × 0.412 = 29.1 g C | Bio-oil 9.7 g C DHA 4.7 g C Biomass waste by difference 14.6 g C |

| 70.6 × 0.047 = 3.3 g N | Bio-oil 0 g N DHA 0 g N Biomass waste by difference 3.3 g N |

| Item | Unit | gCO2eq/Unit | Database |

|---|---|---|---|

| Heat | MJ | 47.3 | EU ETS benchmark [12] |

| Electricity | kWh | 230.7 | EU27 [44] |

| Tap water | L | 0.149 | UK DEFRA [45] |

| Sodium hydroxide (NaOH) | kg | 450 (1) (529.7 × 0.85) | Definition of input data to assess GHG default emissions from biofuels in EU legislation [46] |

| Sodium chlorine (NaCl) | kg | 11.3 (1) (13.3 × 0.85) | |

| Antioxidants | kg | 10,000 | [47] |

| Wastewater | m3 | 272 | UK DEFRA [45] |

| Dry C. cohnii g/L/h | |||||

|---|---|---|---|---|---|

| 0.06 | 0.14 | 0.28 | 0.4 | ||

| Oil % | 30 | 32 | 71 | 84 | 87 |

| 50 | 60 | 81 | 89 | 91 | |

| 70 | 70 | 85 | 91 | 92 | |

| Item | Unit | 2030 gCO2eq/Unit | 2050 gCO2eq/Unit | 2030 gCO2eq/Unit | 2050 gCO2eq/Unit |

|---|---|---|---|---|---|

| Mass Allocation | Energy Allocation | ||||

| Heat | MJ | 5.9 | 5.2 | 35.5 | 31.0 |

| Jet fuel | MJ | 35.9 | 31.4 | 35.5 | 31.0 |

| N-Fertilizer | kg | 1585.2 | 1385.6 | 0.0 | 0.0 |

| DHA | kg | 1585.2 | 1385.6 | 1404.0 | 1227.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, C.; Moniz, P.; Oliveira, A.C.; Vercelli, S.; Reis, A.; da Silva, T.L. Cascading Crypthecodinium cohnii Biorefinery: Global Warming Potential and Techno-Economic Assessment. Energies 2022, 15, 3784. https://doi.org/10.3390/en15103784

Silva C, Moniz P, Oliveira AC, Vercelli S, Reis A, da Silva TL. Cascading Crypthecodinium cohnii Biorefinery: Global Warming Potential and Techno-Economic Assessment. Energies. 2022; 15(10):3784. https://doi.org/10.3390/en15103784

Chicago/Turabian StyleSilva, Carla, Patricia Moniz, Ana Cristina Oliveira, Samuela Vercelli, Alberto Reis, and Teresa Lopes da Silva. 2022. "Cascading Crypthecodinium cohnii Biorefinery: Global Warming Potential and Techno-Economic Assessment" Energies 15, no. 10: 3784. https://doi.org/10.3390/en15103784

APA StyleSilva, C., Moniz, P., Oliveira, A. C., Vercelli, S., Reis, A., & da Silva, T. L. (2022). Cascading Crypthecodinium cohnii Biorefinery: Global Warming Potential and Techno-Economic Assessment. Energies, 15(10), 3784. https://doi.org/10.3390/en15103784