A Noncontact Magneto–Piezo Harvester-Based Vehicle Regenerative Suspension System: An Experimental Study

Abstract

:1. Introduction

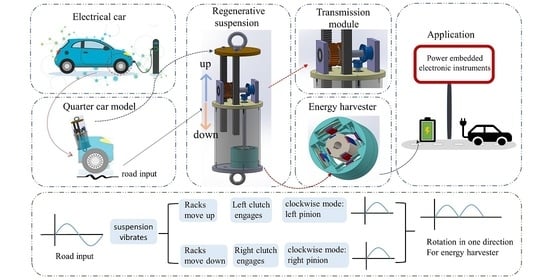

2. Design and Methods

2.1. Details of the Transmission Mechanism

2.2. The Piezoelectric Harvester Module

3. Parametric Study

4. Experimental Setup

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RMS | root mean square |

| MPVEH | magnetically coupled piezoelectric vibration energy harvester |

| PZT | lead zirconate titanate |

References

- Campbell, S.; O’Mahony, N.; Krpalcova, L.; Riordan, D.; Walsh, J.; Murphy, A.; Ryan, C. Sensor technology in autonomous vehicles: A review. In Proceedings of the 2018 29th Irish Signals and Systems Conference (ISSC), Belfast, UK, 21–22 June 2018; pp. 1–4. [Google Scholar]

- Ignatious, H.A.; Hesham-El-Sayed; Khan, M. An overview of sensors in Autonomous Vehicles. Procedia Comput. Sci. 2022, 198, 736–741. [Google Scholar] [CrossRef]

- Morangueira, Y.L.; Pereira, J.C.d.C. Energy harvesting assessment with a coupled full car and piezoelectric model. Energy 2020, 210, 118668. [Google Scholar] [CrossRef]

- Hartley, J.; McLellan, R.; Richmond, J.; Day, A.; Campean, I. Regenerative braking system evaluation on a full electric vehicle. In Innovations in Fuel Economy and Sustainable Road Transport; Elsevier: Amsterdam, The Netherlands, 2011; pp. 73–86. [Google Scholar]

- Lv, C.; Zhang, J.; Li, Y.; Yuan, Y. Mechanism analysis and evaluation methodology of regenerative braking contribution to energy efficiency improvement of electrified vehicles. Energy Convers. Manag. 2015, 92, 469–482. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, G. New evaluation methodology of regenerative braking contribution to energy efficiency improvement of electric vehicles. Energy Convers. Manag. 2016, 119, 389–398. [Google Scholar] [CrossRef]

- Neelakantan, V.A. Modeling, Design, Testing and Control of a Two-Stage Actuation Mechanism Using Piezoelectric Actuators for Automotive Applications; The Ohio State University: Columbus, OH, USA, 2005. [Google Scholar]

- Wang, Z.; Zhang, T.; Zhang, Z.; Yuan, Y.; Liu, Y. A high-efficiency regenerative shock absorber considering twin ball screws transmissions for application in range-extended electric vehicles. Energy Built Environ. 2020, 1, 36–49. [Google Scholar] [CrossRef]

- Zhang, J.-Q.; Peng, Z.-Z.; Zhang, L.; Zhang, Y. A review on energy-regenerative suspension systems for vehicles. In Proceedings of the World Congress on Engineering, London, UK, 3–5 July 2013; Volume 3, pp. 3–5. [Google Scholar]

- Van Schaijk, R.; Elfrink, R.; Oudenhoven, J.; Pop, V.; Wang, Z.; Renaud, M. A MEMS vibration energy harvester for automotive applications. In Proceedings of the International Society for Optics and Photonics, Smart Sensors, Actuators, and MEMS VI, Grenoble, France, 24–26 April 2013; Volume 8763, p. 876305. [Google Scholar]

- Cheah, L.; Evans, C.; Bandivadekar, A.; Heywood, J. Factor of two: Halving the fuel consumption of new US automobiles by 2035. In Reducing Climate Impacts in the Transportation Sector; Springer: Berlin, Germany, 2008; pp. 49–71. [Google Scholar]

- Ali, M.K.A.; Hou, X.; Mai, L.; Chen, B.; Turkson, R.F.; Cai, Q. Reducing frictional power losses and improving the scuffing resistance in automotive engines using hybrid nanomaterials as nano-lubricant additives. Wear 2016, 364, 270–281. [Google Scholar] [CrossRef]

- Zhang, X.; Mi, C. Vehicle Power Management: Modeling, Control and Optimization; Springer Science & Business Media: Heidelberg/Berlin, Germany; New York, NY, USA, 2011. [Google Scholar]

- Ali, M.K.A.; Hou, X.; Elagouz, A.; Essa, F.; Abdelkareem, M.A. Minimizing of the boundary friction coefficient in automotive engines using Al2O3 and TiO2 nanoparticles. J. Nanopartic. Res. 2016, 18, 1–16. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Xu, L.; Ali, M.K.A.; Elagouz, A.; Mi, J.; Guo, S.; Liu, Y.; Zuo, L. Vibration energy harvesting in automotive suspension system: A detailed review. Appl. Energy 2018, 229, 672–699. [Google Scholar] [CrossRef]

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Fontaras, G.; Zacharof, N.G.; Ciuffo, B. Fuel consumption and CO2 emissions from passenger cars in Europe–Laboratory versus real-world emissions. Prog. Energy Combust. Sci. 2017, 60, 97–131. [Google Scholar] [CrossRef]

- Khoshnoud, F.; Zhang, Y.; Shimura, R.; Shahba, A.; Jin, G.; Pissanidis, G.; Chen, Y.K.; De Silva, C.W. Energy regeneration from suspension dynamic modes and self-powered actuation. IEEE/ASME Trans. Mechatron. 2015, 20, 2513–2524. [Google Scholar] [CrossRef] [Green Version]

- Suda, Y.; Shiiba, T. A new hybrid suspension system with active control and energy regeneration. Veh. Syst. Dyn. 1996, 25, 641–654. [Google Scholar] [CrossRef]

- Naruse, Y.; Matsubara, N.; Mabuchi, K.; Izumi, M.; Suzuki, S. Electrostatic micro power generation from low-frequency vibration such as human motion. J. Micromech. Microeng. 2009, 19, 094002. [Google Scholar] [CrossRef]

- Deterre, M.; Risquez, S.; Bouthaud, B.; Dal Molin, R.; Woytasik, M.; Lefeuvre, E. Multilayer out-of-plane overlap electrostatic energy harvesting structure actuated by blood pressure for powering intra-cardiac implants. J. Phys. Conf. Ser. 2013, 476, 012039. [Google Scholar] [CrossRef] [Green Version]

- Zuo, L.; Zhang, P.S. Energy harvesting, ride comfort, and road handling of regenerative vehicle suspensions. J. Vib. Acoust. 2013, 135, 011002. [Google Scholar] [CrossRef]

- Kim, Y.; Hwang, W.; Kee, C.; Yi, H. Active vibration control of a suspension system using an electromagnetic damper. Proc. Inst. Mech. Eng. Part J. Automob. Eng. 2001, 215, 865–873. [Google Scholar] [CrossRef]

- El-Sayed, A.R.; Tai, K.; Biglarbegian, M.; Mahmud, S. A survey on recent energy harvesting mechanisms. In Proceedings of the 2016 IEEE Canadian conference on electrical and computer engineering (CCECE), Vancouver, BC, Canada, 15–18 May 2016; pp. 1–5. [Google Scholar]

- Karnopp, D. Permanent magnet linear motors used as variable mechanical dampers for vehicle suspensions. Veh. Syst. Dyn. 1989, 18, 187–200. [Google Scholar] [CrossRef]

- Nakano, K.; Suda, Y.; Nakadai, S. Self-powered active vibration control using a single electric actuator. J. Sound Vib. 2003, 260, 213–235. [Google Scholar] [CrossRef]

- Li, Z.; Zuo, L.; Luhrs, G.; Lin, L.; Qin, Y.x. Electromagnetic energy-harvesting shock absorbers: Design, modeling, and road tests. IEEE Trans. Veh. Technol. 2012, 62, 1065–1074. [Google Scholar] [CrossRef]

- Nakano, K. Combined type self-powered active vibration control of truck cabins. Veh. Syst. Dyn. 2004, 41, 449–473. [Google Scholar] [CrossRef]

- Salman, W.; Qi, L.; Zhu, X.; Pan, H.; Zhang, X.; Bano, S.; Zhang, Z.; Yuan, Y. A high-efficiency energy regenerative shock absorber using helical gears for powering low-wattage electrical device of electric vehicles. Energy 2018, 159, 361–372. [Google Scholar] [CrossRef]

- Li, Z.; Zuo, L.; Kuang, J.; Luhrs, G. Energy-harvesting shock absorber with a mechanical motion rectifier. Smart Mater. Struct. 2012, 22, 025008. [Google Scholar] [CrossRef]

- Li, H.; Zheng, P.; Zhang, T.; Zou, Y.; Pan, Y.; Zhang, Z.; Azam, A. A high-efficiency energy regenerative shock absorber for powering auxiliary devices of new energy driverless buses. Appl. Energy 2021, 295, 117020. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, L.; Zuo, L. Design, modeling, lab, and field tests of a mechanical-motion-rectifier-based energy harvester using a ball-screw mechanism. IEEE/ASME Trans. Mechatron. 2017, 22, 1933–1943. [Google Scholar] [CrossRef]

- Liu, Y.G.; Zhang, Z.T.; Chen, W.W.; Ke, X.T.; Zhang, X.T.; Pan, H.Y.; Liu, X.L. A Regenerative Vehicle Shock Absorber. Chinese Patent CN105114503, 6 September 2015. [Google Scholar]

- Zhang, Z.; Zhang, X.; Chen, W.; Rasim, Y.; Salman, W.; Pan, H.; Yuan, Y.; Wang, C. A high-efficiency energy regenerative shock absorber using supercapacitors for renewable energy applications in range extended electric vehicle. Appl. Energy 2016, 178, 177–188. [Google Scholar] [CrossRef]

- Roundy, S.; Wright, P.K. A piezoelectric vibration based generator for wireless electronics. Smart Mater. Struct. 2004, 13, 1131. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Z.; Wang, T.; Shi, J.; Zhang, B.; Zhang, R.; Li, M.; Wen, Y. Analysis and application of the piezoelectric energy harvester on light electric logistics vehicle suspension systems. Energy Sci. Eng. 2019, 7, 2741–2755. [Google Scholar] [CrossRef] [Green Version]

- Darabseh, T.; Al-Yafeai, D.; Mourad, A.H.I.; Almaskari, F. Piezoelectric method-based harvested energy evaluation from car suspension system: Simulation and experimental study. Energy Sci. Eng. 2021, 9, 417–433. [Google Scholar] [CrossRef]

- Lee, H.; Jang, H.; Park, J.; Jeong, S.; Park, T.; Choi, S. Design of a piezoelectric energy-harvesting shock absorber system for a vehicle. Integr. Ferroelectr. 2013, 141, 32–44. [Google Scholar] [CrossRef]

- Xie, X.; Wang, Q. Energy harvesting from a vehicle suspension system. Energy 2015, 86, 385–392. [Google Scholar] [CrossRef]

- Alhumaid, S.; Hess, D.; Guldiken, R. Energy regeneration from vehicle unidirectional suspension system by a non-contact piezo-magneto harvester. Eng. Res. Express 2021, 3, 015033. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, T.; Zhang, B.; Shi, J. Energy Harvesting from Vehicle Suspension System by Piezoelectric Harvester. Math. Probl. Eng. 2019, 2019, 1086983. [Google Scholar] [CrossRef] [Green Version]

- Zhao, L.C.; Zou, H.X.; Yan, G.; Liu, F.R.; Tan, T.; Wei, K.X.; Zhang, W.M. Magnetic coupling and flextensional amplification mechanisms for high-robustness ambient wind energy harvesting. Energy Convers. Manag. 2019, 201, 112166. [Google Scholar] [CrossRef]

- Al-Ashtari, W.; Hunstig, M.; Hemsel, T.; Sextro, W. Frequency tuning of piezoelectric energy harvesters by magnetic force. Smart Mater. Struct. 2012, 21, 035019. [Google Scholar] [CrossRef]

- k&J Magnetics. The Original K&J Magnet Calculator. 2011. Available online: https://www.kjmagnetics.com/calculator.asp (accessed on 28 February 2022).

| Parameter | Value |

|---|---|

| The rack module | 1.5 |

| The pinion module | 1.5 |

| The pinion gear pitch diameter | 45 mm |

| The speed ratio of the bevel gears |

| Parameter | Value |

|---|---|

| Piezoelectric disk bender | |

| Brass Diameter | 35 mm |

| Ceramic Diameter | 25 mm |

| Overall Thickness | 0.55 mm |

| Brass Thickness | 0.3 mm |

| Magnet | |

| The residuals flux density | 1.3 T |

| Magnet’s thickness | 3.175 mm |

| Magnet’s width | 9.525 mm |

| Magnet’s length | 25.4 mm |

| Magnet’s volume | 768.14 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhumaid, S.; Hess, D.; Guldiken, R. A Noncontact Magneto–Piezo Harvester-Based Vehicle Regenerative Suspension System: An Experimental Study. Energies 2022, 15, 4476. https://doi.org/10.3390/en15124476

Alhumaid S, Hess D, Guldiken R. A Noncontact Magneto–Piezo Harvester-Based Vehicle Regenerative Suspension System: An Experimental Study. Energies. 2022; 15(12):4476. https://doi.org/10.3390/en15124476

Chicago/Turabian StyleAlhumaid, Saleh, Daniel Hess, and Rasim Guldiken. 2022. "A Noncontact Magneto–Piezo Harvester-Based Vehicle Regenerative Suspension System: An Experimental Study" Energies 15, no. 12: 4476. https://doi.org/10.3390/en15124476

APA StyleAlhumaid, S., Hess, D., & Guldiken, R. (2022). A Noncontact Magneto–Piezo Harvester-Based Vehicle Regenerative Suspension System: An Experimental Study. Energies, 15(12), 4476. https://doi.org/10.3390/en15124476