Resource Efficiency and Thermal Comfort of 3D Printable Concrete Building Envelopes Optimized by Performance Enhancing Insulation: A Numerical Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Model Development

2.2. DPC Mix Designs

2.3. Insulation Materials

2.4. Thermal Transmittance of 3DPC Mix Designs

2.5. Energy Simulation and Optimization Analysis

3. Results and Discussion

3.1. Energy Efficiency and Thermal Comfort Performance

3.2. Operational Carbon Emissions

3.3. The U-Value Effect

4. Conclusions

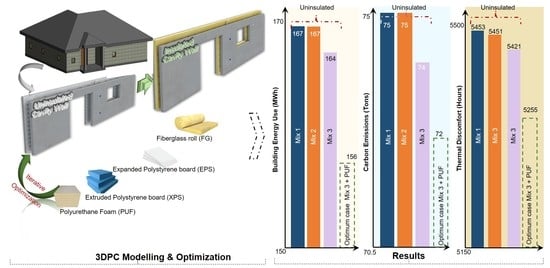

- The polyurethane-insulated wall element saved approximately 9500 KW more energy than the uninsulated models and 1400 KW more than the walls with expanded polystyrene, extruded polystyrene, and fiberglass insulations.

- The analysis also indicated that the PUF-insulated walls lowered summer carbon emissions by an average of 2096 kg and 2800 kg compared to the insulated and uninsulated models, respectively.

- The PUF-insulated building required 187 h less mechanical cooling through the year than the uninsulated envelopes and showed a slight decrease in discomfort hours compared to other insulated models.

- Additionally, the research showed that 3DPC building fabrics with low thermal transmittance make for more habitable and resource-efficient buildings.

- Ultimately, the results characterize the energy-saving potential of PUF-insulated 3D Printed Fiber Reinforced Engineered Cementitious Concrete (3DPFRECC) walls as an optimal combination for sustainable construction. Although the variation in the ecological performance between the insulated and control 3DPC models seems marginal over a one-year span, the cumulative difference would add up to a significant amount of GHG emissions and energy use over the structure’s lifespan.

- Based on the results in this study, it is safe to say that similar improvements in thermal and energy efficiency can be achieved by extending the applicability of polyurethane insulation to other concrete technologies such as cast-in-place concrete walls.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bock, T. The Future of Construction Automation: Technological Disruption and the Upcoming Ubiquity of Robotics. Autom. Constr. 2015, 59, 113121. [Google Scholar] [CrossRef]

- Beyhan, F.; Selçuk, S.A. 3D Printing in Architecture: One Step Closer to a Sustainable Built Environment. Lect. Notes Civ. Eng. 2018, 20, 253–268. [Google Scholar]

- Anjum, T.; Dongre, P.; Misbah, F.; Nanyam, V.P.S.N. Purview of 3DP in the Indian Built Environment Sector. Procedia Eng. 2017, 196, 228–235. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M.; Guerra, F. 3D Printing: State-of-the-art and Future Perspectives. J. Cult. Herit. 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental Study on Mix Proportion and Fresh Properties of Fly Ash Based Geopolymer for 3D Concrete Printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Gatheeshgar, P.; Upasiri, I.; Poologanathan, K.; Nagaratnam, B.; Rajanayagam, H.; Navaratnam, S. Numerical Study of Fire and Energy Performance of Innovative Light-Weight 3D Printed Concrete Wall Configurations in Modular Building System. Sustainability 2021, 13, 2314. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Y.; Zhang, C.; Zhou, H. Energy-Saving Potential of 3D Printed Concrete Building with Integrated Living Wall. Energy Build. 2020, 222, 110110. [Google Scholar] [CrossRef]

- Perkins, I.; Skitmore, M. Three-dimensional Printing in the Construction Industry: A Review. Int. J. Constr. Manag. 2015, 15, 1–9. [Google Scholar] [CrossRef] [Green Version]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti, I.J. Vision of 3D Printing with Concrete—Technical, Economic and Environmental Potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Mahadevan, M.; Francis, A.; Thomas, A. A Simulation-Based Investigation of Sustainability Aspects of 3D Printed Structures. J. Build. Eng. 2020, 32, 101735. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, J.; Li, Z.; Feng, X. Experimental Study on the Thermal Performance of a 3D Printed Concrete Prototype Building. Energy Build. 2021, 241, 110965. [Google Scholar] [CrossRef]

- Paul, S.C.; Van Zijl, G.P.; Tan, M.J.; Gibson, I. A Review of 3D Concrete Printing Systems and Materials Properties: Current Status and Future Research Prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef] [Green Version]

- Rushing, T.S.; Stynoski, P.B.; Barna, L.A.; Al-Chaar, G.K.; Burroughs, J.F.; Shannon, J.D.; Kreiger, M.A.; Case, M.P. Investigation of Concrete Mixtures for Additive Construction. In 3D Concrete Printing Technology; Elsevier: Oxford, UK, 2019; pp. 137–160. [Google Scholar]

- Wolfs, R.; Bos, F.; Salet, T. Early Age Mechanical Behaviour of 3D Printed Concrete: Numerical Modelling and Experimental Testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Zak, G.; Haberer, M.; Park, C.B.; Benhabib, B. Mechanical Properties of Short-Fibre Layered Composites: Prediction and Experiment. Rapid Prototyp. J. 2000, 6, 107–118. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, J.H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Microstructural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef]

- Kim, K.; Park, S.; Kim, W.S.; Jeong, Y.; Lee, J. Evaluation of Shear Strength of RC Beams with Multiple Interfaces Formed Before Initial Setting Using 3D Printing Technology. Materials 2017, 10, 12. [Google Scholar] [CrossRef] [Green Version]

- Marais, H.; Christen, H.; Cho, S.; De Villiers, W.; Van Zijl, G. Computational Assessment of Thermal Performance of 3D Printed Concrete Wall Structures with Cavities. J. Build Eng. 2021, 41, 102431. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Liu, Z.; Lao, W.; Lu, B.; Zhang, D.; Tan, M.J. Printability and Fire Performance of a Developed 3D Printable Fiber Reinforced Cementitious Composites Under Elevated Temperatures. Virtual Phys. Prototyp. 2019, 14, 284–292. [Google Scholar] [CrossRef]

- Zhu, B.; Pan, J.; Nematollahi, B.; Zhou, Z.; Zhang, Y.; Sanjayan, J. Development of 3D Printable Engineered Cementitious Composites with Ultra-High Tensile Ductility for Digital Construction. Mater. Des. 2019, 181, 108088. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M. Digital Concrete Opportunities and Challenges. RILEM Tech. Lett. 2016, 1, 67–75. [Google Scholar] [CrossRef]

- Inozemtcev, A.; Korolev, E.; Qui, D.T. Study of Mineral Additives for Cement Materials for 3D—Printing in Construction. IOP Conf. Ser. Mater. Sci. Eng. 2018, 356, 032009. [Google Scholar] [CrossRef]

- Nerella, V.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline Quantification of Extrudability of Cementitious Materials for Digital Construction. Cem. Concr. Compos. 2019, 95, 260–270. [Google Scholar] [CrossRef]

- Malaeb, A.; Tourbah, F.; Hamzeh, O. 3D Concrete Printing: Machine and Mix Design. 3D Conc. Print. Technol. 2015, 1, 15–136. [Google Scholar]

- Kashani, A.; Ngo, T. Optimisation of Mixture Properties for 3D Printing of Geopolymer Concrete—Department of Infrastructure Engineering, The University of Melbourne, Australia. In Proceedings of the 35th ISARC, Berlin, Germany, 20–25 July 2018; pp. 259–266. [Google Scholar]

- Kaszyńska, M.; Skibicki, S.; Hoffmann, M. 3D Concrete Printing for Sustainable Construction. Energies 2020, 13, 6351. [Google Scholar] [CrossRef]

- Robati, M.; McCarthy, T.J.; Kokogiannakis, G. Incorporating Environmental Evaluation and Thermal Properties of Concrete Mix Designs. Constr. Build. Mater. 2016, 128, 422–435. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Chiang, P.C.; Cai, Y.; Li, C.; Wang, X.; Chen, T.L.; Wei, S.; Huang, Q. Application of Wall and Insulation Materials on Green Building: A Review. Sustainability 2018, 10, 3331. [Google Scholar] [CrossRef] [Green Version]

- Zuo, J.; Zhao, Z.-Y. Green Building Research–Current Status and Future Agenda: A Review. Renew. Sustain. Energy Rev. 2014, 30, 271–281. [Google Scholar] [CrossRef]

- Roldan, L.V.; Perez, L.G.; Amores, L.F.; Ibarra, A. Potential Use of Vegetal Biomass as Insulation in Extreme Climates of Ecuador. Enfoque UTE 2015, 6, 23–41. [Google Scholar]

- Tangjuank, S. Thermal Insulation and Physical Properties of Particle Boards from Pineapple Leaves. Int. J. Phys. Sci. 2011, 6, 4528–4532. [Google Scholar]

- Huang, H.; Zhou, Y.; Huang, R.; Wu, H.; Sun, Y.; Huang, G.; Xu, T. Optimum Insulation Thicknesses and Energy Conservation of Building Thermal Insulation Materials in Chinese Zone of Humid Subtropical Climate. Sustain. Cities Soc. 2020, 52, 101840. [Google Scholar] [CrossRef]

- Chen, S.A. Green Building Information Modelling Approach: Building Energy Performance Analysis and Design Optimization. MATEC Web Conf. 2018, 169, 01004. [Google Scholar] [CrossRef] [Green Version]

- Pomfret, L.; Hashemi, A. Thermal Comfort in Zero Energy buildings. Energy Procedia 2017, 134, 825–834. [Google Scholar] [CrossRef] [Green Version]

- Latha, P.K.; Darshana, Y.; Venugopal, V. Role of Building Material in Thermal Comfort in Tropical Climates—A Review. J. Build. Eng. 2015, 3, 104–113. [Google Scholar] [CrossRef]

- Abanda, F.H.; Byers, L. An Investigation of the Impact of Building Orientation on Energy Consumption in a Domestic Building Using Emerging BIM (Building Information Modelling). J. Energy 2016, 97, 517–527. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix Design and Fresh Properties for High—Performance Printing Concrete. Mater. Struct. Constr. 2012, 45, 1221–1232. [Google Scholar] [CrossRef] [Green Version]

- Law, R.; Buswell, R.A.; Austin, S.A.; Le, T.T.; Gibb, A.G.F.; Lim, S.; Thorpe, T. Hardened Properties of High—Performance Printing Concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar]

- Bao, Y.; Xu, M.; Soltan, D.; Xia, T.; Shih, A.; Clack, H.L.; Li, V.C. Three-dimensional Printing Multifunctional Engineered Cementitious Composites (ECC) for Structural Elements. In Proceedings of the RILEM International Conference on Concrete and Digital Fabrication, Zurich, Switzerland, 9–12 September 2018; pp. 115–128. [Google Scholar]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Ahmed, R. Comparative Analysis of Building Insulation Material Properties and Performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Aisyah, S.; Mustapa, S.; Khairi, M.; Rashid, A. Application of Expanded Polystyrene (EPS) in Buildings and Constructions: A Review. J. Appl. Polym. Sci. 2019, 136, 47529. [Google Scholar]

- Schackow, A.; Effting, C.; Folgueras, M.V.; Güths, S.; Mendes, G.A. Mechanical and Thermal Properties of Lightweight Concretes with Vermiculite and EPS Using Air-Entraining Agent. Constr. Build. Mater. 2014, 57, 190–197. [Google Scholar] [CrossRef]

- Sariisik, A.; Sariisik, G. New Production Process for Insulation Blocks Composed of EPS and Lightweight Concrete Containing Pumice Aggregate. Mater. Struct. 2012, 45, 1345–1357. [Google Scholar] [CrossRef]

- Papadopoulos, A.M. State of the Art in Thermal Insulation Materials and Aims for Future Developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Yang, C.; Fischer, L.; Maranda, S.; Worlitschek, J. Rigid Polyurethane Foams Incorporated with Phase Change Materials: A State-of-the-Art Review and Future Research Pathways. Energy Build. 2015, 87, 25–36. [Google Scholar] [CrossRef]

- Lee, Y.; Choi, S.; Choe, K.; Kim, S. Physical And Mechanical Characteristics of Polyurethane Foam Insulators Blown By HFC. In Proceedings of the Fifteenth International Offshore and Polar Engineering Conference, Seoul, Korea, 19 June 2005; p. ISOPE-I-05-424. [Google Scholar]

- Roy, B. Glass-Wool Insulation: ECBC Compliance and Green Building Aspect. Key Eng. Mater. 2015, 632, 39–44. [Google Scholar] [CrossRef]

- Willoughby, J. Insulation. In Plant Engineer’s Reference Book, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2002; pp. 18–30. [Google Scholar]

- Kim, K.H.; Jeon, S.E.; Jin-Keun, K.; Yang, S. An Experimental Study on Thermal Conductivity of Concrete. Cem. Concr. Res. 2003, 33, 363–371. [Google Scholar] [CrossRef]

- Kosmatka, S.H.; Wilson, M.L. Fly Ash, Slag, Silica fume, and Natural Pozzolans. In Design and Control of Concrete Mixes, 15th ed.; Portland Cement Association: Skokie, IL, USA, 1996; pp. 57–72. [Google Scholar]

- Designbuilder. Available online: https://designbuilder.co.uk/training/tutorials (accessed on 9 September 2021).

- Bernardo, H.; Quintal, E.; Oliveira, F. Using a calibrated building energy simulation model to study the effects of improving the ventilation in a school. Energy Procedia 2017, 113, 151–157. [Google Scholar] [CrossRef]

- Blanco, J.M.; Buruaga, A.; Rojí, E.; Cuadrado, J.; Pelaz, B. Energy Assessment and Optimization of Perforated Metal Sheet Double Skin Facades Through Design Builder; A Case Study in Spain Skin Fac. Energy Build. 2016, 111, 326–336. [Google Scholar] [CrossRef]

- Emond, F.; Ahn, J.; Kim, J.; Kim, J. Computing Thermal Bridge of VIP in Building Retrofits Using DesignBuilder. Energy Procedia 2015, 78, 400–405. [Google Scholar]

- ANSI/ASHRAE Standard 55-2010: Thermal Environmental Conditions for Human Occupancy. Available online: https://www.ashrae.org (accessed on 9 September 2021).

| Materials | Mix Proportions [kg/m3] | ||

|---|---|---|---|

| Mix 1 | Mix 2 | Mix 3 | |

| Portland cement | 579 | 613.7 | 729 |

| Calcium aluminate cement | - | - | 55 |

| Fine Aggregate (Sand) | 1241 | 767.2 | 495 |

| Silica fume | 83 | 57.5 | 110 |

| Water | 232 | 402.8 | 400 |

| Fly ash | 165 | 287.7 | 253 |

| Water-cement ratio | 0.28 | 0.28 | 0.25 |

| Flour Silica | - | - | 55 |

| ANC, HRWA, VMA | - | - | 6,6,6 |

| PVA fiber | - | 21.29 | 26 |

| Source | [37] | [19] | [39] |

| Parameters | Values |

|---|---|

| Thermal conductivity of EPS | 0.035 (W/m.K) |

| Thermal conductivity of FG | 0.0465 (W/m.K) |

| Thermal conductivity of XPS | 0.03 (W/m.K) |

| Thermal conductivity of PUF | 0.028 (W/m.K) |

| Roof Insulation | 0.39 (W/m2K) |

| Floor insulation | 0.46 (W/m2K) |

| Infiltration rate | 0.7 (ac/h) |

| HVAC equipment | Fan coil unit (4-pipe) |

| Lighting power density | 5 W/m2 |

| Occupancy density | 55 m2/person |

| Mix Designs | Control Models | EPS | FG | XPS | PU |

|---|---|---|---|---|---|

| Mix 1 | P0 | InsP-1 | InsP-2 | InsP-3 | InsP-4 |

| Mix 2 | R0 | InsR-1 | InsR-2 | InsR-3 | InsR-4 |

| Mix 3 | S0 | InsS-1 | InsS-2 | InsS-3 | InsS-4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayegba, B.O.; Egbe, K.-J.I.; Matin Nazar, A.; Huang, M.; Hariri-Ardebili, M.A. Resource Efficiency and Thermal Comfort of 3D Printable Concrete Building Envelopes Optimized by Performance Enhancing Insulation: A Numerical Study. Energies 2022, 15, 1069. https://doi.org/10.3390/en15031069

Ayegba BO, Egbe K-JI, Matin Nazar A, Huang M, Hariri-Ardebili MA. Resource Efficiency and Thermal Comfort of 3D Printable Concrete Building Envelopes Optimized by Performance Enhancing Insulation: A Numerical Study. Energies. 2022; 15(3):1069. https://doi.org/10.3390/en15031069

Chicago/Turabian StyleAyegba, Blessing Onyeche, King-James Idala Egbe, Ali Matin Nazar, Mingzhi Huang, and Mohammad Amin Hariri-Ardebili. 2022. "Resource Efficiency and Thermal Comfort of 3D Printable Concrete Building Envelopes Optimized by Performance Enhancing Insulation: A Numerical Study" Energies 15, no. 3: 1069. https://doi.org/10.3390/en15031069

APA StyleAyegba, B. O., Egbe, K. -J. I., Matin Nazar, A., Huang, M., & Hariri-Ardebili, M. A. (2022). Resource Efficiency and Thermal Comfort of 3D Printable Concrete Building Envelopes Optimized by Performance Enhancing Insulation: A Numerical Study. Energies, 15(3), 1069. https://doi.org/10.3390/en15031069