Methods and Techniques for CO2 Capture: Review of Potential Solutions and Applications in Modern Energy Technologies

Abstract

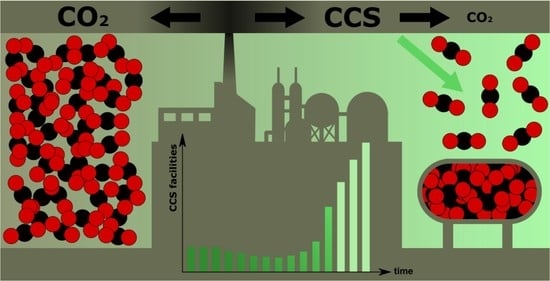

:1. Introduction

- Reducing the use of fossil fuels by:

- ○

- improving the efficiency of energy conversion processes;

- ○

- reducing the demand for energy;

- ○

- using renewable (non-fossil fuel) energy sources, such as hydropower, wind, biomass, solar cells, and nuclear power;

- ○

- increasing the use of green hydrogen, which is produced by splitting water using electricity from renewable energy.

- Replace technologies using fossil fuels with a low carbon to hydrogen C/H2 ratio by replacing coal and oil with gaseous fuels.

- Capturing CO2 from fuel combustion in power plants and other industrial processes and storing it in appropriate geological structures, in exhausted or exploited gas or crude oil deposits (intensification of crude oil extraction, enhanced oil recovery (EOR)), or at the bottom of oceans.

- Limiting deforestation processes and thus storing more CO2 in biomass.

- Pre-combustion carbon capture occurs before the combustion process (through fuel gasification with oxygen, e.g., integrated IGCC coal gasification technology).

- Post-combustion carbon capture occurs after the combustion process (capturing CO2 from flue gas, e.g., using chemical absorption, physical adsorption, membrane separation, or the use of a chemical loop).

- Oxy-combustion carbon capture occurs after the combustion process in an oxygen atmosphere by separating CO2 generated during the oxy-combustion process, e.g., using an oxygen gas turbine. Oxygen atmosphere can be obtained by removing nitrogen from the air before the combustion process.

2. Pre-Combustion CO2 Capture

3. Post-Combustion CO2 Capture

- (a)

- Absorption solvent-based methods

- (b) Adsorption–physical separation

- (c) Membrane separation

- (d) Chemical looping combustion (CLC) and calcium looping process (CLP)

- (e) Cryogenic method

- (f) Application of absorption-based post-combustion capture method

- (g) Converting CO2 into value-added chemicals

4. Oxy-Combustion CO2 Capture

5. Indicators for CO2 Emission Level Assessment

- Specific emission of carbon dioxide, (kgCO2/kWh):

- Relative emissivity of carbon dioxide, (kgCO2/kWh):

- CO2 capture ratio CCR (unitless):

- CO2 emission index, (kgCO2/kJ):

- CO2 captured (kgCO2/kWh):

- CO2 emitted (kgCO2/kWh):

- CO2 avoided (kgCO2/kWh):

- Specific primary energy consumption for CO2 avoided (kWh/kgCO2):

- Specific primary energy consumption cost for CO2 avoided (€/kgCO2):

- Levelized costs of electricity (USD/MWh):

6. Applications of CO2 Capture Technologies on a Large-Industrial Scale

7. Conclusions

- In the case of fossil-fueled power plants, there is a need to use carbon capture utilization and storage methods to reduce CO2 emissions, and, at the end, to minimize the impact of greenhouse gases on the environment.

- Currently, there are 27 CCUS commercial facilities with which the global CO2 capture potential is about 40 MtCO2/year, but this can increase by three times after launching announced CCUS units.

- Based on the prepared review, it can be concluded that most of the operating, large-scale, commercial CCUS facilities are connected with natural gas processing and use CO2 to enhance oil recovery.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Spliethoff, H. Power Generation from Solid Fuels; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Chmielniak, T. Technologie Energetyczn, 2nd ed.; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2021. [Google Scholar]

- Sarkar, S. Fuels and Combustion; University Press: New Delhi, India, 2009. [Google Scholar]

- Madejski, P. (Ed.) Thermal Power Plants, New Trends and Recent Developments; Intech Open Limited: London, UK, 2018; ISBN 978-1-78923-079-6. [Google Scholar] [CrossRef]

- Madejski, P.; Janda, T.; Modliński, N.; Nabagło, D. A Combustion Process Optimization and Numerical Analysis for the Low Emission Operation of Pulverized Coal-Fired Boiler. In Developments in Combustion Technology; Kyprianidis, K., Skvaril, J., Eds.; In Intech Open Limited: London, UK, 2016. [Google Scholar] [CrossRef] [Green Version]

- Energy Technology Perspectives 2020, Special Report on Carbon Capture Utilisation and Storage CCUS in Clean Energy Transitions; IEA: Paris, France, 2020; Available online: https://iea.blob.core.windows.net/assets/7f8aed40-89af-4348-be19-c8a67df0b9ea/Energy_Technology_Perspectives_2020_PDF.pdf (accessed on 2 December 2021).

- Centrum Informacji o Rynku Energii, Cena Emisji CO2 Może Wzrosnąć o Ponad 50% do 2030—Wynika z Projektu UE. Available online: https://www.cire.pl/artykuly/materialy-problemowe/186670-cena-emisji-co2-moze-wzrosnac-o-ponad-50-do-2030-wynika-z-projektu-ue (accessed on 20 October 2021).

- Nord, L.; Bolland, O. Carbon Dioxide Emission Management in Power Generation; Wiley-VCH Verlag GmbH & Co.: Weinheim, Germany, 2020. [Google Scholar]

- Peridas, G.; Mordick Schmidt, B. The role of carbon capture and storage in the race to carbon neutrality. Electr. J. 2021, 34, 106996. [Google Scholar] [CrossRef]

- Wienchol, P.; Szlȩk, A.; Ditaranto, M. Waste-to-energy technology integrated with carbon capture—Challenges and opportunities. Energy 2020, 198, 117352. [Google Scholar] [CrossRef]

- Holz, F.; Scherwath, T.; del Granado, P.C.; Skar, C.; Olmos, L.; Ploussard, Q.; Ramos, A.; Herbst, A. A 2050 perspective on the role for carbon capture and storage in the European power system and industry sector. Energy Econ. 2021, 104, 105631. [Google Scholar] [CrossRef]

- Gładysz, P.; Stanek, W.; Czarnowska, L.; Sładek, S.; Szlęk, A. Thermo-ecological evaluation of an integrated MILD oxy-fuel combustion power plant with CO2 capture, utilisation, and storage—A case study in Poland. Energy 2018, 144, 379–392. [Google Scholar] [CrossRef]

- Shijaz, H.; Attada, Y.; Patnaikuni, V.S.; Vooradi, R.; Anne, S.B. Analysis of integrated gasification combined cycle power plant incorporating chemical looping combustion for environment-friendly utilization of Indian coal. Energy Convers. Manag. 2017, 151, 414–425. [Google Scholar] [CrossRef]

- Mukherjee, S.; Kumar, P.; Yang, A.; Fennell, P. Energy and exergy analysis of chemical looping combustion technology and comparison with pre-combustion and oxy-fuel combustion technologies for CO2 capture. J. Environ. Chem. Eng. 2015, 3, 2104–2114. [Google Scholar] [CrossRef] [Green Version]

- Majchrzak-Kucęba, I.; Wawrzyńczak, D.; Zdeb, J.; Smółka, W.; Zajchowski, A. Treatment of flue gas in a CO2 capture pilot plant for a commercial CFB boiler. Energies 2021, 14, 2458. [Google Scholar] [CrossRef]

- Popa, A.; Edwards, R.; Aandi, I. Carbon capture considerations for combined cycle gas turbine. Energy Procedia 2011, 4, 2315–2323. [Google Scholar] [CrossRef] [Green Version]

- Tramošljika, B.; Blecich, P.; Bonefačić, I.; Glažar, V. Advanced ultra-supercritical coal-fired power plant with post-combustion carbon capture: Analysis of electricity penalty and CO2 emission reduction. Sustainability 2021, 13, 801. [Google Scholar] [CrossRef]

- Theo, W.L.; Lim, J.S.; Hashim, H.; Mustaffa, A.A.; Ho, W.S. Review of pre-combustion capture and ionic liquid in carbon capture and storage. Appl. Energy 2016, 183, 1633–1663. [Google Scholar] [CrossRef]

- Olabi, A.G.; Obaideen, K.; Elsaid, K.; Wilberforce, T.; Sayed, E.T.; Maghrabie, H.M.; Abdelkareem, M.A. Assessment of the pre-combustion carbon capture contribution into sustainable development goals SDGs using novel indicators. Renew. Sustain. Energy Rev. 2022, 153, 1117102022. [Google Scholar] [CrossRef]

- Wu, F.; Dellenback, P.A.; Fan, M. Highly efficient and stable calcium looping based pre-combustion CO2 capture for high-purity H2 production. Mater. Today Energy 2019, 13, 233–238. [Google Scholar] [CrossRef]

- Grande, C.A.; Blom, R.; Andreassen, K.A.; Stensrød, R.E. Experimental Results of Pressure Swing Adsorption (PSA) for Pre-combustion CO2 Capture with Metal Organic Frameworks. Energy Procedia 2017, 114, 2265–2270. [Google Scholar] [CrossRef]

- Wanga, Y.; Zhaoa, L.; Ottoa, A.; Robiniusa, M.; Stoltena, D. A Review of Post-combustion CO2 Capture Technologies from Coal-fired Power Plants. Energy Procedia 2017, 114, 650–665. [Google Scholar] [CrossRef]

- Kuropka, J. Możliwości Ograniczania Emisji Ditlenku Węgla ze Spalin Energetycznych. Available online: http://www.pzits.not.pl/docs/ksiazki/Pol_%202012/Kuropka%20179-188.pdf (accessed on 18 October 2021).

- Vega, F.; Cano, M.; Camino, S.; Fernandez, L.M.G.; Portillo, E.; Navarrete, B. Solvents for Carbon Dioxide Capture. In Carbon Dioxide Chemistry, Capture and Oil Recovery; Intechopen: London, UK, 2018; ISBN 978-1-78923-575-3. [Google Scholar] [CrossRef] [Green Version]

- Artanto, Y.; Jansen, J.; Pearson, P.; Puxty, G.; Cottrell, A.; Meuleman, E.; Feron, P. Pilot-scale evaluation of AMP/PZ to capture CO2 from flue gas of an Australian brown coal–fired power station. Int. J. Greenh. Gas Control 2014, 20, 189–195. [Google Scholar] [CrossRef]

- Boot-Handford, M.; Abanades, J.C.; Anthony, E.J.; Blunt, M.J.; Brandani, S.; Mac Dowell, N.; Fernández, J.R.; Ferrari, M.-C.; Gross, R.; Hallett, J.P.; et al. Carbon capture and storage update. Energy Environ. Sci. 2014, 7, 130–189. [Google Scholar] [CrossRef]

- Bui, M.; Adjiman, C.S.; Bardow, A.; Anthony, E.J.; Boston, A.; Brown, S.; Fennell, P.S.; Fuss, S.; Galindo, A.; Hackett, L.A.; et al. Carbon capture and storage (CCS): The way forward. Energy Environ. Sci. 2018, 11, 1062–1176. [Google Scholar] [CrossRef] [Green Version]

- Barzgali, F.; Lai, S.; Mani, F. Novel non-aqueous amine solvents for reversible CO2 capture. Energy Procedia 2014, 63, 1795–1804. [Google Scholar] [CrossRef]

- Mahi, M.; Mokbel, I.; Negadi, L.; Dergal, F.; Jose, J. Experimental solubility of carbon dioxide in monoethanolamine, or diethanolamine or N-methyldiethanolamine (30 wt%) dissolved in deep eutectic solvent (choline chloride and ethylene glycol solution). J. Mol. Liq. 2019, 289, 111062. [Google Scholar] [CrossRef]

- Sifat, N.S.; Haseli, Y. A critical review of CO2 Capture Technologies and Prospects for Clean Power Generetion. Energies 2019, 12, 4143. [Google Scholar] [CrossRef] [Green Version]

- Osman, A.I.; Hefny, M.; Maksoud, M.I.A.A.; Elgarahy, A.M.; Rooney, D.W. Recent advances in carbon capture storage and utilisation technologies: A review. Environ. Chem. Lett. 2020, 19, 797–849. [Google Scholar] [CrossRef]

- Li, J.-R.; Ma, Y.; McCarthy, M.C.; Sculley, J.; Yu, J.; Jeong, H.-K.; Balbuena, P.B.; Zhou, H.-C. Carbon dioxide capture-related gas adsorption and separation in metal-organic frameworks. Coord. Chem. Rev. 2011, 255, 1791–1823. [Google Scholar] [CrossRef]

- Pires, J.C.M.; Martins, F.G.; Alvim-Ferraz, M.C.M.; Simões, M. Recent developments on carbon capture and storage: An overview. Chem. Eng. Res. Des. 2011, 89, 1446–1460. [Google Scholar] [CrossRef]

- Kárászová, M.; Zach, B.; Petrusová, Z.; Červenka, V.; Bobák, M.; Šyc, M.; Izák, P. Post-combustion carbon capture by membrane separation, Review. Sep. Purif. Technol. 2020, 238, 116448. [Google Scholar] [CrossRef]

- Rakowski, J.; Bocian, P.; Celińska, A.; Świątkowski, B.; Golec, T. Zastosowanie Pętli Chemicznej w Energetyce. Available online: http://elektroenergetyka.pl/upload/file/2016/4/Rakowski_04_2016.pdf (accessed on 15 October 2021).

- Bhavsar, S.; Najera, M.; More, A.; Veser, G. Chemical-looping processes for fuel-flexible combustion and fuel production. In Reactor and Process Design in Sustainable Energy Technology, 1st ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2014; pp. 233–280. [Google Scholar] [CrossRef]

- Tilak, P.; El-Halwagi, M.M. Process integration of Calcium Looping with industrials plants for monetizing CO2 into value-added products. Carbon Resour. Convers. 2018, 1, 191–199. [Google Scholar] [CrossRef]

- Knapik, E.; Kosowski, P.; Stopa, J. Cryogenic liquefaction and separation of CO2 using nitrogen removal unit cold energy. Chem. Eng. Res. Des. 2018, 131, 66–79. [Google Scholar] [CrossRef]

- Song, C.; Liu, Q.; Deng, S.; Li, H.; Kitamura, Y. Cryogenic-based CO2 capture technologies: State-of-the-art developments and current challenges. Renew. Sustain. Energy Rev. 2019, 101, 265–278. [Google Scholar] [CrossRef]

- Mostafavi, E.; Ashrafi, O.; Navarri, P. Assessment of process modifications for amine-based post-combustion carbon capture processes. Clean. Eng. Technol. 2021, 4, 100249. [Google Scholar] [CrossRef]

- Chao, C.; Deng, Y.; Dewil, R.; Baeyens, J.; Fan, X. Post-combustion carbon capture. Renew. Sustain. Energy Rev. 2021, 138, 110490. [Google Scholar] [CrossRef]

- Lungkadee, T.; Onsree, T.; Tangparitkul, S.; Janwiruch, N.; Nuntaphan, A.; Tippayawong, N. Technical and economic analysis of retrofitting a post-combustion carbon capture system in a Thai coal-fired power plant. Energy Rep. 2021, 7, 308–313. [Google Scholar] [CrossRef]

- Otitoju, O.; Oko, E.; Wang, M. Technical and economic performance assessment of post-combustion carbon capture using piperazine for large scale natural gas combined cycle power plants through process simulation. Appl. Energy 2021, 292, 116893. [Google Scholar] [CrossRef]

- El Hadri, N.; Quang, D.V.; Goetheer, E.L.V.; Abu Zahra, M.R.M. Aqueous amine solution characterization for post-combustion CO2 capture process. Appl. Energy 2017, 185, 1433–1449. [Google Scholar] [CrossRef]

- Zhang, Z.; Pan, S.-Y.; Li, H.; Cai, J.; Olabi, A.G.; Anthony, E.J.; Manovic, V. Recent advances in carbon dioxide utilization. Renew. Sustain. Energy Rev. 2020, 125, 109799. [Google Scholar] [CrossRef]

- Agarwal, A.S.; Rode, E.; Sridhar, N.; Hill, D. Conversion of CO2 to Value-Added Chemicals: Opportunities and Challenges. In Handbook Climate Change Mitigigation and Adaptation; Chen, W.Y., Suzuki, T., Lackner, M., Eds.; Springer: New York, NY, USA, 2015; pp. 1–40. [Google Scholar] [CrossRef]

- Pal, T.K.; De, D.; Bharadwaj, P.K. Metal–organic frameworks for the chemical fixation of CO2 into cyclic carbonates. Coord. Chem. Rev. 2020, 408, 213173. [Google Scholar] [CrossRef]

- Kumaravel, V.; Barlett, J.; Pillai, S.C. Photoelectrochemical Conversion of Carbon Dioxide (CO2) into Fuels and Value Added Products. ACS Energy Lett. 2020, 5, 486–529. [Google Scholar] [CrossRef] [Green Version]

- McGrath, O.J. Biological Conversion of Carbon Dioxide to Value-Added Chemicals. Grad. Thesis Diss. Probl. Rep. 2021, 8293. [Google Scholar] [CrossRef]

- Nocito, F.; Dibenedetto, A. Atmospheric CO2 mitigation technologies: Carbon capture utilization and storage. Curr. Opin. Green Sustain. Chem. 2020, 21, 34–43. [Google Scholar] [CrossRef]

- CS Energy, Callide Oxyfuel Project. Available online: https://www.csenergy.com.au/what-we-do/generating-energy/callide-power-station/callide-oxyfuel-project (accessed on 20 October 2021).

- Global CCS Institue. The Compostilla Project OXYCFB300. Available online: https://www.globalccsinstitute.com/archive/hub/publications/137158/Compostilla-project-OXYCFB300-carbon-capture-storage-demonstration-project-knowledge-sharing-FEED-report.pdf (accessed on 20 October 2021).

- Project Negative CO2 Emission Gas Power Plant. Available online: https://nco2pp.mech.pg.gda.pl (accessed on 20 October 2021).

- Ziółkowski, P.; Madejski, P.; Amiri, M.; Kuś, T.; Stasiak, K.; Subramanian, N.; Pawlak-Kruczek, H.; Badur, J.; Niedźwiecki, Ł.; Mikielewicz, D. Thermodynamic Analysis of Negative CO2 Emission Power Plant Using Aspen Plus, Aspen Hysys, and Ebsilon Software. Energies 2021, 14, 6304. [Google Scholar] [CrossRef]

- Ziółkowski, P.; Badur, J.; Pawlak-Kruczek, H.; Niedzwiecki, L.; Kowal, M.; Krochmalny, K. A novel concept of negative CO2 emission power plant for utilization of sewage sludge. In Proceedings of the 6th International Conference on Contemporary Problems of Thermal Engineering CPOTE 2020, Gliwice, Poland, 21–24 September 2020; pp. 531–542. [Google Scholar]

- Cormos, C.C. Oxy-combustion of coal, lignite and biomass: A techno-economic analysis for a large scale Carbon Capture and Storage (CCS) project in Romania. Fuel 2016, 169, 50–57. [Google Scholar] [CrossRef]

- Kindra, V.; Rogalev, A.; Lisin, E.; Osipov, S.; Zlyvko, O. Techno-economic analysis of the oxy-fuel combustion power cycles with near-zero emissions. Energies 2021, 14, 5358. [Google Scholar] [CrossRef]

- Bonalumi, D.; Valenti, G.; Lillia, S.; Fosbol, P.L.; Thomsen, K. A layout for the Carbon Capture with Aqueous Ammonia without Salt Precipitation. Energy Procedia 2016, 86, 134–143. [Google Scholar] [CrossRef] [Green Version]

- Voldsund, M.; Gardarsdottir, S.O.; De Lena, E.; Pérez-Calvo, J.-F.; Jamali, A.; Berstad, D.; Fu, C.; Romano, M.; Roussanaly, S.; Anantharaman, R.; et al. Comparison of Technologies for CO2 Capture from Cement Production—Part 1: Technical Evaluation. Energies 2019, 12, 559. [Google Scholar] [CrossRef] [Green Version]

- Roussanaly, S.; Anantharaman, R. Cost-optimal CO2 capture ratio for membrane-based capture from different CO2 sources. Chem. Eng. J. 2017, 327, 618–628. [Google Scholar] [CrossRef] [Green Version]

- Manzolini, G.; Giuffrida, A.; Cobden, P.D.; van Dijk, H.A.J.; Ruggeri, F.; Consonni, F. Techno-economic assessment of SEWGS technology when applied to integrated steel-plant for CO2 emission mitigation. Int. J. Greenh. Gas Control 2020, 94, 102935. [Google Scholar] [CrossRef]

- Chiesa, P.; Campanari, S.; Manzolini, G. CO2 cryogenic separation from combined cycles integrated with molten carbonate fuel cells. Int. J. Hydrogen Energy 2011, 36, 10355–10365. [Google Scholar] [CrossRef]

- International Energy Agency. Projected Costs of Generating Electricity; OECD Publishing: Paris Cedex, France, 2020. [Google Scholar]

- Carbon Capture, Utilization and Storage, IEA 2021. Available online: https://www.iea.org/fuels-and-technologies/carbon-capture-utilisation-and-storage (accessed on 2 December 2021).

- An Analysis Based on GCCSI (2020), Facilities Database. Available online: https://co2re.co/FacilityData (accessed on 20 October 2021).

- Global CCS Institute. The Global Status of CCS 2019: Targeting Climate Change. Available online: www.globalccsinstitute.com (accessed on 2 December 2021).

- Carbon Capture & Sequestration Technologies. Available online: https://sequestration.mit.edu/tools/projects/sleipner.html (accessed on 2 December 2021).

- Global Institute. Global Status of CCS 2021 CCS Accelerating to Net Zero. Report. Available online: https://www.globalccsinstitute.com/resources/global-status-report/ (accessed on 2 December 2021).

- CCUS in Power. Report. IEA 2021. Available online: https://www.iea.org/reports/ccus-in-power (accessed on 2 December 2021).

- CCUS in Industry and Transformation. IEA 2021. Available online: https://www.iea.org/reports/ccus-in-industry-and-transformation (accessed on 2 December 2021).

| Fuel | LHV | Emission |

|---|---|---|

| MJ/kg | kgCO2/GJ | |

| Hard coal | >23.9 | 94.60 |

| Lignite | <17.4 | 101.20 |

| Crude oil | 43.0 | 74.07 |

| Petrol | 43.4 | 66.00 |

| Paraffin oil | 41.5 | 71.50 |

| Heating oil | 42.8 | 77.37 |

| Diesel | 42.6 | 74.07 |

| Natural gas | 47.1 | 56.10 |

| Hydrogen | 120 | 0.00 |

| Country | Project | Operation Date | Source of CO2 | CO2 Capture Capacity (Mt/Year) | Primary Storage Type |

|---|---|---|---|---|---|

| United States (USA) | Terrell natural gas plants (Val Verde Gas Plants) | 1972 | Natural gas processing | 0.4–0.5 | United States (USA) |

| USA | Enid Fertilizer | 1982 | Fertilizer production | 0.7 | EOR |

| USA | Shute Creek gas processing facility | 1986 | Natural gas processing | 7.0 | EOR |

| Norway | Sleipner CO2 storage project | 1996 | Natural gas processing | 1.0 | Deep saline formation |

| USA/Canada | Great Plains Synfuels (Weyburn/Midale) | 2000 | Synthetic natural gas | 3.0 | EOR |

| Algeria 1 | In Salah CO2 Injection | 2004 | Natural gas processing | 1.0 | Deep saline formation |

| Norway | Snohvit CO2 storage project | 2008 | Natural gas processing | 0.7 | Deep saline formation |

| USA | Century plant | 2010 | Natural gas processing | 8.4 | EOR |

| USA | Air Products steam methane reformer | 2013 | Hydrogen production | 1.0 | EOR |

| USA 1 | Lost Cabin Gas Plant | 2013 | Natural gas processing | 0.9 | EOR |

| USA | Coffeyville Gasification | 2013 | Fertilizer production | 1.0 | EOR |

| Brazil | Petrobras Santos Basin pre-salt oilfield CCS | 2013 | Natural gas processing | 3.0 | EOR |

| Canada | Boundary Dam CCS | 2014 | Power generation (coal) | 1.0 | EOR |

| Canada 1 | Kemper County IGCC Project | 2014 | Natural gas processing | 3.5 | EOR |

| Saudi Arabia | Uthmaniyah CO2 EOR demonstration | 2015 | Natural gas processing | 0.8 | EOR |

| Canada | Quest | 2015 | Hydrogen production | 1.0 | Deep saline formation |

| United Arab Emirates | Abu Dhabi CCS | 2016 | Iron and steel production | 0.8 | EOR |

| USA 1 | Petra Nova | 2017 | Power generation (coal) | 1.4 | EOR |

| USA | Illinois industrial | 2017 | Ethanol production | 1.0 | Deep saline formation |

| China | Jilin oilfield CO2 EOR | 2018 | Natural gas processing | 0.6 | EOR |

| Australia | Gorgon Carbon Dioxide Injection | 2019 | Natural gas processing | 3.4–4.0 | Deep saline formation |

| Qatar | Qatar LNG CCS | 2019 | Natural gas processing | 2.2 | Dedicated geological storage |

| Canada | Alberta Carbon Trunk Line (ACTL) with North West Redwater Partnerships | 2020 | Hydrogen production | 1.3–1.6 | EOR |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madejski, P.; Chmiel, K.; Subramanian, N.; Kuś, T. Methods and Techniques for CO2 Capture: Review of Potential Solutions and Applications in Modern Energy Technologies. Energies 2022, 15, 887. https://doi.org/10.3390/en15030887

Madejski P, Chmiel K, Subramanian N, Kuś T. Methods and Techniques for CO2 Capture: Review of Potential Solutions and Applications in Modern Energy Technologies. Energies. 2022; 15(3):887. https://doi.org/10.3390/en15030887

Chicago/Turabian StyleMadejski, Paweł, Karolina Chmiel, Navaneethan Subramanian, and Tomasz Kuś. 2022. "Methods and Techniques for CO2 Capture: Review of Potential Solutions and Applications in Modern Energy Technologies" Energies 15, no. 3: 887. https://doi.org/10.3390/en15030887

APA StyleMadejski, P., Chmiel, K., Subramanian, N., & Kuś, T. (2022). Methods and Techniques for CO2 Capture: Review of Potential Solutions and Applications in Modern Energy Technologies. Energies, 15(3), 887. https://doi.org/10.3390/en15030887