Triangular Intuitionistic Fuzzy Aggregating and Ranking Function Approach for the Rating of Battery ‘End-of-Life’ Handling Alternatives

Abstract

:1. Introduction

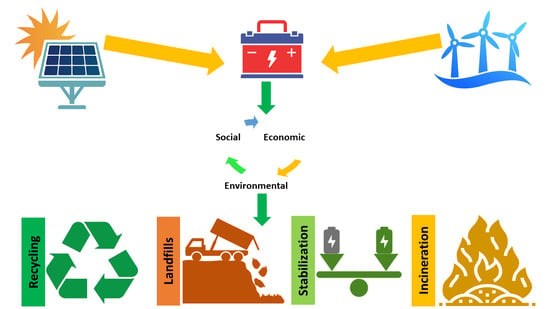

- This paper focused, for the first time, on identifying the most preferred ‘end-of-life’ handling alternatives for batteries.

- The study extends the fuzzy aggregating and ranking function (TIFARF) method proposed by Ref [11] for the evaluation of the ‘end-of-life’ handling alternatives for batteries.

1.1. Environmental Impacts of BSS

1.2. Battery ‘End-of-Life’ Handing Alternatives

1.2.1. Landfill (LF)

1.2.2. Incineration (IN)

1.2.3. Stabilization (SN)

1.2.4. Recycling (RG)

2. Materials and Methods

2.1. Concept of the TIFARF Model

2.2. Definition 1

2.3. TOPSIS Method

2.4. Algorithm of the TIFARF Model

3. Numerical Illustration

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IRENA. Renewable Capacity Statistics 2020, Abu Dhabi. 2020. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2020/Mar/IRENA_RE_Capacity_Statistics_2020.pdf (accessed on 18 February 2022).

- Akinyele, D.O.; Rayudu, R.K. Review of energy storage technologies for sustainable power networks. Sustain. Energy Technol. Assess. 2014, 8, 74–91. [Google Scholar] [CrossRef]

- Babatunde, O.M.; Munda, J.L.; Hamam, Y. A comprehensive state-of-the-art survey on hybrid renewable energy system operations and planning. IEEE Access 2020, 8, 75313–75346. [Google Scholar] [CrossRef]

- Kousksou, T.; Bruel, P.; Jamil, A.; El Rhafiki, T.; Zeraouli, Y. Energy storage: Applications and challenges. Sol. Energy Mater. Sol. Cells 2014, 120, 59–80. [Google Scholar] [CrossRef]

- Haynes, M.W.; Gunawan, A.; Yee, S.K. Techno-Economic Comparison Between Conventional and Innovative Combined Solar Thermal Power and Desalination Methods for Cogeneration. In Proceedings of the ASME 2018 Power Conference Collocated with the ASME 2018 12th International Conference on Energy Sustainability and the ASME 2018 Nuclear Forum, Lake Buena Vista, FL, USA, 24–28 June 2018; p. V002T12A013. Available online: https://asmedigitalcollection.asme.org/POWER/proceedings-abstract/POWER2018/51401/V002T12A013/277508 (accessed on 4 October 2018).

- Khawaja, M.K.; Alkhalidi, A.; Mansour, S. Environmental impacts of energy storage waste and regional legislation to curtail their effects—Highlighting the status in Jordan. J. Energy Storage 2019, 26, 100919. [Google Scholar] [CrossRef]

- Dehghani-Sanij, A.R.; Tharumalingam, E.; Dusseault, M.B.; Fraser, R. Study of energy storage systems and environmental challenges of batteries. Renew. Sustain. Energy Rev. 2019, 104, 192–208. [Google Scholar] [CrossRef]

- Krivik, P.; Baca, P. Electrochemical energy storage. In Energy Storage—Technologies and Applications; IntechOpen: London, UK, 2013. [Google Scholar]

- Dutt, D. Life cycle analysis and recycling techniques of batteries used in renewable energy applications. In Proceedings of the 2013 International Conference on New Concepts in Smart Cities: Fostering Public and Private Alliances (SmartMILE), Gijon, Spain, 11–13 December 2013; pp. 1–7. [Google Scholar]

- Laajimi, M.; Go, Y.I. Energy storage system design for large-scale solar PV in Malaysia: Technical and environmental assessments. J. Energy Storage 2019, 26, 100984. [Google Scholar] [CrossRef]

- Aikhuele, D.O. Development of a fixable model for the reliability and safety evaluation of the components of a commercial lithium-ion battery. J. Energy Storage 2020, 32, 101819. [Google Scholar] [CrossRef]

- Melchor-Martínez, E.M.; Macias-Garbett, R.; Malacara-Becerra, A.; Iqbal, H.M.; Sosa-Hernández, J.E.; Parra-Saldívar, R. Environmental impact of emerging contaminants from battery waste: A mini review. Case Stud. Chem. Environ. Eng. 2021, 3, 100104. [Google Scholar] [CrossRef]

- Gaines, L.; Richa, K.; Spangenberger, J. Key issues for Li-ion battery recycling. MRS Energy Sustain. 2018, 5, E14. [Google Scholar] [CrossRef] [Green Version]

- Lombardo, G.; Ebin, B.; Foreman, M.R.S.J.; Steenari, B.-M.; Petranikova, M. Incineration of EV Lithium-ion batteries as a pretreatment for recycling—Determination of the potential formation of hazardous by-products and effects on metal compounds. J. Hazard. Mater. 2020, 393, 122372. [Google Scholar] [CrossRef]

- Bernardes, A.M.; Espinosa, D.C.R.; Tenório, J.A.S. Recycling of batteries: A review of current processes and technologies. J. Power Sources 2004, 130, 291–298. [Google Scholar] [CrossRef]

- Li, M.; Liu, J.; Han, W. Recycling and management of waste lead-acid batteries: A mini-review. Waste Manag. Res. 2016, 34, 298–306. [Google Scholar] [CrossRef] [PubMed]

- Prengaman, R.D.; Mirza, A.H. Recycling concepts for lead—Acid batteries. In Lead-Acid Batteries for Future Automobiles; Elsevier: Amsterdam, The Netherlands, 2017; pp. 575–598. [Google Scholar]

- Kebede, A.A.; Kalogiannis, T.; Van Mierlo, J.; Berecibar, M. A comprehensive review of stationary energy storage devices for large scale renewable energy sources grid integration. Renew. Sustain. Energy Rev. 2022, 159, 112213. [Google Scholar] [CrossRef]

- Hunt, J.D.; Zakeri, B.; Lopes, R.; Barbosa, P.S.F.; Nascimento, A.; de Castro, N.J.; Brandão, R.; Schneider, P.S.; Wada, Y. Existing and new arrangements of pumped-hydro storage plants. Renew. Sustain. Energy Rev. 2020, 129, 109914. [Google Scholar] [CrossRef]

- Larcher, D.; Tarascon, J.M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015, 7, 19–29. [Google Scholar] [CrossRef] [PubMed]

- Rarotra, S.; Sahu, S.; Kumar, P.; Kim, K.H.; Tsang, Y.F.; Kumar, V.; Kumar, P.; Srinivasan, M.; Veksha, A.; Lisak, G. Progress and challenges on battery waste management: A critical review. ChemistrySelect 2020, 5, 6182–6193. [Google Scholar] [CrossRef]

- Rai, P.K.; Lee, S.S.; Zhang, M.; Tsang, Y.F.; Kim, K.-H. Heavy metals in food crops: Health risks, fate, mechanisms, and management. Environ. Int. 2019, 125, 365–385. [Google Scholar] [CrossRef]

- Aral, H.; Vecchio-Sadus, A. Toxicity of lithium to humans and the environment—A literature review. Ecotoxicol. Environ. Saf. 2008, 70, 349–356. [Google Scholar] [CrossRef]

- Buxton, S.; Garman, E.; Heim, K.E.; Lyons-Darden, T.; Schlekat, C.E.; Taylor, M.D.; Oller, A.R. Concise review of nickel human health toxicology and ecotoxicology. Inorganics 2019, 7, 89. [Google Scholar] [CrossRef] [Green Version]

- Biotto, G.; Silvestri, S.; Gobbo, L.; Furlan, E.; Valenti, S.; Rosselli, R. GIS, multi-criteria and multi-factor spatial analysis for the probability assessment of the existence of illegal landfills. Int. J. Geogr. Inf. Sci. 2009, 23, 1233–1244. [Google Scholar] [CrossRef]

- Heelan, J.; Gratz, E.; Zheng, Z.; Wang, Q.; Chen, M.; Apelian, D.; Wang, Y. Current and prospective Li-ion battery recycling and recovery processes. JOM 2016, 68, 2632–2638. [Google Scholar] [CrossRef] [Green Version]

- Aikhuele, D.O.; Odofin, S. A Generalized Triangular Intuitionistic Fuzzy Geometric Averaging Operator for Decision-Making in Engineering and Management. Information 2017, 8, 78. [Google Scholar] [CrossRef] [Green Version]

- Afsordegan, A. A Contribution to Multi-Criteria Decision Making in Sustainable Energy Management based on Fuzzy and Qualitative Reasoning; Universitat Politècnica de Catalunya: Barcelona, Spain, 2015. [Google Scholar]

- Ighravwe, D.E.; Babatunde, M.O.; Denwigwe, I.H.; Aikhuele, D.O. A STEEP-cum-SWOT approach for maintenance strategy evaluation for an off-grid PV-powered street lighting system. Afr. J. Sci. Technol. Innov. Dev. 2020, 12, 703–714. [Google Scholar] [CrossRef]

- Zhao, H.; Guo, S. Selecting green supplier of thermal power equipment by using a hybrid MCDM method for sustainability. Sustainability 2014, 6, 217–235. [Google Scholar] [CrossRef] [Green Version]

- Turan, F.M.; Aikhuele, D.O.; Johan, K. Reliability information to support decision making for e-government projects. In Proceedings of the 3rd International Conference on Communication and Information Processing, Online, 24 November 2017; ACM: New York, NY, USA, 2017; Volume F1338. [Google Scholar] [CrossRef]

- Gul, M.; Celik, E.; Gumus, A.T.; Guneri, A.F. A fuzzy logic based PROMETHEE method for material selection problems. Beni-Suef Univ. J. Basic Appl. Sci. 2017, 7, 68–79. [Google Scholar] [CrossRef]

| Contaminant | Effects | Reference |

|---|---|---|

| Cadmium | As a simple chemical element, it is impossible to break down cadmium to less noxious constituents when it is released to the environment. When released to the environment, it can be absorbed by plants, and if such plant is consumed by animals or humans, the element is accumulated in the vital organs of the body. The accumulation of cadmium can damage the liver, bones, and kidney. cadmium is carcinogenic in nature. | [21,22] |

| Cobalt | If an environment is exposed to cobalt, humans can come in contact with it through drinking contaminated water, eating contaminated crops (especially fruits), and by breathing contaminated air. When the skin is in contact with a contaminated surface, the probability of exposure is high. Humans and animals may accumulate cobalt in their bodies if they consume contaminated foods (plants or animals). High concentration of cobalt may lead to thyroid damage, heart related problems, vomiting and nausea, and vision problems. Cobalt contamination also has a negative effect on biomass. | [22] |

| Copper | When exposed to the soil, copper can interfere with soil activity and consequently, affect the activities of earthworms and other microorganisms, thereby slowing down the decomposition of organic matter. Ingestion of Copper can result in gastric-related medical challenges, liver damage, and some neurological difficulties. | [22] |

| Lead | Lead released from batteries that are not properly disposed of finds its way into the environment through water, soil, and air. Lead poisoning is reported to have carcinogenic effects and is a major cause of cardiovascular diseases, nervous system complications, and some kidney problems. | [21,22] |

| Lithium | It has been reported that the extraction of lithium impairs the soil and causes air contamination. There have been many reports of dead animals and ruined farms in the areas surrounding where lithium is mined. Although lithium is not as toxic as lead and cadmium, lithium causes changes in the growth of invertebrates and interferes with nucleic acids synthesis. Lithium is a phytotoxin that causes acute phytotoxicity. | [23] |

| Nickel | There are various environmental concerns linked with nickel; some of these include the pollution of soil, air, and water, the destruction of habitats, and greenhouse gas emissions. | [24] |

| S/N | Linguistic Terms | TIFN |

|---|---|---|

| 1 | Moderately Low (ML) | ([0.25, 0.35, 0.55]; 0.20, 0.60) |

| 2 | Low (L) | ([0.40, 0.50, 0.65]; 0.20, 0.65) |

| 3 | Moderately High (MH) | ([0.55, 0.60, 0.70]; 0.30, 0.70) |

| 4 | High (H) | ([0.60, 0.65, 0.75]; 0.45, 0.75) |

| 5 | Extremely High (EH) | ([0.70, 0.75, 0.85]; 0.55, 0.80) |

| Factor | Criteria | Definition | Direction |

|---|---|---|---|

| Economic | Investment cost | This is the starting/capital cost of each alternative, including land, equipment, and other assets. | Non-beneficial |

| Environmental cost | The associated cost invested in cleaning up the environmental pollution caused by the processes of each alternative. | Non-beneficial | |

| Environmental | Air pollution | Emissions and air pollutants associated with each alternative. | Non-beneficial |

| Land and water contamination | The effects of the pollution on the surrounding land and the contamination of the surrounding water bodies or water table. | Non-beneficial | |

| Social | Job opportunities | The number of employment opportunities associated with each alternative. | Beneficial |

| Visual impression | A reflection of the public’s perception of the visual impact of each alternative. | Non-beneficial |

| Criteria | IC | EC | AP | LWC | JO | VI |

|---|---|---|---|---|---|---|

| Alternative | ||||||

| LF | E1-(L), E2-(L), E3-(L) E4-(L) and E5-(MH) | E1-(H), E2-(H), E3-(H) E4-(MH) and E5-(MH) | E1-(H), E2-(H), E3-(H) E4-(H) and E5-(H) | E1-(H), E2-(H), E3-(H) E4-(H) and E5-(L) | E1-(H), E2-(MH), E3-(H) E4-(L) and E5-(EH) | E1-(L), E2-(H), E3-(L) E4-(ML) and E5-(EH) |

| IN | E1-(MH), E2-(ML), E3-(MH) E4-(ML) and E5-(MH) | E1-(MH), E2-(H), E3-(MH) E4-(EH) and E5-(EH) | E1-(MH), E2-(H), E3-(MH) E4-(EH) and E5-(MH) | E1-(L), E2-(MH), E3-(L) E4-(H) and E5-(ML) | E1-(MH), E2-(MH), E3-(MH) E4-(L) and E5-(MH) | E1-(MH), E2-(L), E3-(MH) E4-(ML) and E5-(MH) |

| SN | E1-(MH), E2-(H), E3-(MH) E4-(MH) and E5-(MH) | E1-(MH), E2-(MH), E3-(MH) E4-(H) and E5-(MH) | E1-(MH), E2-(MH), E3-(MH) E4-(MH) and E5-(MH) | E1-(L), E2-(L), E3-(L) E4-(MH) and E5-(MH) | E1-(MH), E2-(MH), E3-(MH) E4-(H) and E5-(MH) | E1-(MH), E2-(L), E3-(MH) E4-(MH) and E5-(H) |

| RG | E1-(H), E2-(ML), E3-(H) E4-(EH) and E5-(L) | E1-(L), E2-(L), E3-(L) E4-(ML) and E5-(MH) | E1-(L), E2-(L), E3-(L) E4-(L) and E5-(ML) | E1-(L), E2-(L), E3-(L) E4-(L) and E5-(ML) | E1-(MH), E2-(H), E3-(MH) E4-(EH) and E5-(MH) | E1-(H), E2-(H), E3-(H) E4-(EH) and E5-(H) |

| IC | EC | AP | LWC | JO | VI | |

| LF | ([0.35, 0.45, 0.60]; 0.18, 0.71) | ([0.53, 0.58, 0.69]; 0.32, 0.78) | ([0.55, 0.60, 0.71]; 0.37, 0.79) | ([0.48, 0.56, 0.68]; 0.30, 0.77) | ([0.52, 0.59, 0.71]; 0.31, 0.78) | ([0.45, 0.54, 0.69]; 0.31, 0.78) |

| IN | ([0.34, 0.43, 0.59]; 0.20, 0.71) | ([0.58, 0.64, 0.75]; 0.38, 0.77) | ([0.56, 0.62, 0.73]; 0.35, 0.79) | ([0.37, 0.46, 0.62]; 0.24, 0.73) | ([0.44, 0.52, 0.64]; 0.21, 0.73) | ([0.41, 0.49, 0.63]; 0.23, 0.74) |

| SN | ([0.52, 0.57, 0.68]; 0.29, 0.77) | ([0.52, 0.57, 0.68]; 0.29, 0.77) | ([0.51, 0.56, 0.67]; 0.27, 0.76) | ([0.45, 0.52, 0.65]; 0.23, 0.74) | ([0.51, 0.56, 0.67]; 0.27, 0.76) | ([0.42, 0.49, 0.64]; 0.25, 0.74) |

| RG | ([0.42, 0.51, 0.66]; 0.27, 0.76) | ([0.38, 0.47, 0.62]; 0.21, 0.73) | ([0.33, 0.43, 0.61]; 0.19, 0.72) | ([0.33, 0.43, 0.61]; 0.19, 0.72) | ([0.55, 0.60, 0.71]; 0.33, 0.79) | ([0.57, 0.63, 0.74]; 0.42, 0.81) |

| Criteria | IC | EC | AP | LWC | JO | VI |

|---|---|---|---|---|---|---|

| Alternative | ||||||

| Wv | 0.42675 | 0.47125 | 0.46852 | 0.53465 | 0.462257 | 0.49375 |

| LF | ([0.15, 0.19, 0.26]; 0.08, 0.30) | ([0.25, 0.27, 0.33]; 0.15, 0.37) | ([0.26, 0.28, 0.33]; 0.17, 0.37) | ([0.26, 0.30, 0.37]; 0.16, 0.41) | ([0.24, 0.27, 0.33]; 0.14, 0.362) | ([0.22, 0.27, 0.34]; 0.15, 0.38) |

| IN | ([0.15, 0.18, 0.25]; 0.08, 0.30) | ([0.28, 0.30, 0.35]; 0.18, 0.36) | ([0.26, 0.29, 0.34]; 0.16 0.37) | ([0.20, 0.24, 0.33]; 0.13, 0.39) | ([0.20, 0.24, 0.30]; 0.10, 0.34) | ([0.20, 0.24, 0.31]; 0.11, 0.36) |

| SN | ([0.22, 0.24, 0.29]; 0.13, 0.33) | ([0.25, 0.27, 0.32]; 0.14, 0.36) | ([0.24, 0.26, 0.32]; 0.13, 0.36) | ([0.24, 0.28, 0.35]; 0.12, 0.40) | ([0.24, 0.26, 0.31]; 0.13, 0.35) | ([0.21, 0.24, 0.32]; 0.12, 0.37) |

| RG | ([0.18, 0.22, 0.28]; 0.11, 0.32) | ([0.18, 0.22, 0.29]; 0.10, 0.34) | ([0.15, 0.20, 0.28]; 0.09, 0.34) | ([0.18, 0.23, 0.32]; 0.10, 0.38) | ([0.25, 0.28, 0.33]; 0.15, 0.38) | ([0.28, 0.31, 0.36]; 0.21, 0.40) |

| Alternative | TIFPI Solution | TIFNI Solution |

|---|---|---|

| LF | 0.806 | 0.119 |

| IN | 0.751 | 0.112 |

| SN | 0.695 | 0.101 |

| RG | 0.668 | 0.084 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babatunde, O.M.; Munda, J.L.; Hamam, Y. Triangular Intuitionistic Fuzzy Aggregating and Ranking Function Approach for the Rating of Battery ‘End-of-Life’ Handling Alternatives. Energies 2022, 15, 2248. https://doi.org/10.3390/en15062248

Babatunde OM, Munda JL, Hamam Y. Triangular Intuitionistic Fuzzy Aggregating and Ranking Function Approach for the Rating of Battery ‘End-of-Life’ Handling Alternatives. Energies. 2022; 15(6):2248. https://doi.org/10.3390/en15062248

Chicago/Turabian StyleBabatunde, Olubayo Moses, Josiah Lange Munda, and Yskandar Hamam. 2022. "Triangular Intuitionistic Fuzzy Aggregating and Ranking Function Approach for the Rating of Battery ‘End-of-Life’ Handling Alternatives" Energies 15, no. 6: 2248. https://doi.org/10.3390/en15062248

APA StyleBabatunde, O. M., Munda, J. L., & Hamam, Y. (2022). Triangular Intuitionistic Fuzzy Aggregating and Ranking Function Approach for the Rating of Battery ‘End-of-Life’ Handling Alternatives. Energies, 15(6), 2248. https://doi.org/10.3390/en15062248