Effects of the Aspect Ratio and Cross-Sectional Area of Rectangular Tubes on Packing Characteristics of Mono-Sized Pebble Beds

Abstract

:1. Introduction

2. Methodology

2.1. Packing Experiments

- Step 1: The volume Vc inside a rectangular container was measured by measuring the inner dimension of the rectangular tube with a vernier caliper or gauging by the drainage method and the mass mr of the rectangular container;

- Step 2: The pebbles with density ρ and diameter d are filled into the rectangular tube from the top opening of the container under gravity in batches. After filling the tube, the pebbles above the container height are scraped off with a steel ruler;

- Step 3: By subtracting the mass mr of the tube container from the total mass mall of the pebble bed filled with pebbles, the total mass mbed of the pebbles inside the container was obtained, mbed = mall − mr;

- Step 4: The total volume ∑Vp of pebbles packed in bed can be calculated using the density ρ and the total mass mbed, ∑Vp = mbed/ρ. The volume ratio of the sum volume ∑Vp of pebbles in the rectangular tube to the volume Vbed of the bed is the average packing fraction γavg of the pebble bed γavg = ∑Vp/Vbed.

2.2. Simulation Method and Parameters

- Step 1: In the top-opening region, which is higher than 60 mm, a certain number of spherical pebbles with a diameter of 1 mm are randomly and uniformly generated without overlaps;

- Step 2: The randomly generated pebbles fall to the bottom of the cavity with an initial velocity of zero under gravity. Meanwhile, a variable number of pebbles will be randomly regenerated in batches at every fixed timestep. Moreover, they continue to move down freely and slowly with an initial zero velocity. During the pebble packing, the total pebble number and the pebble-bed height in the container will gradually increase. The kinetic energy of the inserted pebbles is gradually dissipated by the friction, rolling, sliding, and collision between pebbles. The pebble-packing process can be monitored by the total kinetic energy of the granular assembly;

- Step 3: When the pebble-bed height exceeds 60 mm, the filling process is stopped. With the gradual dissipation of energy, the pebble bed can be stable when the total kinetic energy is reduced to ~10−14 J [7]. Then, the pebbles higher than 60 mm are removed. The simulation continues to make the pebbles reach a stabilized packing state until the total kinetic energy is reduced to ~10−14 J again;

- Step 4: When the stabilized state of pebble packing is achieved, the packing characteristics of the rectangular pebble bed will be analyzed by the in-house Matlab codes.

2.3. Calculation of the Packing Fraction

3. Results and Discussions

3.1. Validation with Experiment Results

3.2. Average Packing Fraction

3.3. Local Packing Fraction Distribution

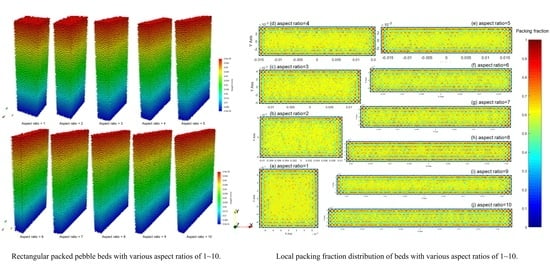

3.3.1. Effect of the Aspect Ratio of Rectangular Tube

3.3.2. Effect of the Cross-Sectional Area of Rectangular Tube

3.4. Coordination Number Distribution

3.4.1. Average Coordination Number

3.4.2. Coordination Number Distribution

3.5. Radial Distribution Function

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mederos, F.S.; Ancheyta, J.; Chen, J. Review on criteria to ensure ideal behaviors in trickle-bed reactors. Appl. Catal. A-Gen. 2009, 355, 1–19. [Google Scholar] [CrossRef]

- Jiang, S.; Tu, J.; Yang, X.; Gui, N. A review of pebble flow study for pebble bed high temperature gas cooled reactor. Exp. Comput. Multiph. Flow 2019, 1, 159–176. [Google Scholar] [CrossRef] [Green Version]

- Gui, N.; Huang, X.; Yang, X.; Tu, J.; Jiang, S. HTR-PM-based 3D pebble flow simulation on the effects of base angle, recirculation mode and coefficient of friction. Ann. Nucl. Energy 2020, 143, 107442. [Google Scholar] [CrossRef]

- Wu, M.; Gui, N.; Wu, H.; Yang, X.; Tu, J.; Jiang, S. Effects of density difference and loading ratio on pebble flow in a three-dimensional two-region-designed pebble bed. Ann. Nucl. Energy 2019, 133, 924–936. [Google Scholar] [CrossRef]

- Wang, X. Preliminary Design and Tritium Assessment of CFETR HCCB TBB, Paper No. O1B.5. In In Proceedings of the 12th International Conference on Tritium Science & Technology, Busan, Korea, 22–26 April 2019. [Google Scholar]

- Wu, X.; Liao, H.; Wang, X.; He, K.; Wang, S.; Cao, Q.; Zhou, B.; Hu, Z.; Li, X.; Feng, K. Design optimization and analysis of CN HCCB TBM-set. Fusion Eng. Des. 2018, 136, 839–846. [Google Scholar] [CrossRef]

- Gong, B.; Feng, Y.; Liao, H.; Liu, Y.; Wang, X.; Feng, K. Discrete element modeling of pebble bed packing structures for HCCB TBM. Fusion Eng. Des. 2017, 121, 256–264. [Google Scholar] [CrossRef]

- Gong, B.; Feng, Y.; Liao, H.; Wu, X.; Wang, S.; Wang, X.; Feng, K. Numerical investigation of the pebble bed structures for HCCB TBM. Fusion Eng. Des. 2018, 136, 1444–1451. [Google Scholar] [CrossRef]

- Kawamura, Y.; Tanigawa, H.; Hirose, T.; Gwon, H.; Nakajima, M.; Takemura, M.; Nakata, M.; Ishioka, M.; Yoshino, S.; Murakami, H.; et al. Status of water cooled ceramic breeder blanket development. Fusion Eng. Des. 2018, 136, 1550–1556. [Google Scholar] [CrossRef]

- Lei, M.; Xu, S.; Wang, J.; Song, Y.; Liu, S.; Lu, K.; Xu, K.; Pei, K. Preliminary assessment on safety performance of updated HCCB blanket module for CFETR. Fusion Eng. Des. 2018, 131, 77–83. [Google Scholar] [CrossRef]

- Wang, J.; Lei, M.; Yang, H.; Xu, S.; Xu, K.; Yin, Z.; Li, C.; Zhao, P.; Song, Y. Study on the packing characteristics of a special “J” shape ceramic packed pebble bed based on discrete element modeling. Powder Technol. 2021, 379, 362–372. [Google Scholar] [CrossRef]

- Fouda, Y.M.; Bayly, A.E. A DEM study of powder spreading in additive layer manufacturing. Granul. Matter 2020, 22, 10. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.; Ge, Y.; Li, M.; Li, Y.; Saxén, H.; He, Z.; Yu, Y. DEM study of the porosity distribution of pellet sandpile formed by ternary size particles. Powder Technol. 2020, 360, 1337–1347. [Google Scholar] [CrossRef]

- Ghodki, B.M.; Patel, M.; Namdeo, R.; Carpenter, G. Calibration of discrete element model parameters: Soybeans. Comput. Part. Mech. 2019, 6, 3–10. [Google Scholar] [CrossRef]

- Jian, F.; Narendran, R.B.; Jayas, D.S. Segregation in stored grain bulks: Kinematics, dynamics, mechanisms, and minimization—A review. J. Stored Prod. Res. 2019, 81, 11–21. [Google Scholar] [CrossRef]

- Singh, H.; Saini, R.; Saini, J. A review on packed bed solar energy storage systems. Renew. Sustain. Energy Rev. 2010, 14, 1059–1069. [Google Scholar] [CrossRef]

- Guo, Z.; Sun, Z.; Zhang, N.; Ding, M. Influence of confining wall on pressure drop and particle-to-fluid heat transfer in packed beds with small D/d ratios under high Reynolds number. Chem. Eng. Sci. 2019, 209, 115200. [Google Scholar] [CrossRef]

- Wongkham, J.; Wen, T.; Lu, B.; Cui, L.; Xu, J.; Liu, X. Particle-resolved simulation of randomly packed pebble beds with a novel fluid-solid coupling method. Fusion Eng. Des. 2020, 161, 111953. [Google Scholar] [CrossRef]

- Zhao, Z.; Feng, K.; Feng, Y. Theoretical calculation and analysis modeling for the effective thermal conductivity of Li4SiO4 pebble bed. Fusion Eng. Des. 2010, 85, 1975–1980. [Google Scholar] [CrossRef]

- Chen, L.; Wang, C.; Moscardini, M.; Kamlah, M.; Liu, S. A DEM-based heat transfer model for the evaluation of effective thermal conductivity of packed beds filled with stagnant fluid: Thermal contact theory and numerical simulation. Int. J. Heat. Mass. Tran. 2019, 132, 331–346. [Google Scholar] [CrossRef]

- Kim, S.G.; Addad, Y.; Liu, M.; Lee, J.I.; Lee, Y. Computational investigation into heat transfer coefficients of randomly packed pebbles in flowing FLiBe. Inter. J. Heat Mass Transf. 2019, 145, 118769. [Google Scholar] [CrossRef]

- Sohn, D.; Lee, Y.; Ahn, M.-Y.; Park, Y.-H.; Cho, S. Numerical prediction of packing behavior and thermal conductivity of pebble beds according to pebble size distributions and friction coefficients. Fusion Eng. Des. 2018, 137, 182–190. [Google Scholar] [CrossRef]

- Mandal, D.; Sathiyamoorthy, D.; Vinjamur, M. Void fraction and effective thermal conductivity of binary particulate bed. Fusion Eng. Des. 2013, 88, 216–225. [Google Scholar] [CrossRef]

- Ying, A.; Reimann, J.; Boccaccini, L.; Enoeda, M.; Kamlah, M.; Knitter, R.; Gan, Y.; van der Laan, J.G.; Magielsen, L.; Di Maio, P.; et al. Status of ceramic breeder pebble bed thermo-mechanics R&D and impact on breeder material mechanical strength. Fusion Eng. Des. 2021, 87, 1130–1137. [Google Scholar]

- Zhou, W.; Xu, K.; Ma, G.; Yang, L.; Chang, X. Effects of particle size ratio on the macro- and microscopic behaviors of binary mixtures at the maximum packing efficiency state. Granum. Matter 2016, 18, 81. [Google Scholar] [CrossRef]

- Annabattula, R.; Gan, Y.; Kamlah, M. Mechanics of binary and polydisperse spherical pebble assembly. Fusion Eng. Des. 2012, 87, 853–858. [Google Scholar] [CrossRef]

- Donne, M.D.; Goraieb, A.; Piazza, G.; Scaffidi-Argentina, F. Experimental investigations on the thermal and mechanical behaviour of a binary beryllium pebble bed. Fusion Eng. Des. 2000, 49–50, 521–528. [Google Scholar] [CrossRef]

- van Antwerpen, W.; Toit, C.; Rousseau, P. A review of correlations to model the packing structure and effective thermal conductivity in packed beds of mono-sized spherical particles. Nucl. Eng. Des. 2010, 240, 1803–1818. [Google Scholar] [CrossRef]

- von Seckendorff, J.; Hinrichsen, O. Review on the structure of random packed-beds. Can. J. Chem. Eng. 2021, 99, S703–S733. [Google Scholar] [CrossRef]

- Feng, Y.; Gong, B.; Cheng, H.; Luo, X.; Wang, L.; Wang, X. Effects of bed dimension, friction coefficient and pebble size distribution on the packing structures of the pebble bed for solid tritium breeder blanket. Fusion Eng. Des. 2021, 163, 112156. [Google Scholar] [CrossRef]

- Feng, Y.; Gong, B.; Cheng, H.; Wang, L.; Wang, X. Effects of fixed wall and pebble size ratio on packing properties and contact force distribution in binary-sized pebble mixed beds at the maximum packing efficiency state. Powder Technol. 2021, 390, 504–520. [Google Scholar] [CrossRef]

- Gong, B.; Cheng, H.; Feng, Y.; Luo, X.; Wang, L.; Wang, X. Effect of pebble size distribution and wall effect on inner packing structure and contact force distribution in tritium breeder pebble bed. Energies 2021, 14, 449. [Google Scholar] [CrossRef]

- Gong, B.; Feng, Y.; Yu, G.; Liao, H.; Wang, X.; Feng, K. Experimental investigation of the effect of particle size on the effective thermal properties of particle beds. J. Eng. Thermophys. 2019, 40, 1151–1159. [Google Scholar]

- Reimann, J.; Vicente, J.; Ferrero, C.; Rack, A.; Gan, Y. 3D tomography analysis of the packing structure of spherical particles in slender prismatic containers. Int. J. Mater. Res. 2020, 111, 65–77. [Google Scholar] [CrossRef]

- Reimann, J.; Vicente, J.; Brun, E.; Ferrero, C.; Gan, Y.; Rack, A. X-ray tomography investigations of monosized sphere packing structures in cylindrical containers. Powder Technol. 2017, 318, 471–483. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Z.; Yang, J.; Wassgren, C.; Curtis, J.S.; Guo, Y. Discrete Element Method Investigation of Binary Granular Flows with Different Particle Shapes. Energies 2020, 13, 1841. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Liu, L.; Zhuang, Y.; Jin, W.; Li, S. Coupling effects of particle size and shape on improving the density of disordered polydisperse packings. Phys. Rev. E 2018, 98, 042903. [Google Scholar] [CrossRef]

- Wang, J.; Lei, M.; Yang, H.; Xu, K.; Xu, S.; Zhao, P.; Song, Y. Effects of coefficient of friction and coefficient of restitution on static packing characteristics of polydisperse spherical pebble bed. Particuology 2021, 57, 1–9. [Google Scholar] [CrossRef]

- du Toit, C.G. Radial variation in porosity in annular packed beds. Nucl. Eng. Des. 2008, 238, 3073–3079. [Google Scholar] [CrossRef]

- Ren, C.; Yang, X.; Sun, Y. Porous Structure Analysis of the Packed Beds in a High-Temperature Reactor Pebble Bed Modules Heat Transfer Test Facility. Chin. Phys. Lett. 2013, 30, 022801. [Google Scholar] [CrossRef]

- Wang, J.; Lei, M.; Xu, S.; Yang, H.; Zhao, P.; Xu, K.; Song, Y. DEM simulation of mechanical behavior in one-dimensional compression of crushable ceramic pebble bed. Fusion Eng. Des. 2021, 168, 112606. [Google Scholar] [CrossRef]

- Reimann, J.; Brun, E.; Ferrero, C.; Vicente, J. Pebble bed structures in the vicinity of concave and convex walls. Fusion Eng. Des. 2015, 98–99, 1855–1858. [Google Scholar] [CrossRef]

- Buchlin, J.; Riethmuller, M.; Ginoux, J. A fluorescence method for the measurement of the local voidage in random packed beds. Chem. Eng. Sci. 1977, 32, 1116–1119. [Google Scholar] [CrossRef]

- Beavers, G.S.; Sparrow, E.M.; Rodenz, D.E. Influence of Bed Size on the Flow Characteristics and Porosity of Randomly Packed Beds of Spheres. J. Appl. Mech. 1973, 40, 655–660. [Google Scholar] [CrossRef]

- Desu, R.; Moorthy, A.; Annabattula, R. DEM simulation of packing mono-sized pebbles into prismatic containers through different filling strategies. Fusion Eng. Des. 2018, 127, 259–266. [Google Scholar] [CrossRef]

- Hamzah, A.B.; Ookawara, S.; Yoshikawa, S.; Matsumoto, H. Numerical study on porosity distribution and hydrodynamics of packed bed in narrow square channels. Chem. Eng. Process. 2020, 151, 107905. [Google Scholar] [CrossRef]

- Wang, S.; Wang, S.; Chen, H. Numerical influence analysis of the packing structure on ceramic breeder pebble beds. Fusion Eng. Des. 2019, 140, 41–47. [Google Scholar] [CrossRef]

- Taguchi, I.; Kurashige, M.; Imai, K. Effects of Cubic Container’s Wall or Floor on Random Packing Structures of Spherical Particles. JSME Int. J. 2006, 49, 265–272. [Google Scholar] [CrossRef] [Green Version]

- Zobel, N.; Eppinger, T.; Behrendt, F.; Kraume, M. Influence of the wall structure on the void fraction distribution in packed beds. Chem. Eng. Sci. 2012, 71, 212–219. [Google Scholar] [CrossRef]

- Jaggannagari, S.R.; Desu, R.K.; Reimann, J.; Gan, Y.; Moscardini, M.; Annabattula, R.K. DEM simulations of vibrated sphere packings in slender prismatic containers. Powder Technol. 2021, 393, 31–59. [Google Scholar] [CrossRef]

- Oğuz, E.C.; Marechal, M.; Ramiro-Manzano, F.; Rodriguez, I.; Messina, R.; Meseguer, F.J.; Löwen, H. Packing Confined Hard Spheres Denser with Adaptive Prism Phases. Phys. Rev. Lett. 2012, 109, 218301. [Google Scholar] [CrossRef] [Green Version]

- Pistocchini, L.; Garone, S.; Motta, M. Porosity and pressure drop in packed beds of spheres between narrow parallel walls. Chem. Eng. J. 2016, 284, 802–811. [Google Scholar] [CrossRef]

- Romkes, S.; Dautzenberg, F.; Bleek, C.V.D.; Calis, H. CFD modelling and experimental validation of particle-to-fluid mass and heat transfer in a packed bed at very low channel to particle diameter ratio. Chem. Eng. J. 2003, 96, 3–13. [Google Scholar] [CrossRef]

- Bauer, T.; Haase, S. Comparison of structured trickle-bed and monolithic reactors in Pd-catalyzed hydrogenation of alpha-methylstyrene. Chem. Eng. J. 2011, 169, 263–269. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Ding, W.; Chen, R.; Tian, W.; Qiu, S.; Su, G. Numerical investigation of dynamic characteristics of debris bed formation based on CFD-DEM method. Ann. Nucl. Energy 2023, 180, 109492. [Google Scholar] [CrossRef]

- Ding, W.; Xiao, X.; Cai, Q.; Chen, R.; Guo, K.; Tian, W.; Qiu, S.; Su, G. Numerical investigation of fluid–solid interaction during debris bed formation based on MPS-DEM. Ann. Nucl. Energy 2022, 175, 109244. [Google Scholar] [CrossRef]

- Chen, R.; Guo, K.; Zhang, Y.; Tian, W.; Qiu, S.; Su, G.H. Numerical analysis of the granular flow and heat transfer in the ADS granular spallation target. Nucl. Eng. Des. 2018, 330, 59–71. [Google Scholar] [CrossRef]

- Guo, K.; Chen, R.; Li, Y.; Qiu, S.; Su, G. Numerical investigation of the fluid-solid mixture flow using the FOCUS code. Prog. Nucl. Energy 2017, 97, 197–213. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Wu, Y.; Tang, S.; Liu, D.; Qiu, S.; Su, G.; Tian, W. DEM-CFD simulation of helium flow characteristics in randomly packed bed for fusion reactors. Prog. Nucl. Energy 2018, 109, 29–37. [Google Scholar] [CrossRef]

- LIGGGHTS(R)-PUBLIC Documentation, Version 3. X. Available online: http://www.liggghts.com (accessed on 2 November 2022).

- Kloss, C.; Goniva, C.; Hager, A.; Amberger, S.; Pirker, S. Models, algorithms and validation for opensource DEM and CFD-DEM. Prog. Comput. Fluid Dyn. Int. J. 2012, 12, 140–152. [Google Scholar] [CrossRef]

- Kou, B.; Cao, Y.; Li, J.; Xia, C.; Li, Z.; Dong, H.; Zhang, A.; Zhang, J.; Kob, W.; Wang, Y. Granular materials flow like complex fluids. Nature 2017, 551, 360–363. [Google Scholar] [CrossRef] [Green Version]

- Yang, R.Y.; Zou, R.P.; Yu, A.B. Computer simulation of the packing of fine particles. Phys. Rev. E 2000, 62, 3900–3908. [Google Scholar] [CrossRef]

- Hopkins, A.B.; Stillinger, F.H.; Torquato, S. Disordered strictly jammed binary sphere packings attain an anomalously large range of densities. Phys. Rev. E 2013, 88, 022205. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Young’s modulus (GPa) | 90 |

| Poisson ratio | 0.24 |

| Density (g/cm3) | 2.323 |

| Restitution coefficient | 0.9 |

| Static friction coefficient for pebble–pebble | 0.1 |

| Static friction coefficient for pebble–wall | 0.1 |

| Pebble diameter, d (mm) | 1.0 |

| Height of pebble bed (mm) | ~ 60 |

| Scs = Lx × Ly | 100 d2 | 225 d2 | 400 d2 | 900 d2 | 1600 d2 |

| α = Lx/Ly | Lx/Ly | Lx/Ly | Lx/Ly | Lx/Ly | Lx/Ly |

| 1 | 10.00/10.00 | 15.00/15.00 | 20.00/20.00 | 30.00/30.00 | 40.00/40.00 |

| 2 | 14.14/7.07 | 21.21/10.61 | 28.28/14.14 | 42.43/21.21 | 56.57/28.28 |

| 3 | 17.32/5.77 | 25.98/8.66 | 34.64/11.55 | 51.96/17.32 | 69.28/23.09 |

| 4 | 20.00/5.00 | 30.00/7.50 | 40.00/10.00 | 60.00/15.00 | 80.00/20.00 |

| 5 | 22.36/4.47 | 33.54/6.71 | 44.72/8.94 | 67.08/13.42 | 89.44/17.89 |

| 6 | 24.49/4.08 | 36.74/6.12 | 48.99/8.16 | 73.48/12.25 | 97.98/16.33 |

| 7 | 26.46/3.78 | 39.69/5.67 | 52.92/7.56 | 79.37/11.34 | 105.83/15.12 |

| 8 | 28.28/3.54 | 42.43/5.30 | 56.57/7.07 | 84.85/10.61 | 113.14/14.14 |

| 9 | 30.00/3.33 | 45.00/5.00 | 60.00/6.67 | 90.00/10.00 | 120.00/13.33 |

| 10 | 31.62/3.16 | 47.43/4.74 | 63.25/6.32 | 94.87/9.49 | 126.49/12.65 |

| Scale Ratios (Lx/d) | Experimental Results | |||

|---|---|---|---|---|

| 1 | 2 | 3 | Mean Value ± Std Dev | |

| 10.372 | 0.5938 | 0.5899 | 0.5891 | 0.5909 ± 0.0025 |

| 15.558 | 0.6053 | 0.6045 | 0.6053 | 0.6050 ± 0.0005 |

| 22.364 | 0.6165 | 0.6176 | 0.6166 | 0.6169 ± 0.0006 |

| 26.280 | 0.6215 | 0.6231 | 0.6188 | 0.6211 ± 0.0022 |

| 29.749 | 0.6229 | 0.6249 | 0.6259 | 0.6246 ± 0.0015 |

| 33.546 | 0.6246 | 0.6246 | 0.6251 | 0.6248 ± 0.0003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, B.; Cheng, H.; Yan, J.; Wang, L.; Feng, Y.; Wang, X. Effects of the Aspect Ratio and Cross-Sectional Area of Rectangular Tubes on Packing Characteristics of Mono-Sized Pebble Beds. Energies 2023, 16, 570. https://doi.org/10.3390/en16010570

Gong B, Cheng H, Yan J, Wang L, Feng Y, Wang X. Effects of the Aspect Ratio and Cross-Sectional Area of Rectangular Tubes on Packing Characteristics of Mono-Sized Pebble Beds. Energies. 2023; 16(1):570. https://doi.org/10.3390/en16010570

Chicago/Turabian StyleGong, Baoping, Hao Cheng, Juemin Yan, Long Wang, Yongjin Feng, and Xiaoyu Wang. 2023. "Effects of the Aspect Ratio and Cross-Sectional Area of Rectangular Tubes on Packing Characteristics of Mono-Sized Pebble Beds" Energies 16, no. 1: 570. https://doi.org/10.3390/en16010570

APA StyleGong, B., Cheng, H., Yan, J., Wang, L., Feng, Y., & Wang, X. (2023). Effects of the Aspect Ratio and Cross-Sectional Area of Rectangular Tubes on Packing Characteristics of Mono-Sized Pebble Beds. Energies, 16(1), 570. https://doi.org/10.3390/en16010570