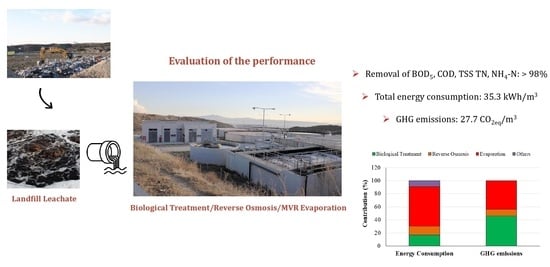

Evaluating the Operation of a Full-Scale Sequencing Batch Reactor–Reverse Osmosis–Evaporation System Used to Treat Landfill Leachates: Removal of Pollutants, Energy Consumption and Greenhouse Gas Emissions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Landfill Leachates Treatment Plant

2.2. Monitoring the System

2.3. Analytical Methods

2.4. Empirical Model for GHG Emissions

3. Results and Discussion

3.1. Characteristics of Landfill Leachates and Performance of the System

3.2. Energy Consumption

3.3. GHG Emissions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Papachristou, E.; Hadjianghelou, H.; Darakas, E.; Alivanis, K.; Belou, A.; Ioannidou, D.; Paraskevopoulou, E.; Poulios, K.; Koukourikou, A.; Kosmidou, N.; et al. Perspectives for integrated municipal solid waste management in Thessaloniki, Greece. Waste Manag. 2009, 29, 1158–1162. [Google Scholar] [CrossRef] [PubMed]

- ESDA. National Waste Management Plan 2020–2030; Greek Ministry of Environment and Energy: Athens, Greece, 2020. Available online: http://www.opengov.gr/minenv/wp-content/uploads/downloads/2020/08/%CE%95%CE%A3%CE%94%CE%91-%CE%94%CE%99%CE%91%CE%92%CE%9F%CE%A5%CE%9B%CE%95%CE%A5%CE%A3%CE%97-6-8-2020.pdf (accessed on 27 June 2023). (In Greek)

- Podlasek, A. Modeling leachate generation: Practical scenarios for municipal solid waste landfills in Poland. Environ. Sci. Pollut. Res. 2023, 30, 13256–13269. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Zeng, Y.; Cheng, Y.; He, D.; Pan, X. Recent advances in municipal landfill leachate: A review focusing on its characteristics, treatment, and toxicity assessment. Sci. Total Environ. 2020, 703, 135468. [Google Scholar] [CrossRef]

- Nika, M.C.; Ntaiou, K.; Elytis, K.; Thomaidi, V.S.; Gatidou, G.; Kalantzi, O.I.; Thomaidis, N.S.; Stasinakis, A.S. Wide-scope target analysis of emerging contaminants in landfill leachates and risk assessment using RQ methodology. J. Hazard. Mater. 2020, 394, 122493. [Google Scholar] [CrossRef] [PubMed]

- Tchobanoglous, G.; Kreith, F. Handbook of Solid Waste Management; McGraw Hill Professional: New York, NY, USA, 2002. [Google Scholar]

- Beaven, R.P.; Knox, K. Leachate Recirculation, Solid Waste Landfilling; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 703–727. [Google Scholar]

- de Almeida, R.; Porto, R.F.; Quintaes, B.R.; Bila, D.M.; Lavagnolo, M.C.; Campos, J.C. A review on membrane concentrate management from landfill leachate treatment plants: The relevance of resource recovery to close the leachate treatment loop. Waste Manag. Res. 2023, 41, 264–284. [Google Scholar] [CrossRef] [PubMed]

- Brennan, R.B.; Clifford, E.; Devroedt, C.; Morrison, L.; Healy, M.G. Treatment of landfill leachate in municipal wastewater treatment plants and impacts on effluent ammonium concentrations. J. Environ. Manag. 2017, 188, 64–72. [Google Scholar] [CrossRef]

- Renou, S.; Givaudan, J.G.; Poulain, S.; Dirassouyan, F.; Moulin, P. Landfill leachate treatment: Review and opportunity. J. Hazard. Mater. 2008, 150, 468–493. [Google Scholar] [CrossRef]

- Abuabdou, S.; Ahmad, W.; Ng, C.; Bashir, M. A review of anaerobic membrane bioreactors (AnMBR) for the treatment of highly contaminated landfill leachate and biogas production: Effectiveness, limitations and future perspectives. J. Clean. Prod. 2020, 255, 120215. [Google Scholar] [CrossRef]

- Tatsi, A.A.; Zouboulis, A.I.; Matis, K.A.; Samaras, P. Coagulation–flocculation pretreatment of sanitary landfill leachates. Chemosphere 2003, 53, 737–744. [Google Scholar] [CrossRef]

- Petruzzelli, D.; Boghetich, G.; Petrella, M.; Dell’Erba, A.; L’Abbate, P.; Sanarica, S.; Miraglia, M. Pre-treatment of industrial landfill leachate by Fenton’s oxidation. Glob. NEST J. 2007, 9, 51–56. [Google Scholar] [CrossRef]

- Chen, W.; Gu, Z.; Ran, G.; Li, Q. Application of membrane separation technology in the treatment of leachate in China: A review. Waste Manag. 2021, 121, 127–140. [Google Scholar] [CrossRef] [PubMed]

- Alfaia, R.G.S.M.; de Almeida, R.; Nascimento, K.S.; Campos, J.C. Landfill leachate pretreatment effects on nanofiltration and reverse osmosis membrane performance. Process Saf. Environ. Prot. 2023, 172, 273–281. [Google Scholar] [CrossRef]

- Glarakis, J.; Remmas, N.; Azis, K.; Melidis, P. Retrofitting a full-scale multistage landfill leachate treatment plant by introducing coagulation/flocculation/sedimentation and ultrafiltration process steps. Environ. Monit. Assess. 2023, 195, 326. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Mosquera, L.F.; Arias-Giraldo, S.; Zuluaga-Meza, A. Landfill leachate treatment using hydrodynamic cavitation: Exploratory evaluation. Heliyon 2022, 8, e09019. [Google Scholar] [CrossRef]

- Bis, M.; Montusiewicz, A.; Ozonek, J.; Pasieczna-Patkowska, S. Application of hydrodynamic cavitation to improve the biodegradability of mature landfill leachate. Ultrason. Sonochemistry 2015, 26, 378–387. [Google Scholar] [CrossRef]

- Hernandez-Sancho, F.; Molino-Senante, M.; Sala-Garrido, R. Energy efficiency in Spanish wastewater treatment plants: A non-radial DEA approach. Sci. Total Environ. 2011, 409, 2693–2699. [Google Scholar] [CrossRef]

- Mamais, D.; Noutsopoulos, C.; Dimopoulou, A.; Stasinakis, A.; Lekkas, T.D. Wastewater treatment process impact on energy savings and greenhouse gas emissions. Water Sci. Technol. 2015, 71, 303–308. [Google Scholar] [CrossRef]

- Topal, A.D.; Atasoy, A.D. Reverse osmosis treatment system for landfill leachate: Operation conditions, advantages and challenges. Environ. Res. Technol. 2022, 5, 119–127. [Google Scholar] [CrossRef]

- Modi, R.; Kavaiya, A.R.; Vanzara, P.B.; Raval, H.D. Membranes in zero-liquid-discharge systems for efficient processes toward sustainable environment: A review. J. Environ. Eng. 2022, 148, 03122004. [Google Scholar] [CrossRef]

- Di Maria, F.; Sisani, F.; Contini, S.; Ghosh, S.K. Impact of different schemes for treating landfill leachate. Waste Manag. 2018, 71, 255–266. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, K.; Huang, X. Full-scale MBR applications for leachate treatment in China: Practical, technical, and economic features. J. Hazard. Mater. 2020, 389, 122138. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jia, M.; Zhang, C.; Chen, S.; Cai, Z. Leachate treatment in landfills is a significant N2O source. Sci. Total Environ. 2017, 596–597, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Nuraiti, T.; Izhar, T.; Xuan, L.P. The estimation of greenhouse gas emission in leachate treatment plant and its carbon credit revenue. Earth Environ. Sci. 2021, 646, 012067. [Google Scholar] [CrossRef]

- Chiemchaisri, C.; Chiemchaisri, W.; Manochai, N. Methane and nitrous oxide emissions from a two stage membrane bioreactor applied in municipal landfill leachate treatment. J. Mater. Cycles Waste Manag. 2020, 22, 365–374. [Google Scholar] [CrossRef]

- Nuansawan, N.; Boonnorat, J.; Chiemchaisri, W.; Chiemchaisri, C. Effect of hydraulic retention time and sludge recirculation on greenhouse gas emission and related microbial communities in two-stage membrane bioreactor treating solid waste leachate. Bioresour. Technol. 2016, 210, 35–42. [Google Scholar] [CrossRef]

- Boonnorat, J.; Honda, R.; Panichnumsin, P.; Boonapatcharoen, N.; Yenjam, N.; Krasaesueb, C.; Wachirawat, M.; Seemuang-on, S.; Jutakanoke, R.; Teeka, J.; et al. Treatment efficiency and greenhouse gas emissions of non-floating and floating bed activated sludge system with acclimatized sludge treating landfill leachate. Bioresour. Technol. 2021, 330, 124952. [Google Scholar] [CrossRef]

- Wang, X.; Jia, M.; Chen, X.; Xu, Y.; Lin, X.; Kao, C.M.; Chen, S. Greenhouse gas emissions from landfill leachate treatment plants: A comparison of young and aged landfill. Waste Manag. 2014, 34, 1156–1164. [Google Scholar] [CrossRef]

- Hua, J.; Bai, S.Y.; Zhang, J.; Li, Z.Y. Greenhouse gas emission reduction and carbon credit revenue in a waste leachate treatment plant. Earth Environ. Sci. 2018, 191, 012082. [Google Scholar] [CrossRef]

- Dhruvanth, S.S.; Reddy, K.S.; Sai, P.S.; Gatla, R.K.; Sridhar, P.; Babu, T.R. Power Factor Correction: Its Importance and Improvements. In Proceedings of the International Conference on Augmented Intelligence and Sustainable Systems, Trichy, India, 23–25 August 2022; pp. 1293–1297. [Google Scholar]

- APHA. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington DC, USA, 2005. [Google Scholar]

- Snip, L. Quantifying the Greenhouse Gas Emissions of Wastewater Treatment Plants. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2010; p. 97. [Google Scholar]

- Corominas, L.; Flores-Alsina, X.; Snip, L.; Vanrolleghem, P.A. Comparison of different modeling approaches to better evaluate greenhouse gas emissions from whole wastewater treatment plants. Biotechnol. Bioeng. 2012, 109, 2854–2863. [Google Scholar] [CrossRef]

- Koutsou, O.P.; Gatidou, G.; Stasinakis, A.S. Domestic wastewater management in Greece: Greenhouse gas emissions estimation at country scale. J. Clean. Prod. 2018, 188, 851–859. [Google Scholar] [CrossRef]

- Koumalas, A.; Barampouti, E.; Dounavis, A.; Mai, S. Leachates from Landfill Sites in Thessaloniki, Greece: Effect of Aging. Environ. Res. Eng. Manag. 2019, 75, 30–39. [Google Scholar] [CrossRef]

- Tsilogeorgis, J.; Zouboulis, A.; Samaras, P.; Zamboulis, D. Application of a membrane sequencing batch reactor for landfill leachate treatment. Desalination 2008, 221, 483–493. [Google Scholar] [CrossRef]

- Ab Hamid, N.H.; Smart, S.; Wang, D.K.; Koh, K.W.J.; Ng, K.J.C.; Ye, L. Economic, energy and carbon footprint assessment of integrated forward osmosis membrane bioreactor (FOMBR) process in urban wastewater treatment. Environ. Sci. Water Res. Technol. 2020, 6, 153–165. [Google Scholar] [CrossRef]

| Processes 1 | Equations Used for GHG Emission Estimation (kg CO2eq/d) | ||

|---|---|---|---|

| Biological treatment | On-site GHG emissions | Production of GHGs from biomass decay | CO2,biomassdecay = Xdecay × 1.947 (Xdecay = Q × HRT × MLVSS × bH) |

| Production of GHGs from BOD oxidation and production of biomass | CO2,BODoxidation = RO2 × 1.1 (RO2 = [f − ] × EH × Q × Fo) | ||

| Consumption of GHGs from nitrification | CO2 = 0.308 × Nnitro (Nnitro = Ntotal − Nbio − (NH4-N)out − Norgout) | ||

| Production of GHGs from nitrification–denitrification | Ν2Oemission = Ntotal × 0.005 (CO2,eq = Ν2Oemission × GWPN2O = Ν2Oemission × 296) | ||

| Off-site GHG emissions | Production of GHGs from net power consumption | CO2,electricity = Erequired × Σ(Fi × EFi) | |

| Production of GHGs from treated leachates discharge to the aquatic environment | Ν2Oemission = NEffluent × EFEffluent × (44/28) (CO2,eq = Ν2Oemission × GWPN2O = Ν2Oemission × 296) | ||

| Tertiary treatment | Operation of the RO and evaporators | Emissions (CO2, CH4, N2O) = Electrical energy consumption × emissions (CO2, CH4, N2O) per electrical energy consumption × Q (CO2,eq = CO2 + (28 × CH4) + (296 × N2O) |

| Type of Sample | Conductivity (μS/cm) | pH | TSS (mg/L) | COD (mg/L) | BOD5 (mg/L) | TN (mg/L) | NH4-N (mg/L) |

|---|---|---|---|---|---|---|---|

| Raw leachate | 23,015 (2973) | 7.5 (0.2) | 166 (97) | 3286 (1910) | 909 (1242) | 1360 (300) | 941 (224) |

| Primary treatment | 19,278 (1274) | 8.4 (0.1) | 363 (127) | 2953 (950) | 1014 (598) | 997 (266) | 785 (200) |

| SBR effluent | 16,719 (2117) | 8.0 (0.3) | 217 (158) | 1302 (418) | 90 (50) | 747 (210) | 22 (46) |

| RO permeate | 405 (163) | 7.3 (0.5) | 4 (5) | 15 (8) | 11 (7) | 15 (9) | <1 |

| Processes | GHG Emission (kg CO2eq/d) | ||

|---|---|---|---|

| Secondary treatment | On-site GHG emissions | Production of GHGs from the decay of biomass | 2862.1 |

| Production of GHGs from BOD oxidation and production of biomass | 477.2 | ||

| Consumption of GHG from nitrification | −122.4 | ||

| Production of GHGs from nitrification–denitrification | 704.5 | ||

| Off-site GHG emissions | Production of GHGs from net power consumption | 492.0 | |

| Production of GHG from treated leachates discharge to the aquatic environment | 9.3 | ||

| GHG emissions from the biological treatment | 4422.7 | ||

| Tertiary treatment | GHG production from RO | 988.4 | |

| GHG production from evaporators | 4275.8 | ||

| GHG emissions from the advanced treatment | 5264.2 | ||

| Total GHG emissions | 9686.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsompanoglou, K.; Koutsou, O.P.; Stasinakis, A.S. Evaluating the Operation of a Full-Scale Sequencing Batch Reactor–Reverse Osmosis–Evaporation System Used to Treat Landfill Leachates: Removal of Pollutants, Energy Consumption and Greenhouse Gas Emissions. Energies 2023, 16, 6872. https://doi.org/10.3390/en16196872

Tsompanoglou K, Koutsou OP, Stasinakis AS. Evaluating the Operation of a Full-Scale Sequencing Batch Reactor–Reverse Osmosis–Evaporation System Used to Treat Landfill Leachates: Removal of Pollutants, Energy Consumption and Greenhouse Gas Emissions. Energies. 2023; 16(19):6872. https://doi.org/10.3390/en16196872

Chicago/Turabian StyleTsompanoglou, Konstantinos, Olga P. Koutsou, and Athanasios S. Stasinakis. 2023. "Evaluating the Operation of a Full-Scale Sequencing Batch Reactor–Reverse Osmosis–Evaporation System Used to Treat Landfill Leachates: Removal of Pollutants, Energy Consumption and Greenhouse Gas Emissions" Energies 16, no. 19: 6872. https://doi.org/10.3390/en16196872

APA StyleTsompanoglou, K., Koutsou, O. P., & Stasinakis, A. S. (2023). Evaluating the Operation of a Full-Scale Sequencing Batch Reactor–Reverse Osmosis–Evaporation System Used to Treat Landfill Leachates: Removal of Pollutants, Energy Consumption and Greenhouse Gas Emissions. Energies, 16(19), 6872. https://doi.org/10.3390/en16196872