1. Introduction

Global warming resulting from the use of non-renewable energy sources such as fossil fuels is increasingly considered to be one of the major challenges the world is facing today. Improving industrial energy management in order to increase energy efficiency in industry is one of the most important means to deal with this challenge, as industry together with transportation are the highest energy-using sectors in the world [

1]. About one-third of global energy use and 40% of carbon dioxide (CO

2) emissions are attributable to the manufacturing industry [

2]. Therefore, it is of the utmost importance that the industrial sector contributes proportionately towards energy savings and climate change mitigation.

Energy efficiency is also one of the most significant areas where companies have turned their attention towards voluntary environmental agreements and standards [

3]. One such international standard, which has achieved global success in the last two decades, is ISO 14001 [

4], containing specifications for the implementation of environmental management systems (EMS). Such a system “is a set of management processes and procedures that allow an organization to analyze, control and reduce the environmental impact of its operations and services to achieve cost savings, greater efficiency and oversight, and streamlined regulatory compliance” [

5]. Of central importance in an EMS are the concepts of continuous incremental improvement (the Plan-Do-Check–Act Cycle) and management by objectives (MBO), which, in turn, are based on goal-setting theory [

6]. During the period from 1996, when it first became possible to certify to ISO 14001, until now, more than 300,000 organizations worldwide have chosen to certify their EMS. In addition to the widespread adoption of ISO 14001, European industrial facilities have, to some extent, also adopted the Eco-Management and Audit Scheme (EMAS) regulation (about 3000 registered companies), which is partly based on ISO 14001 [

7]. As a result of the popularity of the EMS approach, national and international standards for more specific energy management systems (EnMS) have been developed during the last few years, culminating in the launch of the ISO 50001 certifiable standard in 2011 [

8]. This standard uses quite similar methodology concerning creation, structure, implementation process and auditing by a third party to ISO 14001 [

9] and the Plan-Do-Check-Act Cycle is central also in EnMSs [

10].

At the time when ISO 14001 was first launched, advocates of EMS argued that the system could provide a structured and systematic way to deal with organizational environmental issues [

11]. It was argued that companies with poor environmental performance can use EMS as a valuable management tool and that the tool can provide more ambitious companies with a benchmark that can be used to identify weaknesses in the existing management system [

12]. Furthermore, it was claimed that EMS standards can reduce environmental impact as well as generate cost savings and business opportunities [

13]. Critical voices were also heard, and it was claimed that an ISO 14001-based system is an inadequate tool, since it does not require certified companies to measure environmental performance nor to disclose results [

14]. The standard ISO 14001 itself was criticized for lack of transparency [

15]. Furthermore, scholars claimed that the standard gives the companies the possibility to apply the standard’s specification in a way that makes it possible for them to get a certificate without achieving any real improvements [

16]. This early literature with a theoretical perspective energy management is often seen as an environmental issue among others. This perception was challenged by an empirical study in which it was found that energy management is separated from EMS in Norwegian industry, and the study argues for joint management of energy and environmental issues [

17]. However, a somewhat more recent Swedish study focusing on the manufacturing industry showed that energy was one of the most common areas in the companies’ environmental objectives [

6].

With the study presented in this paper, we want to contribute to the knowledge base concerning the usefulness of the voluntary management system approach for improving the energy efficiency of industrial processes. Due to the nature of previous empirical studies, we aim to do this by means of objective environmental data, in which we have extracted specific energy-related data. The purpose of this paper is to assess the impact of voluntary management systems on energy efficiency in the Swedish manufacturing industry. Specific focus is on EMSs based on ISO 14001. Even though EnMS is gaining momentum with the launch of ISO 50001, we have opted to specifically focus on the more general ISO 14001 since the number of certifications is much greater and most EnMSs have only been in use for a limited period of time.

Results from a study based on industrial energy-related data derived from mandatory annual environmental reports from 116 manufacturing facilities in Sweden are presented. After presenting the results of previous studies in this field of research in the second section, a more specific hypothesis is derived in

Section 3. Following the problem description and hypothesis development, the data set and the statistical methods used in the study are outlined in

Section 4. Results are presented in

Section 5 followed by

Section 6 where the results are discussed. Conclusions are then drawn in the final section.

2. Literature Review

The worldwide distribution and commercial success of ISO 14001 has led to extensive research on the adoption of EMSs based on the standard [

18,

19]. Studies concentrating on the possible benefits of the EMS approach are popular among scholars. A majority of these rely heavily on company representatives’ perception of benefits, and a much more limited number of studies are based on environmental data originating from physical measurements [

20]. The more fact-based studies that do exist have mainly targeted various types of emissions. To our knowledge, no such study has been performed that specifically targets the impact of EMSs on energy efficiency. However, amongst the rather considerable amount of scholarly literature grounded on perceived effects and benefits, there are some examples that provide some insights concerning the usefulness of EMSs for organizational energy management and energy efficiency. The findings in these studies are briefly presented here.

In the only existing trans-international study of relevance, Summers Raines [

21] studied, by means of a questionnaire, the possible differences in benefits of ISO 14001 adoption in developing countries and developed countries. She found that a vast majority of the companies, independent of where they operate, had reached significant environmental improvements due to ISO 14001. Commonly reported improvements were energy savings, overall reduced resource usage and reduced waste disposal.

Ammenberg et al. [

22] belong to the group of European scholars who argue that EMSs lead to a reduction in energy use in general. In addition to the positive effect on energy use in a network of small and medium-sized companies, they also found substantial improvements concerning other aspects, for example, improved recycling of waste, substitution of chemicals and reduction of transports. A similar impact was identified by Pedersen [

23] in a large questionnaire-based study of EMAS-registered companies. The highest ranked benefits from EMAS adoption were environmental improvements such as decreased energy consumption and waste disposal. Both of these studies strengthen the findings of two earlier studies in the European context. Christensen and Rasmussen [

24] found, by means of a multiple case study, that Danish companies within the printing house industry were achieving concrete improvements—for example, reduction of paper and printing ink waste, volatile organic compounds (VOC) reductions as well as reduction of energy use and wastewater production. In a UK chemical manufacturing company, Robinson and Clegg [

25] found positive effects both concerning management issues (e.g., reduced health and safety risks) and more concrete improvements (e.g., reduced energy use and introduction of a recycling system).

A clear majority of the studies performed outside Europe also show a positive picture after EMS adoption. Two early studies, one action-research-based study performed in Mexico [

26] and another survey in Japan [

27], show mostly positive results. Besides a number of organizationally related improvements, the Mexican companies also experienced reduction of materials and energy use. About half of the Japanese manufacturing companies reported reduction of electricity use as well as reduction of paper, chemicals and toxic materials, fuel and packaging volume. However, air and water emissions and the frequency of environmental accidents were not affected. A few years later, interviewed representatives from a wide variety of Australian companies attributed even greater impact to the EMSs [

28]. About 70% of the representatives reported a positive change in environmental performance in areas such as energy and water use in addition to a number of management improvements. At about the same time, a survey in Malaysia indicated reduced energy consumption, waste reduction and fewer environmental accidents in various types of industries due to the EMS [

29], and another survey in Cameroon revealed that more than 90% of the companies with an EMS had realized environmentally related benefits—for example, improvements in energy management and reductions concerning waste, accidents, noise pollution and various emissions [

30]. In a more recent study, Brazilian companies commonly reported in a questionnaire that they were experiencing reduction in energy, water, gas and fuel oil consumption after EMS adoption [

31].

Even if most studies, regardless of their geographical origin, have been rather optimistic concerning the usefulness of EMSs, there are exceptions. In contrast, Hamschmidt and Dyllick [

32] claim that EMSs seem to be useful in Swiss companies, but not sufficiently, however, for them to lead to effective ecological improvements. Only 10% of the companies in Switzerland reported a large decrease in energy and material flows in relation to turnover due to ISO 14001 implementation. The researchers argue that their findings have to be considered as rather modest since the areas covered typically represent easy win-win situations, as economic benefits run in parallel with those kinds of measures. These findings are consistent with those of Rigling et al. [

33] in four case companies in the US and Thailand. In these manufacturing companies management benefits, for example, employee awareness and improved public relations were identified, rather than concrete improvements, in environmental performance. However, some indications of improved energy resource use were reported by company representatives.

3. Problem Description and Hypothesis Development

As mentioned above, with few exceptions, studies on the influence of EMS rely heavily on one company representative’s perception of benefits, which is an approach with a number of drawbacks [

18,

19,

34]. The problem with the representatives’ statements is that they must be seen as subjective perceptions [

35], which is associated with methodological weaknesses [

36]. The findings might be different if more objective evidence was collected [

19,

32]. Another weakening factor is that the representatives often have a personal interest in overvaluing the performance variables they are providing [

19]. Additionally, they inevitably have to communicate their own social role within the company as a positive one, and hence will not give any information that could harm the company or themselves as experts. This might lead to biases that cannot be eliminated [

34,

35].

Moreover, previous studies have tended to focus on companies’ overall environmental performance, not identifying differences in different environmental aspects [

3,

18,

19]. Existing studies that concentrate on specific environmental aspects have mainly targeted various types of emissions to air or water. Some of these studies show positive results following the adoption of EMSs [

37,

38,

39,

40], while others are more pessimistic in their evaluation [

41,

42,

43,

44], and some show inconclusive results [

45,

46,

47]. Additionally, a majority of previous studies have concentrated on the influence on organizational issues rather than actual changes in environmental or energy efficiency performance [

3].

Considering the fact that the standardized management system approach in the shape of EMSs based on ISO 14001 has been used for quite some time, the ability to generalize is of utmost importance. Therefore, there is a strong need to complement the more qualitative studies with studies that are based on more objective, fact-based industrial energy data, in order to make it possible to generalize from the results. The nature and inconclusive results of previous studies, together with the fact that no previous quantitative study has focused specifically on the connection between EMS implementation and ISO 14001 certification and energy efficiency, provides a good argument for further studies in this field. As a result of previous research and its empirical evidence, we have chosen to collect empirical industrial energy data with a low degree of subjectivity and use this data and relevant statistical tests to test the following null hypothesis and alternative hypothesis:

H0 = the change in energy efficiency for ISO 14001-certified companies does not differ significantly from the corresponding change for non-certified companies;

HA = the change in energy efficiency for ISO 14001-certified companies differs significantly from the corresponding change for non-certified companies.

4. Methods and Data

The design and structure of this study has been inspired by previous work with a focus on the impact of ISO 14001-based EMSs on industrial waste generation [

48]. The same research approach as in the previous study is used in this study, except the fact that this study focuses entirely on industrial energy efficiency. When studying the impact of EMSs on energy efficiency, focus must be on changes in efficiency over time, as EMS is a tool for continuous improvement and does not establish any absolute performance levels. Furthermore, companies without an EMS must also be included to enable comparison [

49]. Finally, the performance of companies prior to the introduction of the EMS must be taken into account in order to address any possible selection effects where better performance precedes adoption [

36,

50].

4.1. Research Approach

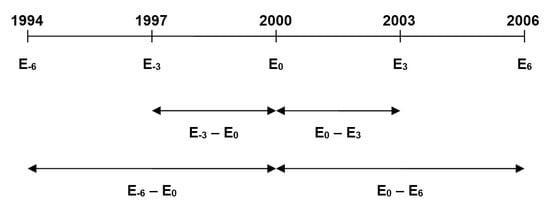

In this study, we have chosen 2000 as the base year, and we choose to study the change in energy efficiency over three-year intervals over the period 1994–2006, i.e., six years prior to certification and six years after certification. The three-year intervals were chosen primarily in order to limit the amount of data. A schematic picture of the time periods over which the change in energy efficiency has been measured is shown in

Figure 1. The basis for analysis has not been the improvements as such, but rather the change in the rate of energy efficiency improvement before and after ISO 14001 certification and the corresponding periods for non-certified companies. Before analysis, all parameters (e.g., electricity) have been normalized to each company’s production rate (e.g., total weight of products or total weight of input raw material), in order to be able to study changes in energy efficiency independent of the level of production. Since we are using the change in energy efficiency improvement measured in percent, we have been able to use the individual indicators of production rate for each company, as these are provided in each company’s environmental permit and reported in its annual environmental report. This means that we have studied changes in eco-efficiency (e.g., Mwh electricity/ton products, year) rather than changes in absolute numbers.

We chose to analyze differences over six-year periods (2000–2006 compared to 1994–2000) since we wanted a fairly long time period but not so long that too much has changed in the companies’ production setup and product mixes, thus making analysis of energy efficiency hard to perform. We also wanted to focus specifically on the period immediately before and after ISO 14001 certification, and, therefore, also chose to analyze differences over three-year periods (2000–2003 compared to 1997–2000). The shorter period 1997–2003 has the advantage that the production most probably has not changed so much during the period, and it is therefore easier to follow changes in performance. In addition, it was easier to find energy data from the years 1997, 2000 and 2003. In contrast, it might be a drawback that there is a risk that changes are rather small. The major disadvantage with the longer period is that energy data from 1994 was hard to find, which made the statistical analysis more difficult. The change in the energy efficiency improvement has been calculated for two different energy categories: electricity and fossil fuel consumption. These two categories were chosen as they are both of great importance concerning environmental impact, especially regarding global warming. In addition, it is also suitable to study these categories, as electricity and fossil fuel consumption are commonly available in the environmental reports that we have used as source in this study. The parameters that have been the subject of analysis are the following if the designations from

Figure 1 are used:

In order to make what is actually calculated and analysed clear, an example from one of the included companies is presented in

Table 1.

4.2. Data Collection

To gain access to energy data that have been reported with limited elements of subjectivity, mandatory yearly environmental reports from companies with regulatory environmental permits have been used. Environmental reports have been collected from both ISO 14001-certified companies and non-certified companies. We have chosen to study manufacturing companies (NACE (nomenclature of economic activities) code 15–37) since energy efficiency is likely to be an important environmental issue in these companies and the adoption of certified EMSs are widespread in this business category. Complete information from all County Administrative Boards in Sweden showed that the total number of such companies was 2331. A list of these companies was integrated with a compilation of companies with an ISO 14001 certificate.

The peak regarding new ISO 14001-certified manufacturing Swedish companies occurred in year 2000 and this year was therefore chosen as base year for the study. It would have been possible to use more recent data, but this would have resulted in a considerably smaller population of companies. However, since the ISO 14001 standard has only undergone minor changes since the year 2000, the data collected should be the best choice in this case considering the fact that potential changes are most likely small and as large a population as possible is desirable. A total of 130 such companies could be found. A comparative equally sized random sample was created from the total population of non-certified manufacturing companies with a permit. Environmental reports for the years 1994, 1997, 2000, 2003 and 2006 were collected from the companies’ local and regional environmental agencies. Documents were received for 217 of the 260 companies (83%). All 217 companies were not included in the study for various reasons. For example, not enough necessary documents could be found, the facility had closed down, or there was poor document quality. After the removal of non-usable companies, 66 certified companies and 50 non-certified companies remained.

Summary statistics of the two samples are illustrated in

Table 2. The fact that average company size is smaller for the non-certified companies (

t-test,

p < 0.05) should be considered when the results of this study are interpreted, since the data from the two groups of companies might be biased concerning company size. Unfortunately, this was unavoidable because company size was not available in the original lists of companies that we received from the County Administrative Boards. The size of the companies in the random sample was identified after the sample was drawn.

4.3. Statistical Methods

Certified and non-certified companies were compared using the

t-test, which is the preferred test for comparing two samples with normally distributed data and where the assumptions regarding equal variances apply [

51,

52]. In order for the

t-test to have a high degree of validity, the data must be normally distributed and the variances must be equal. The assumption of normally distributed data was tested using the parameters standardized skewness and standardized kurtosis [

53]. Variances were tested by means of Levene’s test, which is a commonly used test to compare variances between groups. When extreme values are present, the standard method included in the software IBM SPSS Statistics 22 has been used for identification of outliers.

5. Results

When analyzing the change in improvements of energy efficiency, two different parameters were used: electricity and fossil fuel consumption (excluding fuels for internal transports). Fossil fuel use often consists only of consumption of fuel oil but can sometimes include several fossil fuels such as oil, liquefied petroleum gas (LPG) and natural gas. In such cases, the total energy content of the various fuels was calculated. Renewable energy is not possible to include in our analysis even though such data sporadically are reported in the environmental reports. This is because an increase in the use of renewable energy sources can be counted either as an improvement (if fossil fuels are replaced) or as deterioration (if the total energy use increases).

On several occasions (

Section 5.1 and

Section 5.2), we have used SPSS to identify extreme values (outliers) in the data set. We have followed each of those values back to the original data source, i.e., the environmental reports, and we have searched through the reports to try to find explanations for the extreme values (It is mandatory to report major changes in production in the reports.). For all the outliers that we have removed, we are certain that it must be some kind of reporting error or that the companies have not reported the total consumption of electricity or fossil fuel.

5.1. Time Period 1997–2003

Only a relatively small number of non-certified companies reported electricity use in 1994 (

Table 3), but we are still able to perform a

t-test with enough validity for a comparison between the two groups of companies since a common rule of thumb is that one should at least have more than ten observations in a sample [

52]. In

Table 3, we can see that one of the values of standardized skewness is outside the range limit of +2, but it is rather close and we should still be able to consider the distribution as normally distributed. Furthermore, we see that the mean value of the change in the rate of improvement indicates a slight increase in efficiency for both certified (1.53%) and non-certified companies (4.05%). A

t-test, after one outlier has been identified and removed in the certified group, gives the value

p = 0.839, and we can therefore not reject the null hypothesis and can be rather certain that there are no differences between the two groups of companies. Levene’s test shows no significant differences (

p = 0.067) regarding variances, and the

t-test is therefore also valid in this regard.

Almost twice as many of the non-certified companies have reported their use of fossil fuel compared to the use of electricity (

Table 4), and a

t-test, therefore, should have slightly more explanatory power. The

t-test has a high degree of validity in this case, as skewness and kurtosis values are well within the limits, and Levene’s test gives a high

p-value of 0.86. The poor fossil fuel efficiency in the non-certified companies after the base year compared to the previous period (average change −34.2%) gives us cause to suspect that the certified companies are performing better. Indeed, after the removal of one outlier in the non-certified sample and five outliers in the certified sample, a

t-test gives us

p = 0.019, which makes the difference significant (and we can reject the null hypothesis). The low

p-value means that we can be relatively certain that the certified companies are performing better regarding their work towards improved electricity efficiency in production for the shorter time period close to the ISO 14001 certification year.

5.2. Time Period 1994–2006

In the same regard as for the shorter time period, non-usable environmental reports for the time period 1994–2006 have a negative effect on the possibility to identify differences between the two groups of companies. There are only seven observations in the non-certified sample, and we should, therefore, be careful when interpreting the results. However, the average changes in both groups are limited in their extent, and the change seems to be very similar in both groups (

Table 5 (2.03% in the certified group and 2.46% in the non-certified group)). Despite the fact that one of the kurtosis values is somewhat outside the limit, a

t-test can be regarded as valid, both regarding normality and the assumption of equal variances (Levene’s Test gives

p = 0.536). After the removal of one outlier in the non-certified sample and two outliers in the certified sample, a

t-test gives us no reason to question the null hypothesis (

p = 0.977). Even though we have such few observations in the non-certified sample, the results seem to be rather robust, and we have no reason to believe that there is a difference between the two groups of companies.

As before, we are also somewhat limited by a low count of observations regarding fossil fuel use over the longer time period, due primarily to the quality of the 1994 environmental reports from the non-certified companies (

Table 6).

Nevertheless, the data is evenly distributed, and there is no reason to believe that we cannot regard the variances as equal (Levene’s test gives p = 0.485). After the removal of one outlier in the non-certified sample and two outliers in the certified sample, a t-test gives us p = 0.171, which does not make the difference significant (and we cannot reject the null hypothesis), even though the non-certified companies seem to perform rather poorly after the base year. However, we have reason to suspect that the certified companies are also performing better than the non-certified regarding fossil fuel use in the longer time period.

6. Discussion

To summarize the results of our study, we have found some evidence that companies adopting an EMS and certifying to ISO 14001 might improve their energy efficiency concerning fossil fuel use at a faster rate than companies choosing not to certify. We were not able to find significant differences comparing the development over six-year intervals before and after ISO 14001 certification, even if a difference between the two groups of companies could be suspected. However, over a shorter interval of three years closer to the certification year, we can conclude that certified companies perform better. In contrast, we were not able to find any significant differences concerning electricity use. The differences in the results are not easily explained, but it might be the case that the certified companies estimate that the use of fossil fuel in production is a more important environmental issue than energy efficiency related to the use of electricity, and, therefore, focus their improvement effort on fossil fuels. Such a choice might be natural since fossil fuel use is a rather high profile issue and the electricity production mix in Sweden is not associated with a high degree of CO2 emissions as it originates almost exclusively from nuclear and hydro power.

However, we should be somewhat careful in our conclusions since the data set used is associated with some weaknesses. Our data is evenly distributed, and it is clear that the distribution of the data does not influence the statistical methods used. In contrast, the variances in the energy data both from the ISO 14001-certified companies and the non-certified companies are large, hindering us from seeing clearer differences. Nevertheless, we have been able to limit the variation to some extent by identifying and removing outliers in the data set. After having gone back to the environmental reports in which the analyzed data originates, we are certain that it was appropriate to remove the outliers. However, it should be noted that the removal of outliers in a data set might have an effect on the validity of the analysis. The large variances are somewhat surprising considering that the data is derived from mandatory environmental reports. One factor influencing the variances might be the methods used by the companies to measure energy parameters. It is obvious when studying the reports that most companies do not measure the use of electricity or fossil fuel themselves. Instead, they rely on data from suppliers. Additionally, the average size of the companies in the two groups differs. It was not possible to deal with this beforehand considering the nature of the original databases. How this fact affects the results is unclear since the literature does not help us with any evidence concerning the influence of firm size on actual environmental benefits from EMS adoption. On the other hand, we have every reason to believe that the approach taken in this study to try to exclude the effects of factors other than the introduction of EMSs is accurate.

We have not been able to find any other quantitative studies focusing on similar energy parameters as those in our study to compare with. However, our rather mixed results seem to be in line with the overall picture given by the quantitative studies addressing the effects of ISO 14001 on emissions cited in

Section 3. In addition, somewhat surprisingly, our results can only to some degree be regarded as being in line with the majority of the previous research, based on subjective perceptions of company representatives presented in

Section 2. These studies, for the most part, show a rather significant influence of certified EMS on energy parameters (for example, [

23,

28,

30,

31]), even if two studies are more pessimistic regarding the usefulness of EMSs for energy efficiency improvements [

32,

33]. It seems that the suspicion regarding biased results derived from subjective qualitative data might be valid.

7. Conclusions

Considering the wide adoption of ISO 14001 in many types of industries over the globe, we have to regard our research findings as rather disappointing, especially considering the fact that the energy management standard ISO 50001 is showing a similar increase in popularity to ISO 14001 in its early years [

7]. Our rather mixed results concerning the possible energy-related benefits of ISO 14001-based EMSs provide important input for companies already certified as well as for those considering certification. It seems as if a positive outcome from system adoption and third party certification is no guarantee for energy management improvement even though the literature review has shown that there are many examples in which the systems have been successful. Managers in certified companies and companies that want to or are externally pressured (e.g., by other companies in their supply chain) to implement an EMS should be aware that they have to give their support and sufficient resources to system development and integration in operations. Policy makers should take the finding in this study, and in other studies in this field, into consideration when they embed voluntary management systems into State-implemented industrial energy efficiency programs or energy-related legislation. The findings in this study also provide input for the ISO organization issuing the management system standards. However, it looks as though the ISO organization has successfully identified and discussed findings in this research field, as the new version of ISO 14001, published at the end of 2015, has more focus on management by environmental objectives as well as specifications concerning the assessment of environmental performance [

54]. These changes have also been integrated into ISO 50001 [

10].

Despite the partly disappointing findings in this study, it is too early to generally regard voluntary management system approaches such as ISO 14001-based EMSs as unsuccessful regarding their ability to improve industrial energy efficiency. The mixed results in quantitative fact-based studies focusing on emissions to air and water, the differences in results in fact-based studies compared to the findings in studies based on subjective perceptions, and the lack of studies that specifically focus on energy-related parameters, are all reasons for performing further studies in this field so that we can better understand the role of voluntary management systems for energy efficiency and climate change mitigation. It might also be a good idea for further studies to analyze the influence of the ISO 50001 standard, since research addressing the usefulness of this standard is still lacking. Future studies should preferably be based on objective energy efficiency data from a large number of companies so that small differences in performance can be detected.