Exploitation Contradictions Concerning Multi-Energy Resources among Coal, Gas, Oil, and Uranium: A Case Study in the Ordos Basin (Western North China Craton and Southern Side of Yinshan Mountains)

Abstract

:1. Introduction

2. Resources in the Study Area

2.1. Brief Introduction to the Ordos Basin

2.2. Resources in the Ordos Basin

3. Mutualism and Accompanying Situation among the Multiple Resources in the Ordos Basin

3.1. General Development Induction of Coal Resources

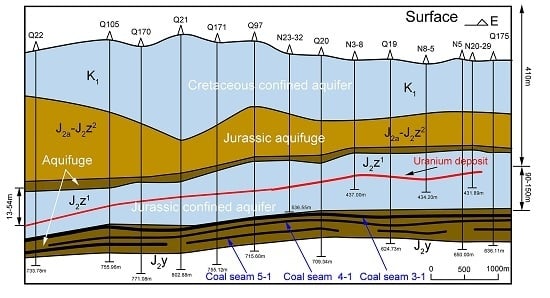

3.2. Development Contradictions between Coal and Uranium

3.3. Exploitation Mode of Uranium

3.4. Development Contradictions between Coal and Natural Gas

3.5. Experience Reference from Integrated Coal and Gas Production

4. Discussion and Future Outlook

5. Conclusions

- (1)

- The energy structure of China has long been dominated by its “rich coal, meager oil, and deficient gas”. Hence, coal has contributed greatly to China’s economy. However, coal production in the northeastern, eastern, and southern regions of China is now facing various types of problems, which forces coal production to transfer to the western and northern regions of China. There are multiple resources, such as uranium, natural gas, coal, and oil, in these regions, which induce exploitation contradictions among them.

- (2)

- The Ordos Basin is the largest energy-based resources aggregation area in China, and many types of minerals were reserved in different evolution periods; mutualistic and accompanying occurrence patterns of different resources are common. The conflicts and contradictions among oil/gas, coal, and uranium are becoming increasingly prominent.

- (3)

- The coal mining procedure leaves numerous cracks in the strata above/below the gob area, which provide channels for water migration. Upper uranium mining can leave radioactive elements in water and will severely influence the workers’ health and the natural water system. Hence, the coal mining procedure should leave sufficient space and time for the uranium mining procedure. During the exploitation of uranium, the measure of the unbalanced injection and extraction should be adopted to avoid the migration of radioactive elements in the underground water system.

- (4)

- The extraction of oil/gas must be equipped with a sufficient number of pipelines and drillings, which bring some hidden dangers to the coal mining procedure. Additionally, the durations for mining rights of oil/gas and coal also conflict greatly with each other. Experience from integrated coal and gas production can be learned to coordinate the contradiction between coal and gas/oil exploitation, which is a foreseeable measure to be widely applied in the Ordos Basin.

- (5)

- A widely accepted consensus should first be reached among the different mining rights of different energy resources and between mining corporations and governments. Each energy resource has its special role in industrial society. It is unwise to choose a fertile resource and abandon an infertile one or to choose one that is easy to exploit and ignore the remainder. A sustainable, environmentally friendly, and comprehensive resources utilization system must be established and popularized.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ministry of Land and Resources of the People’s Republic of China. China Mineral Resources 2014; Geological Publishing House: Beijing, China, 2015.

- U.S. Energy Information Administration, International Energy Data and Analysis. Available online: http://www.eia.gov/beta/aeo/?src=-f2 (accessed on 13 November 2015).

- Wang, L.; Watanabe, T.; Xu, Z. Monetization of external costs using life cycle analysis: A comparative case study of coal-fired and biomass Power Plants in Northeast China. Energies 2015, 8, 1440–1467. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, N.; Gong, L.; Xue, F.; Zheng, X. Application of a backfilling method in coal mining to realise an ecologically sensitive “Black gold” industry. Energies 2015, 8, 3628–3639. [Google Scholar] [CrossRef]

- General Office of the State Council of the People's Republic of China, Energy Development Strategic Action Plan from 2014 to 2020. Available online: http://www.gov.cn/zhengce/content/2014-11/19/content_9222.htm (accessed on 14 November 2015).

- Yuan, L. Theory and practice of integrated coal production and gas extraction. Int. J. Coal Sci. Technol. 2015, 2, 3–11. [Google Scholar] [CrossRef]

- Hu, G.; Xu, J.; Zhang, F.; Zhao, C.; Qin, W.; Zhu, Y. Coal and coalbed methane co-extraction technology based on the ground movement in the Yangquan Coalfield, China. Energies 2015, 8, 6881–6897. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, L.; Liu, H.; Kong, S.; Yang, Q.; Zhu, J.; Tu, Q. Definition, theory, methods, and applications of the safe and efficient simultaneous extraction of coal and gas. Int. J. Coal Sci. Technol. 2015, 2, 52–65. [Google Scholar] [CrossRef]

- Xu, Y. Using basalt geochemistry to constrain Mesozoic-Cenozoic evolution of the lithosphere beneath North China Craton. Earth Sci. Front. 2006, 13, 93–104. [Google Scholar]

- Bi, L.; He, H.; Wei, Z.; Feng, S. Fractal properties of landforms in the Ordos block and surrounding areas, China. Geomorphology 2012, 175–176, 151–162. [Google Scholar] [CrossRef]

- Wang, C.; Sandvol, E.; Zhu, L.; Lou, H.; Yao, Z.; Luo, X. Lateral variation of crustal structure in the Ordos block and surrounding regions, North China, and its tectonic implications. Earth Planet. Sci. Lett. 2014, 387, 198–211. [Google Scholar] [CrossRef]

- Ren, Z.; Zhang, S.; Gao, S.; Cui, J.; Xiao, Y.; Xiao, H. Tectonic thermal history and its significance on the formation of oil and gas accumulation and mineral deposit in Ordos Basin. Sci. China Ser. D Earth Sci. 2007, 50, 27–38. [Google Scholar] [CrossRef]

- Li, R.; Li, Y. The geologic features of mineralization at the Dongsheng uranium deposit in the northern Ordos basin (Central China). Russ. Geol. Geophys. 2011, 52, 593–602. [Google Scholar]

- Wang, M.; Luo, J.; Li, M.; Bai, X.; Cheng, C.; Yan, L. Provenance and tectonic setting of sandstone-type uranium deposit in Dongsheng area, Ordos basin: Evidence from U-Pb age and Hf isotopes of detrital zircons. Acta Petrol. Sin. 2013, 29, 2746–2758. [Google Scholar]

- Gao, G.; Kang, G.; Li, G.; Bai, C. Crustal magnetic anomaly in the Ordos region and its tectonic implications. J. Asian Earth Sci. 2015, 109, 63–73. [Google Scholar] [CrossRef]

- Booth, C.J. The effects of longwall coal mining on overlying aquifers. Geol. Soc. 2002, 198, 17–45. [Google Scholar] [CrossRef]

- Peng, S.S. Coal Mine Ground Control, 3rd ed.; China University of Mining and Technology Press: Xuzhou, China, 2013. [Google Scholar]

- Du, J.; Meng, X. Mining Science; China University of Mining and Technology Press: Xuzhou, China, 2009. [Google Scholar]

- Singh, R.N.; Atkins, A.S. Design considerations for mine workings under accumulations of water. Int. J. Mine Water 1982, 1, 35–56. [Google Scholar] [CrossRef]

- Kendorski, F.S. Effect of full-extraction underground mining on ground and surface waters: A 25-year retrospective. In Proceedings of the 25th International Conference on Ground Control in Mining, Morgantown, WV, USA, 1–3 August 2006; pp. 425–430.

- Fan, G.; Zhang, D. Mechanisms of aquifer protection in underground coal mining. Mine Water Environ. 2015, 34, 95–104. [Google Scholar] [CrossRef]

- Singh, R.; Mandal, P.K.; Singh, A.K.; Kumar, R.; Maiti, J.; Ghosh, A.K. Upshot of strata movement during underground mining of a thick coal seam below hilly terrain. Int. J. Rock Mech. Min. 2008, 45, 29–46. [Google Scholar] [CrossRef]

- Singh, M.M.; Kendorski, F.S. Strata disturbance prediction for mining beneath surface water and waste impoundments. In Proceedings of the 1st Conference on Ground Control in Mining, Morgantown, WV, USA, 27–29 July 1981; pp. 76–89.

- Yavuz, H. An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int. J. Rock Mech. Min. 2004, 41, 193–205. [Google Scholar] [CrossRef]

- Du, J.; Wang, L. Special Coal Mining Method; China University of Mining and Technology Press: Xuzhou, China, 2003. [Google Scholar]

- Tewari, R.; Horemans, N.; Nauts, R.; Wannijn, J.; Van Hees, M.; Vandenhove, H. Uranium exposure induces nitric oxide and hydrogen peroxide generation in Arabidopsis thaliana. Environ. Exp. Bot. 2015, 120, 55–64. [Google Scholar] [CrossRef]

- Joksic, A.S.; Katz, S.A. Chelation therapy for treatment of systemic intoxication with uranium: A review. J. Environ. Sci. Health Part A Toxic Hazard. Subst. Environ. Eng. 2015, 50, 1479–1488. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Cheng, Y.; Liu, H. An analysis of fatal gas accidents in Chinese coal mines. Saf. Sci. 2014, 62, 107–113. [Google Scholar] [CrossRef]

- Xue, F.; Zhang, N.; Feng, X.; Zheng, X.; Kan, J. Strengthening borehole configuration from the retaining roadway for greenhouse gas reduction: A Case Study. PLoS ONE 2015, 10, e115874. [Google Scholar] [CrossRef] [PubMed]

- IPCC, 2007: Climate Change 2007: Synthesis Report. Contribution of Working Groups I, II and III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Pachauri, R.K.; Reisinger, A. (Eds.) IPCC: Geneva, Switzerland, 2007; p. 104.

- Wang, L.; Cheng, Y.; An, F.; Zhou, H.; Kong, S.; Wang, W. Characteristics of gas disaster in the Huaibei coalfield and its control and development technologies. Nat. Hazards 2014, 71, 85–107. [Google Scholar] [CrossRef]

- Lu, S.; Cheng, Y.; Qin, L.; Li, W.; Zhou, H.; Guo, H. Gas desorption characteristics of the high-rank intact coal and fractured coal. Int. J. Min. Sci. Technol. 2015, 25, 819–825. [Google Scholar] [CrossRef]

- Tao, S.; Tang, D.; Xu, H.; Gao, L.; Fang, Y. Factors controlling high-yield coalbed methane vertical wells in the Fanzhuang block, Southern Qinshui Basin. Int. J. Coal Geol. 2014, 134–135, 38–45. [Google Scholar] [CrossRef]

- Bustin, R.M.; Cui, X.; Chikatamarla, L. Impacts of volumetric strain on CO2 sequestration in coals and enhanced CH4 recovery. AAPG Bull. 2008, 92, 15–29. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D. Modelling permeability for coal reservoirs: A review of analytical models and testing data. Int. J. Coal Geol. 2012, 92, 1–44. [Google Scholar] [CrossRef]

- Wang, W.; Li, X.; Lin, B.; Zhai, C. Pulsating hydraulic fracturing technology in low permeability coal seams. Int. J. Min. Sci. Technol. 2015, 25, 681–685. [Google Scholar] [CrossRef]

- Shen, C.; Lin, B.; Sun, C.; Zhang, Q.; Li, Q. Analysis of the stress-permeability coupling property in water jet slotting coal and its impact on methane drainage. J. Petrol. Sci. Eng. 2015, 126, 231–241. [Google Scholar] [CrossRef]

- Yu, H.; Jing, R.; Wang, P.; Chen, L.; Yang, Y. Preferential adsorption behaviour of CH4 and CO2 on high-rank coal from Qinshui Basin, China. Int. J. Min. Sci. Technol. 2014, 24, 491–497. [Google Scholar] [CrossRef]

- Xiao, X.; Pan, Y.; Lu, X.; Yang, X. Mechanism of methane permeability enhance through ultrasonic irradiating on low permeable coal seam. Chin. J. Geophys. 2013, 56, 1726–1733. (In Chinese) [Google Scholar]

| Stratigraphic Horizon | Coal | Natural Gas | Coalbed Methane | Uranium | Kaolinite | Oil Shale |

|---|---|---|---|---|---|---|

| Quaternary | ||||||

| Palaeogene | ||||||

| Cretaceous | ● | |||||

| Jurassic | ● | ● | ● | ● | ● | ● |

| Triassic | ● | |||||

| Permian | ● | ● | ● | ● | ||

| Carboniferous | ● | ● | ● | ● | ||

| Ordovician | ● |

| Strength Rank of the Overlying Strata | Thickness of the Fractured Zone (m) |

|---|---|

| Strong | |

| Medium strong | |

| Weak | |

| Very weak |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, X.; Zhang, N.; Chen, X.; Gong, L.; Lv, C.; Guo, Y. Exploitation Contradictions Concerning Multi-Energy Resources among Coal, Gas, Oil, and Uranium: A Case Study in the Ordos Basin (Western North China Craton and Southern Side of Yinshan Mountains). Energies 2016, 9, 119. https://doi.org/10.3390/en9020119

Feng X, Zhang N, Chen X, Gong L, Lv C, Guo Y. Exploitation Contradictions Concerning Multi-Energy Resources among Coal, Gas, Oil, and Uranium: A Case Study in the Ordos Basin (Western North China Craton and Southern Side of Yinshan Mountains). Energies. 2016; 9(2):119. https://doi.org/10.3390/en9020119

Chicago/Turabian StyleFeng, Xiaowei, Nong Zhang, Xiaoting Chen, Lianyuan Gong, Chuangxin Lv, and Yu Guo. 2016. "Exploitation Contradictions Concerning Multi-Energy Resources among Coal, Gas, Oil, and Uranium: A Case Study in the Ordos Basin (Western North China Craton and Southern Side of Yinshan Mountains)" Energies 9, no. 2: 119. https://doi.org/10.3390/en9020119

APA StyleFeng, X., Zhang, N., Chen, X., Gong, L., Lv, C., & Guo, Y. (2016). Exploitation Contradictions Concerning Multi-Energy Resources among Coal, Gas, Oil, and Uranium: A Case Study in the Ordos Basin (Western North China Craton and Southern Side of Yinshan Mountains). Energies, 9(2), 119. https://doi.org/10.3390/en9020119