Effectiveness of Using Phase Change Materials on Reducing Summer Overheating Issues in UK Residential Buildings with Identification of Influential Factors

Abstract

:1. Introduction

2. Methodology

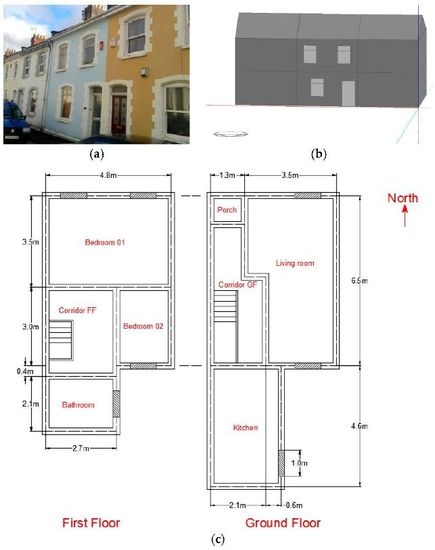

2.1. Case Study Building

2.2. Building Performance Simulation

2.2.1. Construction Settings

2.2.2. Behaviour Settings

2.2.3. Weather Data

2.3. Experimental Phase Change Material

3. Results

- (1)

- how effective is PCM in overcoming current UK residential overheating in summer; and

- (2)

- what factors may influence its effectiveness. For this purpose, the following analysis has been split into three sub-sections.

3.1. Contribution of Phase Change Material in Reducing UK Residential Overheating Issues

3.2. Climatic Parameters

3.2.1. Geographical Location within the UK

3.2.2. Climate Change/Global Warming

3.3. Building-Related Parameters

- (1)

- the location within the building where the PCM layer is added to;

- (2)

- various insulation levels of the external façade; and

- (3)

- whether the structure type is lightweight or heavyweight. In the following analysis, the weather data measured at Sutton Bonnington (Nottinghamshire) was used, as it reflects the current summer condition in the UK (at the East Midlands).

3.3.1. Placement Location of the Phase Change Material inside the Building

3.3.2. Thermal Insulation of External Façade (U-Value)

3.3.3. Lightweight and Heavyweight Building

4. Conclusions

- Results show that the PCM has a significant impact in mitigating overheating in UK residential buildings.

- The impact on reducing overheating depends on prevailing weather patterns (i.e., geographical location).

- Due to the climatic change/global warming, PCMs will benefit all UK regions, even for those not experiencing severe overheating issues now.

- Placement of PCMs affects their performance but the reasons for this need further exploration.

- Building thermal insulation may also influence the need of PCMs, and well-insulated houses need PCMs more than those poor-insulated ones.

- Installing PCMs is mainly to increase the thermal mass of the house so ‘lightweight’ buildings enjoy a greater benefit from the use of PCMs than “heavyweight” buildings.

Author Contributions

Conflicts of Interest

References

- Zero Carbon Hub. Overheating in Homes—An Introduction for Planners, Designers and Property Owners. Available online: http://www.zerocarbonhub.org/sites/default/files/resources/reports/Overheating_in_Homes-Where_to_Start_Introduction_for_Planners_Designers_and_Property_Owners.pdf (accessed on 9 June 2016).

- National House Building Council Foundation. Overheating in New Homes: A Review of the Evidence. Available online: http://www.zerocarbonhub.org/sites/default/files/resources/reports/Overheating_in_New_Homes-A_review_of_the_evidence_NF46.pdf (accessed on 9 June 2016).

- Heatwave Plan for England: Protecting Health and Reducing Harm from Extreme Heat and Haetwaves; Public Health England: London, UK, 2015.

- Zhang, Y.; Zhou, G.; Lin, K.; Zhang, Q.; Di, H. Application of latent heat thermal energy storage in buildings: State-of-the-art and outlook. Build. Environ. 2007, 42, 2197–2209. [Google Scholar] [CrossRef]

- Gómez, M.A.; Álvarez Feijoo, M.A.; Comesaña, R.; Eguía, P.; Míguez, J.L.; Porteiro, J. CFD Simulation of a Concrete Cubicle to Analyze the Thermal Effect of Phase Change Materials in Buildings. Energies 2012, 5, 2093–2111. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368. [Google Scholar] [CrossRef]

- Akeiber, H.J.; Hosseini, S.E.; Wahid, M.A.; Hussen, H.M.; Mohammad, A.T. Phase Change Materials-Assisted Heat Flux Reduction: Experiment and Numerical Analysis. Energies 2016, 9, 30. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016. [Google Scholar] [CrossRef]

- Iten, M.; Liu, S.; Shukla, A. A review on the air-PCM-TES application for free cooling and heating in the buildings. Renew. Sustain. Energy Rev. 2016, 61, 175–186. [Google Scholar] [CrossRef]

- Kuznik, F.; David, D.; Johannes, K.; Roux, J.J. A review on phase change materials integrated in building walls. Renew. Sustain. Energy Rev. 2011, 15, 379–391. [Google Scholar] [CrossRef]

- Behzadi, S.; Farid, M.M. Experimental and numerical investigations on the effect of using phase change materials for energy conservation in residential buildings. HVAC R Res. 2011, 17, 366–376. [Google Scholar] [CrossRef]

- Shi, X.; Memonb, S.A.; Tang, W.; Cui, H.; Xing, F. Experimental assessment of position of macro encapsulated phase change material in concrete walls on indoor temperatures and humidity levels. Energy Build. 2014, 71, 80–87. [Google Scholar] [CrossRef]

- Alam, M.; Jamil, H.; Sanjayan, J.; Wilson, J. Energy saving potential of phase change materials in major Australian cities. Energy Build. 2014, 78, 192–201. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; De Masi, R.F.; De’ Rossi, F.; Vanoli, G.P. Energy refurbishment of existing buildings through the use of phase change materials: Energy savings and indoor comfort in the cooling season. Appl. Energy 2014, 113, 990–1007. [Google Scholar] [CrossRef]

- Voelker, C.; Kornadt, O.; Ostry, M. Temperature reduction due to the application of phase change materials. Energy Build. 2008, 40, 937–944. [Google Scholar] [CrossRef]

- Fernandes, N.T.A.; Costa, V.A.F. Use of Phase-Change Materials as Passive Elements for Climatization Purposes in Summer: The Portuguese Case. Int. J. Green Energy 2009, 6, 302–311. [Google Scholar] [CrossRef]

- Ozdenefe, M.; Dewsbury, J. Thermal performance of a typical residential Cyprus building with phase change materials. Build. Serv. Eng. Res. Technol. 2016, 37, 85–102. [Google Scholar] [CrossRef]

- Seong, Y.B.; Biwole, J.H. Energy Saving Potentials of Phase Change Materials Applied to Lightweight Building Envelopes. Energies 2013, 6, 5219–5230. [Google Scholar] [CrossRef]

- Randall, C. Housing; Social Trends 41; Office for National Statistics: South Wales, UK, 2011.

- DesignBuilder. DesignBuilder—Simulation Made Easy. Available online: http://www.designbuilder.co.uk/ (accessed on 9 June 2016).

- EnergyPlus. Available online: https://energyplus.net/ (accessed on 9 June 2016).

- Neymark, J.; Judkoff, R.; Alexander, D.; Felsmann, C.; Strachan, P.; Wijsman, A. IEA BESTEST multi-zone non-airflow in-depth diagnostic cases. In Proceedings of the Building Simulation 2011 Conference, Sydney, Australia, 14–16 November 2011.

- Ozdenefe, M.; Dewsbury, J. Dynamic thermal simulation of a PCM lined building with energy plus. In Proceedings of the WSEAS International Conference on Energy and Environment, Kos, Greece, 14–17 July 2012.

- Tabares-Velasco, P.C.; Christensen, C.; Bianchi, M. Verification and validation of EnergyPlus phase change material model for opaque wall assemblies. Build. Environ. 2012, 54, 186–196. [Google Scholar] [CrossRef]

- Ling, H.; Chen, C.; Qin, H.; Wei, S.; Lin, J.; Li, N.; Zhang, M.; Yu, N.; Li, Y. Indicators evaluating thermal inertia performance of envelops with phase change material. Energy Build. 2016, 122, 175–184. [Google Scholar] [CrossRef]

- Guide A: Environmental Analysis; Chartered Institution of Building Services Engineers: London, UK, 2015.

- Wei, S.; Wang, X.; Jones, R.; De Wilde, P. Using building performance simulation to save residential space heating energy: A pilot testing. In Proceedings of the 8th Windsor Conference: Counting the Cost of the Comfort in a Changing World, Windsor, UK, 10–13 April 2014.

- DesignBuilder. Adiabatic component blocks. Available online: http://www.designbuilder.co.uk/helpv2/Content/Component_Block.htm#Adiabati (accessed on 9 June 2016).

- Eames, M.; Kershaw, T.; Coley, D. On the creation of future probabilistic design weather years from UKCP09. Build. Serv. Eng. Res. Technol. 2011, 32, 127–142. [Google Scholar] [CrossRef] [Green Version]

- Our Research on the Net. Mean Maximum Temperature July Average 1981–2010. Available online: http://ourresearch.net/climate-zones-uk.html (accessed on 9 June 2016).

- Ling, H.S.; Chen, C.; Wei, S.; Guan, Y.; Ma, C.; Xie, G.; Li, N.; Chen, Z. Effect of phase change materials on indoor thermal environment under different weather conditions and over a long time. Appl. Energy 2015, 140, 329–337. [Google Scholar] [CrossRef]

- Guan, Y.; Chen, C.; Han, Y.; Ling, H.; Yan, Q. Experimental and modelling analysis of a three-layer wall with phase-change thermal storage in a Chinese solar greenhouse. J. Build. Phys. 2015, 38, 548–559. [Google Scholar] [CrossRef]

- Ling, H.; Chen, C.; Guan, Y.; Wei, S.; Chen, Z.; Li, N. Active heat storage characteristics of active–passive triple wall with phase change material. Sol. Energy 2014, 110, 276–285. [Google Scholar] [CrossRef]

- Chen, C.; Guo, H.; Liu, Y.; Yue, H.; Wang, C. A new kind of phase change material (PCM) for energy-storing wallboard. Energy Build. 2008, 40, 882–890. [Google Scholar] [CrossRef]

- Approved Document L1B: Conservation of Fuel and Power in Existing Dwellings; Her Majesty’s Government: Welsh, UK, 2015.

- Claes, K.; de Boever, L.; Breesch, H. Design Recommendations for Robust Thermal Summer Comfort in Residential Lightweight Buildings in a Moderate Climate. Energy Procedia 2015, 78, 2832–2837. [Google Scholar] [CrossRef]

- Němeček, M.; Kalousek, M. Influence of thermal storage mass on summer thermal stability in a passive wooden house in the Czech Republic. Energy Build. 2015, 107, 68–75. [Google Scholar] [CrossRef]

- ASHRAE. Standards, Research & Technology. Available online: https://www.ashrae.org/standards-research--technology (accessed on 9 June 2016).

- Hagentoft, C.E. Introduction to Building Physics; Studentlitteratur AB: Lund, Sweden, 2001. [Google Scholar]

| Construction | Name of the Material | Thickness (m) | λ (W/mK) | Cp (J/kgK) | ρ (kg/m3) |

|---|---|---|---|---|---|

| External walls (U-value 1.580 W/m2K) | Brickwork 1 | 0.100 | 0.84 | 800 | 1700 |

| Air gap | 0.100 | - | - | - | |

| Brickwork 2 | 0.100 | 0.62 | 800 | 1700 | |

| Gypsum plastering | 0.013 | 0.40 | 1000 | 1000 | |

| Partitions (U-value 1.923 W/m2K) | Gypsum plasterboard | 0.025 | 0.25 | 1000 | 900 |

| Air gap | 0.100 | - | - | - | |

| Gypsum plasterboard | 0.025 | 0.25 | 1000 | 900 | |

| Ceiling element (U-value 3.106 W/m2K) | Gypsum plastering | 0.013 | 0.25 | 1000 | 900 |

| Floor (U-value 2.574 W/m2K) | Floor blocks | 0.25 | 0.14 | 1200 | 650 |

| Ground floor (U-value 1.463 W/m2K) | Cast concrete | 0.100 | 1.13 | 1000 | 2000 |

| Screed | 0.070 | 0.41 | 840 | 1200 | |

| Timber flooring | 0.030 | 0.14 | 1200 | 650 | |

| Roof (U-value 0.372 W/m2K) | Clay tile | 0.025 | 1.00 | 800 | 2000 |

| Stone wool | 0.100 | 0.40 | 840 | 30 | |

| Roofing felt | 0.005 | 0.19 | 837 | 960 |

| Room Type | Bathroom | Bedroom 1 | Bedroom 2 | Corridors | Kitchen | Living Room |

|---|---|---|---|---|---|---|

| Activity (W/person) | Standing relaxed (126) | Sleeping (72) | Sleeping (72) | Standing walking (133) | Cooking (180) | Lecture (115) |

| Occupancy profiles | Until: 07:00, 0 Until: 08:00, 0.5 Until: 19:00, 0 Until: 20:00, 0.5 Until: 24:00, 0 | Until: 07:00, 1 Until: 23:00, 0 Until: 24:00, 1 | Until: 24:00, 0 | Until: 24:00, 0 | Until: 08:00, 0 Until: 09:00, 1 Until: 12:00, 0 Until: 13:00, 1 Until: 17:00, 0 Until: 18:00, 1 Until: 24:00, 0 | Until: 10:00, 0 Until: 12:00, 1 Until: 13:00, 0 Until: 17:00, 1 Until: 18:00, 0 Until: 23:00, 1 Until: 24:00, 0 |

| Equipment heat gains (W/m2) | 15 | 0 | 0 | 0 | 45 | 20 |

| Characteristics | BJUT PCM | Unit |

|---|---|---|

| Roughness | Rough | - |

| Thickness | 0.2 | m |

| λ | 0.5 | W/mK |

| ρ | 900 | kg/m3 |

| Cp | 2900 | J/kgK |

| Thermal absorbance | 0.9 | - |

| Solar absorbance | 0.68 | - |

| Visible absorbance | 0.68 | - |

| Temperature (°C) | Enthalpy (J/kg) | Temperature (°C) | Enthalpy (J/kg) |

|---|---|---|---|

| 0.0 | 0 | 20.2 | 70,226 |

| 7.2 | 10,214 | 22.4 | 73,789 |

| 8.7 | 13,112 | 23.1 | 77,214 |

| 10.8 | 18,981 | 24.0 | 86,265 |

| 15.9 | 42,684 | 25.1 | 92,638 |

| 17.3 | 52,504 | 25.9 | 95,029 |

| 18.3 | 61,502 | 31.1 | 104,936 |

| 19.4 | 68,778 | 41.2 | 122,873 |

| Construction | Name of the Material | Thickness (m) | λ (W/mK) | Cp (J/kgK) | ρ (kg/m3) |

|---|---|---|---|---|---|

| External walls–Low Insulation (U-value = 1.580 W/m2K) | Brickwork 1 | 0.100 | 0.84 | 800 | 1700 |

| Air gap | 0.100 | - | - | - | |

| Brickwork 2 | 0.100 | 0.62 | 800 | 1700 | |

| Gypsum plastering | 0.013 | 0.40 | 1000 | 1000 | |

| External walls–High Insulation (U-value = 0.287 W/m2K) | Brickwork 1 | 0.100 | 0.84 | 800 | 1700 |

| Air gap | 0.100 | - | - | - | |

| Brickwork 2 | 0.100 | 0.62 | 800 | 1700 | |

| Gypsum plastering | 0.013 | 0.40 | 1000 | 1000 | |

| Glass fibre slab | 0.100 | 0.035 | 1000 | 25 |

| Construction | Name of the Material | Thickness (m) | λ (W/mK) | Cp (J/kgK) | ρ (kg/m3) |

|---|---|---|---|---|---|

| Lightweight-External Walls | Metallic cladding | 0.006 | 0.29 | 1000 | 1250 |

| Air gap | 0.050 | - | - | - | |

| Gypsum plastering | 0.013 | 0.40 | 1000 | 1000 | |

| Heavyweight-External Walls | Brickwork | 0.105 | 0.84 | 800 | 1700 |

| Air gap | 0.050 | - | - | - | |

| Concrete | 0.100 | 0.51 | 1000 | 1400 | |

| Gypsum plastering | 0.013 | 0.40 | 1000 | 1000 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Auzeby, M.; Wei, S.; Underwood, C.; Tindall, J.; Chen, C.; Ling, H.; Buswell, R. Effectiveness of Using Phase Change Materials on Reducing Summer Overheating Issues in UK Residential Buildings with Identification of Influential Factors. Energies 2016, 9, 605. https://doi.org/10.3390/en9080605

Auzeby M, Wei S, Underwood C, Tindall J, Chen C, Ling H, Buswell R. Effectiveness of Using Phase Change Materials on Reducing Summer Overheating Issues in UK Residential Buildings with Identification of Influential Factors. Energies. 2016; 9(8):605. https://doi.org/10.3390/en9080605

Chicago/Turabian StyleAuzeby, Marine, Shen Wei, Chris Underwood, Jess Tindall, Chao Chen, Haoshu Ling, and Richard Buswell. 2016. "Effectiveness of Using Phase Change Materials on Reducing Summer Overheating Issues in UK Residential Buildings with Identification of Influential Factors" Energies 9, no. 8: 605. https://doi.org/10.3390/en9080605

APA StyleAuzeby, M., Wei, S., Underwood, C., Tindall, J., Chen, C., Ling, H., & Buswell, R. (2016). Effectiveness of Using Phase Change Materials on Reducing Summer Overheating Issues in UK Residential Buildings with Identification of Influential Factors. Energies, 9(8), 605. https://doi.org/10.3390/en9080605