Wood Density and Mechanical Properties of Pinus kesiya Royle ex Gordon in Malawi

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Plant Material and Sampling

2.3. Sample Processing and Measurement

2.4. Statistical Analysis

3. Results and Discussion

3.1. Wood Density, Modulus of Elasticity and Modulus of Rupture

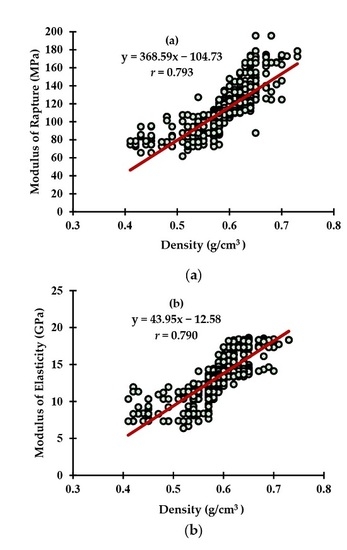

3.2. The Relationship Between Wood Density and Mechanical Properties

3.3. Grade Yield of Juvenile and Mature Woods

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of variance |

| FFPRI | Forestry and Forest Products Research Institute |

| GLM | Generalized Linear Model |

| LSD | Least Significant Difference |

| MC | Moisture Content |

| MoE | Modulus of Elasticity |

| MoR | Modulus of Rupture |

| PROC | Procedure |

| SAS | Statistical Analysis System |

References

- Gogoi, B.R.; Sharma, M.; Sharma, C.L. Ring width variations of Khasi pine (Pinus kesiya Royle ex Gordon) at breast height. J. Indian Acad. Wood Sci. 2014, 11, 87–92. [Google Scholar] [CrossRef]

- Missio, R.F.; Silva, A.M.; Dias, L.A.S.; Moraes, M.L.T.; Resende, M.D.V. Estimates of genetic parameters and prediction of additive genetic values in Pinus kesiya progenies. Crop Breed. Appl. Biotechnol. 2005, 5, 394–401. [Google Scholar] [CrossRef]

- Anoop, E.V.; Jijeesh, C.M.; Sindhumathi, C.R.; Jayasree, C.E. Wood physical, anatomical and mechanical properties of big leaf Mahogany (Swietenia macrophylla Roxb) a potential exotic for South India. Res. J. Agric. For. Sci. 2014, 2, 7–13. [Google Scholar]

- Johnson, G.R.; Gartner, B.L. Genetic variation in basic density and modulus of elasticity of coastal Douglas-fir. Tree Genet. Genomes 2006, 3, 25–33. [Google Scholar] [CrossRef]

- Steffenrema, A.; Saranpää, P.; Lundqvistc, S.; Skrøppa, T. Variation in wood properties among five full-sib families of Norway spruce (Picea abies). Ann. For. Sci. 2007, 64, 799–806. [Google Scholar] [CrossRef]

- Zobel, B.J.; van Buijtenen, J.P. Wood Variation: Its Causes and Control; Springer-Verlag: Berlin, Germany, 1989. [Google Scholar]

- Kord, B.; Kialashaki, A; Kord, B. The within-tree variation in wood density and shrinkage and their relationship in Populus euramericana. Turk. J. Agric. For. 2010, 34, 121–126. [Google Scholar]

- Shmulsky, R; Jones, P.D. Forest Products and Wood Science, An Introduction, 6th ed.; Wiley Blackwell: West Sussex, UK, 2011. [Google Scholar]

- Stanger, T.K. Variation and Genetic Control of Wood Properties in the Juvenile Core of Pinus patula Grown in South Africa. Ph.D. Thesis, Department of Forestry, Graduate Faculty of North Carolina State University, Raleigh, NC, USA, May 2003. [Google Scholar]

- Kamala, F.D.; Sakagami, H.; Matsumura, J. Mechanical properties of small clear wood specimens of Pinus patula planted in Malawi. Open J. For. 2014, 4, 8–13. [Google Scholar]

- Deresse, T. The Influence of Age and Growth Rate on Selected Properties of Maine-Grown Red Pine. Ph.D. Thesis, University of Maine, Orono, ME, USA, March 1998. [Google Scholar]

- Cave, I.D.; Walker, J.C.F. Stiffness of wood in fast-grown plantation softwoods: The influence of microfibril angle. For. Prod. J. 1994, 44, 43–48. [Google Scholar]

- Zhang, S.Y. Effect of growth rate on wood specific gravity and selected mechanical properties in individual species from distinct wood categories. Wood Sci. Technol. 1995, 29, 451–465. [Google Scholar] [CrossRef]

- Harris, P.; Petherick, R.; Andrews, M. Wood testing tool. In Proceeding of 13th International Symposium on non-destructive testing of wood, University of California Berkeley, California, CA, USA, 19–21 August 2002; 2003; pp. 195–201. [Google Scholar]

- Missanjo, E.; Kamanga-Thole, G.; Manda, V. Estimation of genetic and phenotypic parameters for growth traits in a clonal seed orchard of Pinus kesiya in Malawi. ISRN For. 2013, 2013. [Google Scholar] [CrossRef]

- Missanjo, E.; Kamanga-Thole, G. Impact of site disturbances from harvesting and logging on soil physical properties and Pinus kesiya tree growth. Int. Sch. Res. Not. 2014, 2014. [Google Scholar] [CrossRef]

- SAS Institute Inc. Qualification Tools User’s Guide; SAS Institute Inc.: Cary, NC, USA, 2004. [Google Scholar]

- Missanjo, E.; Matsumura, J. Radial variation in tracheid length and growth ring width of Pinus kesiya Royle ex Gordon in Malawi. Inter. J. Res. Agric. For. 2016, 3, 13–21. [Google Scholar]

- South African National Standard (SANS). South African National Standard. The Structural Use of Timber. Part I. Limit States Design; SABS Standards Division: Pretoria, South Africa, 2003. [Google Scholar]

- ES EN 338. In European Standard. Structural Timber–Strength Classes; CEN: Brussels, Belgium, 2003.

- Akachuku, A.E. The possibility of tree selection and breeding for genetic improvement of wood property of Gmelina arborea. For. Sci. 1984, 30, 275–283. [Google Scholar]

- Izekor, D.N.; Fuwape, J.A.; Oluyege, A.O. Effects of density on variations in the mechanical properties of plantation grown Tectona grandis wood. Arch. Appl. Res. 2010, 2, 113–120. [Google Scholar]

- Fuwape, J.A.; Fabiyi, J.S. Variations in strength properties of plantation grown Nauclea diderichii wood. J. Trop. For. Prod. 2003, 9, 45–53. [Google Scholar]

- Uetimane, J.E.; Ali, A.H. Relationship between mechanical properties and selected anatomical features of ntholo (Pseudolachnostylis maprounaefolia). J. Trop. For. Sci. 2011, 23, 166–176. [Google Scholar]

- Ishiguri, F.; Hiraiwa, T.; Lizuka, K.; Yokota, S.; Priadi, D.; Sumiasri, N.; Yoshizawa, N. Radial variation of anatomical characteristics in Paraseriantles falcataria planted in Indonesia. IAWA J. 2009, 30, 343–352. [Google Scholar] [CrossRef]

- Ishiguri, F.; Wahyudi, I.; Takeuchi, M.; Takashima, Y.; Lizuka, K.; Yokota, S.; Yoshizawa, N. Wood properties of Pericopsis mooniana grown in a plantation in Indonesia. Wood Sci. 2011, 57, 241–246. [Google Scholar] [CrossRef]

- Getahun, Z.; Poddar, P.; Sahu, O. The Influence of physical and mechanical properties on quality of wood produced from Pinus patula tree grown at Arsi Forest. Adv. Res. J. Plant Ani. Sci. 2014, 2, 32–41. [Google Scholar]

- Ogunsanwo, O.Y.; Akinlade, A.S. Effects of age and sampling position on wood property variations in Nigerian grown Gmelina Arborea. J. Agric. Soc. Res. 2011, 11, 103–112. [Google Scholar]

- Larson, P.R. Wood Formation and the Concept of Wood Technology; McGraw Hill: New York, NY, USA, 1969; Volume 1. [Google Scholar]

- Wahab, R.; Mustafa, T.M.; Amini, M.; Rasat, M.S.M. Anatomy and strength properties between tropical bamboo Gigantochloa levis and G. scortechinii. In Proceedings of the 2nd International Conference on Kenaf and Allied Fibres 2013 (ICKAF 2013), Selangor, Malaysia, 3–5 December 2013.

- Sharma, S.K.; Rao, R.V.; Shukla, S.R.; Kumar, P.; Sudheendra, R.; Sujatha, M.; Dubey, Y.M. Wood quality of coppiced Eucalyptus tereticornis for value addition. IAWA J. 2005, 26, 137–147. [Google Scholar] [CrossRef]

- Ridley-Ellis, D. Introduction to Timber Grading: The European System of Machine Strength Grading; Edinburgh Napier University: Edinburgh, UK, 2011. [Google Scholar]

| Grading Standard | Grade | MoE (GPa) | MoR (MPa) |

|---|---|---|---|

| South African standard for pine | xxx | <7.8 | |

| S5 | 7.8–9.5 | ||

| S7 | 9.6–11.9 | ||

| S10 | ≥12.0 | ||

| South East Asia and Pacific Regions standard for softwood species | I | <7.45 | <58.9 |

| II | 7.45–10.3 | 58.9–82.4 | |

| III | 10.4–13.2 | 82.5–107.0 | |

| IV | 13.3–16.2 | 107.1–130.9 | |

| V | ≥16.3 | ≥131.0 | |

| European standard for softwood species | C14 | 7 | |

| C16 | 8 | ||

| C18 | 9 | ||

| C20 | 9.5 | ||

| C22 | 10 | ||

| C24 | 11 | ||

| C27 | 11.5 | ||

| C30 | 12 | ||

| C35 | 13 | ||

| C40 | 14 | ||

| C45 | 15 | ||

| C50 | 16 |

| Variable | Description | n | Density (g/cm3) | MoE (GPa) | MoR (MPa) |

|---|---|---|---|---|---|

| Family | A (ZW701) | 180 | 0.590 ± 0.044 a | 13.81 ± 0.20 a | 118.25 ± 1.77 a |

| B (ZW703) | 180 | 0.593 ± 0.003 a | 13.53 ± 0.20 a | 114.40 ± 1.35 a | |

| C (ZW705) | 180 | 0.580 ± 0.003 a | 13.20 ± 0.18 a | 110.03 ± 1.30 a | |

| D (ZW709) | 180 | 0.599 ± 0.003 a | 13.27 ± 0.12 a | 112.76 ± 1.28 a | |

| E (ZW712) | 180 | 0.592 ± 0.002 a | 13.45 ± 0.15 a | 113.72 ± 1.37 a | |

| F (ZW716) | 180 | 0.602 ± 0.003 a | 13.49 ± 0.13 a | 112.89 ± 1.14 a | |

| Stem height (m) above the ground | 1.3 | 270 | 0.597 ± 0.002 a | 13.74 ± 0.14 a | 116.93 ± 1.21 a |

| 3.3 | 270 | 0.594 ± 0.002 a,b | 13.56 ± 0.13 a,b | 115.05 ± 1.14 a,b | |

| 5.3 | 270 | 0.591 ± 0.003 a,b | 13.43 ± 0.15 a,b | 113.94 ± 1.09 a,b | |

| 7.3 | 270 | 0.587 ± 0.003 b | 13.12 ± 0.13 b | 108.77 ± 1.05 b | |

| Inner (Ring 1–5) | 360 | 0.574 ± 0.002 b | 11.80 ± 0.12 b | 106.32 ± 0.90 b | |

| Radial direction | Middle (Ring 12–18) | 360 | 0.593 ± 0.002 a | 14.19 ± 0.12 a | 115.99 ± 0.99 a |

| Outer (Ring 21–28) | 360 | 0.601 ± 0.002 a | 14.39 ± 0.12 a | 118.70 ± 1.03 a | |

| Mean | 0.593 ± 0.001 | 13.46 ± 0.07 | 113.67 ± 0.57 | ||

| CV % | 6.57 | 6.35 | 5.95 | ||

| R2 | 0.869 | 0.837 | 0.863 | ||

| Description | MoE (GPa) | MoR (MPa) |

|---|---|---|

| Juvenile Wood | 11.80 ± 0.12 b | 106.32 ± 1.0 b |

| Mature Wood | 14.29 ± 0.12 a | 117.35 ± 1.0 a |

| Mean | 13.46 ± 0.12 | 113.67 ± 1.0 |

| CV (%) | 6.46 | 6.28 |

| R2 | 0.813 | 0.816 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Missanjo, E.; Matsumura, J. Wood Density and Mechanical Properties of Pinus kesiya Royle ex Gordon in Malawi. Forests 2016, 7, 135. https://doi.org/10.3390/f7070135

Missanjo E, Matsumura J. Wood Density and Mechanical Properties of Pinus kesiya Royle ex Gordon in Malawi. Forests. 2016; 7(7):135. https://doi.org/10.3390/f7070135

Chicago/Turabian StyleMissanjo, Edward, and Junji Matsumura. 2016. "Wood Density and Mechanical Properties of Pinus kesiya Royle ex Gordon in Malawi" Forests 7, no. 7: 135. https://doi.org/10.3390/f7070135

APA StyleMissanjo, E., & Matsumura, J. (2016). Wood Density and Mechanical Properties of Pinus kesiya Royle ex Gordon in Malawi. Forests, 7(7), 135. https://doi.org/10.3390/f7070135