Gelatin-Alginate Complexes for EGF Encapsulation: Effects of H-Bonding and Electrostatic Interactions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Construction of Phase Diagrams

2.3. Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR-FTIR)

2.4. Encapsulation of EGF in GA-SA Coacervates (EGF-Coacervate)

2.5. Preparation of Freeze-Dried Samples and Electron Microscopy

2.6. Trypsin Digestion Assay of EGF-Coacervate

2.7. Human Dermal Fibroblast (HDF) Scratch Wound Assay

3. Results

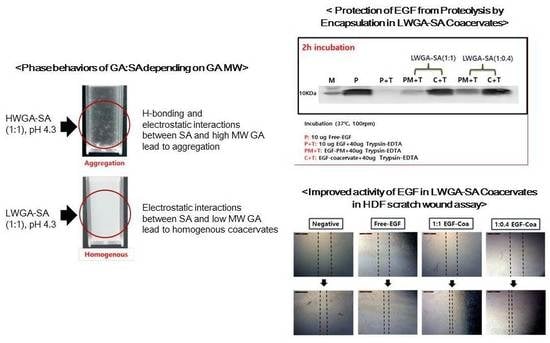

3.1. Phase Diagrams of HWGA-SA and LWGA-SA

3.2. ATR-FTIR

3.3. Encapsulation of EGF in GA-SA Coacervate

3.4. Fabrication of Freeze-Dried Sample

3.5. Protection of EGF from Trypsin Digestion

3.6. HDF Scratch Wound Assay

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chung, K.H.; Park, S.H.; Kim, M.K.; Park, H.D.; Son, T.I. Stabilization of epidermal growth factor on thermal and proteolytic degradation by conjugating with low molecular weight chitosan. J. Appl. Polym. Sci. 2006, 102, 5072–5082. [Google Scholar] [CrossRef]

- Okumura, K.; Kiyohara, Y.; Komada, F.; Iwakawa, S.; Hirai, M.; Fuwa, T. Improvement in wound healing by epidermal growth factor (EGF) ointment. I. Effect of nafamostat, gabexate, or gelatin on stabilization and efficacy of EGF. Pharm. Res. 1990, 7, 1289–1293. [Google Scholar] [CrossRef] [PubMed]

- Lau, H.-C.; Kim, A. Pharmaceutical perspectives of impaired wound healing in diabetic foot ulcer. J. Pharm. Investig. 2016, 46, 403–423. [Google Scholar] [CrossRef]

- Kim, H.; Kong, W.H.; Seong, K.Y.; Sung, D.K.; Jeong, H.; Kim, J.K.; Yang, S.Y.; Hahn, S.K. Hyaluronate-Epidermal Growth Factor Conjugate for Skin Wound Healing and Regeneration. Biomacromolecules 2016, 17, 3694–3705. [Google Scholar] [CrossRef]

- Hwang, D.S.; Zeng, H.; Srivastava, A.; Krogstad, D.V.; Tirrell, M.; Israelachvili, J.N.; Waite, J.H. Viscosity and interfacial properties in a mussel-inspired adhesive coacervate. Soft Matter 2010, 6, 3232–3236. [Google Scholar] [CrossRef] [Green Version]

- Chu, H.; Johnson, N.R.; Mason, N.S.; Wang, Y. A [polycation:heparin] complex releases growth factors with enhanced bioactivity. J. Control. Release 2011, 150, 157–163. [Google Scholar] [CrossRef]

- Chu, H.; Gao, J.; Chen, C.W.; Huard, J.; Wang, Y. Injectable fibroblast growth factor-2 coacervate for persistent angiogenesis. Proc. Natl. Acad. Sci. USA 2011, 108, 13444–13449. [Google Scholar] [CrossRef] [Green Version]

- Chu, H.; Chen, C.W.; Huard, J.; Wang, Y. The effect of a heparin-based coacervate of fibroblast growth factor-2 on scarring in the infarcted myocardium. Biomaterials 2013, 34, 1747–1756. [Google Scholar] [CrossRef]

- Johnson, N.R.; Wang, Y. Controlled delivery of heparin-binding EGF-like growth factor yields fast and comprehensive wound healing. J. Control. Release 2013, 166, 124–129. [Google Scholar] [CrossRef]

- Comunian, T.A.; Thomazini, M.; Alves, A.J.G.; Matos Junior, F.E.; Carvalhobalieiro, J.C.; Favaro-Trindade, C.S. Microencapsulation of ascorbic acid by complex coacervation protein and controlled release. Food Res. Int. 2013, 52, 373–379. [Google Scholar] [CrossRef]

- Johnson, N.R.; Ambe, T.; Wang, Y. Lysine-based polycation:heparin coacervate for controlled protein delivery. Acta Biomater. 2014, 10, 40–46. [Google Scholar] [CrossRef] [PubMed]

- Awada, H.K.; Long, D.W.; Wang, Z.; Hwang, M.P.; Kim, K.; Wang, Y. A single injection of protein-loaded coacervate-gel significantly improves cardiac function post infarction. Biomaterials 2017, 125, 65–80. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bohidar, H.B. Coacervates: A novel state of soft matter—An overview. J. Surf. Sci. Technol. 2008, 24, 105–124. [Google Scholar]

- Kamla, R.; Bohider, H.B. Coacervate in biopolymers. Phys. Chem. Biophys. 2014, 165. [Google Scholar] [CrossRef]

- Wang, Q.; Schlenoff, J.B. The Polyelectrolyte Complex/Coacervate Continuum. Macromolecules 2014, 47, 3108–3116. [Google Scholar] [CrossRef]

- Johnson, N.R.; Wang, Y. Coacervate delivery systems for proteins and small molecule drugs. Expert Opin. Drug Deliv. 2014, 11, 1829–1832. [Google Scholar] [CrossRef]

- Lau, H.-C.; Jeong, S.; Kim, A. Gelatin-alginate coacervates for circumventing proteolysis and probing intermolecular interactions by SPR. Int. J. Biol. Macromol. 2018, 117, 427–434. [Google Scholar] [CrossRef]

- Haug, I.J.; Draget, K.I. Gelatin. In Handbook of Hydrocolloids, 2nd ed.; Phillips, G.O., Williams, P.A., Eds.; Woodhead Publishing: Cambridge, UK, 2009; pp. 149–151. [Google Scholar]

- Ogino, S.; Morimoto, N.; Sakamoto, M.; Jinno, C.; Taira, T.; Suzuki, S. Efficacy of gelatin gel sheets sustaining epidermal growth factor for murine skin defects. J. Surg. Res. 2016, 201, 446–454. [Google Scholar] [CrossRef]

- Jaipan, P.; Nguyen, A.; Narayan, R.J. Gelatin-based hydrogels for biomedical applications. MRS Commun. 2017, 7, 416–426. [Google Scholar] [CrossRef]

- Kim, J.; Park, J.; Lee, J.; Kim, M.; Min, H.; Moon, J.; Choi, C.; Kim, B.; Kim, D. Coacervate microcapsules of vitamin U optimized by composite design (CCD). J. Pharm. Investig. 2019, 49, 313–321. [Google Scholar] [CrossRef]

- Gashti, M.P.; Stir, M.; Hulliger, J. Growth of strontium hydrogen phoshpate/gelatin composites: A biomimetic approach. New J. Chem. 2016, 6, 5495–5500. [Google Scholar] [CrossRef]

- Gashti, M.P.; Burgener, M.; Stir, M.; Hulliger, J. Barium hydrogen phosphate/gelatin composites versus gelatin-free barium hydrogen phosphate: Synthesis and characterization of properties. J. Colloid Interface Sci. 2014, 431, 149–156. [Google Scholar] [CrossRef] [PubMed]

- Devi, N.; Hazarika, D.; Deka, C.; Kakati, D.K. Study of complex coacervation of Gelatin A and sodium alginate for microencapsulation of olive oil. J. Macromol. Sci. 2012, 49, 936–945. [Google Scholar] [CrossRef]

- Goh, C.H.; Heng, P.W.S.; Chan, L.W. Alginates as a useful natural polymer for microencapsulation and therapeutic applications. Carbohydr. Polym. 2012, 88, 1–12. [Google Scholar] [CrossRef]

- Aderibigbe, B.A.; Buyana, B. Alginate in Wound Dressings. Pharmaceutics 2018, 10, 42. [Google Scholar] [CrossRef] [PubMed]

- Guadarrama-Acevedo, M.C.; Mendoza-Flores, R.A.; Del Prado-Audelo, M.L.; Urban-Morlan, Z.; Giraldo-Gomez, D.M.; Magana, J.J.; Gonzalez-Torres, M.; Reyes-Hernandez, O.D.; Figueroa-Gonzalez, G.; Caballero-Floran, I.H.; et al. Development and Evaluation of Alginate Membranes with Curcumin-Loaded Nanoparticles for Potential Wound-Healing Applications. Pharmaceutics 2019, 11, 389. [Google Scholar] [CrossRef] [PubMed]

- Comert, F.; Malanowski, A.J.; Azarikia, F.; Dubin, P.L. Coacervation and precipitation in polysaccharide-protein systems. Soft Matter 2016, 12, 4154–4161. [Google Scholar] [CrossRef]

- Priftis, D.; Laugel, N.; Tirrell, M. Thermodynamic characterization of polypeptide complex coacervation. Langmuir 2012, 28, 15947–15957. [Google Scholar] [CrossRef]

- Li, R.; Wu, J.; Lin, Z.; Nangle, M.R.; Li, Y.; Cai, P.; Liu, D.; Ye, L.; Xiao, Z.; He, C.; et al. Single injection of a novel nerve growth factor coacervate improves structural and functional regeneration after sciatic nerve injury in adult rats. Exp. Neurol. 2017, 288, 1–10. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Sun, N.; Wang, Y.; Lin, S. Formation and evaluation of casein-gum arabic coacervates via pH-dependent complexation using fast acidification. Int. J. Biol. Macromol. 2018, 120 Pt A, 783–788. [Google Scholar] [CrossRef]

- Kayitmazer, A.B.; Koksal, A.F.; Kilic Iyilik, E. Complex coacervation of hyaluronic acid and chitosan: Effects of pH, ionic strength, charge density, chain length and the charge ratio. Soft Matter 2015, 11, 8605–8612. [Google Scholar] [CrossRef] [PubMed]

- Obermeyer, A.C.; Mills, C.E.; Dong, X.H.; Flores, R.J.; Olsen, B.D. Complex coacervation of supercharged proteins with polyelectrolytes. Soft Matter 2016, 12, 3570–3581. [Google Scholar] [CrossRef] [PubMed]

- Chollakup, R.; Beck, J.B.; Dirnberger, K.; Tirrell, M.; Eisenbach, C.D. Polyelectrolyte molecular weight and salt effects on the phase behavior and coacervation of aqueous solution of poly (acrylic acid) sodium salt and poly (allylamine) hydrochloride. Macromolecules 2013, 46, 2376–2390. [Google Scholar] [CrossRef]

- Huang, H.; Grun, I.U.; Ellersieck, M.; Clarke, A.D. Measurement of total sodium alginate in restructured fish products using fourier transform infrared spectroscopy. Semant. Sch. 2017, 11, 33–45. [Google Scholar]

- Pavia, D.L.; Gary, M.L.; Kriz, G.S.; Vyvyan, J.A. Introduction to Spectroscopy, 5th ed.; Brooks Cole, Cengage Learning Korea Ltd.: Seoul, Korea, 2015. [Google Scholar]

- Guo, L.; Sato, T.; Hashimoto, T.; Ozaki, Y. FTIR Study on Hydrogen-Bonding Interactions in Biodegradable Polymer Blends of Poly(3-hydroxybutyrate) and Poly(4-vinylphenol). Macromolecules 2010, 43, 3897–3902. [Google Scholar] [CrossRef]

- Guerin, A.C.; Riley, K.; Rupnik, K.; Kuroda, D.G. Determining the Energetics of the Hydrogen Bond through FTIR: A Hands-On Physical Chemistry Lab Experiment. Chem. Educ. 2016, 93, 1124–1129. [Google Scholar] [CrossRef]

- Iwashita, K.; Handa, A.; Shiraki, K. Coacervates and coaggregates: Liquid-liquid and liquid-solid phase transitions by native and unfolded protein complexes. Int. J. Biol. Macromol. 2018, 120 Pt A, 10–18. [Google Scholar] [CrossRef]

- Miller, D.S.; Chirayil, S.; Ball, H.L.; Luebke, K.J. Manipulating cell migration and proliferation with a light-activated polypeptide. Chembiochem 2009, 10, 577–584. [Google Scholar] [CrossRef]

| HWGA-SA (1:0.4) | |||||||

|---|---|---|---|---|---|---|---|

| pH | 5.97 (0.01) | 4.82 c (0.01) | 4.55 φ (0) | 4.36 (0.01) | 4.26 (0) | 4.17 (0.01) | 4.09 (0) |

| Turbidity | 0.03 (0) | 1.68 (0.03) | 2.09 (0) | 2.00 (0) | 1.99 (0) | 1.90 (0) | 1.73 (0) |

| Zeta potential | −51.60 (3.31) | −26.80 (0.2) | −30.07 (0.80) | −27.30 (0.50) | −25.50 (0.79) | −24.33 (1.39) | −23.47 (0.21) |

| Z-average (d.nm) | 521.50 (101.76) | 726.60 (79.29) | 2130.67 (859.60) | 3650.00 (115.21) | 7481.00 (5542.93) | 1474.33 (279.06) | 2373.33 (844.92) |

| PDI | 0.85 (0.051) | 0.47 (0.035) | 1 (0) | 1 (0) | 0.73 (0.24) | 0.63 (0.322) | 0.84 (0.273) |

| LWGA-SA 1:0.4 | |||||||

| pH | 6.00 (0.01) | 4.78 c (0.01) | 4.52 (0.01) | 4.34 (0) | 4.25 φ (0.01) | 4.14 (0) | 4.07 (0) |

| Turbidity | 0.03 (0) | 1.32 (0) | 1.91 (0) | 2.01 (0) | 1.97 (0) | 1.88 (0) | 1.69 (0) |

| Zeta potential | −34.97 (0.38) | −25.00 (0.26) | −24.37 (0.61) | −22.30 (0.56) | −22.27 (0.71) | −21.57 (1.51) | −16.47 (1.12) |

| Z-average (d.nm) | 699.27 (62.57) | 923.60 (25.91) | 364.40 (10.89) | 1191.00 (70.79) | 2688.67 (476.82) | 2422.67 (894.91) | 1810.67 (123.87) |

| PDI | 0.94 (0.098) | 0.50 (0.021) | 0.14 (0.016) | 0.33 (0.025) | 0.94 (0.098) | 0.59 (0.267) | 0.49 (0.116) |

| Peak Assignment | Amide III (C–N Stretching, N–H Deformation) | Amide II (C–N–H Deformation) | Amide I (C=O Stretching) | C–H Vibration | Amide B Stretching (–NH3+ Stretching) | COO–Stretching Vibration (C=O) | COOH (C=O Stretching) | Pyranose Ring (C–O–C Stretching) |

|---|---|---|---|---|---|---|---|---|

| HWGA powder | 1236 | 1531 | 1633 | ~2937 | ~3076 | N/A | N/A | N/A |

| SA powder | N/A | N/A | N/A | ~2937 | N/A | 1595 | 1734 | 1211 |

| Physical mixture of powder HWGA-SA | 1236 | split | * | No change | * | * | 1734 | 1211 |

| One phase solution HWGA-SA (pH 5.97) | 1240 | Triple split | Weak split | - | 3076 | - | - | - |

| Coacervates HWGA-SA (pH 4.82) | 1240 | Triple split | Weak split | - | 3076 | - | - | - |

| Precipitates HWGA-SA (pH 4.09) | Weak split | Quadruple split | Weak split | - | 3076 | - | - | - |

| Peak Assignment | Amide III (C–N Stretching, N–H Deformation) | Amide II (C–N–H Deformation) | Amide I (C=O Stretching) | C–H Vibration | Amide B Stretching (–NH3+ Stretching) | COO–Stretching Vibration (C=O) | COOH (C=O Stretching) | Pyranose Ring (C–O–C Stretching) |

|---|---|---|---|---|---|---|---|---|

| LWGA powder | 1236 | 1525 | 1635 | ~2937 | ~3070 | N/A | N/A | N/A |

| SA powder | N/A | N/A | N/A | ~2937 | N/A | 1595 | 1734 | 1211 |

| Physical mixture of powder LWGA-SA | 1240 | Split | * | No change | * | * | 1734 | 1211 |

| One phase solution LWGA-SA (pH 5.97) | 1238 | Double Split | 1635 | No change | 3078 | - | 1730 | 1203 |

| Coacervates LWGA-SA (pH 4.82) | 1238 | Triple Split | Weak split | No change | 3076 | - | 1724 | - |

| Precipitates LWGA-SA (pH 4.09) | 1238 | Triple split | Weak split | No change | 3078 | - | - | - |

| GA:SA Ratio of EGF-Coa (Reaction pH) | Encapsulation Efficiency (%) Mean (SD) n = 3 | Loading Efficiency (%) Mean (SD) n = 3 |

|---|---|---|

| 1:1 (4.14) | 40.3 (1.03) | 0.7 (0.02) |

| 1:0.4 (4.34) | 81.3 (0.35) | 2.1 (0.01) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, S.; Kim, B.; Lau, H.-C.; Kim, A. Gelatin-Alginate Complexes for EGF Encapsulation: Effects of H-Bonding and Electrostatic Interactions. Pharmaceutics 2019, 11, 530. https://doi.org/10.3390/pharmaceutics11100530

Jeong S, Kim B, Lau H-C, Kim A. Gelatin-Alginate Complexes for EGF Encapsulation: Effects of H-Bonding and Electrostatic Interactions. Pharmaceutics. 2019; 11(10):530. https://doi.org/10.3390/pharmaceutics11100530

Chicago/Turabian StyleJeong, Seonghee, ByungWook Kim, Hui-Chong Lau, and Aeri Kim. 2019. "Gelatin-Alginate Complexes for EGF Encapsulation: Effects of H-Bonding and Electrostatic Interactions" Pharmaceutics 11, no. 10: 530. https://doi.org/10.3390/pharmaceutics11100530

APA StyleJeong, S., Kim, B., Lau, H. -C., & Kim, A. (2019). Gelatin-Alginate Complexes for EGF Encapsulation: Effects of H-Bonding and Electrostatic Interactions. Pharmaceutics, 11(10), 530. https://doi.org/10.3390/pharmaceutics11100530