In-Depth Understanding of Granule Compression Behavior under Variable Raw Material and Processing Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. X-Ray Powder Diffraction (XRPD)

2.3. Scanning Electron Microscopy (SEM)

2.4. Water Binding Capacity

2.5. Bulk and Tapped Density

2.6. Loss on Drying

2.7. Granule Preparation

2.8. Particle Size Analysis

2.9. Dynamic Compaction Analysis

2.10. Design of Experiments: Effect Analysis and Design Space Estimation

2.11. Multivariate Data Analysis: PCA, O2PLS, OPLS-DA

3. Results and Discussion

3.1. The Influence of Input Variables on Granule Characteristics

3.1.1. Average Particle Size (Xa) and Size Distribution (Span)

3.1.2. Compact Tensile Strength (TS)

3.1.3. Detachment Stress (DS) and Ejection Stress (ES)

3.1.4. Work of Compression, Elastic Recovery and Solid Fraction

3.2. Quantifying the Influence of Input Variability on Compressibility, Compactibility and Tabletability Profiles

3.2.1. Compressibility

3.2.2. Compactibility

3.2.3. Tabletability

3.3. Influence of Input Variability on Compression Parameters

3.4. Selecting a Robust Formulation—Building the Design Space

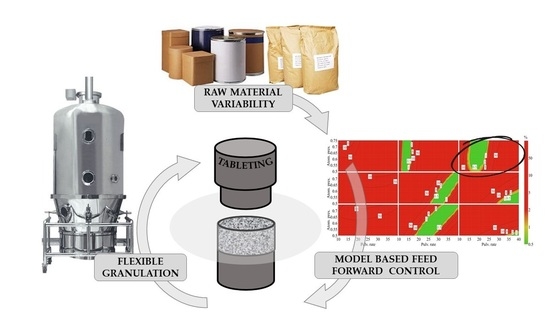

3.5. Practical Implications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Stauffer, F.; Vanhoorne, V.; Pilcer, G.; Chavez, P.F.; Vervaet, C.; De Beer, T. Managing API raw material variability in a continuous manufacturing line—Prediction of process robustness. Int. J. Pharm. 2019, 569, 118525. [Google Scholar] [CrossRef]

- Stauffer, F.; Vanhoorne, V.; Pilcer, G.; Chavez, P.F.; Rome, S.; Schubert, M.A.; Aerts, L.; De Beer, T. Raw material variability of an active pharmaceutical ingredient and its relevance for processability in secondary continuous pharmaceutical manufacturing. Eur. J. Pharm. Biopharm. 2018, 127, 92–103. [Google Scholar] [CrossRef]

- Ilyés, K.; Casian, T.; Hales, D.; Borodi, G.; Rus, L.; Știufiuc, R.; Tomuță, I. Applying the principles of quality by design (qbd) coupled with multivariate data analysis (mvda) in establishing the impact of raw material variability for extended release tablets. Farmacia 2021, 69, 481–497. [Google Scholar] [CrossRef]

- Stauffer, F.; Vanhoorne, V.; Pilcer, G.; Chavez, P.F.; Schubert, M.A.; Vervaet, C.; De Beer, T. Managing active pharmaceutical ingredient raw material variability during twin-screw blend feeding. Eur. J. Pharm. Biopharm. 2019, 135, 49–60. [Google Scholar] [CrossRef] [PubMed]

- Gavan, A.; Iurian, S.; Casian, T.; Porfire, A.; Porav, S.; Voina, I.; Oprea, A.; Tomuta, I. Fluidised bed granulation of two APIs: QbD approach and development of a NIR in-line monitoring method. Asian J. Pharm. Sci. 2020, 15, 506–517. [Google Scholar] [CrossRef] [PubMed]

- Fonteyne, M.; Correia, A.; De Plecker, S.; Vercruysse, J.; Ilić, I.; Zhou, Q.; Vervaet, C.; Remon, J.P.; Onofre, F.; Bulone, V.; et al. Impact of microcrystalline cellulose material attributes: A case study on continuous twin screw granulation. Int. J. Pharm. 2015, 478, 705–717. [Google Scholar] [CrossRef] [PubMed]

- Stauffer, F.; Vanhoorne, V.; Pilcer, G.; Chavez, P.F.; Vervaet, C.; De Beer, T. Managing API raw material variability during continuous twin-screw wet granulation. Int. J. Pharm. 2019, 561, 265–273. [Google Scholar] [CrossRef] [PubMed]

- Hwang, K.M.; Cho, C.H.; Yoo, S.D.; Cha, K.I.; Park, E.S. Continuous twin screw granulation: Impact of the starting material properties and various process parameters. Powder Technol. 2019, 356, 847–857. [Google Scholar] [CrossRef]

- Matsunami, K.; Nagato, T.; Hasegawa, K.; Sugiyama, H. Determining key parameters of continuous wet granulation for tablet quality and productivity: A case in ethenzamide. Int. J. Pharm. 2020, 579, 119160. [Google Scholar] [CrossRef] [PubMed]

- Peltonen, L. Design space and QbD approach for production of drug nanocrystals by wet media milling techniques. Pharmaceutics 2018, 10, 104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- von Stosch, M.; Schenkendorf, R.; Geldhof, G.; Varsakelis, C.; Mariti, M.; Dessoy, S.; Vandercammen, A.; Pysik, A.; Sanders, M. Working within the design space: Do our static process characterization methods suffice? Pharmaceutics 2020, 12, 562. [Google Scholar] [CrossRef]

- Sun, F.; Xu, B.; Dai, S.; Zhang, Y.; Lin, Z.; Qiao, Y. A novel framework to aid the development of design space across multi-unit operation pharmaceutical processes—a case study of Panax notoginseng saponins immediate release tablet. Pharmaceutics 2019, 11, 474. [Google Scholar] [CrossRef] [Green Version]

- Diab, S.; Gerogiorgis, D.I. Design space identification and visualization for continuous pharmaceutical manufacturing. Pharmaceutics 2020, 12, 235. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Casian, T.; Iurian, S.; Bogdan, C.; Rus, L.; Moldovan, M.; Tomuta, I. QbD for pediatric oral lyophilisates development: Risk assessment followed by screening and optimization. Drug Dev. Ind. Pharm. 2017, 43, 1932–1944. [Google Scholar] [CrossRef] [PubMed]

- Mathe, R.; Casian, T.; Tomuţă, I. Multivariate feed forward process control and optimization of an industrial, granulation based tablet manufacturing line using historical data. Int. J. Pharm. 2020, 591, 119988. [Google Scholar] [CrossRef]

- Osamura, T.; Takeuchi, Y.; Onodera, R.; Kitamura, M.; Takahashi, Y.; Tahara, K.; Takeuchi, H. Characterization of tableting properties measured with a multi-functional compaction instrument for several pharmaceutical excipients and actual tablet formulations. Int. J. Pharm. 2016, 510, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Osamura, T.; Takeuchi, Y.; Onodera, R.; Kitamura, M.; Takahashi, Y.; Tahara, K.; Takeuchi, H. Formulation design of granules prepared by wet granulation method using a multi-functional single-punch tablet press to avoid tableting failures. Asian J. Pharm. Sci. 2018, 13, 113–119. [Google Scholar] [CrossRef] [PubMed]

- El Hagrasy, A.S.; Hennenkamp, J.R.; Burke, M.D.; Cartwright, J.J.; Litster, J.D. Twin screw wet granulation: Influence of formulation parameters on granule properties and growth behavior. Powder Technol. 2013, 238, 108–115. [Google Scholar] [CrossRef]

- Sochon, R.P.J.; Zomer, S.; Cartwright, J.J.; Hounslow, M.J.; Salman, A.D. The variability of pharmaceutical granulation. Chem. Eng. J. 2010, 164, 285–291. [Google Scholar] [CrossRef]

- Skelbæk-Pedersen, A.L.; Vilhelmsen, T.K.; Rantanen, J.; Kleinebudde, P. The relevance of granule fragmentation on reduced tabletability of granules from ductile or brittle materials produced by roll compaction/dry granulation. Int. J. Pharm. 2021, 592, 120035. [Google Scholar] [CrossRef]

- Macho, O.; Gabrišová, Ľ.; Brokešová, J.; Svačinová, P.; Mužíková, J.; Galbavá, P.; Blaško, J.; Šklubalová, Z. Systematic study of paracetamol powder mixtures and granules tabletability: Key role of rheological properties and dynamic image analysis. Int. J. Pharm. 2021, 608, 121110. [Google Scholar] [CrossRef] [PubMed]

- Veronica, N.; Goh, H.P.; Kang, C.Y.X.; Liew, C.V.; Heng, P.W.S. Influence of spray nozzle aperture during high shear wet granulation on granule properties and its compression attributes. Int. J. Pharm. 2018, 553, 474–482. [Google Scholar] [CrossRef] [PubMed]

- Hibare, S.; Sivanathan, R.; Nadakatti, S. Behaviour of soft granules under compression: Effect of reactive and non-reactive nature of the binder on granule properties. Powder Technol. 2011, 210, 241–247. [Google Scholar] [CrossRef]

- Jonsson, H.; Frenning, G. Investigations of single microcrystalline cellulose-based granules subjected to confined triaxial compression. Powder Technol. 2016, 289, 79–87. [Google Scholar] [CrossRef]

- Steffens, K.E.; Wagner, K.G. Compression behaviour of granules produced via twin-screw melt granulation: Effect of initial particle size on granulation efficiency. Powder Technol. 2020, 374, 430–442. [Google Scholar] [CrossRef]

- Takahashi, T.; Toyota, H.; Kuroiwa, Y.; Kondo, H.; Dohi, M.; Hakomori, T.; Nakamura, M.; Takeuchi, H. Application of novel compaction indicator for the optimization of compaction conditions based on a compaction simulation study. Int. J. Pharm. 2020, 587, 119574. [Google Scholar] [CrossRef]

- Vasiljević, I.; Turković, E.; Piller, M.; Zimmer, A.; Parojčić, J. An investigation into applicability of different compression behaviour assessment approaches for multiparticulate units characterization. Powder Technol. 2021, 379, 526–536. [Google Scholar] [CrossRef]

- Iurian, S.; Ilie, L.; Achim, M.; Tomuță, I. The evaluation of dynamic compaction analysis as a qbd tool for paediatric orodispersible minitablet formulation. Farmacia 2020, 68, 999–1010. [Google Scholar] [CrossRef]

- Casian, T.; Borbás, E.; Ilyés, K.; Démuth, B.; Farkas, A.; Rapi, Z.; Bogdan, C.; Iurian, S.; Toma, V.; Știufiuc, R.; et al. Electrospun amorphous solid dispersions of meloxicam: Influence of polymer type and downstream processing to orodispersible dosage forms. Int. J. Pharm. 2019, 569, 118593. [Google Scholar] [CrossRef]

- Dai, S.; Xu, B.; Zhang, Z.; Yu, J.; Wang, F.; Shi, X.; Qiao, Y. A compression behavior classification system of pharmaceutical powders for accelerating direct compression tablet formulation design. Int. J. Pharm. 2019, 572, 118742. [Google Scholar] [CrossRef]

- Casian, T.; Iurian, S.; Gavan, A.; Revnic, C.; Porav, S.; Porfire, A.; Vlase, L.; Tomuță, I. Near Infra-Red spectroscopy for content uniformity of powder blends—Focus on calibration set development, orthogonality transfer and robustness testing. Talanta 2018, 188, 404–416. [Google Scholar] [CrossRef]

- Casian, T.; Farkas, A.; Ilyés, K.; Démuth, B.; Madarász, L.; Rapi, Z.; Farkas, B.; Balogh, A.; Domokos, A.; Marosi, G.; et al. Data fusion strategies for performance improvement of a Process Analytical Technology platform consisting of four instruments: An electrospinning case study. Int. J. Pharm. 2019, 567, 118473. [Google Scholar] [CrossRef]

- Rauca, V.-F.; Vlase, L.; Casian, T.; Sesarman, A.; Gheldiu, A.-M.; Mocan, A.; Banciu, M.; Toiu, A. Biologically active Ajuga species extracts modulate supportive processes for cancer cell development. Front. Pharmacol. 2019, 10, 334. [Google Scholar] [CrossRef] [Green Version]

- Parker, M.D.; York, P.; Rowe, R.C. Binder-substrate interactions in wet granulation. 3: The effect of excipient source variation. Int. J. Pharm. 1992, 80, 179–190. [Google Scholar] [CrossRef]

- Shah, U.V.; Karde, V.; Ghoroi, C.; Heng, J.Y.Y. Influence of particle properties on powder bulk behaviour and processability. Int. J. Pharm. 2017, 518, 138–154. [Google Scholar] [CrossRef] [PubMed]

- Skelbæk-Pedersen, A.L.; Vilhelmsen, T.K.; Wallaert, V.; Rantanen, J. Investigation of the effects of particle size on fragmentation during tableting. Int. J. Pharm. 2020, 576, 118985. [Google Scholar] [CrossRef] [PubMed]

- Wünsch, I.; Finke, J.H.; John, E.; Juhnke, M.; Kwade, A. The influence of particle size on the application of compression and compaction models for tableting. Int. J. Pharm. 2021, 599, 120424. [Google Scholar] [CrossRef]

- Sun, C.C. Decoding powder tabletability: Roles of particle adhesion and plasticity. J. Adhes. Sci. Technol. 2011, 25, 483–499. [Google Scholar] [CrossRef]

- Chattoraj, S.; Sun, C.C. Crystal and Particle Engineering Strategies for Improving Powder Compression and Flow Properties to Enable Continuous Tablet Manufacturing by Direct Compression. J. Pharm. Sci. 2018, 107, 968–974. [Google Scholar] [CrossRef]

- Thapa, P.; Lee, A.R.; Choi, D.H.; Jeong, S.H. Effects of moisture content and compression pressure of various deforming granules on the physical properties of tablets. Powder Technol. 2017, 310, 92–102. [Google Scholar] [CrossRef]

- Drašković, M.; Djuriš, J.; Ibrić, S.; Parojčić, J. Functionality and performance evaluation of directly compressible co-processed excipients based on dynamic compaction analysis and percolation theory. Powder Technol. 2018, 326, 292–301. [Google Scholar] [CrossRef]

- Kalman, H. Phenomenological study of particulate materials compression—From individual through bed compression to tableting. Powder Technol. 2020, 372, 161–177. [Google Scholar] [CrossRef]

- Järvinen, K.; Hoehe, W.; Järvinen, M.; Poutiainen, S.; Juuti, M.; Borchert, S. In-line monitoring of the drug content of powder mixtures and tablets by near-infrared spectroscopy during the continuous direct compression tableting process. Eur. J. Pharm. Sci. 2013, 48, 680–688. [Google Scholar] [CrossRef]

- Mir, V.G.; Heinämäki, J.; Antikainen, O.; Colarte, A.I.; Airaksinen, S.; Karjalainen, M.; Revoredo, O.B.; Nieto, O.M.; Yliruusi, J. Effects of moisture on tablet compression of chitin. Carbohydr. Polym. 2011, 86, 477–483. [Google Scholar] [CrossRef]

- Salleh, F.S.M.; Yusof, Y.A.; Anuar, M.S.; Chin, N.L. Understanding the tabletting characteristics of Ficus deltoidea powder by fitting into compression models. J. Food Process. Eng. 2015, 38, 250–261. [Google Scholar] [CrossRef]

- Portier, C.; Vigh, T.; Di Pretoro, G.; Leys, J.; Klingeleers, D.; De Beer, T.; Vervaet, C.; Vanhoorne, V. Continuous twin screw granulation: Impact of microcrystalline cellulose batch-to-batch variability during granulation and drying—A QbD approach. Int. J. Pharm. X 2021, 3, 100077. [Google Scholar] [CrossRef] [PubMed]

- Fang, L.; Yin, X.; Wu, L.; He, Y.; He, Y.; Qin, W.; Meng, F.; York, P.; Xu, X.; Zhang, J. Classification of microcrystalline celluloses via structures of individual particles measured by synchrotron radiation X-ray micro-computed tomography. Int. J. Pharm. 2017, 531, 658–667. [Google Scholar] [CrossRef] [PubMed]

- Thoorens, G.; Krier, F.; Rozet, E.; Carlin, B.; Evrard, B. Understanding the impact of microcrystalline cellulose physicochemical properties on tabletability. Int. J. Pharm. 2015, 490, 47–54. [Google Scholar] [CrossRef]

- Thoorens, G.; Krier, F.; Leclercq, B.; Carlin, B.; Evrard, B. Microcrystalline cellulose, a direct compression binder in a quality by design environment—A review. Int. J. Pharm. 2014, 473, 64–72. [Google Scholar] [CrossRef] [Green Version]

- Staniforth, J.N.; Baichwal, A.R.; Hart, J.P.; Heng, P.W.S. Effect of addition of water on the rheological and mechanical properties of microcrystalline celluloses. Int. J. Pharm. 1988, 41, 231–236. [Google Scholar] [CrossRef]

- Djuris, J.; Milovanovic, S.; Medarevic, D.; Dobricic, V.; Dap, A.; Ibric, S. Selection of the suitable polymer for supercritical fl uid assisted preparation of carvedilol solid dispersions. Int. J. Pharm. 2019, 554, 190–200. [Google Scholar] [CrossRef] [PubMed]

- Pitt, K.G.; Webber, R.J.; Hill, K.A.; Dey, D.; Gamlen, M.J. Compression prediction accuracy from small scale compaction studies to production presses. Powder Technol. 2015, 270, 490–493. [Google Scholar] [CrossRef]

| Factor Name | Type | Investigated Variation Levels |

|---|---|---|

| Spray rate (rpm) | quantitative | 10 (5 g/min); 25 (12.5 g/min); 40 (20 g/min) |

| Atomizing pressure (atm) | quantitative | 0.5; 0.75 |

| PAR type | qualitative | PAR-A; PAR-B; PAR-C |

| IBU type | qualitative | IBU-A; IBU-B; IBU-C |

| MCC type | qualitative | MCC-A; MCC-B |

| Response | R2 | Q2 | Validity | Reproducibility | ANOVA Regression | ANOVA Lack of Fit |

|---|---|---|---|---|---|---|

| Xa | 0.877 | 0.835 | 0.606 | 0.965 | 2.120 × 10−5 | 2.074 × 10−1 |

| Span | 0.835 | 0.776 | 0.936 | 0.685 | 1.823 × 10−4 | 7.746 × 10−1 |

| TS | 0.960 | 0.947 | 0.473 | 0.993 | 6.981 × 10−9 | 1.221 × 10−1 |

| DS | 0.925 | 0.902 | 0.748 | 0.953 | 1.490 × 10−6 | 3.654 × 10−1 |

| ES | 0.911 | 0.885 | 0.442 | 0.987 | 6.432 × 10−6 | 1.075 × 10−1 |

| Work of compression | 0.989 | 0.974 | 0.311 | 0.999 | 1.860 × 10−15 | 6.383 × 10−2 |

| Elastic recovery | 0.997 | 0.952 | 0.510 | 0.999 | 1.111 × 10−17 | 1.414 × 10−1 |

| Solid fraction | 0.874 | 0.800 | 0.426 | 0.984 | 9.166 × 10−5 | 1.008 × 10−1 |

| Compressibility | Compactibility | Tabletability | |

|---|---|---|---|

| Modeled Responses | Compaction Pressure & Solid Fraction | TS & Solid Fraction | Compaction Pressure & TS |

| Model structure | 2 + 2 + 0 | 2 + 2 + 0 | 2 + 2 + 0 |

| R2X (P1) | 0.063 | 0.067 | 0.066 |

| R2X (P2) | 0.089 | 0.108 | 0.120 |

| R2X (O1) | 0.265 | 0.272 | 0.265 |

| R2X (O2) | 0.142 | 0.138 | 0.139 |

| R2Y (P1) | 0.956 | 0.968 | 0.964 |

| R2Y (P2) | 0.044 | 0.032 | 0.036 |

| Q2 | 0.914 | 0.861 | 0.947 |

| Exp No. | Spray Rate | Atomizing Pressure | PAR | IBU | Xa | Span |

|---|---|---|---|---|---|---|

| N7 | 10 | 0.5 | PAR A | IBU B | 287 | 1.6 |

| N26 | 10 | 0.75 | PAR A | IBU B | 257 | 1.5 |

| N25 | 40 | 0.5 | PAR A | IBU B | 329 | 1.7 |

| N8 | 40 | 0.75 | PAR A | IBU B | 280 | 1.7 |

| N27 | 10 | 0.5 | PAR B | IBU B | 275 | 1.6 |

| N10 | 10 | 0.75 | PAR B | IBU B | 215 | 1.8 |

| N28 | 25 | 0.75 | PAR B | IBU B | 268 | 1.6 |

| N9 | 40 | 0.5 | PAR B | IBU B | 310 | 1.7 |

| N33 | 10 | 0.5 | PAR B | IBU C | 280 | 1.5 |

| N16 | 10 | 0.75 | PAR B | IBU C | 287 | 1.4 |

| N15 | 25 | 0.5 | PAR B | IBU C | 322 | 1.4 |

| N34 | 40 | 0.75 | PAR B | IBU C | 369 | 1.5 |

| N29 | 10 | 0.5 | PAR C | IBU B | 249 | 1.7 |

| N12 | 10 | 0.75 | PAR C | IBU B | 294 | 2.1 |

| N11 | 25 | 0.5 | PAR C | IBU B | 280 | 1.8 |

| N30 | 40 | 0.75 | PAR C | IBU B | 290 | 1.7 |

| Material Properties | MCC A | MCC B |

|---|---|---|

| d50 (µm) | 46.021 | 48.600 |

| Bulk density (g/mL) | 0.353 ± 0.004 | 0.340 ± 0.002 |

| Tapped density (g/mL) | 0.442 ± 0.002 | 0.461 ± 0.001 |

| Loss on drying (%) | 2.330 ± 0.3 × 10−3 | 4.537 ± 0.6 × 10−3 |

| Water binding capacity (%) | 208.209 ± 0.905 | 221.431 ± 2.990 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casian, T.; Iurian, S.; Gâvan, A.; Porfire, A.; Pop, A.L.; Crișan, S.; Pușcaș, A.M.; Tomuță, I. In-Depth Understanding of Granule Compression Behavior under Variable Raw Material and Processing Conditions. Pharmaceutics 2022, 14, 177. https://doi.org/10.3390/pharmaceutics14010177

Casian T, Iurian S, Gâvan A, Porfire A, Pop AL, Crișan S, Pușcaș AM, Tomuță I. In-Depth Understanding of Granule Compression Behavior under Variable Raw Material and Processing Conditions. Pharmaceutics. 2022; 14(1):177. https://doi.org/10.3390/pharmaceutics14010177

Chicago/Turabian StyleCasian, Tibor, Sonia Iurian, Alexandru Gâvan, Alina Porfire, Anca Lucia Pop, Simona Crișan, Anda Maria Pușcaș, and Ioan Tomuță. 2022. "In-Depth Understanding of Granule Compression Behavior under Variable Raw Material and Processing Conditions" Pharmaceutics 14, no. 1: 177. https://doi.org/10.3390/pharmaceutics14010177

APA StyleCasian, T., Iurian, S., Gâvan, A., Porfire, A., Pop, A. L., Crișan, S., Pușcaș, A. M., & Tomuță, I. (2022). In-Depth Understanding of Granule Compression Behavior under Variable Raw Material and Processing Conditions. Pharmaceutics, 14(1), 177. https://doi.org/10.3390/pharmaceutics14010177