Numerical Modeling of Particle Dynamics Inside a Dry Powder Inhaler

Abstract

:1. Introduction

Related Work

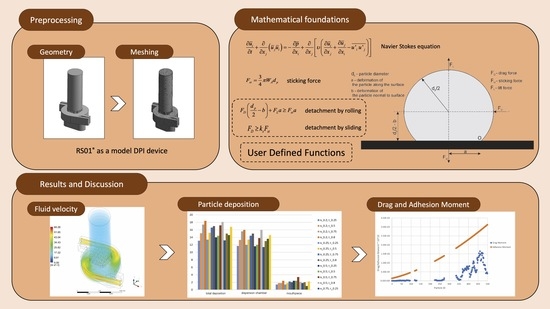

2. Materials and Methods

2.1. Geometry and Meshing

2.2. CFD Modeling

2.3. Particle Sticking Process

2.4. Particle Detachment Process

2.4.1. Detachment by Rolling

2.4.2. Detachment by Sliding

2.5. User Defined Functions (UDF)

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Used Symbols

| Symbol | Parameter Name |

| Fluid velocity | |

| Fluid velocity component parallel to the wall | |

| Fluid velocity component normal to the wall | |

| p | Pressure |

| Kinematic viscosity | |

| Kronecker delta symbol | |

| k | Specific turbulent energy |

| Sticking force | |

| Drag force | |

| Lift force | |

| Deformation of the particle along the surface | |

| Particle diameter | |

| Normal (impact) velocity | |

| Critical (capture) velocity | |

| Wall shear velocity | |

| Wall shear velocity for rolling | |

| Wall shear velocity for sliding | |

| Distance of the first grid point from the wall | |

| Drag coefficient | |

| Reynolds coefficient | |

| Kc | Composite Young’s modulus |

| Young’s modulus for surface | |

| Young’s modulus for particle | |

| Work of adhesion | |

| Poisson’s ratio for surface | |

| Poisson’s ratio for particle | |

| Particle density | |

| Mixture density | |

| Air density (at 1013.25 hPa (abs) and 15 °C) | |

| Dynamic viscosity of fluid (air) | |

| Correction factor for the near wall | |

| Cunningham correction factor | |

| Static coefficient of friction |

References

- Alagusundaram, M.; Chengaiah, B.; Gnanaprakash, K.; Ramkanth, S.; Madhusudhana, C.; Dhachinamoorthi, D. Nasal drug delivery system—An overview. Int. J. Res. Pharm. Sci. 2010, 1, 454–465. [Google Scholar]

- Razavi Rohani, S.S.; Abnous, K.; Tafaghodi, M. Preparation and characterization of spray-dried powders intended for pulmonary delivery of Insulin with regard to the selection of excipients. Int. J. Pharm. 2014, 465, 464–478. [Google Scholar] [CrossRef] [PubMed]

- Daniher, D.I.; Zhu, J. Dry powder platform for pulmonary drug delivery. Particuology 2008, 6, 225–238. [Google Scholar] [CrossRef]

- Zheng, Z.; Leung, S.S.Y.; Raghvendra, G. Flow and Particle Modelling of Dry Powder Inhalers: Methodologies, Recent Development and Emerging Applications. Pharmaceutics 2021, 13, 189. [Google Scholar] [CrossRef] [PubMed]

- Islam, N.; Cleary, M. Developing an efficient and reliable dry powder inhaler for pulmonary drug delivery—A review for multidisciplinary researchers. Med. Eng. Phys. 2012, 34, 409–427. [Google Scholar] [CrossRef] [PubMed]

- Tong, Z.; Yu, A.; Chan, H.-K.; Yang, R. Discrete Modelling of Powder Dispersion in Dry Powder Inhalers—A Brief Review. Curr. Pharm. Des. 2015, 21, 3966–3973. [Google Scholar] [CrossRef]

- Tong, Z.B.; Zheng, B.; Yang, R.; Yu, A.; Chan, H.K. CFD-DEM investigation of the dispersion mechanisms in commercial dry powder inhalers. Powder Technol. 2013, 240, 19–24. [Google Scholar] [CrossRef]

- Wong, W.; Fletcher, D.; Traini, D.; Chan, H.-K.; Young, P. The use of computational approaches in inhaler development. Adv. Drug Deliv. Rev. 2012, 64, 312–322. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Schmalfuß, S. Numerical Analysis of Carrier Particle Motion in a Dry Powder Inhaler. J. Fluids Eng. 2016, 138, 041308. [Google Scholar] [CrossRef]

- Finlay, W.H.; Martin, A. Modeling of aerosol deposition with interface devices. J. Aerosol Med. Pulm. Drug Deliv. 2007, 20, S19–S28. [Google Scholar] [CrossRef]

- Yang, Y.; Knudsen Kær, S. Comparison of Reynolds Averaged Navier-Stokes Based Simulation and Large-eddy Simulation for One Isothermal Swirling Flow. J. Therm. Sci. 2012, 21, 154–161. [Google Scholar] [CrossRef]

- Ruzycki, C.; Javaheri, E.; Finlay, W. The use of computational fluid dynamics in inhaler design. Expert Opin. Drug Deliv. 2013, 10, 307–323. [Google Scholar] [CrossRef] [PubMed]

- Milenkovic, J.; Alexopoulos, A.H.; Kiparissides, C. Flow and particle deposition in the Turbuhaler: A CFD simulation. Int. J. Pharm. 2013, 448, 205–213. [Google Scholar] [CrossRef] [PubMed]

- Milenkovic, J.; Alexopoulos, A.H.; Kiparissides, C. Deposition and fine particle production during dynamic flow in a dry powder inhaler: A CFD approach. Int. J. Pharm. 2014, 461, 129–136. [Google Scholar] [CrossRef] [PubMed]

- Vulovic, A.; Sustersic, T.; Cvijic, S.; Ibric, S.; Filipovic, N. Coupled in silico platform: Computational fluid dynamics (CFD) and physiologically-based pharmacokinetic (PBPK) modelling. Eur. J. Pharm. Sci. 2018, 113, 171–184. [Google Scholar] [CrossRef]

- Feng, Y.; Kleinstreuer, C. Micron-particle transport, interactions and deposition in triple lung-airway bifurcations using a novel modeling approach. J. Aerosol Sci 2014, 71, 1–15. [Google Scholar] [CrossRef]

- de Boer, A.; Hagedoorn, P.; Woolhouse, R.; Wynn, E. Computational fluid dynamics (CFD) assisted performance evaluation of the Twincer™ disposable high-dose dry powder inhaler. J. Pharm. Pharmacol. 2012, 64, 1316–1325. [Google Scholar] [CrossRef]

- Moskal, A.; Sosnowski, T. Computational fluid dynamics (CFD) and direct visualization studies of aerosol release from two cyclohaler-type dry powder inhalers. J. Drug Deliv. Sci. Technol. 2012, 22, 161–165. [Google Scholar] [CrossRef]

- Zhou, Q.; Tong, Z.; Tang, P. CFD analysis of the aerosolization of carrier-based dry powder inhaler formulations. AIP Conf. Proc. 2013, 1542, 113. [Google Scholar]

- Donovan, M.; Hyen Kim, S.; Raman, V.; Smyth, H. Dry Powder Inhaler Device Influence on Carrier Particle Performance. J. Pharm. Sci. 2012, 101, 1097–1107. [Google Scholar] [CrossRef]

- Coates, M.S.; Fletcher, D.F.; Chan, H.-K.; Raper, J.A. Effect of Design on the Performance of a Dry Powder Using Computational Fluid Dynamics. Part 1: Grid Structure and Mouthpiece Length. J. Pharm. Sci. 2004, 93, 2863–2876. [Google Scholar] [CrossRef] [PubMed]

- Coates, M.S.; Chan, H.-K.; Fletcher, D.F.; Raper, J.A. Effect of Design on the Performance of a Dry Powder Inhaler Using Computational Fluid Dynamics. Part 2: Air Inlet Size. J. Pharm. Sci. 2006, 95, 1382–1392. [Google Scholar] [CrossRef] [PubMed]

- Coates, M.S.; Chan, H.-K.; Fletcher, D.F.; Chiou, H. Influence of Mouthpiece Geometry on the Aerosol Delivery Performance of a Dry Powder Inhaler. Pharm. Res. 2007, 24, 1450–1456. [Google Scholar] [CrossRef] [PubMed]

- Milenkovic, J.; Alexopoulos, A.; Kiparissides, C. Optimization of a DPI Inhaler: A Computational Approach. J. Pharm. Sci. 2016, 106, 850–858. [Google Scholar] [CrossRef] [PubMed]

- Ignjatović, J.; Šušteršič, T.; Bodić, A.; Cvijić, S.; Đuriš, J.; Rossi, A.; Dobričić, V.; Ibrić, S.; Filipović, N. Comparative assessment of in vitro and in silico methods for aerodynamic characterization of powders for inhalation. Pharmaceutics 2021, 13, 1831. [Google Scholar] [CrossRef]

- Abdelrahim, M. Emitted dose and lung deposition of inhaled terbutaline from Turbuhaler at different conditions. Respir. Med. 2010, 104, 682–689. [Google Scholar] [CrossRef] [Green Version]

- De Koning, V.J.M.; Oelen, G.; de Boer, A.; Van der Mark, T.W.; Coenegracht, P.; Tromp, T.; Frijlink, H. Effect of Peak Inspiratory Flow and Flow Increase Rate on In Vitro Drug Deposition from Four Dry Powder Inhaler Devices. In Dry Powder Inhalation: Technical and Physiological Aspects, Prescribing and Use; Rijksuniversiteit Groningen: Groningen, The Netherlands, 2001. [Google Scholar]

- Milenkovic, J.M. Ροή αέρα και εναιόθεση σωματιδίων σε εισπνευστήρα ξηράς σκόνης (Airflow and Particle Deposition in a Dry Powder Inhaler. A CFD and Particle Computational Approach). Ph.D. Thesis, Aristotle University of Thessaloniki, Thessaloniki, Greece, 2015. [Google Scholar]

- Mahler, D. Peak Inspiratory Flow Rate as a Criterion for Dry Powder Inhaler Use in Chronic Obstructive Pulmonary Disease. Ann. Am. Thorac. Soc. 2017, 14, 1103–1107. [Google Scholar]

- El-Batsh, H.H. Numerical investigation of the effect of ash particle deposition on the flow field through turbine cascades. In Proceedings of the ASME Turbo Expo 2002, Amsterdam, The Netherlands, 3–6 June 2002. [Google Scholar]

- Meseguer, J.; Slobozhanin, L.; Perales, J. A review on the stability of liquid bridges. Adv. Space Res. 1995, 16, 5–14. [Google Scholar] [CrossRef] [Green Version]

- Soltani, M.; Ahmadi, G. On particle adhesion and removal mechanisms in turbulent flow. J. Adhes. Sci. Technol. 1994, 8, 763–785. [Google Scholar] [CrossRef]

- Dahneke, B. Further measurements of the bouncing of small latex spheres. J. Colloid Interface Sci. 1974, 51, 58–65. [Google Scholar] [CrossRef]

- Brach, R.; Dunn, P. A mathematical model of the impact and adhesion of microspheres. Aerosol Sci. Technol. 1992, 16, 51–64. [Google Scholar] [CrossRef]

- Alden, A.M.H.; Diab, A. Assessment of losses in annual energy production of wind turbines subjected to sand erosion. In Proceedings of the International Conference on Fluid Dynamics, Le Méridien PyramidsHotel, Cairo, Egypt, 19–20 December 2016. [Google Scholar]

- Gill, R. Improvements to Prediction and Measurement Capabilities for Airborne Dust Deposition, with Application to Redesign of a Low-Reynolds Number Valve. Master’s Theies, University of Windsor, Windsor, ON, Canada, 2016. [Google Scholar]

- Wang, H. Effects of inceptive motion on particle detachment from surfaces. Aerosol Sci. Technol. 1990, 13, 386–393. [Google Scholar] [CrossRef]

| Parameter Name | Symbol | Value | Unit | Reference |

|---|---|---|---|---|

| Young’s modulus for surface | 4.1e9 | Pa | [28] | |

| Young’s modulus for particle | 1e9 | Pa | [28] | |

| work of adhesion | 0.039 | J/m2 | [9,32] | |

| Poisson’s ratio for surface | 0.35 | / | [28] | |

| Poisson’s ratio for particle | 0.4 | / | [28] | |

| particle density | 1230 | kg/m3 | [25] | |

| air density (at 1013.25 hPa (abs) and 15 °C) | 1.225 | kg/m3 | [28] | |

| dynamic viscosity of fluid (air) | 1.7894e−5 | N s/m2 | [28] | |

| correction factor for the near wall | 1.7 | / | [9,32] | |

| Cunningham correction factor | 1 (for spherical particles) | / | [9,32] | |

| static coefficient of friction | 0.5 | / | [9,32] |

| COR_Normal | |||||

|---|---|---|---|---|---|

| COR_tangential | 0.20 | 0.25 | 0.50 | 0.75 | |

| 0.25 | 13.1 | 13.4 | 14.0 | 13.2 | |

| 0.50 | 15.1 | 15.2 | 14.4 | 15.0 | |

| 0.75 | 17.4 | 16.6 | 17.2 | 14.6 | |

| 0.80 | 18.4 | 17.0 | 18.1 | 16.8 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šušteršič, T.; Bodić, A.; Ignjatović, J.; Cvijić, S.; Ibrić, S.; Filipović, N. Numerical Modeling of Particle Dynamics Inside a Dry Powder Inhaler. Pharmaceutics 2022, 14, 2591. https://doi.org/10.3390/pharmaceutics14122591

Šušteršič T, Bodić A, Ignjatović J, Cvijić S, Ibrić S, Filipović N. Numerical Modeling of Particle Dynamics Inside a Dry Powder Inhaler. Pharmaceutics. 2022; 14(12):2591. https://doi.org/10.3390/pharmaceutics14122591

Chicago/Turabian StyleŠušteršič, Tijana, Aleksandar Bodić, Jelisaveta Ignjatović, Sandra Cvijić, Svetlana Ibrić, and Nenad Filipović. 2022. "Numerical Modeling of Particle Dynamics Inside a Dry Powder Inhaler" Pharmaceutics 14, no. 12: 2591. https://doi.org/10.3390/pharmaceutics14122591

APA StyleŠušteršič, T., Bodić, A., Ignjatović, J., Cvijić, S., Ibrić, S., & Filipović, N. (2022). Numerical Modeling of Particle Dynamics Inside a Dry Powder Inhaler. Pharmaceutics, 14(12), 2591. https://doi.org/10.3390/pharmaceutics14122591