Evaluation of the Construction and Investment Process of a High-Pressure Gas Pipeline with Use of the Trenchless Method and Open Excavation Method. Analytic Hierarchy Process (AHP)

Abstract

:1. Introduction

- -

- selecting projects co-financed from European Union funds (SAW, EXPROM),

- -

- supporting bilateral negotiations (F-SAW, F-TOPSIS),

- -

- selection of employees (AHP, PROMETHEE II).

- Pilot drilling. The drilling is performed with use of the drilling rig, drill string, drilling tools, and a navigation system. The circulation system of the drilling fluid is closed.

- Drilling diameter expansion.

- Installation of the carrier pipe. The pipe is placed on rollers, and then it is fastened to a swivel and pulled into the drilling borehole with use of the drilling rig and the drill [44].

2. Research Methodology

- The existence of numerous objectives or attributes (the decision maker has to define the set of objectives or attributes that will be suitable for the analysed decision-making issue).

- Lack of a universal measure for the criteria—each of the objectives or attributes may have a different measurement unit. The existence of both quantitative criteria (estimated directly) and qualitative criteria (presented verbally), which, in practice, often play the main role in the decision-making process.

- The issue of searching for the best solution or selecting the best variant from among a small number of variants.

- The decision-making process takes place in the conditions of missing information or information of an uncertain (fuzzy, probabilistic) nature.

- The need to realise the decision-making process in a relatively short time and by a small number of decision makers.

- One-off choice (at least for the period of operation of the gas pipeline—even up to several decades), i.e., for the life cycle of the system).

- with use of the open excavation method,

- with use of the trenchless Horizontal Directional Drilling (HDD) method.

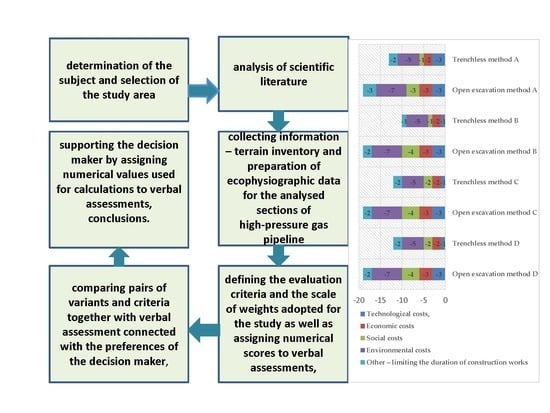

- determination of the subject and selection of study area;

- analysis of scientific literature;

- collecting information—terrain inventory and preparation of ecophysiographic data for the analysed sections of high-pressure gas pipeline;

- defining the evaluation criteria and the scale of weights adopted for the study, as well as assigning numerical scores to verbal assessments;

- comparing pairs of variants and criteria together with verbal assessment connected with the preferences of the decision maker;

- supporting the decision maker by assigning numerical values used for calculations to verbal assessments.

- Q1:

- Are the technological and economic costs of the application of the open excavation method used in the construction of a high-pressure gas pipeline really lower than in the horizontal directional drilling (HDD) method, with higher environmental costs?

- Q2:

- Can the environmental and social costs of constructing high-pressure gas pipelines influence the decision on the application of the trenchless method (horizontal directional drilling (HDD)) for the construction of gas pipelines in naturally valuable areas?

- technological costs,

- economic costs,

- social costs,

- environmental costs.

3. Results and Discussion

3.1. Characteristics of the Realisation of the Investment with Use of the Horizontal Directional Drilling Method (HDD) and Open Excavation Method

3.2. Characteristics of the Pipes, and the Technological, Economic, Social, and Environmental Costs of the Evaluated Investment

3.2.1. Technological Costs

3.2.2. Economic Cost

- cots of damage to private property;

- costs of damage to adjacent infrastructure;

- costs of damage and wear of road surface;

- costs resulting from increased expenditure on road maintenance;

- costs of moving the existing infrastructure that interferes with the construction works;

- costs of environmental supervision and actions to minimise negative impact.

3.2.3. Social Costs

- traffic organisation problems;

- safety issues in the vicinity of the construction site;

- interference with commercial and recreational activity in the project area;

- landscape factors;

- human factors (connected with the negative influence of the investment-related works on the inhabitants of the neighbouring areas).

3.3.4. Environmental Costs

- air,

- soil,

- water,

- physical factors,

- natural factors.

3.3. Comparison of Alternative Methods of the Realisation of Gas Pipeline

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Saaty, T.L. The Analytic Hierarchy Process; Mcgrew Hill, New York, International, Translated to Russian, Portuguesses and Chinese, Revised edition, Paperback, 2000; RWS Publications: Pittsburgh, PA, USA, 1996. [Google Scholar]

- Saaty, T.L. Decision Making for Leaders: The Analytic Hierarchy Process for Decisions in a Complex World; RWS Publications: Pittsburgh, PA, USA, 1990. [Google Scholar]

- Asgari, N.; Hassani, A.; Jones, D.; Nguye, H.H. Sustainability ranking of the UK major ports: Methodology and case study. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 19–39. [Google Scholar] [CrossRef]

- Saaty, T.L.; Vargas, L.G. Models, Methods, Concepts and Applications of the Analytic Hierarchy Process; Kluwer Academic Publishers: Boston, MA, USA, 2000. [Google Scholar]

- Saaty, T.L. Rank from Comparisons and from Ratings in the Analytic Hierarchy, Network Processes; University of Pittsburgh: Pittsburgh, PA, USA, 2000. [Google Scholar]

- Saaty, T.L. Creative Thinking, Problem Solving & Decision Making; RWS Publication: Pittsburgh, PA, USA, 2001. [Google Scholar]

- Saaty, T.L. Deriving the AHP 1–9 scale from first principles. In Proceedings of the ISAHP, Berne, Switzerland, 2–4 August 2001. [Google Scholar]

- Saaty, T.L. How to Make a Decision: The Analytic Hierarchy Process. Interfaces 1994, 24, 19–43. [Google Scholar] [CrossRef]

- Rosmuller, N.; Beroggi, G.E.G. Group decision making in infrastructure safety planning. Saf. Sci. 2004, 42, 325–349. [Google Scholar] [CrossRef]

- Skorupski, J. Multi-criteria group decision making under uncertainty with application to air traffic safety. Expert Syst. Appl. 2014, 41, 7406–7414. Available online: http://skorupski.waw.pl/publikacje/Multi-Criteria%20Group%20Decision%20Making%20Under%20Uncertainty%20with%20Application%20to%20Air%20Traffic%20Safety.pdf (accessed on 20 March 2019).

- Roszkowska, E. Multi-criteria decision making models by applying the topsis method to crisp and interval data. In Multiple Criteria Decision Making 10–11; Trzaskalik, T., Wachowicz, T., Eds.; The University of Economics in Katowice: Katowice, Poland, 2011; Available online: http://mcdm.ue.katowice.pl/files/mcdm11.pdf (accessed on 20 March 2019).

- Lai, Y.J.; Liu, T.Y.; Hwang, C.L. TOPSIS for MODM. Eur. J. Op. Res. 1994, 76, 486–500. [Google Scholar] [CrossRef]

- Jahanshahloo, G.R.; Hosseinzadeh, L.F.; Izadikhah, M. An algorithmic method to extend TOPSIS for decision-making problems with interval data. Appl. Math. Comput. 2006, 175, 1375–1384. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yoon, K. Multiple Attribute Decision Making. Lecture Notes in Economics and Mathematical Systems 186; Springer: Berlin, Germany, 1981; Available online: https://www.springer.com/gp/book/9783540105589 (accessed on 10 April 2019).

- Trzaskalik, T.; Wydział Informatyki i Komunikacji; Uniwersytet Ekonomiczny w Katowicach. Wielokryterialne wspomaganie decyzji. Przegląd metod i zastosowań. Zeszyty Naukowe Politechniki Śląskiej Seria Organizacja Zarządzanie 2014, z. 74, 239–263. Available online: http://www.woiz.polsl.pl/znwoiz/z74/2_11_Trzaskalik_T_po_recenzji_final.pdf (accessed on 10 April 2019).

- Roszkowska, E.; Wachowicz, T. Application of fuzzy TOPSIS to scoring the negoti ation offers in illstructured negotiation problems. Eur. J. Op. Res. 2015, 242, 920–932. [Google Scholar]

- Roszkowska, E.; Wachowicz, T. Ocena ofert negocjacyjnych spoza dopuszczalnej przestrzeni negocjacyjnej. Prace Naukowe Uniwersytetu Ekonomicznego Wrocławiu 2015, 385, 202–209. [Google Scholar] [CrossRef]

- Roszkowska, A.; Filipowicz-Chomko, M.; Wachowicz, T. Wykorzystanie metody TOPSIS do oceny zróżnicowania rozwoju województw Polski w latach 2010–2014 w kontekście kształtowania się ładu instytucjonalnego [The Application of TOPSIS Method for the Evaluation of Diversification of Polish Voivodeships between 2010–2014 in the Context of Forming of Institutional]. Prace Naukowe Uniwersytetu Ekonomicznego Wrocławiu 2017, 469, 149–158. Available online: https://www.researchgate.net/publication/322581029_Wykorzystanie_metody_TOPSIS_do_oceny_zroznicowania_rozwoju_wojewodztw_Polski_w_latach_2010 2014_w_kontekscie_ksztaltowania_sie_ladu_instytucjonalnego (accessed on 10 April 2019).

- Jahanshshloo, G.R.; Hosseinzadeh Lotfi, F.; Izadikhah, M. Extension of the TOPSIS method for decision-making problems with fuzzy data. Appl. Math. Comput. 2006, 181, 1544–1551. [Google Scholar] [CrossRef]

- Trzaskalik, T. Modelowanie preferencji w wielokryterialnych dyskretnych problemach decyzyjnych [Preference modelingin multicriteria discrete decision making problems]. Prace Naukowe Uniwersytetu Ekonomicznego Wrocławiu [Res. Pap. Wroc. Univ. Econ.] 2016, 426. [Google Scholar] [CrossRef]

- Tecle, A. Choice of Multi-Criteria Decision-Making Techniques for Watershed Management. Ph.D. Thesis, University of Arizona, Tuscon, AZ, USA, 1988. Available online: https://www.researchgate.net/publication/35576215_Choice_of_Multicriterion_Decision_MakingTechniques_for_Watershed_Management (accessed on 10 April 2019).

- Tzeng, G.H.; Huang, J.J. Multiple Attribute Decision Making. Methods and Applications; CRC Press: London, UK, 2011. [Google Scholar]

- Zalewski, W. Zastosowanie metody TOPSIS do oceny kondycji finansowej spółek dystrybucyjnych energii elektrycznej [Application of TOPSIS method for evaluation of financial condition of the power distribution companies]. Econ. Manag. 2012, 4, 137–145. Available online: http://jem.pb.edu.pl/data/magazine/article/103/en/4.1_zalewski.pdf (accessed on 9 April 2019).

- Gershon, M. Model Choice in Multi-Objective Decision-Making in Natural Resource Systems. Ph.D. Thesis, University of Arizona, Tuscon, AZ, USA, 1981. [Google Scholar]

- Briggs, C.A. Risk Assessment in the Upstream Crude Oil Supply Chain: Leveraging Analytic Hierarchy Process. Ph.D. Thesis, North Dakota State University, Fargo, ND, USA, 2010. (UMI No. 748837971). [Google Scholar]

- Deason, K.S.; Jefferson, T. A systems approach to improving fleet policy compliance within the US Federal Government. Energy Policy 2010, 38, 2865–2874. [Google Scholar] [CrossRef]

- Steele, K.; Carmel, Y.; Cross, J.; Wilcox, C. Uses and misuses of multicriteria decision analysis (MCDA) in environmental decision-making. Soc. Risk Anal. 2009, 29, 26–33. [Google Scholar] [CrossRef] [PubMed]

- Kozioł, W.; Piotrowski, Z.; Pomykała, R.; Machniak, Ł.; Baic, I.; Witkowska-Kita, B.; Lutyński, A.; Blaschke, W. Zastosowanie analitycznego procesu hierarchicznego (AHP) do wielokryterialnej oceny innowacyjności technologii zagospodarowania odpadów z górnictwa kamiennego. Rocznik Ochrona Środowiska 2011, 13, 1619–1634. Available online: https://ros.edu.pl/images/roczniki/archive/pp_2011_103.pdf (accessed on 27 December 2018).

- Imam, E.; Tesfamichael, G.Y. Use of remote sensing, GIS and analytical hierarchy process (AHP) in wildlife habitat suitability analysis. J. Mater. Environ. Sci. 2013, 4, 460–467. Available online: http://www.jmaterenvironsci.com/ (accessed on 12 April 2019).

- Aragonés-Beltrán, P.; Chaparro-González, F.; Pastor-Ferrando, J.P.; Pla-Rubio, A. An AHP (Analytic Hierarchy Process)/ANP (Analytic Network Process)-based multi-criteria decision approach for the selection of solar-thermal power plant investment projects. Energy 2014, 66, 222–238. [Google Scholar] [CrossRef]

- Grošelj, P.; Malovrh, Š.; Stirn, L.Z. Methods based on data envelopment analysis for deriving group priorities in analytic hierarchy process. Cent. Eur. J. Oper. Res. 2011, 19, 267–284. [Google Scholar] [CrossRef]

- Křupka, J.; Provazníková, R.; Švejcar, J. Multiple criteria decision analysis of EU project implementation benefits for the impacted micro-region. Int. J. Math. Model. Methods Appl. Sci. 2011, 5, 1354–1362. Available online: http://www.naun.org/. (accessed on 12 April 2019).

- Roux, I.J. Applying the Analytic Hierarchy Process to Oil Sands Environmental Compliance Risk Management. Ph.D. Thesis, Walden University, Minneapolis, MN, USA, 2015. Available online: https://scholarworks.waldenu.edu/cgi/viewcontent.cgi?article=1163&context=dissertations (accessed on 28 December 2018).

- Saaty, T.L. Fundamentals of Decision-Making and Priority Theory with the Analytical Hierarchy Process Vol. VI of the AHP Series; RWS Publications: Pittsburgh, PA, USA, 2006. [Google Scholar] [CrossRef]

- Saaty, T.L.; Zoffer, H.J. Nina’s decision: How to make better decisions and resolve conflicts. Int. J. Anal. Hierarchy Process 2012, 4, 78–86. Available online: http://www.ijahp.org/ (accessed on 12 April 2019).

- Talib, F.; Rahman, Z.; Qureshi, M.N. Prioritizing the practices of total quality management: An analytic hierarchy process analysis for the service industries. Total Qual. Manag. Bus. Excell. 2011, 22, 1331–13510. [Google Scholar] [CrossRef]

- Castro, D.M.; Parreiras, F.S. A review on multi-criteria decision-making for energy efficiency in automotive engineering. Appl. Comput. Inform. 2018. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P.K. Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, R.; Barrett, D.; Gao, L.; Zhou, M.; Renzullo, L.; Emelyanova, I. A spatial assessment framework for evaluating flood risk under extreme climates. Sci. Total Environ. 2015, 538, 512–523. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Javid, R.J.; Nejat, A.; Hayhoe, K. Selection of CO2 mitigation strategies for road transportation in the United States using a multi-criteria approach. Renew. Sustain. Energy Rev. 2014, 38, 960–972. [Google Scholar] [CrossRef]

- Párez, J.C.; Carrillo, M.H.; Montoya-Torres, J.R. Multi-criteria approaches for urban passenger transport systems: A literature review. Ann. Oper. Res. 2014, 226, 69–87. [Google Scholar] [CrossRef]

- Dağdeviren, M. Decision making in equipment selection: An integrated approach with AHP and promethee. J. Intell. Manuf. 2008, 19, 397–406. [Google Scholar] [CrossRef]

- Kwast-Kotlarek, U.; Hełdak, M.; Szczepański, J. Introducing bentonite into the environment in the construction stage of linear underground investment using the HDD method. Appl. Sci. 2018, 8, 2210. [Google Scholar] [CrossRef]

- Zwierzchowska, A. Technologie Bezwykopowej Budowy Sieci Gazowych, Wodociągowych i Kanalizacyjnych; Wydawnictwo Politechniki Świetokrzyskiej: Kielce, Polska, 2006. (In Polish) [Google Scholar]

- Ariaratnam, S.T. Perspektywy globalnego wpływu technologii bezwykopowych na rozwój gospodarczy. Nowoczesne Budownictwo Inżynieryjne. 2012, 2, 62–66. Available online: http://www.nbi.com.pl/assets/NBI-pdf/2012/2_41_2012/pdf/15_samule_ariaratnam_wplyw_technologii_bezwykopowych_na_gospodarke.pdf (accessed on 20 March 2019).

- Chojnacki, A.; Szwedo, O. Wybór systemu klasy ERP metodą AHP [An AHP method to ERP system selection]. Biuletyn Instytutu Systemów Informatycznych 2010, 5, 13–22. Available online: file:///C:/Users/KGP/Downloads/httpwww_bg_utp_edu_plartbisi52010bisi520101322.pdf (accessed on 9 April 2019).

- Kuliczkowski, A.; Zwierzchowska, A. The optimization of trenchless pipe laying technologies and the specificty of pipe laying in urban conditions. Struct. Environ. 2010, 2, 31–38. [Google Scholar]

- Allouche, E.N.; Ariaratnam, S.T.; Lueke, J.S. Horizontal directional drilling: Profile of an emerging industry. J. Constr. Eng. Manag. 2000, 126, 68–76. [Google Scholar] [CrossRef]

- Atalah, A.; Kariuki, J. Cost comparison between horizontal directional drilling and open-cut construction methods in Nairobi, Kenya. In Proceedings of the International Conference on Pipelines and Trenchless Technology (ICPTT) 2009, Shanghai, China, 18–21 October 2009. [Google Scholar] [CrossRef]

- Vilfrant, E.C. Analysis of Parameters Affecting Costs of Horizontal Directional Drilling Projects in the United States for Municipal Infrastructure. Master’s Thesis, Arizona State University, Phoenix, AZ, USA, December 2010. Available online: https://repository.asu.edu/attachments/56065/content/Vilfrant_asu_0010N_10038.pdf (accessed on 20 March 2019).

- Michael, D.; Lubrecht, L.G. Horizontal directional drilling: A green and sustainable technology for site remediation. Environ. Sci. Technol. 2012, 46, 2484–2489. [Google Scholar] [CrossRef]

- Manacorda, G.; Miniati, M.; Bracciali, S.; Dei, D.; Scott, H.F.; Koch, E.; Pinchbeck, D.; Murgier, S. Development of a bore-head GPR for Horizontal Directional Drilling (HDD) equipment. In Proceedings of the 13th International Conference on Ground Penetrating Radar, Lecce, Italy, 21–25 June 2010. [Google Scholar]

| Section ID | Approximate Length, Location | Description of the Natural Values |

|---|---|---|

| A | km 10 + 330–10 + 515 | An approximately 185 m long section, covering a eutrophic reservoir 3150 with yellow water-lilies, surrounded by reed rushes. Breeding places of the grass frog (Rana temporaria), common water frog (Rana esculenta), and common toad (Bufo bufo). Habitat of the mallard (Anas platyrhynchos) and great reed warbler (Acrocephalus arundinaceus), and probably the breeding place of common pochard (Aythya farina), tufted duck (Aythya fuligula), little grebe (Tachybaptus ruficollis), common grasshopper warbler (Locustella naevia), and Eurasian red warbler (Acrocephalus scirpaceus). Breeding of sedge warbler (Acrocephalus schoenobaenus) is also possible. To the E from the pond there are riparian woods with grey alder (Alnus incana) *91E0-3 along the Struga water course. Probably the breeding place of bluethroat (Luscinia svecica) (a species from Anndex I of the Birds Directive) and of numerous other bird species. Habitat of viviparous lizard (Zootoca vivipara) and grass snake (Natrix natrix). |

| B | km 12 + 830–13 + 126 | An approximately 300 m long section, covering a mosaic of meadows and single shrubs, which is the habitat of numerous animal species. Habitat of a rare plant—mouse garlic (Allium angulosum L.). |

| C | km 4 + 600–5 + 050 | An approximately 500 m long section, covering alluvial forests with Alnus glutinosa and Fraxinus excelsior 91E0* (approxiamtely 2.00 ha). |

| D | km 24 + 000–24 + 700 | An approximately 650 m long section, covering alluvial forests with Alnus glutinosa and Fraxinus excelsior and alder swamps 91E0* (approx. 2.91 ha). A 250 m wide belt along the pipeline—part of the Natura 2000 area Kumaki Dobrej and a marsh or flooded meadow near the forest. |

| Verbal Assessment | Numerical Score |

|---|---|

| Extreme | 5 |

| Very strongly | 4 |

| Strongly | 3 |

| Moderately | 2 |

| Equivalently | 1 |

| Indirect preference | 6, 7, 8, 9 |

| Reverse preference | Reciprocal of the number |

| Cost of Earth Works * | Description | Section Length < 50 m | Section Length 50–200 m | Section Length > 200 m |

|---|---|---|---|---|

| Weight | −5 | −3 | −1 | |

| Drainage costs | Description | Drainage of excavations is prohibited (use of alternative realisation methods) | Standard drainage | trenchless methods (do not require drainage) |

| weight | −2 | −1 | 0 | |

| Costs of weighing down the pipeline | Description | - | Weighing down is necessary due to high ground water level | No need to weigh down |

| weight | - | −1 | 0 | |

| Cost of environmental supervision | Description | on the whole length of excavation | for sending and receiving chambers | Supervision not required |

| weight | −2 | −1 | 0 | |

| Costs of minimising activities = “−1” for each activity, (e.g., narrowing the assembly belt, protecting excavations with use of herpetological fences, collecting and re-sowing seeds, maintaining flow in a water course) | ||||

| Safety on the construction site—size of the construction site (excavation length) | Description | Whole length of section | Places where sending and receiving chambers will be located | - |

| weight | −2 | −1 | - | |

| Landscape factors—time for restoring the conditions from before construction, re-growing the removed trees and bushes | Description | Whole length of section | Places where sending and receiving chambers will be located, outside the naturally valuable area | - |

| weight | −2 | −1 | - | |

| impact on the atmosphere—amount of fuel used to make the excavation and to transport machinery together with exhaust gas emission to the atmosphere | Description | Higher amount of construction equipment and frequency of truck deliveries | lower amount of construction equipment, routes of trucks limited to the area of sending and receiving chambers | - |

| weight | −2 | −1 | - | |

| Impact on soil—amount of humus and soil removed from excavations | Description | Higher amount of removed humus layer and soil removed from excavations | Humus is removed only in the area of sending and receiving chambers | - |

| weight | −2 | −1 | - | |

| Impact on water—potential disturbance of the aquatic environment (lowered quality and level of ground and surface waters) | Description | High probability of disturbance of the water relations or of water pollution (high ground water level, prohibition on excavation drainage) | Likely disturbance of water relations or water pollution (standard drainage) | No impact on water relations and water pollution |

| weight | −2 | −1 | 0 | |

| Impact on physical factors—noise emission and vibrations | Description | Higher level of noise emission and vibrations | Lower level of noise emission and vibrations | - |

| weight | −3 | −1 | - | |

| Impact on natural factors—influence of the investment on vegetation conditions in the area and on the existing habitats and protected species | Description | Necessity to remove trees and bushes from the assembly belt, interference with habitats, threat for amphibians and reptiles on the whole length of the section | No interference with habitats, trees and bushes are cut only in the areas with sending and receiving chambers, low risk for amphibians and reptiles | - |

| weight | −1 | 0 | - | |

| Other—limiting the duration of construction works | Description | Requirement to interrupt the works for the birds’ breeding season | No limitations of the construction period | - |

| weight | −1 | 0 | - | |

| Realisation Variant | Areas for Which Variants of Realisation Were Considered | ||||

|---|---|---|---|---|---|

| Open Excavation Method | Trenchless Method | Open Excavation Method | Trenchless Method | ||

| Section ID | A | B | |||

| Approx. length of the section | approx. km 10 + 330–10 + 515 | approx. km 12 + 830–13 + 126 | |||

| Evaluation criterion | Weights | ||||

| Technological costs | Cost of earth works | 0 | −3 | 0 | −1 |

| Drainage costs | Trench drainage prohibited −2 | 0 | Trench drainage prohibited −2 | 0 | |

| Costs of weighing down the pipeline | −1 | 0 | −1 | 0 | |

| Economic costs | Cost of environmental supervision | −1 | −1 | −1 | −1 |

| Cost of actions minimising the negative environmental impact of the investment | Protection of trenches with use of herpetological fences Narrowing the construction belt −2 | Protection of trenches with use of herpetological fences −1 | Protection of trenches with use of herpetological fences Narrowing the construction belt −2 | Protection of trenches with use of herpetological fences −1 | |

| Social costs | Safety issues in the vicinity of the construction site | −2 | −1 | −2 | −1 |

| Landscape factors | −1 | 0 | −1 | 0 | |

| Environmental costs | Air | −2 | −1 | −2 | −1 |

| Soil | −2 | −1 | −2 | −1 | |

| Water | −1 | 0 | −1 | 0 | |

| Physical factors | −1 | −3 | −1 | −3 | |

| Natural factors | −1 | 0 | −1 | 0 | |

| Other—limiting the duration of construction works | Optionally, considering the interruption of works for the breeding season of birds, amphibians, and reptiles It is recommended to conduct the works in winter −3 | Optionally, considering the interruption of works for the breeding season of birds, amphibians, and reptiles −2 | Optionally, considering the interruption of works for the breeding season of birds Optionally, performing the works outside the vegetation season −2 | Optionally, considering the interruption of works for the breeding season of birds −1 | |

| TOTAL WEIGHTS | −19 | −15 | −18 | −10 | |

| Realisation Variant | Areas for Which Variants of Realisation Were Considered | ||||

|---|---|---|---|---|---|

| Open Excavation Method | Trenchless Method | Open Excavation Method | Trenchless Method | ||

| Approx. Length of the Section | Approx. km 4 + 600–5 + 050 | Approx. km 24 + 000–24 + 700 | |||

| Section ID | C | D | |||

| Evaluation criterion | Weights | ||||

| Technological costs | Cost of earth works | 0 | −1 | 0 | −1 |

| Drainage costs | Trench drainage prohibited −2 | 0 | Trench drainage prohibited −2 | 0 | |

| Costs of weighing down the pipeline | −1 | 0 | −1 | 0 | |

| Economic costs | Cost of environmental supervision | −1 | −1 | −1 | −1 |

| Cost of actions minimising the negative environmental impact of the investment | Protection of trenches with use of herpetological fences Narrowing the construction belt −2 | Protection of trenches with use of herpetological fences −1 | Protection of trenches with use of herpetological fences Narrowing the construction belt −2 | Protection of trenches with use of herpetological fences −1 | |

| Social costs | Safety issues in the vicinity of the construction site | −2 | −1 | −2 | −1 |

| Landscape factors | −2 | −1 | −2 | −1 | |

| Environmental costs | Air | −2 | −1 | −2 | −1 |

| Soil | −2 | −1 | −2 | −1 | |

| Water | −1 | 0 | −1 | 0 | |

| Physical factors | −1 | −3 | −1 | −3 | |

| Natural factors | −1 | 0 | −1 | 0 | |

| Other—limiting the duration of construction works | Optionally, considering the interruption of works for the breeding season of birds, amphibians, and reptiles −2 | Optionally, considering the interruption of works for the breeding season of birds, amphibians, and reptiles −2 | Optionally, considering the interruption of works for the breeding season of birds, amphibians, and reptiles −2 | Optionally, considering the interruption of works for the breeding season of birds, amphibians, and reptiles −2 | |

| TOTAL WEIGHTS | −19 | −12 | −19 | −12 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwast-Kotlarek, U.; Hełdak, M. Evaluation of the Construction and Investment Process of a High-Pressure Gas Pipeline with Use of the Trenchless Method and Open Excavation Method. Analytic Hierarchy Process (AHP). Sustainability 2019, 11, 2438. https://doi.org/10.3390/su11082438

Kwast-Kotlarek U, Hełdak M. Evaluation of the Construction and Investment Process of a High-Pressure Gas Pipeline with Use of the Trenchless Method and Open Excavation Method. Analytic Hierarchy Process (AHP). Sustainability. 2019; 11(8):2438. https://doi.org/10.3390/su11082438

Chicago/Turabian StyleKwast-Kotlarek, Urszula, and Maria Hełdak. 2019. "Evaluation of the Construction and Investment Process of a High-Pressure Gas Pipeline with Use of the Trenchless Method and Open Excavation Method. Analytic Hierarchy Process (AHP)" Sustainability 11, no. 8: 2438. https://doi.org/10.3390/su11082438

APA StyleKwast-Kotlarek, U., & Hełdak, M. (2019). Evaluation of the Construction and Investment Process of a High-Pressure Gas Pipeline with Use of the Trenchless Method and Open Excavation Method. Analytic Hierarchy Process (AHP). Sustainability, 11(8), 2438. https://doi.org/10.3390/su11082438