Effects of Short-Term Aging on the Compactibility and Volumetric Properties of Asphalt Mixtures Using the Response Surface Method

Abstract

:1. Introduction

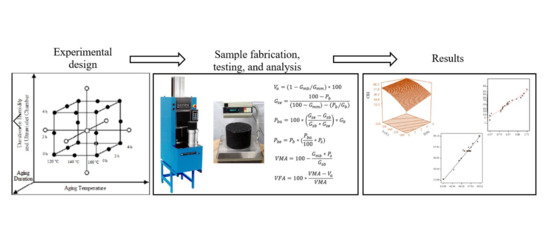

2. Materials and Methods

2.1. Research Methodology

2.2. Materials

2.3. Method

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, J. The Influence of Mineral Aggregates and Binder Volumetrics on Bitumen Ageing; University of Nottingham: Nottingham, UK, 2009. [Google Scholar]

- Yin, F.; Martin, A.E.; Arambula, E.; Newcomb, D.E. Short-term aging of asphalt mixtures. Asphalt paving technology. In Proceedings of the 90th Association of Asphalt Paving Technologists’ Annual Meeting, Portland, OR, USA, 8–11 March 2015. [Google Scholar]

- Rahbar-Rastegar, R.; Zhang, R.; Sias, J.E.; Dave, E.V. Evaluation of laboratory ageing procedures on cracking performance of asphalt mixtures. Road Mater. Pavement Des. 2019, 20, S647–S662. [Google Scholar] [CrossRef]

- Iroth, M.W.; Tjaronge, M.W.; Pasra, M. Influence of short term oven aging on volumetric properties of asphalt concrete mixture containing modified Buton asphalt and limestone powder filler. In Proceedings of the 3rd International Conference on Civil and Environmental Engineering (ICCEE 2019), Bali, Indonesia, 29–30 August 2019. [Google Scholar]

- Sadek, H.; Rahaman, M.Z.; Lemke, Z.; Bahia, H.U.; Reichelt, S.; Swiertz, D. Performance Comparison of Laboratory-Produced Short-Term Aged Mixtures with Plant-Produced Mixtures. Available online: https://ascelibrary.org/doi/10.1061/%28ASCE%29MT.1943-5533.0002980 (accessed on 29 July 2020).

- Kwon, O.; Choubane, B.; Hernando, D.; Allick, W., Jr. Evaluation of the impact of asphalt mix segregation on pavement performance. Transp. Res. Rec. 2019, 2673, 310–316. [Google Scholar] [CrossRef]

- Hernando, D.; del Val, M.A. A comprehensive overview on main distress mechanisms in composite pavements. Int. J. Pavement Res. Technol. 2013, 6, 737–744. [Google Scholar]

- Hamzah, M.O.; Omranian, S.R.; Golchin, B. A review on the effects of aging on properties of asphalt binders and mixtures. Casp. J. Appl. Sci. Res. 2015, 4, 15–34. [Google Scholar]

- Daniel, J.S.; Yin, F.; Martin, A.E.; Arambula-Mercado, E.; Newcomb, D.; Planche, J.P.; Pauli, A.; Farrar, M.; Huang, S.C.; Reinke, G.; et al. Relationships of Laboratory Mixture Aging to Asphalt Mixture Performance. Available online: http://onlinepubs.trb.org/onlinepubs/circulars/ec234.pdf (accessed on 29 July 2020).

- Sirin, O.; Paul, D.K.; Kassem, E.; Ohiduzzaman, M. Evaluation of short-term aging protocol for asphalt mixtures. Appl. Sci. 2019, 9, 2783. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.R.; Castorena, C.; Elwardany, M.D.; Rad, F.Y.; Underwood, S.; Akshay, G.; Gudipudi, P.; Farrar, J.M.; Glaser, R.R. Long-term aging of asphalt mixtures for performance testing and prediction. NCHRP Res. Rep. 2018, 871, 127. [Google Scholar]

- Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Understanding the bitumen ageing phenomenon: A review. Constr. Build. Mater. 2018, 192, 593–609. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Omranian, S.R. Effects of extended short-term aging duration on asphalt binder behaviour at high temperatures. Balt. J. Road Bridge Eng. 2016, 11, 302–312. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Falchetto, A.C.; Wistuba, M.P.; Hofko, B.; Porot, L.; Di Benedetto, H. (Eds.) RILEM 252-CMB Symposium: Chemo-Mechanical Characterization of Bituminous Materials; Springer: Braunschweig, Germany, 2018; Volume 20. [Google Scholar]

- Wang, D.; Falchetto, A.C.; Poulikakos, L.; Hofko, B.; Porot, L. RILEM TC 252-CMB Report: Rheological Modeling of Asphalt Binder under Different Short and Long-Term Aging Temperatures. Available online: https://link.springer.com/article/10.1617/s11527-019-1371-8 (accessed on 29 July 2020).

- Huang, S.C.; Di Benedetto, H. (Eds.) Advances in Asphalt Materials: Road and Pavement Construction; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Mousavi, M.; Pahlavan, F.; Oldham, D.; Hosseinnezhad, S.; Fini, E.H. Multiscale investigation of oxidative aging in biomodified asphalt binder. J. Phys. Chem. 2016, 120, 17224–17233. [Google Scholar] [CrossRef]

- Huner, M.H.; Brown, E.R. Effects of Re-Heating and Compaction Temperature on Hot Mix Asphalt Volumetrics. Available online: https://pdfs.semanticscholar.org/6d32/34089e952decf2ae6516d9bc606c7ff5878c.pdf?_ga=2.237411075.2016746420.1596069690-1910073216.1592942705 (accessed on 29 July 2020).

- Hand, A.; Epps, A. Effects of test variability on mixture volumetrics and mix design verification. Asph. Paving Technol. 2000, 69, 635–674. [Google Scholar]

- Mason, R.L.; Gunst, R.F.; Hess, J.L. Statistical Design and Analysis of Experiments: With Applications to Engineering and Science; John Wiley and Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Haghshenas, H.F.; Rea, R.; Byre, D.; Haghshenas, D.F.; Reinke, G.; Zaumanis, M. Asphalt Binder Laboratory Short-Term Aging: Effective Parameters and New Protocol for Testing. Available online: https://ascelibrary.org/doi/10.1061/%28ASCE%29MT.1943-5533.0002978 (accessed on 29 July 2020).

- Khodaii, A.; Haghshenas, H.F.; Tehrani, H.K. Effect of grading and lime content on HMA stripping using statistical methodology. Constr. Build. Mater. 2012, 34, 131–135. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Omranian, S.R.; Golchin, B.; Hainin, M.R. Evaluation of effects of extended short-term aging on the rheological properties of asphalt binders at intermediate temperatures using respond surface method. J. Technol. 2015, 73, 133–139. [Google Scholar] [CrossRef] [Green Version]

- Haghshenas, H.F.; Khodaii, A.; Saleh, M. Long term effectiveness of anti-stripping agents. Constr. Build. Mater. 2015, 76, 307–312. [Google Scholar] [CrossRef]

- Malaysian Public Works Department (PWD). Standard Specification for Road Works, Section 4, Flexible Pavement; Kerja Raya Malaysia: Kuala Lumpur, Malaysia, 2008.

- Omranian, S.R.; Hamzah, M.O.; Valentin, J.; Hasan, M.R.M. Determination of optimal mix from the standpoint of short term aging based on asphalt mixture fracture properties using response surface method. Constr. Build. Mater. 2018, 179, 35–48. [Google Scholar] [CrossRef]

- Elwardany, M.D.; Rad, F.Y.; Castorena, C.; Kim, Y.R. Factors Affecting Oxidation Reaction Mechanisms in Asphalt Concrete (No. 17-05969). In Proceedings of the Transportation Research Board 96th Annual Meeting, Washington, DC, USA, 8–12 January 2017. [Google Scholar]

- Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures. Available online: http://file.yizimg.com/175706/2012010611310817.pdf (accessed on 30 July 2020).

- AASHTO Standard Method of Test for Bulk Specific Gravity (Gmb) of Compacted Hot-Mix Asphalt (HMA) Using Saturated Surface-Dry Specimens T166. Available online: https://standards.globalspec.com/std/10040164/AASHTO%20T%20166 (accessed on 30 July 2020).

- Faheem, A.F.; Bahia, H.U. Using Gyratory Compactor to Measure Mechanical Stability of Asphalt Mixtures; Wisconsin Highway Research Program: Madison, WI, USA, 2004.

- Hamzah, M.O.; Omranian, S.R. Effects of Aging on Pavement Air Voids during Mixture Transportation from Plant to Field. Available online: https://www.tandfonline.com/doi/abs/10.1179/1432891714Z.0000000001159?journalCode=ymri20 (accessed on 30 July 2020).

- Omranian, S.R.; Hamzah, M.O.; Gungat, L.; Teh, S.Y. Evaluation of asphalt mixture behavior incorporating warm mix additives and reclaimed asphalt pavement. J. Traffic Transp. Eng. 2018, 5, 181–196. [Google Scholar] [CrossRef]

- Williams, S.G. The Effects of HMA Mixture Characteristics on Rutting Susceptibility. Available online: File:///D:/The_Effects_of_HMA_Mixture_Characteristics_on_Rutt.pdf (accessed on 30 July 2020).

- Douries, W.J. Factors Influencing Asphalt Compactibility and Its Relation to Asphalt Rutting Performance. Ph.D. Thesis, University of Stellenbosch, Stellenbosch, South Africa, 2004. [Google Scholar]

- Hu, W.; Jia, X.; Huang, B.; Park, H. Evaluation of compactability of asphalt mixture utilizing asphalt vibratory compactor. Constr. Build. Mater. 2017, 139, 419–429. [Google Scholar] [CrossRef]

- Soenen, H.; Lu, X.; Laukkanen, O.V. Oxidation of bitumen: Molecular characterization and influence on rheological properties. Rheol. Acta 2016, 55, 315–326. [Google Scholar] [CrossRef]

| Material | Test | Results | Standards | Binder Content | |

|---|---|---|---|---|---|

| Binder | A60 | Penetration at 25 °C (dmm) | 62 | ASTM D 5 | 4.8% |

| Softening point (°C) | 50 | ASTM D 36 | |||

| Ductility at 25 °C (cm) | >100 | ASTM D 113 | |||

| A80 | Penetration at 25 °C (dmm) | 81 | ASTM D 5 | 4.8% | |

| Softening point (°C) | 47 | ASTM D 36 | |||

| Ductility at 25 °C (cm) | >100 | ASTM D 113 | |||

| B80 | Penetration at 25 °C (dmm) | 80 | ASTM D 5 | 5.02% | |

| Softening point (°C) | 46 | ASTM D 36 | |||

| Ductility at 25 °C (cm) | >100 | ASTM D 113 | |||

| Aggregate | Coarse aggregate bulk specific gravity (kg/cm3) | 2.62 | AASHTO T85 | ||

| Absorption (%) | 0.40 | AASHTO T85 | |||

| Course aggregate angularity (%) | 49.50 | AASHTO TP56 (Method A) | |||

| Fine aggregate bulk specific gravity (kg/cm3) | 2.57 | AASHTO T84 | |||

| Absorption (%) | 0.54 | AASHTO T84 | |||

| Fine aggregate angularity (%) | 47.30 | AASHTO T33 (Method A) | |||

| Flat and elongated (%) | 23.30 | ASTM D4791 | |||

| Los Angeles abrasion (%) | 23.86 | AASHTO T96 | |||

| Aggregate crushing value (%) | 19.25 | MS 30–8:1995 | |||

| Sieve Size (mm) | Lower Limit (%) | Median (%) | Upper Limit (%) |

|---|---|---|---|

| 20 | 100 | 100 | 100 |

| 14 | 90 | 95 | 100 |

| 10 | 76 | 81 | 86 |

| 5 | 50 | 56 | 62 |

| 3.35 | 40 | 47 | 54 |

| 1.18 | 18 | 26 | 34 |

| 0.425 | 12 | 18 | 24 |

| 0.15 | 6 | 10 | 14 |

| 0.075 | 4 | 6 | 8 |

| Binder | No. | Factors or IVs | Responses or DVs | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | Duration (h) | H & UV (h) | Gmb (g/mm3) | CEI (a.u.) | Va (%) | VMA (%) | VFA (%) | ||

| A60 | 1 | 140 | 4 | 2 | 2.38 | 59.4 | 4.1 | 13.4 | 69.8 |

| 2 | 140 | 2 | 2 | 2.38 | 54.1 | 3.8 | 13.2 | 71.4 | |

| 3 | 160 | 4 | 0 | 2.38 | 47.0 | 3.5 | 13.0 | 72.7 | |

| 4 | 120 | 0 | 0 | 2.39 | 58.0 | 3.7 | 13.1 | 71.7 | |

| 5 | 120 | 0 | 4 | 2.38 | 55.5 | 3.7 | 13.2 | 71.5 | |

| 6 | 140 | 2 | 4 | 2.38 | 55.9 | 4.0 | 13.4 | 70.1 | |

| 7 | 140 | 2 | 2 | 2.39 | 51.9 | 3.7 | 13.1 | 71.7 | |

| 8 | 120 | 4 | 0 | 2.36 | 66.1 | 4.3 | 13.7 | 68.5 | |

| 9 | 140 | 2 | 2 | 2.38 | 51.9 | 4.0 | 13.3 | 70.3 | |

| 10 | 160 | 2 | 2 | 2.38 | 41.6 | 3.3 | 12.8 | 74.0 | |

| 11 | 160 | 0 | 4 | 2.38 | 31.9 | 3.0 | 12.5 | 75.9 | |

| 12 | 160 | 4 | 4 | 2.37 | 46.5 | 3.6 | 13.0 | 72.5 | |

| 13 | 160 | 0 | 0 | 2.34 | 31.9 | 3.0 | 12.5 | 75.9 | |

| 14 | 140 | 0 | 2 | 2.38 | 48.7 | 3.5 | 12.9 | 73.1 | |

| 15 | 140 | 2 | 0 | 2.35 | 57.4 | 4.0 | 13.3 | 70.4 | |

| 16 | 120 | 2 | 2 | 2.37 | 64.1 | 4.2 | 13.5 | 69.3 | |

| 17 | 140 | 2 | 2 | 2.37 | 54.8 | 3.9 | 13.3 | 70.7 | |

| 18 | 140 | 2 | 2 | 2.38 | 56.7 | 3.9 | 13.2 | 71.0 | |

| 19 | 120 | 4 | 4 | 2.38 | 65.4 | 4.3 | 13.6 | 68.6 | |

| A80 | 20 | 140 | 4 | 2 | 2.39 | 51.6 | 3.5 | 12.4 | 72.0 |

| 21 | 140 | 2 | 2 | 2.39 | 47.8 | 3.3 | 12.2 | 72.8 | |

| 22 | 160 | 4 | 0 | 2.39 | 46.7 | 3.4 | 12.3 | 72.1 | |

| 23 | 120 | 0 | 0 | 2.40 | 46.2 | 3.3 | 12.2 | 73.3 | |

| 24 | 120 | 0 | 4 | 2.40 | 49.2 | 3.3 | 12.2 | 73.0 | |

| 25 | 140 | 2 | 4 | 2.39 | 48.4 | 3.4 | 12.1 | 72.1 | |

| 26 | 140 | 2 | 2 | 2.39 | 48.0 | 3.3 | 12.2 | 73.0 | |

| 27 | 120 | 4 | 0 | 2.38 | 56.6 | 3.7 | 12.6 | 70.6 | |

| 28 | 140 | 2 | 2 | 2.39 | 48.5 | 3.3 | 12.2 | 72.9 | |

| 29 | 160 | 2 | 2 | 2.39 | 39.8 | 3.3 | 12.2 | 72.8 | |

| 30 | 160 | 0 | 4 | 2.39 | 29.5 | 2.9 | 11.8 | 75.8 | |

| 31 | 160 | 4 | 4 | 2.38 | 48.0 | 3.3 | 12.2 | 73.3 | |

| 32 | 160 | 0 | 0 | 2.39 | 29.6 | 2.9 | 11.8 | 75.7 | |

| 33 | 140 | 0 | 2 | 2.39 | 41.5 | 3.1 | 12.1 | 74.0 | |

| 34 | 140 | 2 | 0 | 2.38 | 48.0 | 3.4 | 12.3 | 72.5 | |

| 35 | 120 | 2 | 2 | 2.39 | 54.5 | 3.4 | 12.3 | 72.2 | |

| 36 | 140 | 2 | 2 | 2.39 | 48.8 | 3.2 | 12.1 | 73.5 | |

| 37 | 140 | 2 | 2 | 2.38 | 48.9 | 3.3 | 12.2 | 73.0 | |

| 38 | 120 | 4 | 4 | 2.39 | 58.5 | 3.7 | 12.6 | 70.3 | |

| B80 | 39 | 140 | 4 | 2 | 2.40 | 35.0 | 2.9 | 14.2 | 79.3 |

| 40 | 140 | 2 | 2 | 2.40 | 30.9 | 3.0 | 14.2 | 79.0 | |

| 41 | 160 | 4 | 0 | 2.40 | 34.6 | 3.7 | 14.9 | 75.1 | |

| 42 | 120 | 0 | 0 | 2.41 | 34.8 | 2.6 | 13.9 | 81.2 | |

| 43 | 120 | 0 | 4 | 2.36 | 34.5 | 2.6 | 13.9 | 81.4 | |

| 44 | 140 | 2 | 4 | 2.40 | 32.6 | 2.8 | 14.0 | 80.2 | |

| 45 | 140 | 2 | 2 | 2.40 | 32.8 | 3.0 | 14.3 | 78.8 | |

| 46 | 120 | 4 | 0 | 2.40 | 41.7 | 3.4 | 14.6 | 76.6 | |

| 47 | 140 | 2 | 2 | 2.40 | 30.9 | 3.3 | 14.5 | 77.6 | |

| 48 | 160 | 2 | 2 | 2.39 | 30.0 | 3.5 | 14.6 | 76.4 | |

| 49 | 160 | 0 | 4 | 2.40 | 26.4 | 2.7 | 14.0 | 80.6 | |

| 50 | 160 | 4 | 4 | 2.39 | 34.2 | 2.9 | 14.2 | 79.3 | |

| 51 | 160 | 0 | 0 | 2.39 | 25.5 | 2.4 | 13.7 | 82.4 | |

| 52 | 140 | 0 | 2 | 2.40 | 30.5 | 2.9 | 14.1 | 79.9 | |

| 53 | 140 | 2 | 0 | 2.39 | 31.9 | 2.8 | 14.1 | 80.1 | |

| 54 | 120 | 2 | 2 | 2.40 | 41.0 | 3.0 | 14.2 | 79.0 | |

| 55 | 140 | 2 | 2 | 2.39 | 32.6 | 3.0 | 14.3 | 78.8 | |

| 56 | 140 | 2 | 2 | 2.38 | 32.5 | 2.7 | 14.0 | 80.6 | |

| 57 | 120 | 4 | 4 | 2.39 | 42.5 | 3.1 | 14.3 | 78.5 | |

| Binders | Responses | Best-Fitted Model | Factors | Sum of Squares | F Value | Prob > F |

|---|---|---|---|---|---|---|

| A60 | CEI | Quadratic | A | 1215.29 | 360.50 | <0.0001 * |

| B | 340.59 | 101.03 | <0.0001 * | |||

| C | 2.87 | 0.85 | 0.3800 | |||

| A2 | 25.69 | 7.62 | 0.0221 * | |||

| B2 | 9.21 | 2.73 | 0.1327 | |||

| C2 | 1.31 | 0.39 | 0.5478 | |||

| AB | 17.20 | 5.10 | 0.0503 | |||

| AC | 0.85 | 0.25 | 0.6273 | |||

| BC | 0.18 | 0.05 | 0.8210 | |||

| Va | Quadratic | A | 1.39 | 228.80 | <0.0001 * | |

| B | 0.79 | 130.78 | <0.0001 * | |||

| C | 0.00 | 0.10 | 0.7530 | |||

| A2 | 0.07 | 11.08 | 0.0088 * | |||

| B2 | 0.05 | 7.84 | 0.0207 * | |||

| C2 | 0.02 | 2.73 | 0.1329 | |||

| AB | 0.00 | 0.00 | 0.9648 | |||

| AC | 0.00 | 0.05 | 0.8257 | |||

| BC | 0.00 | 0.00 | 0.9648 | |||

| VMA | Quadratic | A | 1.16 | 210.15 | <0.0001 * | |

| B | 0.66 | 118.44 | <0.0001 * | |||

| C | 0.00 | 0.18 | 0.6807 | |||

| A2 | 0.06 | 10.47 | 0.0102 * | |||

| B2 | 0.03 | 6.04 | 0.0363 * | |||

| C2 | 0.01 | 2.38 | 0.1575 | |||

| AB | 0.00 | 0.00 | 0.9631 | |||

| AC | 0.00 | 0.06 | 0.8175 | |||

| BC | 0.00 | 0.02 | 0.8898 | |||

| VFA | Quadratic | A | 45.80 | 230.86 | <0.0001 * | |

| B | 25.79 | 130.02 | <0.0001 * | |||

| C | 0.03 | 0.14 | 0.7154 | |||

| A2 | 2.36 | 11.91 | 0.0073 * | |||

| B2 | 1.58 | 7.96 | 0.0200 * | |||

| C2 | 0.52 | 2.61 | 0.1409 | |||

| AB | 0.03 | 0.16 | 0.7007 | |||

| AC | 0.00 | 0.02 | 0.8774 | |||

| BC | 0.00 | 0.00 | 0.9631 | |||

| A80 | CEI | Quadratic | A | 507.09 | 613.86 | <0.0001 * |

| B | 427.58 | 517.62 | <0.0001 * | |||

| C | 4.22 | 4.11 | 0.0631 | |||

| A2 | 3.92 | 4.75 | 0.0500 * | |||

| B2 | 8.96 | 10.84 | 0.0064 * | |||

| C2 | 0.01 | 0.01 | 0.9216 | |||

| AB | 31.88 | 35.02 | 0.0002 * | |||

| AC | 1.70 | 1.87 | 0.2047 | |||

| BC | 0.01 | 0.01 | 0.9225 | |||

| Va | Linear | A | 0.27 | 45.67 | <0.0001 * | |

| B | 0.47 | 78.26 | <0.0001 * | |||

| C | 0.00 | 0.20 | 0.6588 | |||

| VMA | Linear | A | 0.22 | 44.59 | <0.0001 * | |

| B | 0.38 | 76.13 | <0.0001 * | |||

| C | 0.01 | 1.67 | 0.2163 | |||

| VFA | Linear | A | 10.46 | 38.58 | <0.0001 * | |

| B | 18.20 | 67.09 | <0.0001 * | |||

| C | 0.01 | 0.04 | 0.8392 | |||

| B80 | CEI | Quadratic | A | 190.53 | 121.37 | <0.0001 * |

| B | 132.64 | 84.50 | <0.0001 * | |||

| C | 0.32 | 0.21 | 0.6604 | |||

| A2 | 19.82 | 12.63 | 0.0062 * | |||

| B2 | 0.01 | 0.01 | 0.9371 | |||

| C2 | 0.89 | 0.57 | 0.4701 | |||

| AB | 0.52 | 0.33 | 0.5790 | |||

| AC | 0.00 | 0.00 | 0.9912 | |||

| BC | 0.01 | 0.01 | 0.9344 | |||

| Va | Linear | A | 0.03 | 0.48 | 0.5002 | |

| B | 0.82 | 13.48 | 0.0023 * | |||

| C | 0.07 | 1.21 | 0.2885 | |||

| VMA | Linear | A | 0.02 | 0.51 | 0.4846 | |

| B | 0.64 | 13.80 | 0.0021 * | |||

| C | 0.06 | 1.268 | 0.2778 | |||

| VFA | Linear | A | 0.89 | 0.46 | 0.5100 | |

| B | 27.66 | 14.18 | 0.0019 * | |||

| C | 2.20 | 1.13 | 0.3050 |

| Binder | Responses | Title | Sum of Squares | DF | F Value | Prob >F | Model Type |

|---|---|---|---|---|---|---|---|

| A60 | CEI | Model | 1638.80 | 4 | 131.97 | <0.0001 | Quadratic (Sig) |

| Residual Error | 43.46 | 14 | |||||

| Lack of Fit Test | 26.95 | 10 | 0.65 | 0.7343 | (Not Sig) | ||

| R2 | >0.97 | ||||||

| Equation | CEI = −11.02 × A + 5.84 × B − 3.73 × A2 + 1.47 × A × B + 54.52 | ||||||

| Va | Model | 2.39 | 4 | 115.61 | <0.0001 | Quadratic (Sig) | |

| Residual Error | 0.07 | 14 | |||||

| Lack of Fit Test | 0.04 | 10 | 0.39 | 0.8963 | (Not Sig) | ||

| R2 | >0.97 | ||||||

| Equation | Va = −0.37 × A + 0.28 × B − 0.13 × A2 − 0.10 × B2 + 3.88 | ||||||

| VMA | Model | 1.98 | 4 | 107.47 | <0.0001 | Quadratic (Sig) | |

| Residual Error | 0.06 | 14 | |||||

| Lack of Fit Test | 0.03 | 10 | 0.35 | 0.9181 | (Not Sig) | ||

| R2 | >0.96 | ||||||

| Equation | VMA = −0.34 × A + 0.26 × B − 0.12 × A2 − 0.085 × B2 + 13.26 | ||||||

| VFA | Model | 78.64 | 4 | 116.28 | <0.0001 | Quadratic (Sig) | |

| Residual Error | 2.37 | 14 | |||||

| Lack of Fit Test | 1.09 | 10 | 0.34 | 0.9225 | (Not Sig) | ||

| R2 | >0.97 | ||||||

| Equation | VFA = 2.14 × A − 1.61 × B + 0.77 × A2 + 0.60 × B2 + 70.81 | ||||||

| A80 | CEI | Model | 1000.39 | 6 | 201.84 | <0.0001 | Quadratic (Sig) |

| Residual Error | 9.91 | 12 | |||||

| Lack of Fit Test | 8.98 | 8 | 4.79 | 0.0735 | (Not Sig) | ||

| R2 | >0.99 | ||||||

| Equation | CEI = −7.12 × A + 6.54 × B − 1.11 × A2 − 1.68 × B2 + 2 × A × B + 48.31 | ||||||

| Va | Model | 0.74 | 2 | 65.21 | <0.0001 | Linear (Sig) | |

| Residual Error | 0.09 | 16 | |||||

| Lack of Fit Test | 0.08 | 12 | 4.48 | 0.0798 | (Not Sig) | ||

| R2 | >0.89 | ||||||

| Equation | Va = −0.17 × A + 0.22 × B + 3.31 | ||||||

| VMA | Model | 0.61 | 2 | 57.94 | <0.0001 | Linear (Sig) | |

| Residual Error | 0.08 | 16 | |||||

| Lack of Fit Test | 0.08 | 12 | 5.18 | 0.0625 | (Not Sig) | ||

| R2 | >0.87 | ||||||

| Equation | VMA = −0.15 × A + 0.20 × B + 12.21 | ||||||

| VFA | Model | 28.66 | 2 | 56.20 | <0.0001 | Linear (Sig) | |

| Residual Error | 4.08 | 16 | |||||

| Lack of Fit Test | 3.83 | 12 | 5.11 | 0.0641 | (Not Sig) | ||

| R2 | >0.87 | ||||||

| Equation | VFA = 1.02 × A − 1.35 × B + 72.87 | ||||||

| B80 | CEI | Model | 348.84 | 3 | 108.28 | <0.0001 | Quadratic (Sig) |

| Residual Error | 16.11 | 15 | |||||

| Lack of Fit Test | 12.52 | 11 | 1.27 | 0.4438 | (Not Sig) | ||

| R2 | >0.95 | ||||||

| Equation | CEI = −4.37 × A + 3.64 × B + 2.33 × A2 + 32.19 | ||||||

| Va | Model | 0.82 | 1 | 13.74 | 0.0018 | Linear (Sig) | |

| Residual Error | 1.02 | 17 | |||||

| Lack of Fit Test | 0.88 | 13 | 1.88 | 0.2845 | (Not Sig) | ||

| R2 | >0.44 | ||||||

| Equation | Va = 0.29 × B + 2.96 | ||||||

| VMA | Model | 0.64 | 1 | 13.98 | 0.0016 | Linear (Sig) | |

| Residual Error | 0.78 | 17 | |||||

| Lack of Fit Test | 0.68 | 13 | 1.93 | 0.2764 | (Not Sig) | ||

| R2 | >0.45 | ||||||

| Equation | VMA = 0.25 × B + 14.20 | ||||||

| VFA | Model | 27.66 | 1 | 14.54 | 0.0014 | Linear (Sig) | |

| Residual Error | 32.33 | 17 | |||||

| Lack of Fit Test | 27.64 | 13 | 1.81 | 0.2985 | (Not Sig) | ||

| R2 | >0.46 | ||||||

| Equation | VFA = −1.66 × B + 79.19 | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omranian, S.R.; Hamzah, M.O.; Pipintakos, G.; Van den bergh, W.; Vuye, C.; Hasan, M.R.M. Effects of Short-Term Aging on the Compactibility and Volumetric Properties of Asphalt Mixtures Using the Response Surface Method. Sustainability 2020, 12, 6181. https://doi.org/10.3390/su12156181

Omranian SR, Hamzah MO, Pipintakos G, Van den bergh W, Vuye C, Hasan MRM. Effects of Short-Term Aging on the Compactibility and Volumetric Properties of Asphalt Mixtures Using the Response Surface Method. Sustainability. 2020; 12(15):6181. https://doi.org/10.3390/su12156181

Chicago/Turabian StyleOmranian, Seyed Reza, Meor Othman Hamzah, Georgios Pipintakos, Wim Van den bergh, Cedric Vuye, and Mohd Rosli Mohd Hasan. 2020. "Effects of Short-Term Aging on the Compactibility and Volumetric Properties of Asphalt Mixtures Using the Response Surface Method" Sustainability 12, no. 15: 6181. https://doi.org/10.3390/su12156181

APA StyleOmranian, S. R., Hamzah, M. O., Pipintakos, G., Van den bergh, W., Vuye, C., & Hasan, M. R. M. (2020). Effects of Short-Term Aging on the Compactibility and Volumetric Properties of Asphalt Mixtures Using the Response Surface Method. Sustainability, 12(15), 6181. https://doi.org/10.3390/su12156181