Evaluation of Food Waste Prevention Measures—The Use of Fish Products in the Food Service Sector

Abstract

:1. Introduction

1.1. Setting the Scene

1.2. Use of Convenience Food Products in the Food Service Sector

1.3. Food Waste and Sustainability Aspects Related to Using Convenience Food Products

1.4. Goal and Focus of this Study

2. Materials and Methods

2.1. Case Study Description and Inventory Data

2.2. Definitions and Food Waste Measures under Study

2.3. Sustainability Assessment Framework for Evaluating Measures

2.4. Application of the Sustainability Assessment Framework to the Case Study

2.4.1. Functional Unit

2.4.2. Effectiveness

2.4.3. Sustainability across Three Dimensions

3. Results

3.1. Effectiveness

3.2. Sustainability across Three Dimensions

3.2.1. Environmental Assessment: Carbon Footprint

3.2.2. Economic Assessment

3.2.3. Social Assessment

4. Discussion

4.1. Reflections on the Effectiveness of the Food Waste Measures

4.1.1. Data Inventory: Fish Processing

4.1.2. Meal Components Saved

4.2. The Magnitude of the Food Waste Addressed by the Measures and the Potential to Scale up to Other Food Products

4.3. Reflections on the Sustainability of the Food Waste Measures

4.3.1. Environmental Dimension

4.3.2. Economic Dimension

4.3.3. Social Dimension

4.4. Contribution of the Food Waste Measures to the Greater Societal Goal of Meeting the SDGs and Moving towards a Circular Economy

5. Conclusions

5.1. Study Results

5.2. Implications and Limitations of the Study

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). Global food losses and food waste—Extent, Causes and Prevention. In Proceedings of the SAVE FOOD: Global Initiative on Food Loss and Waste Reduction, Düsseldorf, Germany, 16–17 May 2011; FAO: Rome, Italy, 2011. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Food Wastage Footprint: Impacts on Natural Resources—Summary Report; FAO: Rome, Italy, 2013. [Google Scholar]

- Stenmarck, Å.; Jensen, C.; Quested, T.; Moates, G. Estimates of European Food Waste Levels. FUSIONS Deliverable. FUSIONS (Food Use for Social Innovation by Optimising Waste Prevention Strategies); EU FP7 Project: Stockholm, Sweden, 2016. [Google Scholar]

- European Commission. Frequently Asked Questions: Reducing Food Waste in the EU; European Commission: Brussels, Belgium, 2019; Available online: https://ec.europa.eu/commission/presscorner/detail/en/QANDA_19_6706 (accessed on 14 August 2020).

- Edwards, J.S.A. What is food service? J. Foodserv. 2009, 20, 1–3. [Google Scholar]

- Göbel, C.; Blumenthal, A.; Niepagenkemper, L.; Baumkötter, d.; Teitscheid, P.; Wetter, C. Reduktion von Warenverlusten und Warenvernichtung in der AHV—ein Beitrag zur Steigerung der Ressourceneffizienz; Report for Institut für Nachhaltige Ernährung und Ernährungswirtschaft—iSuN: Fachhochschule Münster, Germany, 2014. [Google Scholar]

- Von Borstel, T.; Prenzel, G.K.; Waskow, F. Ein Drittel landet in der Tonne. Zwischenbilanz 2017: Fakten und Messergebnisse zum deutschlandweiten Lebensmittelabfall in der Außer-Haus-Verpflegung; United Against Waste e.V. (UAW): Biberach/Riss, Germany, 2017. [Google Scholar]

- WRAP. Waste in the UK Hospitality and Food Service Sector; Full Technical Report for WRAP: Banbury, UK, 2012. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). The State of Food and Agriculture 2019. Moving Forward on Food Loss and Waste Reduction; FAO: Rome, Italy, 2019. [Google Scholar]

- Hanson, C. Guidance on Interpreting Sustainable Development Goal Target 12.3. A Champions 12.3 Publication; WRI: Washington, DC, USA, 2017. [Google Scholar]

- Goossens, Y.; Wegner, A.; Schmidt, T. Sustainability Assessment of Food Waste Prevention Measures: Review of Existing Evaluation Practices. Front. Sustain. Food Syst. 2019, 3, 33. [Google Scholar] [CrossRef]

- Caldeira, C.; de Laurentis, V.; Sala, S. Assessment of Food Waste Prevention Actions. Development of an Evaluation Framework to Assess the Performance of Food Waste Prevention Actions; Technical Report for European Commission Joint Research Centre (EC-JRC): Ispra, Italy, 2019. [Google Scholar]

- Blum, O. Convenience. DGE-Zertifikate—Die Convenience-Stufen. Available online: http://institut-gastro.de/tag/convenience/ (accessed on 20 February 2020).

- DGE. DGE-Qualitätsstandard für die Betriebsverpflegung; Deutsche Gesellschaft für Ernährung (German Nutrition Society): Bonn, Germany, 2018. [Google Scholar]

- NDR. Welche Arten von Convenience Food Gibt es? Wird im Restaurants Noch Richtig Gekocht? Available online: https://www.ndr.de/ratgeber/verbraucher/Welche-Arten-von-Convenience-Food-gibt-es,conveniencefood100.html (accessed on 20 February 2020).

- Engström, R.; Carlsson-Kanyama, A. Food losses in food service institutions Examples from Sweden. Food Policy 2004, 29, 203–213. [Google Scholar] [CrossRef]

- Cerutti, A.K.; Ardente, F.; Contu, S.; Donno, D.; Beccaro, G.L. Modelling, assessing, and ranking public procurement options for a climate-friendly catering service. Int. J. Life Cycle Assess. 2018, 23, 95–115. [Google Scholar] [CrossRef] [Green Version]

- WRAP. Strategies to Achieve Economic and Environmental Gains by Reducing Food Waste; WRAP: Banbury, UK, 2015. [Google Scholar]

- Berlin, J.; Sund, V. Environmental Life Cycle Assessment (LCA) of Ready Meals. LCA of Two Meals; Pork and Chicken & Screening Assessments of Six Ready Meals. SIK Report No 804 2010; Report for SIK the Swedish Institute for Food and Biotechnology: Goteborg, Sweden, 2010. [Google Scholar]

- Calderón, L.A.; Iglesias, L.; Laca, A.; Herrero, M.; Díaz, M. The utility of Life Cycle Assessment in the ready meal food industry. Resour. Conserv. Recycl. 2010, 54, 1196–1207. [Google Scholar] [CrossRef]

- Davis, J.; Sonesson, U. Life cycle assessment of integrated food chains—A Swedish case study of two chicken meals. Int. J. Life Cycle Assess. 2008, 13, 574–584. [Google Scholar] [CrossRef]

- Espinoza-Orias, N.; Azapagic, A. Understanding the impact on climate change of convenience food: Carbon footprint of sandwiches. Sustain. Prod. Consum. 2018, 15, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Hanssen, O.J.; Vold, M.; Schakenda, V.; Tufte, P.-A.; Møller, H.; Olsen, N.V.; Skaret, J. Environmental profile, packaging intensity and food waste generation for three types of dinner meals. J. Clean. Prod. 2017, 142, 395–402. [Google Scholar] [CrossRef]

- Heard, B.R.; Bandekar, M.; Vassar, B.; Miller, S.A. Comparison of life cycle environmental impacts from meal kits and grocery store meals. Resour. Conserv. Recycl. 2019, 147, 189–200. [Google Scholar] [CrossRef]

- Schmidt Rivera, X.C.; Azapagic, A. Life cycle costs and environmental impacts of production and consumption of ready and home-made meals. J. Clean. Prod. 2016, 112, 214–228. [Google Scholar] [CrossRef]

- Schmidt Rivera, X.C.; Espinoza Orias, N.; Azapagic, A. Life cycle environmental impacts of convenience food: Comparison of ready and home-made meals. J. Clean. Prod. 2014, 73, 294–309. [Google Scholar] [CrossRef]

- Gee, I.M.; Davidson, F.T.; Speetles, B.L.; Webber, M.E. Deliver Me from food waste: Model framework for comparing the energy use of meal-kit delivery and groceries. J. Clean. Prod. 2019, 236, 117587. [Google Scholar] [CrossRef]

- Davies, T.; Konisky, D.M. Environmental Implications of the Foodservice and Food Retail Industries. Discussion Paper 00-11; Resources for the Future: Washington, DC, USA, 2000. [Google Scholar]

- Eberle, U.; Fels, J. Environmental impacts of German food consumption and food losses. Int J. Life Cycle Assess. 2016, 21, 759–772. [Google Scholar] [CrossRef]

- Daxbeck, H.; David, P.; Holler, C.; Strelec, M.; Moudry, J. Entwicklung einer Methode für die Bilanzierung. In Möglichkeiten von Großküchen zur Reduktion ihrer CO2-Emissionen (Maßnahmen, Rahmenbedingungen und Grenzen); Sustainable Kitchen (Projekt SUKI): Wien, Austria, 2011. [Google Scholar]

- KErn. Im Mittelpunkt is(s)t der Mensch. ENKÜ—die energieeffiziente Küche; Bayerischen Staatsministeriums für Ernährung, Landwirtschaft und Forsten: München, Germany, 2018. [Google Scholar]

- Baldwin, C.; Wilberforce, N.; Kapur, A. Restaurant and food service life cycle assessment and development of a sustainability standard. Int J. Life Cycle Assess. 2011, 16, 40–49. [Google Scholar] [CrossRef]

- WRAP. Overview of Waste in the UK Hospitality and Food Service Sector; WRAP: Banbury, UK, 2013. [Google Scholar]

- Göbel, C.; Teitscheid, P.; Ritter, G.; Blumenthal, A.; Friedrich, S.; Frick, T.; Grotstollen, L.; Möllenbeck, C.; Rottstegge, L.; Pfeiffer, C.; et al. Verringerung von Lebensmittelabfällen—Identifikation von Ursachen und Handlungsoptionen in Nordrhein-Westfalen. Studie für den Runden Tisch „Neue Wertschätzung von Lebensmitteln“ des Ministeriums für Klimaschutz, Umwelt, Landwirtschaft, Naturund Verbraucherschutz des Landes Nordrhein-Westfalen; Institut für Nachhaltige Ernährung und Ernährungswirtschaft—iSuN, Fachhochschule: Münster, Germany, 2012. [Google Scholar]

- Dallinger, I.; Magnini, V.P. Chefs’ perceptions of using convenience food products versus scratch cooking. J. Foodserv. Bus. Res. 2017, 20, 34–49. [Google Scholar] [CrossRef]

- Riley, M. Food and beverage management. Int. J. Contemp. Hosp. Mngt. 2005, 17, 88–93. [Google Scholar] [CrossRef]

- Robinson, R.N.S.; Barron, P.E. Developing a framework for understanding the impact of deskilling and standardisation on the turnover and attrition of chefs. Int. J. Hosp. Manage. 2007, 26, 913–926. [Google Scholar] [CrossRef]

- Olsson, A.; Petterson, M.; Jönson, G. Packaging demands in the food service industry. Food Service Technology 2004, 4, 99–105. [Google Scholar] [CrossRef]

- Östergren, K.; Gustavvson, J.; Bos-Brouwers, H.; Timmermans, T.; Hanssen, O.J.; Møller, H.; Anderson, G.; O’Connor, C.; Soethoudt, H.; Quested, T.; et al. FUSIONS (Food Use for Social Innovation by Optimising Waste Prevention Strategies); EU FP7 Project: Stockholm, Sweden, 2014. [Google Scholar]

- Stevens, J.R.; Newton, R.W.; Tlusty, M.; Little, D.C. The rise of aquaculture by-products: Increasing food production, value, and sustainability through strategic utilisation. Mar. Policy 2018, 90, 115–124. [Google Scholar] [CrossRef] [Green Version]

- Caldeira, C.; de Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef]

- Roels, K.; Van Gijseghem, D. Monitoring Food Waste and Food Losses: Prevention and Valorization. Monitoring Flanders 2015; Flemish Food Supply Chain Platform for Food Loss (Vlaams Ketenplatform Voedselverlies): Brussels, Belgium, 2017. [Google Scholar]

- Roels, K.; Vanhee, M. Monitor Voedselreststromen en Voedselverliezen: Preventie en Valorisatie. Monitoring Vlaanderen 2017; Flemish Food Supply Chain Platform for Food Loss (Vlaams Ketenplatform Voedselverlies): Brussels, Belgium, 2019. [Google Scholar]

- Zampori, L.; Saouter, E.; Schau, E.; Cristobal, J.; Castellani, V.; Sala, S. Guide for Interpreting Life Cycle Assessment Result; Technical Report for European Commission Joint Research Centre (EC-JRC): Ispra, Italy, 2016. [Google Scholar]

- ReFED. A Roadmap to Reduce US Food Waste by 20%; ReFED: New York, NY, USA, 2016. [Google Scholar]

- Cicatiello, C.; Franco, S.; Pancino, B.; Blasi, E. The value of food waste: An exploratory study on retailing. Journal of Retailing and Consumer Services 2016, 30, 96–104. [Google Scholar] [CrossRef]

- Hafner, G.; Barabosz, J.; Schneider, F.; Lebersorger, S.; Scherhaufer, S.; Schuller, H.; Leverenz, D.; Kranert, M. Determination of Discarded Food and Proposals for a Minimization of Food Wastage in Germany; Report for German Federal Ministry of Food, Agriculture and Consumer Protection: Berlin, Germany, 2012. [Google Scholar]

- Wunder, S.; McFarland, K.; Hirschnitz-Garbers, M.; Parfitt, J.; Luyckx, K.; Jarosz, D.; Youhanan, L.; Stenmarck, A.; Colin, F.; Burgos, S.; et al. Food waste prevention and valorisation: Relevant EU policy areas. In REFRESH Deliverable D3.3 Review of EU Policy Areas with Relevant Impact on Food Waste Prevention and Valorization; REFRESH, EU Horizon 2020 Research Project: Wageningen, The Netherlands, 2018. [Google Scholar]

- Winther, U.; Ziegler, F.; Skontorp Hognes, E.; Emanuelsson, A.; Sund, V.; Ellingsen, H. Carbon Footprint and Energy Use of Norwegian Seafood Products; SINTEF Fisheries and Aquaculture: Trondheim, Norway, 2009. [Google Scholar]

- Kranert, M.; Hafner, G.; Barabosz, J.; Schuller, H.; Leverenz, D.; Kölbig, A.; Schneider, F.; Lebersorger, S.; Scherhaufer, S. Ermittlung der weggeworfenen Lebensmittelmengen und Vorschläge zur Verminderung der Wegwerfrate bei Lebensmitteln in Deutschland. Projektförderung: Bundesanstalt für Landwirtschaft und Ernährung (BLE); ISWA, University of Stuttgart: Stuttgart, Germany, 2012. [Google Scholar]

- Thrane, M. Environmental Impacts from Danish Fish Products: Hot Spots and Environmental Policies. Ph.D. Thesis, Institut for Samfundsudvikling og Planlægning, Aalborg Universitet, Aalborg, Denmark, 2004. [Google Scholar]

- BDEW. BDEW-Strompreisanalyse Januar 2019; BDEW Bundesverband der Energie- und Wasserwirtschaft e.V: Berlin, Germany, 2019. [Google Scholar]

- AquacultureTechnology. Fishfarming Equipment, Processing Machines. Available online: http://www.aquaculture-com.net/processing.htm (accessed on 9 December 2019).

- Khalid, N.I.; Saulaiman, U.S.; Nasiruddin, N.A.; Hatdran, M.M.; Ab Aziz, N.; Nor Khaizura, M.A.R.; Hasnan, N.Z.N.; Taip, F.S.; Sobri, S. Integrating cleaning studies with industrial practice: Case study of an effective cleaning program for a frozen meat patties SME factory. J. Clean. Prod. 2019, 235, 688–700. [Google Scholar] [CrossRef]

- Pelletier, N.; Tyedmers, P.; Sonesson, U.; Scholz, A.; Ziegler, F.; Flysjo, A.; Kruse, S.; Cancino, B.; Silverman, H. Not all salmon are created equal: Life cycle assessment (LCA) of global salmon farming systems. Environ. Sci. Technol. 2009, 43, 8730–8736. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Convenience Grade | Description | Example Food Products |

|---|---|---|

| 0 | No-convenience food | All original raw food |

| 1 | Kitchen-ready food, inedible parts have been removed | Boneless meat, filleted fish, cleaned vegetables |

| 2 | Ready-to-cook foods | Fish or meat portions, frozen vegetables or fruit, pre-baked bread |

| 3 | Prepared foods, often require heating and adding other ingredients | Powders for mashed potatoes, desserts, sauces or soups |

| 4 | Food ready for regeneration, only needs to be heated | Individual ready-made components (such as sauces) or ready-made menus (such as stews) |

| 5 | Ready-to-serve foods, can be consumed after packaging removal/opening | Cold sauces, smoothies and ready-to-eat salads and desserts |

| Scenario | Step | Location | Destination of Cut-Offs |

|---|---|---|---|

| Purchase of whole fish (Convenience grade 0) | Filleting | Hotel kitchen | 100% bin (AD) |

| Portioning | Hotel kitchen | 5% bin (AD); 95% used internally for fish pans or staff meals in the hotel | |

| Purchase of fillets (Convenience grade 1) | Filleting | Supplier | 1% bin (AD); 62% valorised as animal feed; 37% used for human consumption |

| Portioning | Hotel kitchen | 5% bin (AD); 95% used internally for fish pans or staff meals in the hotel | |

| Purchase of portions (Convenience grade 2) | Filleting | Supplier | 1% bin (AD); 62% valorised as animal feed; 37% used for human consumption |

| Portioning | Supplier | 100% used internally for fish pans, terrines, minced fish |

| Scenario | Description | Unit |

|---|---|---|

| CONV_0 | Purchase of whole fish (Convenience grade 0) | Expressed per portion or per year |

| CONV_1 | Purchase of fillets (Convenience grade 1) | |

| CONV_2 | Purchase of portions (Convenience grade 2) | |

| BAU | Business As Usual. Represents the situation of 2018, whereby the kitchen under study purchased a combination of whole salmon, fillets and portions. | Expressed per year |

| Impact Elements | Step | Description |

|---|---|---|

| Embodied impacts | a | Aquaculture (fish farming in Norway). |

| b | Transport to the supplier manufacturing site (excl. tertiary packaging). | |

| c | Packaging materials: secondary packaging (reusable plastic crate, ice cubes, plastic cover sheet); no individual primary packaging applicable. | |

| d | Electricity use for storage at the supplier. | |

| e | Refrigerated transport from supplier manufacturing site to its distribution centres, and from there to the hotel kitchens. | |

| f | Electricity use for storage in the hotel kitchen. | |

| g | Disposal of packaging: plastic sheet disposal at the hotel; disposal of reusable plastic crates at the supplier (taking into account reuse rate). | |

| Food waste disposal impacts | h | Disposal of storage losses at supplier and hotel kitchen. |

| i | Disposal of filleting and portioning cut-offs at supplier and hotel kitchen. | |

| Implementation impacts | j | Use of filleting/portioning machine at the supplier (electricity use, excl. capital good). |

| k | Use of water at supplier or at the hotel during filleting/portioning and for cleaning afterwards. |

| Cost Elements | Step | Description |

|---|---|---|

| Embodied costs | a | Purchase of food (commodity purchasing price) by the hotel. |

| b | Storage in fridge at the hotel. | |

| c | Disposal of packaging materials at the hotel. | |

| Food waste disposal costs | d | Disposal of storage losses at hotel kitchen. |

| e | Disposal of filleting and portioning cut-offs at hotel kitchen. | |

| Implementation costs | f | Labour costs for manual filleting/portioning at the hotel kitchen. |

| g | Use of water at hotel for cleaning the filleting/portioning workspace. | |

| h | Net costs for the hotel associated with internal use of portioning cut-offs for fish pans as compared to purchasing them from the supplier in case portioning is outsourced to the supplier |

| CONV_0 | CONV_1 | CONV_2 | |||

|---|---|---|---|---|---|

| Whole Salmon | Fillet | Portion | |||

| Food Waste Volumes | Filleting and portioning cut-offs thrown in bin | g/portion | 59.08 | 1.55 | 0.77 |

| Storage losses, thrown in bin | g/portion | 7.96 | 5.53 | 3.19 | |

| Total food waste along the chain | g/portion | 67.05 | 7.08 | 3.96 | |

| Destination of the filleting and portioning cut-offs: | |||||

| kept within the food chain (human consumption), | % | 20% | 49% | 50% | |

| removed from the food chain and valorised as animal feed | % | 0% | 49% | 49% | |

| removed from the food chain and thrown in the bin | % | 80% | 2% | 1% | |

| Environmental Assessment | Embodied impacts | g CO2 eq/portion | 444.30 | 372.01 | 373.03 |

| Disposal impacts | g CO2 eq/portion | −4.91 ×10−03 | −5.31 × 10−04 | −2.97 × 10−04 | |

| Implementation impacts | g CO2 eq/portion | 3.74 × 10−03 | 0.56 | 1.11 | |

| Total climate change impacts | g CO2 eq/portion | 444.29 | 372.57 | 374.13 | |

| Economic Assessment | Embodied costs | €/portion | 1.49 | 1.36 | 1.72 |

| Disposal costs | €/portion | 6.22 × 10−03 | 4.52 × 10−04 | 1.55 × 10−04 | |

| Implementation costs | €/portion | 0.18 | 0.10 | 0.08 | |

| Total costs | €/portion | 1.67 | 1.45 | 1.79 |

| CONV_0 | CONV_1 | CONV_2 | BAU | |||

|---|---|---|---|---|---|---|

| Whole Salmon | Fillet | Portion | ||||

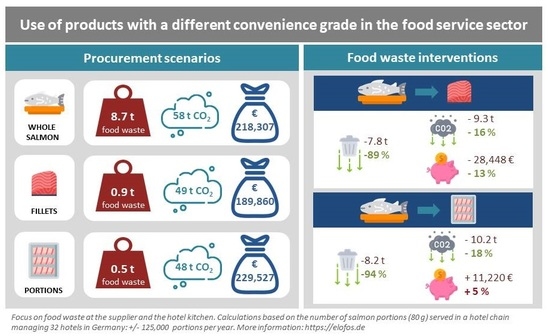

| Food Waste Volumes | Total food waste along the chain | kg/year | 8753 | 924 | 506 | 2073 |

| Amount of food waste set in comparison to what is purchased | g food waste/kg food | 436 | 74 | 49 | 154 | |

| Cascade index | 8.00 | 9.67 | 9.80 | 9.32 | ||

| Environmental Assessment | Total climate change impacts | kg CO2 eq/year | 58,003 | 48,639 | 47,847 | 49,999 |

| Economic Assessment | Total costs | €/year | 218,307 | 189,860 | 229,527 | 196,048 |

| CONV_1 | CONV_2 | |||

|---|---|---|---|---|

| Fillet | Portion | |||

| Effectiveness | Food waste reduction along the chain | kg/year | −7829 | −8247 |

| % | −89% | −94% | ||

| Environmental Assessment | Net environmental impacts | kg CO2 eq/year | −9364 | −10,156 |

| % | −16% | −18% | ||

| Economic Assessment | Net cost balance | €/year | −28,448 | 11,220 |

| % | −13% | +5% | ||

| CONV_0 | CONV_1 | CONV_2 | |||

|---|---|---|---|---|---|

| Whole Salmon | Fillet | Portion | |||

| Embodied Impacts | a | Aquaculture | 62.38% | 73.33% | 71.44% |

| b | Transport to supplier | 14.05% | 16.51% | 16.09% | |

| c | Packaging materials | 4.89% | 1.65% | 2.60% | |

| d | Electricity use: storage at supplier | <1% | <1% | <1% | |

| e | Transport for distribution by supplier: supplier manufacturing site—distribution centre—hotel | 18.60% | 8.33% | 9.53% | |

| f | Electricity use—storage at hotel | <1% | <1% | <1% | |

| g | Disposal of packaging materials | <1% | <1% | <1% | |

| Food Waste Disposal Impacts | h | Disposal storage losses, at hotel and supplier | <1% | <1% | <1% |

| i | Disposal filleting/portioning losses, at hotel and supplier | <1% | <1% | <1% | |

| Implementation Impacts | j | Use of filleting/portioning machine at supplier (electricity and water use), incl. cleaning afterwards | 0% | <1% | <1% |

| k | Manual filleting/portioning at hotel (water use for cleaning) | <1% | <1% | 0% | |

| CONV_0 | CONV_1 | CONV_2 | |||

|---|---|---|---|---|---|

| Whole Salmon | Fillet | Portion | |||

| Embodied Costs | a | Purchase of fish (whole fish, fillets or portions) | 88.87% | 93.35% | 95.79% |

| b | Storage at hotel | <1% | <1% | <1% | |

| c | Disposal packaging plastics (residual waste) | <1% | <1% | <1% | |

| Food Waste Disposal Costs | d | Disposal filleting/portioning losses at hotel | <1% | <1% | 0% |

| e | Disposal storage losses at hotel | <1% | <1% | <1% | |

| Implementation Costs | f | Labour costs for filleting/portioning at hotel | 10.73% | 6.61% | 0% |

| g | Use of water (for cleaning after filleting/portioning) at hotel | <1% | <1% | 0% | |

| h | Purchase of tail pieces and bits & pieces (for fish pans) from supplier in the absence of own portioning cut-offs | 0% | 0% | 4.19% | |

| CONV_0 | CONV_1 | CONV_2 | |||

|---|---|---|---|---|---|

| Annual Costs | Annual Costs | Net Cost Balance | Annual Costs | Net Cost Balance | |

| (€/year) | (€/year) | (%) | (€/year) | (%) | |

| Initial calculations | 218,307 | 189,860 | −13% | 229,527 | +5% |

| Higher fillet/portion price (+10%) | 218,307 | 207,583 | −5% | 251,514 | +15% |

| Lower fillet/portion price (−10%) | 218,307 | 172,136 | −21% | 207,541 | −5% |

| Lower portion price (−5.12%) | 218,307 | n.a. | n.a. | 218,273 | 0% |

| Improved filleting skills (+50% labour costs) | 226,258 | 194,630 | −14% | 229,527 | +1% |

| CONV_0 | CONV_1 | CONV_2 | BAU | ||

|---|---|---|---|---|---|

| Total food waste in the hotel chain under study | tonnes/year | 3242 | 3234 | 3233 | 3235 |

| Share of salmon-related food waste in the hotel chain under study | kg/year | 8550 | 621 | 209 | 1785 |

| % | 0.26% | 0.02% | 0.01% | 0.06% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goossens, Y.; Schmidt, T.G.; Kuntscher, M. Evaluation of Food Waste Prevention Measures—The Use of Fish Products in the Food Service Sector. Sustainability 2020, 12, 6613. https://doi.org/10.3390/su12166613

Goossens Y, Schmidt TG, Kuntscher M. Evaluation of Food Waste Prevention Measures—The Use of Fish Products in the Food Service Sector. Sustainability. 2020; 12(16):6613. https://doi.org/10.3390/su12166613

Chicago/Turabian StyleGoossens, Yanne, Thomas G. Schmidt, and Manuela Kuntscher. 2020. "Evaluation of Food Waste Prevention Measures—The Use of Fish Products in the Food Service Sector" Sustainability 12, no. 16: 6613. https://doi.org/10.3390/su12166613

APA StyleGoossens, Y., Schmidt, T. G., & Kuntscher, M. (2020). Evaluation of Food Waste Prevention Measures—The Use of Fish Products in the Food Service Sector. Sustainability, 12(16), 6613. https://doi.org/10.3390/su12166613