1. Introduction

For decades, concrete has been used in the construction industry due to its cost efficiency and availability. Ordinary Portland cement (OPC), as the most common cement used in concrete, possesses several advantageous properties such as high performance in thermal conductivity and mechanical strength. On the downside, it exhibits a huge burden on the environment due to large CO

2 emissions during its production [

1]. The production process involves calcination, where limestone is heated at 1500 °C, breaking down into calcium oxide and CO

2 [

2]. As reported, 50% of the total CO

2 emission from cement production is generated from the calcination, while the indirect emissions are caused by the fuel combustion used to heat the kiln. As such, OPC production was claimed to be a major source of greenhouse gas (GHG) emissions worldwide as cement production was found to account for 5–7% of global CO

2 emissions [

1,

2]. This has raised global awareness of the need to invent different sustainable cementitious material options to mitigate the huge environmental burdens from the construction industry [

3].

In recent years, an alkali-activated binder, known as geopolymer cement, appears to be a solution to replace conventional concrete. The term ‘geopolymer’ was firstly introduced by Davidovits in the late 1970s [

4] to describe a type of mineral binders that are produced by a process namely, geopolymerisation. It is a synthesis reaction between the aluminosilicate mineral (precursors) and alkali polysilicates (activator) to form an Al-O-Si bond [

5]. Amongst the reported approaches to induce geopolymerisation, alkaline activation is widely known as an effective approach to form Si- and Al- precursors [

6]. In geopolymer concrete (GPC) production, the cement is partially or entirely substituted with materials with high SiO

2 and Al

2O

3 contents (e.g., pozzolanic material) and is activated by an alkali solution [

4]. In fact, industrial waste such as fly ash (FA) and ground granulated blast furnace slag (GGBFS), as well as other naturally occurring materials such as thermally activated clay or pozzolan, can serve this purpose [

5], while sodium or potassium hydroxide and silicate are the most commonly used alkali activators in current technology [

6].

The technical advantages of geopolymers over traditional cement materials have been widely reported—such as their mechanical performance [

7,

8] and chemical resistance [

9]. Most of the geopolymer studies revealed their advantageous properties such as high initial strength [

7], superior fire resistance [

10,

11], acid resistance [

5,

12], and shorter setting time [

7,

12]. GPC showed 1.5 times the compressive strength of OPC, and it exhibited high early strength that can prevent breakage during transportation [

7]. As revealed in previous studies, the presence of calcium in fly ash-based geopolymer is the reason for its flash setting properties [

7,

8]. These results suggest a functional use of geopolymers in precast industries [

7] and prevent aluminosilicate waste materials from being disposed of in a landfill [

10].

The underlying concept of geopolymer technology [

13] applied to the construction industry is the improvement of sustainability. Considering the fact that geopolymer production does not involve the clinker calcination process and kiln heating process, its production is rendered to be green. Moreover, geopolymer technology has allowed the valorisation and beneficiation of industrial waste such as fly ash and granulated blast furnace slag [

14]. For this reason, the environmental evaluation of geopolymers has taken off in the past several decades [

15,

16,

17]. Amongst sustainability evaluations, life-cycle assessment (LCA) is commonly adopted to systematically evaluate the environmental burdens associated with the feedstock extraction for the production and the disposal of geopolymer product during its lifetime [

10,

12,

15,

18,

19,

20]. Due to its high mechanical strength [

21,

22], geopolymer had been widely investigated in order to curb the consumption of Portland cement [

23]. It was identified that the GPC production entails an environmental advantage over OPC and that a reduction of GHG emissions from 42% to 64% can be achieved in the absence of clinker production [

10,

15,

17]. Knowing that the LCA results are not straightforwardly comparable [

15], the environmental viability of geopolymer was highlighted with regard to the global warming burdens.

On the other hand, the sustainability of geopolymer was challenged by several recent studies claiming that geopolymer materials has presented worse impacts in certain environmental damage categories due to the Chlor-alkali process, which is not required in OPC production. For instance, Dontriros et al. [

19] had recognised that a brick made of geopolymer induces higher burdens to ozone depletion, human toxicity, terrestrial ecotoxicity, and fossil depletion. This finding is consistent with the study by Salas et al. [

15] and Bajpai et al. [

24], suggesting that GPC production is undesirable to human health. The use of alkali activators [

15,

16,

25,

26,

27] and the electricity used during its production [

26] turned out to be the main environmental burdens within the geopolymer life cycle. As suggested by Gomes et al. [

28], the electrolysis of alkali activators is an energy-intensive process responsible for 36% to 58% of the impacts of GPC production. In the light of enhancing the sustainability performance of geopolymer, several authors had recommended reducing the demand for alkali activators during production [

12,

24,

29,

30]. Other studies demonstrated the possibility of fabricating the geopolymer using ambient temperature curing with the use of alkaline activators of lower alkalinity [

31,

32]. It was observed that changing the curing energy and alkali activator type can reduce the GHG emissions of geopolymer by 30% [

33].

A review by Salas et al. [

34] revealed that most of the LCA studies concerning cement and concrete did not intentionally include any impact allocations of the use of byproducts. The latest revision of the EU regulation also defined industrial waste to be a source of pollution if it is economically profitable [

35]. This new definition suggested a different perspective by which to consider the environmental impacts of byproducts [

18] and the necessity for a reasonable allocation method to present the long-term sustainability damages of a material.

Besides this, the logistics of geopolymers were found to be debatable because it is not an established product and its transport is not ready to be scaled-up for a comparable assessment of its sustainability [

36]. Due to the inclusion of various life-cycle phases, the results of LCA may vary extensively due to a more accurate analysis concerning the transport of the raw materials and their disposal. It has been claimed that the change of transportation modes can attain a 25% reduction of GHG emissions for the GPC [

33]. These findings argued that the geopolymer materials may have an unfavourable performance in sustainability, depending on the type of transportation mode—which is contrary to the intrinsic assumption that geopolymer materials always deals less environmental damage than OPC [

33].

These findings raised the question that the results of the previous assessment may not substantially reveal the environmental burdens of geopolymer products, as they had limited consideration of the extraction and transportation of the byproducts. Whilst it is recognised that choices in methodological LCA may influence geopolymer’s sustainability performance significantly [

27,

31], an environmental evaluation of the latest geopolymer concrete production with special attention given to the treatment of byproducts and transportation is needed to present the key factors that contribute to the sustainability of geopolymers in the building sector.

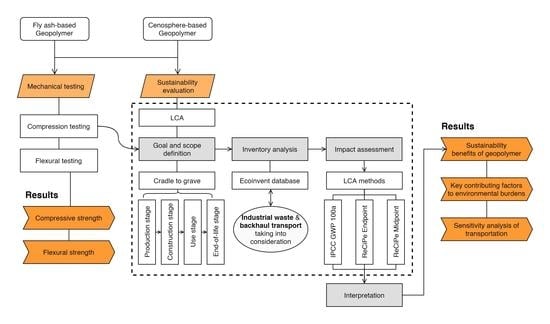

Hence, the aim of this study was to evaluate the mechanical properties of two geopolymers made of fly ash, cenospheres, GGBFS, and activated by sodium silicate (Na2SiO3), and examine their environmental performance by scaling up the life-cycle inventory (LCI) developed at laboratory scale to industrial scale. The significance is to reveal the most critical factors needed to develop a sustainable solution for geopolymers in the future. In summary, this study suggests that geopolymer entails advantages over OPC on GWP, but it exhibits significant damages to the environment, especially regarding water consumption and contamination. From the findings, the alkali activator and the fly ash as byproducts were observed to be major parameters that should be given special attention to further enhance the sustainability of the geopolymer mix.

4. Discussion

4.1. Mechanical Performance

Changing any variable affects the geopolymerisation process and its resultant microstructure. From previous studies [

37,

41] the following general trends were observed for increased strength development:

Higher GGBFS/FA ratio and reduced water content are known to affect the strength positively, while other variables like activator type and content, and binder type, can have variable effects.

The strength of the material will increase accordingly, if it has a higher bulk density. Higher bulk density is reflected by the absence of pores/voids in the sample and by the material used.

GGBFS has a smaller average particle size and a lower distribution of particle sizes (finer) compared to FA, and thus higher amounts of GGBFS should help in increasing the density of the material and its mechanical strength.

Among the analysed geopolymers, the FA-based geopolymer establishes a remarkable mechanical performance when compared to ceno-based geopolymer, due to the hollow microstructure of cenospheres. As observed, cenospheres are hollow particles that reduce the overall weight of the material, and by introducing more inherent pores to the mortars have unavoidably decreased its mechanical strength. As a result, the G-FA’s flexural strength and compressive strength are higher than those of the G-C. These findings suggest that a potential mix of geopolymer made of fly ash can be developed and optimised to obtain a structural material, while the geopolymer made of cenospheres can potentially be used for other applications as a lightweight material due to its low bulk density. Therefore, while it makes sense to compare the mechanical and environmental performance of G-FA, NAC, and RAC, being materials suitable for structural applications, a different approach should be investigated to compare the performance of G-C with other lightweight construction materials sharing similar applications.

4.2. Global Warming Potential (GWP)

The result indicates that the production of G-FA exhibits a lower GWP burden than OPC concretes by emitting 32.3% less GHGs (473 kg CO

2-eq) as compared to the production of OPC made with natural aggregates (699 kg CO

2-eq). While assessing their whole functional life, the observation is consistent with the results of previous studies regarding the geopolymer materials [

10,

17,

27]. Throughout its functional life, the use of sodium silicates in geopolymers contributes 33.4% to the GWP, while the extraction of FA or cenospheres presents noticeable impacts up to 18.16%. The reason for this finding is likely to be because the manufacture of the alkali activators (Na

2SiO

3) is energy-intensive in nature, and the chemical reactions during their production involve huge carbon dioxide emissions. Based on the impact-allocation approach as detailed in the product stage subsection, the results also suggest that the extraction of FA and cenospheres is a crucial process that contributes to the environmental impacts of geopolymers. These may also indicate why G-C, which is lower in density, requires a lesser amount of sodium silicate and cenospheres than G-FA to produce the same functional unit of material and has contributed the least (357 kg CO

2-eq) to the GWP.

Comparing the OPC concretes, the cement is responsible for more than 66.9% of their total life-cycle impacts. The high contribution of cement has suggested that RAC, which requires a higher amount of cement to bind the recycled aggregates, has a higher burden (727 kg CO2-eq) on GWP than NAC.

4.3. Endpoint Assessment

As observed, the life cycle of OPC concretes has the highest adverse impacts on the human health damage category (HH). GHGs emissions and energy consumption of 1.8 GJ/tones during the manufacturing of cement is the main reason for the high negative impacts of OPC concretes [

24]. This has explained that the production of geopolymers that does not involve the manufacture of cement has a reduction of 23.7% (G-FA) to 41.6% (G-C) over NAC. However, the fusion of soda ash and silica sand during the production of sodium silicate adversely affected several indicators such as carcinogens, ionising radiation, and ozone layer depletion [

62], resulting in non-negligible negative impacts of geopolymer on the HH. Human toxicity is found to be one of the key environmental impacts of geopolymer other than global warming [

27].

Concerning the ecosystem quality damage category (EQ), the functional life of OPC concretes presented 12.3% to 33.2% more damage than those of geopolymers. This can be explained by the cement production that utilises high energy-consuming machinery leading to a large number of harmful emissions to terrestrial, freshwater, etc., that disturb the ecosystem [

24]. Geopolymer does not require cement, causing lesser damage to the EQ, with G-C exhibiting the least impact. This finding is credibly due to the lesser amount of the ingredients used to produce G-C and hence, lesser impacts are associated with the production of 1 m

3 of G-C than of G-FA.

The damage to the resources damage category (RD) during the functional life of G-FA is higher than that of the two OPC concretes and G-C. It can be explained by the great negative impacts of alkali activator to the RD [

62] due to the utilisation of sodium chloride, water, sodium carbonate, silica sand, furnace oil, and electricity during the preparation of Na

2SiO

3 [

15]. Eventually, the functional life of OPC concrete that does not involve sodium silicate production causes 15.6% to 42.3% less damage to RD than the geopolymer.

Identification of Contributing Factors

As shown in

Figure 6, the majority of the negative impacts from G-FA are caused by the alkaline activator, sodium silicate and mostly on HH. As observed, Na

2SiO

3 contributes 45.6% of impacts to the functional life of G-FA. This observation agrees with the reported results by Salas et al. [

15] whereby sodium silicate production emits a considerable quantity of GHGs and pollutes the surrounding water system due to the disposal of wastewater [

24]. Other important observations are the effects of FA and cenospheres on the environmental impacts. In this analysis, the economic allocation procedure was used in a way that a partial load from the primary production impacts was allocated to their waste, such as FA and cenospheres, that were used to produce G-FA and G-C. As a result, high environmental loads (25.2%) from the FA and cenospheres are observed and this can be explained by the production system from coal power plants that emit large quantities of airborne pollutants such as CO

2, NO

2, and SO

2, etc. The finding suggests that after impact allocation, the byproducts can result in a significant contribution to the overall negative impacts of the geopolymer life cycle.

Considering the OPC concretes, cement is responsible for 83.4% to 85.1% of environmental impacts and HH is the most affected category. This is due to the high pollutant emission mining activity of the calcareous and argillaceous materials and the manufacturing of cement in the plant [

24]. This finding supports that the reduction of the use of cement can be the most efficient solution to mitigate the environmental impacts by OPC concretes.

4.4. Midpoint Assessment

In the midpoint level assessment, G-FA presents higher impacts in IRP over OPC concretes. It suggests that the involvement of the electrolysis process in the manufacturing of sodium silicate will increase the adsorption of ionised radiation and decrease the stratospheric ozone [

24], which are causally linked to the incidents of various cancer diseases [

60]. However, OPC concretes present similar impacts as G-FA in ODP because the calcination of limestone in a kiln at high temperatures will release carbon dioxide waste [

28].

In human toxicity and ecotoxicity categories, geopolymers show higher impacts than OPC concretes. This is mainly attributed to the chemical reaction during sodium silicate production, which releases 1,4-DCB to the air and produces contaminated water that will pollute the water bodies [

24], including fresh waters and marine water. OPC concretes have smaller impacts on ecotoxicity due to the absence of an alkaline activator during its life cycle. However, it is observed that the production of cement will also cause substantial pollution to the natural soils due to the heat production in the coke furnace.

It is known that the concrete-making process involves a considerable quantity of water use; however, the treatment of byproducts such as blast furnace slag and fly ash require a more significant amount of water. Consequently, high water demand is observed for geopolymers by consuming 54.8% to 81.3% more water during their life cycle. A similar trend is observed in eutrophication categories as the production of alkaline activator will dissolve inorganic nitrogen and phosphorous in waterbodies as well as the coal thermal power plant operation.

Concerning the soil quality, the result suggests that the use of cement has a large contribution to the acidification of soils and noticeable effects in fossil depletion due to the extraction of limestone and large fuel consumption in the production plant. However, the chemical reaction of sodium silicate and the production of GGBFS in the geopolymer life cycle will also substantially affect the ore grade.

4.5. Sensitivity Analysis

In the sensitivity analysis presented in

Section 3.5 appears that geopolymer will be affected to a greater extent due to the transportation of material and waste concrete than the transportation of raw materials in its life cycle. Observing

Figure 11, an increment of raw materials transport distance by 254 km was found to impact geopolymers by 3.4% more, while increasing the transport distance of the mortar and disposing of the concrete by 350 km causes 19.7% more impact. A similar trend was observed in

Figure 12 that S1 entails 2.7% to 4.6% more impact than the main case while S2 entails 15.8% to 27.0% more impact than the main case in three categories.

Collectively, it presents a finding that the environmental impacts are critically affected not only by the transport distance of the materials, but also the density of the materials due to the proportional relationships between the weight, distance, and transport energy consumption. In this study, the transport distance of mortar or concrete was found to deal with higher impacts than the transport distance of raw materials, by which token the raw materials that are lightweight do not exhibit the same impact on the environmental burdens of G-FA. This is contrary to the findings that the transportation of raw materials is the greater cause of the environmental burdens by the geopolymers.

In the present research, 60% of fronthaul distances were estimated for backhaul transportation. This approach and its findings support the transport of raw materials, such as fly ash, that can be extended to greater distances, and the geopolymer still exhibits high sustainability in its life cycle [

63]. The density of materials is the key factor to reduce the transportation impacts from geopolymers, and it is very much a key component in future attempts to improve the transportation schemes of geopolymer life cycle in order to resolve the environmental burdens of geopolymers.

5. Conclusions

In this work, the mechanical properties of two geopolymers, FA-based and ceno-based geopolymers, and their sustainability performance based on a cradle-to-grave assessment were presented. In summary, two geopolymer mortar mixes were developed and the key factors that contribute to the environmental burdens by the entire geopolymer life cycle were studied. The contribution of this work is the development of two geopolymers that can be potential substitutions of conventional concretes with moderate compressive strength (i.e., 20 to 65 MPa after 28 days of curing) and the identification of factors that can contribute to the future development of a sustainable geopolymer mix.

Flexural and compressive strength testing were used to examine the mechanical properties of the geopolymers. It was observed that the FA-based geopolymer demonstrated high compressive and flexural strength over ceno-based geopolymer due to the hollow microstructure of cenospheres that introduce more inherent pores to the material—hence reducing its mechanical strength. The flexural strength and compressive strength of FA-based geopolymer were 6.03 MPa and 64.56 MPa, respectively, while the same properties for ceno-based geopolymer were 3.13 MPa and 19.09 MPa. This result showed that cenospheres, as hollow particles, induce a high reduction to the overall material weight and the mechanical strength of the geopolymer. This result encourages us to investigate this material for different lightweight applications. To facilitate the transition toward a more sustainable, energy-efficient, and comfortable built environment and contribute to an effective circular economy in the building sector, the materials could be further investigated and optimised for building envelope applications. Additionally, its environmental impact should be compared with commonly used lightweight construction materials having, among other, similar thermal and acoustic performance.

Concerning the sustainability performance, the geopolymer entailed advantages over OPC concretes on global warming potential, but it exhibited significant environmental damages such as high-water consumption and causes to ecotoxicity. Amongst the factors that contributed to the environmental damages, alkali activator and fly ash were found to be the major components that entailed the impacts. Na2SiO3 contributes 45.6% of impacts to the functional life of FA-based geopolymer, while 25.2% of impacts result from the industrial byproducts (i.e. fly ash and cenospheres). From the perspective of long-term development for geopolymer, these components should be given special attention to ensure the sustainability advantages of geopolymer in the building sector. Future studies should focus on exploring the greener alternatives for sodium silicate as an alkali activator (e.g., using renewable energy in its energy-intensive production process) and a more productive way to abstract the byproducts such as fly ash, cenospheres, and GGBFS from their main production. Besides the density of the materials, researchers should also consider the transportation mode, such as sea freight, in order to improve the sustainability of the geopolymer life cycle.