Opportunities for Waste to Energy in the Milk Production Industry: Perspectives for the Circular Economy

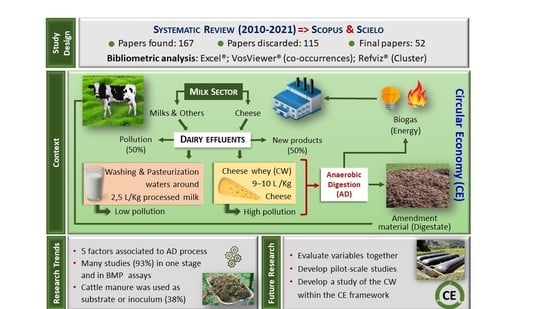

Abstract

:1. Introduction

2. Materials and Methods

2.1. Search Strategy

2.2. Information Synthesis and Analysis

3. Results and Analysis

3.1. Bibliometric Analysis

3.1.1. Geographical Location of the Studies and its Evolution over Time

3.1.2. Author and Word Co-Occurrence, Top Journals, Main Articles, and Cluster Identification

3.2. Research Trends around the Degradation of Cheese Whey

3.2.1. Trends Associated with the Inoculum

3.2.2. Trends Associated with the Substrate (CW)

- Substrate mix

| Waste | Mixing Ratio | pH | Temperature (°C) | Inoculum | Size reactor (L) | Source | ||

|---|---|---|---|---|---|---|---|---|

| CM, CW, and PS | 50CM:40CW:10PS * | -- | 35.5 | -- | 128 | Riggio et al. [72] | ||

| CW and PM | 75CW:25PM | 50CW:50PM | 25CW:75PM * | -- | 37 | WWTP fed with agricultural waste | 5 | Carlini et al. [73] |

| PS, CWF, CWS, CM | 100PS | 100PS:50CWF:1CM | 100PS:70CWS:10CM | -- | 37 | Primary sludge digester WWTP | 2 | Brown et al. [74] |

| 100PS:30CWF:10CM | 100PS:30CWF:10CM | 100PS:70CWS:1CM *** | ||||||

| 100PS:70CWF:10CM | 100PS:30CWS:10CM | |||||||

| 100PS:50CWF:10CM | 100PS:30CWS:1CM | |||||||

| CW, ULVA | 0ULVA:100CW | 25ULVA:75CW | 100ULVA:0CW * | pH adjusted with NaOH | 35 | Sewage from WWTP | 2 | Jung et al. [57] |

| 50ULVA:50CW | 75ULVA:25CW | |||||||

| CW, AIW and MS | 60AIW:20CW:20MS | 40:AIW:20CM:20CW:20MS * | 7.8–8.0 | 40 | -- | -- | Muscolo et al. [41] | |

| CW | -- | -- | 37 | Cattle slurry | 0.1 | Escalante et al. [14] | ||

| CW, SS, FW, CG, CM, and GW | 100SS | 95SS:5FW | 90SS:5FW:5CG ** | -- | 35 | -- | 3 | Maragkaki et al. [54] |

| 95SS:5GR | 95SS:5CG | |||||||

| 90SS:10CW | 90SS:5CM:5CG | |||||||

| AS and mix CW with FW | 100AS:0 CW-FW | 95AS:5CW-FW | 7 | 36 | Sewage from WWTP | 1 | Hallaji et al. [75] | |

| 90 AS:10 CW-FW | 85AS:15 CW-FW | |||||||

| CW and PP | 0CW:100PP | 50CW:50PP | 100CW:0PP * | 6.5, 7.0, 7.5, 8.0, 8.5 with NaOH or HCl | 35 | Treated pig slurry | 0.1 | Marchetti et al. [76] |

| 25CW:75PP | 75CW:25PP | |||||||

| CW and G | 100CW:0G | 96CW:4G | -- | 50–55 | UASB reactor treating vinasse | 5.6 | De Albuquerque et al. [15] | |

| 98CW:2G | 88CW:12G * | |||||||

| CW and HH | 70CW:30HH | 30CW:70HH * | -- | 36–38 | Digester treating buffalo manure | 0.1 | Papirio et al. [16] | |

| OMW, CW, and LCM | 55OMW:40CW:5 LCM | 50LCM:50OMW *** | 50OMW:50CW | -- | 35 | -- | 0.75 and 4 | Vavouraki et al. [55] |

| SS and CW | 100SS:0CW | 60SS:40CW | 25SS:75CW | -- | 30 | Sewage sludge from WWTP of the brewery | 0.12 | Iglesias-Iglesias et al. [77] |

| 50SS:50CW | 40SS:60CW | 0SS:100CW ** | ||||||

- Ratio C/N

- pH

3.2.3. Trends Associated with the Digestate

3.2.4. Trends Associated with the Related Microbiology Processes

3.2.5. Trends Associated with Reactor Configuration

- Type of reactor and bed

- Stages

- Organic Loading Rate (OLR)

- Hydraulic Retention Time (HRT)

| Factor | Variable | Conclusion | Source |

|---|---|---|---|

| Inoculum | The inoculum most used is from WWTP. Mixing pretreatment inoculum can improve the biogas production. | El Achkar et al. [56]; Koch et al. [65] | |

| Substrate | Substrate mix | Increases the presence of nutrients and the buffer capacity of the system. | Cárdenas-Cleves et al. [61] |

| One option to mix the substrates is 75:25, 50:50, 25:75 to cover the entire spectrum of possible configurations to find the best ratio. | |||

| C/N | When C/N ratio is high (>35), there may be problems of nutrient deficiency and/or low buffer capacity; in contrast, if the C/N ratio is low (<18), there may be inhibition problems associated with the presence of ammonia. | Parawira [78]; Fernandes et al. [79] | |

| pH | The variable that requires constant monitoring in the anaerobic process. It is better to be near to neutrality and use NaOH or CaCO3 to increase pH. | Mirmohamadsadeghi et al. [66]; Marchetti and Vasmara, [76] | |

| Digestate | The type of substrate influenced the characteristics of the digestate and some soil parameters, such as organic matter and soil catalase. Through digestate from CW, struvite can be obtained, which is better than inorganic fertilizers. | Musculo et al. [41]; Escalante et al. [14] | |

| Microbiology | Microbial dynamics in the reactor will be predominantly influenced by the characteristics of the inoculum, substrates, and operating conditions. | Pagliano et al. [89] | |

| Reactor configuration | Type and bed | UASBs are suitable for the treatment of high organic-resistance wastewater such as CW because of their low use of energy and their suitability for operating with high OLR. AnMBR does not remove salts from the effluent; the liquid cannot be used for agricultural applications without an additional process. The charcoal bed was the best option for the fixation of biogas-producing bacteria. | Ribera-Pi et al. [52]; Diamantis et al. [90]; Sánchez-Sánchez et al. [94] |

| Stages | Depending on the substrate (in a single phase), problems may arise as the result of the accumulation of VFAs, which triggers inhibition of some bacteria. In biphasic AD, it presents advantages, such as (i) a stable system, (ii) a synergistic effect on microorganisms, (iii) a lower HRT, (iv) the obtaining of a greater number of products (VFAs, H2, CH4), and (v) achieving nutrient balance, | Jin et al. [96]; Begum et al. [97]; Negri et al. [98] | |

| OLR | Very high organic loads could accelerate the production of VFAs and inhibit the process as a result of the decrease in pH. | Wang et al. [99] | |

| UASB supports greater organic loads than the SBR as the maximum acidification occurs at lower loads in the SBR as compared to the USB | Calero et al. [101] | ||

| HRT | HRT can range between 10 and 40 days. | Dareioti and Kornaros, [49]; Kothari et al. [104] | |

3.3. Advances in the Inclusion of CE in the Biological Use by AD/ACOD of CW

4. Research and Reflection Trends

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A-COD | Anaerobic Codigestion |

| AD | Anaerobic Digestion |

| ADCM | Anaerobically Digestated Cattle Manure |

| AIW | Agricultural waste |

| AS | Activated Sludge |

| AnMBR | Anaerobic Membrane Bioreactors |

| BMP | Biochemical Methane Potential |

| CaCO3 | Calcium Carbonate |

| CE | Circular Economy |

| CG | Crude Glycerol |

| COD | Chemical Oxygen Demand |

| CH4 | Methane |

| CM | Cow Manure |

| C/N | Carbon/Nitrogen Ratio |

| CSTR | Continuous Stirred-Tank Reactor |

| CW | Cheese Whey |

| CWF | Cheese Whey Fresh |

| FAO | Food and Agricultural Organization |

| FV | Fruit and Vegetables |

| FVW | Fruit Vegetable and Waste |

| FW | Food Waste |

| G | Glycerin |

| gCOD L−1d−1 | Grams of Chemical Oxygen Demand per Litre.Día |

| GHG | Greenhouse Gas |

| GM | Grape Marc |

| GW | Grape Wastes |

| GR | Grape Residues |

| H2 | Hydrogen |

| Hydraulic retention time | Hrt |

| HCl | Chlorhydric Acid |

| HH | Hurds Hemp |

| kgCDO/m3d−1 | Kilogram of chemical oxigen demand/cubic meter.day |

| kJ/kg | kilojoule/kilogram |

| LA | Latin America |

| LCM | Liquid Manure |

| MgNH4 PO4 6H2O | Ammonium Magnesium Phosphate Hexahydrate |

| MS | Maize Silage |

| NaOH | Sodium Hydroxide |

| NTK | Total Kjeldahl Nitrogen |

| OLR | Organic Loading Rate |

| OMW | Olive Mills Wastewater |

| PM | Poultry Manure |

| PP | Pork Purin |

| PS | Primary Sludge |

| RS | Rice Straw |

| SBR | Sequencing Batch Reactor |

| SDG | Sustainable Development Goals |

| SM | Sheep Manure |

| SS | Sewage Sludge |

| UASB | Upflow Anaerobic Sludge Mantle Reactor |

| ULVA | Sea Lettuce |

| VFAs | Volatile Fatty Acids |

| VS/L: gVS/L | Volatile Solids/Litre: Grams Volatile Solids/Litre |

| v/v | Volume/Volume |

| WAS | Waste Activated Sludge |

| WOL | Wastewater From Oil Mills |

| w/w | Weight To Weight |

| WWTP | Wastewater Treatment Plants |

References

- FAO. The Future of Food and Agriculture: Trends and Challenges; FAO: Rome, Italy, 2017; Volume 4, ISBN 1815-6797. [Google Scholar]

- Mollea, C.; Marmo, L.; Bosco, F. Valorisation of Cheese Whey, a By-Product from the Dairy Industry; Intechopen: London, UK, 2020; pp. 1–15. [Google Scholar] [CrossRef] [Green Version]

- Eurostast. Agriculture, Forestry and Fisheries Statistics; Eurostast: London, UK, 2018. [Google Scholar]

- Think USA Dairy Discover U.S. Dairy. Available online: https://www.thinkusadairy.org/industry-facts-and-figures/product-portfolio (accessed on 15 August 2021).

- OECD-FAO. Chapter 7. Dairy and Dairy Products; FAO: Rome, Italy, 2018. [Google Scholar]

- Chatzipaschali, A.A.; Stamatis, A.G. Biotechnological Utilization with a Focus on Anaerobic Treatment of Cheese Whey: Current Status and Prospects. Energies 2012, 5, 3492–3525. [Google Scholar] [CrossRef] [Green Version]

- Bosco, F.; Carletto, R.A.; Marmo, L. An integrated cheese whey valorization process. Chem. Eng. Trans. 2018, 64, 379–384. [Google Scholar] [CrossRef]

- Prazeres, A.R.; Carvalho, F.; Rivas, J. Cheese whey management: A review. J. Environ. Manage. 2012, 110, 48–68. [Google Scholar] [CrossRef]

- Asunis, F.; De Gioannis, G.; Dessì, P.; Isipato, M.; Lens, P.N.L.; Muntoni, A.; Polettini, A.; Pomi, R.; Rossi, A.; Spiga, D. The dairy biorefinery: Integrating treatment processes for cheese whey valorisation. J. Environ. Manag. 2020, 276, 111240. [Google Scholar] [CrossRef] [PubMed]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Review of high-value food waste and food residues biorefineries with focus on unavoidable wastes from processing. Resour. Conserv. Recycl. 2019, 149, 413–426. [Google Scholar] [CrossRef]

- Perna, V.; Castelló, E.; Wenzel, J.; Zampol, C.; Fontes Lima, D.M.; Borzacconi, L.; Varesche, M.B.; Zaiat, M.; Etchebehere, C. Hydrogen production in an upflow anaerobic packed bed reactor used to treat cheese whey. Int. J. Hydrogen Energy 2013, 38, 54–62. [Google Scholar] [CrossRef]

- Rocha, J.M.; Guerra, A. On the valorization of lactose and its derivatives from cheese whey as a dairy industry by-product: An overview. Eur. Food Res. Technol. 2020, 246, 2161–2174. [Google Scholar] [CrossRef]

- UPME-UNAL. Estimación del Potencial de Conversión a Biogás de la Biomasa en Colombia y Su Aprovechamiento; Inf. Unidad planeación Min. Energética UPME-Universidad Nacional de Colombia: Bogotá, Colombia, 2018; pp. 1–216.

- Escalante, H.; Castro, L.; Amaya, M.P.; Jaimes, L.; Jaimes-Estévez, J. Anaerobic digestion of cheese whey: Energetic and nutritional potential for the dairy sector in developing countries. Waste Manag. 2018, 71, 711–718. [Google Scholar] [CrossRef] [PubMed]

- De Albuquerque, J.N.; Paulinetti, A.P.; Lovato, G.; Albanez, R.; Ratusznei, S.M.; Rodrigues, J.A.D. Anaerobic Sequencing Batch Reactors Co-digesting Whey and Glycerin as a Possible Solution for Small and Mid-size Dairy Industries: Environmental Compliance and Methane Production. Appl. Biochem. Biotechnol. 2020, 192, 979–998. [Google Scholar] [CrossRef]

- Papirio, S.; Matassa, S.; Pirozzi, F.; Esposito, G. Anaerobic Co-Digestion of Cheese Whey and Industrial Hemp Residues Opens New Perspectives for the Valorization of Agri-Food Waste. Energies 2020, 13, 2820. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Tabatabaei, M.; Hosseini, S.S.; Dashti, B.; Mojarab Soufiyan, M. Performance assessment of a wind power plant using standard exergy and extended exergy accounting (EEA) approaches. J. Clean. Prod. 2018, 171, 127–136. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2014: Mitigation of Climate Change; OMM, PNUMA: Geneve, Switzerland, 2014. [Google Scholar]

- United Nations Sustainable Development Goals. Available online: https://sdgs.un.org/es/goals (accessed on 29 June 2021).

- Shahriari, H.; Warith, M.; Hamoda, M.; Kennedy, K.J. Anaerobic digestion of organic fraction of municipal solid waste combining two pretreatment modalities, high temperature microwave and hydrogen peroxide. Waste Manag. 2012, 32, 41–52. [Google Scholar] [CrossRef] [PubMed]

- Ogunmakinde A Review of Circular Economy Development Models in China, Germany and Japan. Recycling 2019, 4, 27. [CrossRef] [Green Version]

- Nußholz, J.L.K. Circular business models: Defining a concept and framing an emerging research field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef] [Green Version]

- Nußholz, J.L.K. A circular business model mapping tool for creating value from prolonged product lifetime and closed material loops. J. Clean. Prod. 2018, 197, 185–194. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Torres-Guevara, L.E.; Ormazabal, M.; Jaca, C. Beyond the circular economy theory: Implementation methodology for industrial SMEs. J. Ind. Eng. Manag. 2021, 14, 425–438. [Google Scholar] [CrossRef]

- Kimming, M.; Sundberg, C.; Nordberg, Å.; Baky, A.; Bernesson, S.; Hansson, P.-A. Replacing fossil energy for organic milk production-potential biomass sources and greenhouse gas emission reductions. J. Clean. Prod. 2015, 106, 400–407. [Google Scholar] [CrossRef]

- Dolman, M.A.; Sonneveld, M.P.W.; Mollenhorst, H.; De Boer, I.J.M. Benchmarking the economic, environmental and societal performance of Dutch dairy farms aiming at internal recycling of nutrients. J. Clean. Prod. 2014, 73, 245–252. [Google Scholar] [CrossRef]

- Stanchev, P.; Vasilaki, V.; Egas, D.; Colon, J.; Ponsá, S.; Katsou, E. Multilevel environmental assessment of the anaerobic treatment of dairy processing effluents in the context of circular economy. J. Clean. Prod. 2020, 261, 121139. [Google Scholar] [CrossRef]

- Jaimes-Estévez, J.; Castro, L.; Escalante, H.; Carrillo, D.; Portillo, S.; Sotres, A.; Morán, A. Cheese whey co-digestion treatment in a tubular system: Microbiological behaviour along the axial axis. Biomass Convers. Biorefinery 2020, 4, 1–10. [Google Scholar] [CrossRef]

- Chen, C. Science Mapping: A Systematic Review of the Literature. J. Data Inf. Sci. 2017, 2, 1–40. [Google Scholar] [CrossRef] [Green Version]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Duriau, V.J.; Reger, R.K.; Pfarrer, M.D. A content analysis of the content analysis literature in organization studies: Research themes, data sources, and methodological refinements. Organ. Res. Methods 2007, 10, 5–34. [Google Scholar] [CrossRef] [Green Version]

- York, L.; Heffernan, C.; Rymer, C. A systematic review of policy approaches to dairy sector greenhouse gas (GHG) emission reduction. J. Clean. Prod. 2018, 172, 2216–2224. [Google Scholar] [CrossRef]

- Mancebo, R.; da Cunha Reis, A.; Medeiros Rios, E.; de Araújo Santos Martins, J.; Oliveira Soares, L.; Aparecida de Sá Machado, V.; Rodrigues de Moraes, D. Waste-to-Energy Technologies Towards Circular Economy: A Systematic Literature Review and Bibliometric Analysis. Water Air Soil Pollut. 2021, 7, 1–25. [Google Scholar] [CrossRef]

- Reyes-Torres, M.; Oviedo-Ocaña, E.R.; Dominguez, I.; Komilis, D.; Sánchez, A. A systematic review on the composting of green waste: Feedstock quality and optimization strategies. Waste Manag. 2018, 77, 486–499. [Google Scholar] [CrossRef] [PubMed]

- Tsai, F.M.; Bui, T.D.; Tseng, M.L.; Lim, M.K.; Hu, J. Municipal solid waste management in a circular economy: A data-driven bibliometric analysis. J. Clean. Prod. 2020, 275, 124132. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Oviedo-Ocaña, R.; Torres-Lozada, P.; Fernando Marmolejo-Rebellón, L.; Manyoma-Velásquez, P.C. Composting of biowaste: Research trends and relevance in developing countries. Rev. DYNA 2017, 84, 334–342. [Google Scholar] [CrossRef]

- Parra Orobio, B.A.; Nieto Mendoza, M.; Rivera Henao, D.; Manyoma Vélasquez, P.C.; Torres Lozada, P.; Parra-Orobio, B.A.; Nieto-Mendoza, M.; Rivera-Henao, D.; Manyoma-Velásquez, P.C.; Torres-Lozada, P. Selection of inocula conditioning methodologies for the anaerobic digestion of food waste. Rev. Fac. Ing. Univ. Antioq. 2019, 90, 9–18. [Google Scholar] [CrossRef] [Green Version]

- Jan van Eck, N.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Chernicharo, C.; Van Lier, J.; Noyola, A. Anaerobic sewage treatment: State of the art, constraints and challenges. Rev. Environ. Sci. Bio/Technol. 2015, 14, 649–679. [Google Scholar] [CrossRef]

- Silva-Martínez, R.D.; Sanches-Pereira, A.; Ortiz, W.; Gómez Galindo, M.F.; Coelho, S.T. The state-of-the-art of organic waste to energy in Latin America and the Caribbean: Challenges and opportunities. Renew. Energy 2020, 156, 509–525. [Google Scholar] [CrossRef]

- Muscolo, A.; Settineri, G.; Papalia, T.; Attinà, E.; Basile, C.; Panuccio, M.R. Anaerobic co-digestion of recalcitrant agricultural wastes: Characterizing of biochemical parameters of digestate and its impacts on soil ecosystem. Sci. Total Environ. 2017, 586, 746–752. [Google Scholar] [CrossRef]

- Kassongo, J.; Shahsavari, E.; Ball, A.S. molecules Co-Digestion of Grape Marc and Cheese Whey at High Total Solids Holds Potential for Sustained Bioenergy Generation. Molecules 2020, 25, 5754. [Google Scholar] [CrossRef] [PubMed]

- Gameiro, T.; Novais, R.M.; Correia, C.L.; Carvalheiras, J.; Seabra, M.P.; Tarelho, L.A.C.; Labrincha, J.A.; Capela, I. Role of waste-based geopolymer spheres addition for pH control and efficiency enhancement of anaerobic digestion process. Bioprocess Biosyst. Eng. 2021, 1, 3. [Google Scholar] [CrossRef] [PubMed]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van, W. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018; Volume 4, ISBN 9781464813290. [Google Scholar]

- Casallas-Ojeda, M.; Marmolejo-Rebellón, L.; Torres-Lozada, P. Identification of Factors and Variables that Influence the Anaerobic Digestion of Municipal Biowaste and Food Waste. Waste Biomass Valorization 2020, 1–16. [Google Scholar] [CrossRef]

- Zamri, M.F.M.A.; Hasmady, S.; Akhiar, A.; Ideris, F.; Shamsuddin, A.H.; Mofijur, M.; Fattah, I.M.R.; Mahlia, T.M.I. A comprehensive review on anaerobic digestion of organic fraction of municipal solid waste. Renew. Sustain. Energy Rev. 2021, 137, 110637. [Google Scholar] [CrossRef]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Improving the sustainability of organic waste management practices in the food-energy-water nexus: A comparative review of anaerobic digestion and composting. Renew. Sustain. Energy Rev. 2018, 89, 151–167. [Google Scholar] [CrossRef]

- Kassongo, J.; Shahsavari, E.; Ball, A.S. Renewable energy from the solid-state anaerobic digestion of grape marc and cheese whey at high treatment capacity. Biomass Bioenergy 2020, 143, 105880. [Google Scholar] [CrossRef]

- Dareioti, M.A.; Kornaros, M. Anaerobic mesophilic co-digestion of ensiled sorghum, cheese whey and liquid cow manure in a two-stage CSTR system: Effect of hydraulic retention time. Bioresour. Technol. 2015, 175, 553–562. [Google Scholar] [CrossRef]

- Treu, L.; Tsapekos, P.; Peprah, M.; Campanaro, S.; Giacomini, A.; Corich, V.; Kougias, P.G.; Angelidaki, I. Microbial profiling during anaerobic digestion of cheese whey in reactors operated at different conditions. Bioresour. Technol. 2019, 275, 375–385. [Google Scholar] [CrossRef] [PubMed]

- Liew, Y.X.; Chan, Y.J.; Manickam, S.; Chong, M.F.; Chong, S.; Tiong, T.J.; Lim, J.W.; Pan, G.T. Enzymatic pretreatment to enhance anaerobic bioconversion of high strength wastewater to biogas: A review. Sci. Total Environ. 2020, 713, 136373. [Google Scholar] [CrossRef] [PubMed]

- Ribera-Pi, J.; Marina Badia-Fabregat, M.; Calderer, M.; Polášková, M.; Svojitka, J.; Rovira, M.; Jubany, I.; Xavier, M.-L. Anaerobic Membrane Bioreactor (AnMBR) for the Treatment of Cheese Whey for the Potential Recovery of Water and Energy. Waste Biomass Valorization 2020, 11, 1821–1835. [Google Scholar] [CrossRef]

- Fernández, C.; Cuetos, M.J.; Martínez, E.J.; Gómez, X. Thermophilic anaerobic digestion of cheese whey: Coupling H2 and CH4 production. Biomass Bioenergy 2015, 81, 55–62. [Google Scholar] [CrossRef]

- Maragkaki, A.E.; Fountoulakis, M.; Kyriakou, A.; Lasaridi, K.; Manios, T. Boosting biogas production from sewage sludge by adding small amount of agro-industrial by-products and food waste residues. Waste Manag. 2018, 71, 605–611. [Google Scholar] [CrossRef]

- Vavouraki, A.I.; Zakoura, M.V.; Dareioti, M.A.; Kornaros, M. Biodegradation of Polyphenolic Compounds from Olive Mill Wastewaters (OMW) During Two-Stage Anaerobic Co-digestion of Agro-industrial Mixtures. Waste Biomass Valorization 2020, 11, 5783–5791. [Google Scholar] [CrossRef]

- El Achkar, J.H.; Ziade, R.; Louka, N.; Maroun, R.G.; Hobaika, Z. Treatment of dairy waste by anaerobic digestion to produce methane as green energy. In Proceedings of the 5th International Conference on Renewable Energies for Developing Countries (REDEC), Marrakech, Morocco, 9–30 June 2020; pp. 8–13. [Google Scholar] [CrossRef]

- Jung, H.; Kim, J.; Lee, C. Continuous anaerobic co-digestion of Ulva biomass and cheese whey at varying substrate mixing ratios: Different responses in two reactors with different operating regimes. Bioresour. Technol. 2016, 221, 366–374. [Google Scholar] [CrossRef]

- Pilarska, A.A.; Pilarski, K.; Witaszek, K.; Waliszewska, H.; Zborowska, M.; Waliszewska, B.; Kolasiński, M.; Szwarc-Rzepka, K. Treatment of dairy waste by anaerobic co-digestion with sewage sludge. Ecol. Chem. Eng. S 2016, 23, 99–115. [Google Scholar] [CrossRef] [Green Version]

- Gomez-Romero, J.; Gonzalez-Garcia, A.; Chairez, I.; Torres, L.; García-Peña, E.I. Selective adaptation of an anaerobic microbial community: Biohydrogen production by co-digestion of cheese whey and vegetables fruit waste. Int. J. Hydrogen Energy 2014, 39, 12541–12550. [Google Scholar] [CrossRef]

- Charalambous, P.; Vyrides, I. In situ biogas upgrading and enhancement of anaerobic digestion of cheese whey by addition of scrap or powder zero-valent iron (ZVI). J. Environ. Manag. 2021, 280, 111651. [Google Scholar] [CrossRef]

- Cárdenas Cleves, L.M.; Parra Orobio, B.A.; Torres Lozada, P.; Vásquez Franco, C.H. Perspectivas del ensayo de Potencial Bioquímico de Metano—PBM para el control del proceso de digestión anaerobia de residuos. Rev. ION 2016, 29, 95–108. [Google Scholar] [CrossRef] [Green Version]

- Casallas-Ojeda, M.; Marmolejo-Rebellón, L.; Torres-Lozada, P. Evaluation of simultaneous incidence of head space and temperature on biochemical methane potential in food waste. Cogent Eng. 2020, 7, 1729514. [Google Scholar] [CrossRef]

- Gutiérrez, H.; De la Vara, R. Análisis y Diseño de Experimentos, 2nd ed.; McGraw Hill: Ciudad de México, Mexico, 2008; ISBN 970-10-6526-3. [Google Scholar]

- Raposo, F.; De La Rubia, M.A.; Fernández-Cegrí, V.; Borja, R. Anaerobic digestion of solid organic substrates in batch mode: An overview relating to methane yields and experimental procedures. Renew. Sustain. Energy Rev. 2012, 16, 861–877. [Google Scholar] [CrossRef]

- Koch, K.; Lippert, T.; Drewes, J.E. The role of inoculum’s origin on the methane yield of different substrates in biochemical methane potential (BMP) tests. Bioresour. Technol. 2017, 243, 457–463. [Google Scholar] [CrossRef]

- Mirmohamadsadeghi, S.; Karimi, K.; Tabatabaei, M.; Aghbashlo, M. Biogas production from food wastes: A review on recent developments and future perspectives. Bioresour. Technol. Rep. 2019, 7, 100202. [Google Scholar] [CrossRef]

- Nohra, J.A.; Barrington, S.; Frigon, J.C.; Guiot, S.R. In storage psychrophilic anaerobic digestion of swine slurry. Resour. Conserv. Recycl. 2003, 38, 23–37. [Google Scholar] [CrossRef]

- Ohemeng-Ntiamoah, J.; Datta, T. Perspectives on variabilities in biomethane potential test parameters and outcomes: A review of studies published between 2007 and 2018. Sci. Total Environ. 2019, 664, 1052–1062. [Google Scholar] [CrossRef]

- Van Nguyen, Q.; Jensen, L.S.; Bol, R.; Wu, D.; Triolo, J.M.; Vazifehkhoran, A.H.; Bruun, S. Biogas digester hydraulic retention time affects oxygen consumption patterns and greenhouse gas emissions after application of digestate to soil. J. Environ. Qual. 2017, 46, 1114–1122. [Google Scholar] [CrossRef] [Green Version]

- Martí-Herrero, J.; Soria-Castellón, G.; Diaz-de-Basurto, A.; Alvarez, R.; Chemisana, D. Biogas from a full scale digester operated in psychrophilic conditions and fed only with fruit and vegetable waste. Renew. Energy 2019, 133, 676–684. [Google Scholar] [CrossRef]

- Yamashiro, T.; Lateef, S.A.; Chun, Y.; Nilmini Beneragama, Y.; Lukic, M.; Masahiro, I.; Ihara, I.; Nishida, T.; Umetsu, K. Anaerobic co-digestion of dairy cow manure and high concentrated food processing waste. J. Mater. Cycles Waste Manag. 2013, 15, 539–547. [Google Scholar] [CrossRef]

- Riggio, V.A.; Comino, E.; Rosso, M. Above ground part of common reed to enhance anaerobic co-digestion of farm biomasses: Potential, monitoring and efficiency. Ecol. Eng. 2015, 79, 35–41. [Google Scholar] [CrossRef] [Green Version]

- Carlini, M.; Castellucci, S.; Moneti, M. Biogas production from poultry manure and cheese whey wastewater under mesophilic conditions in batch reactor. Energy Procedia 2015, 82, 811–818. [Google Scholar] [CrossRef] [Green Version]

- Brown, N.; Güttler, J.; Shilton, A. Overcoming the challenges of full scale anaerobic co-digestion of casein whey. Renew. Energy 2016, 96, 425–432. [Google Scholar] [CrossRef]

- Hallaji, S.M.; Kuroshkarim, M.; Moussavi, S.P. Enhancing methane production using anaerobic co-digestion of waste activated sludge with combined fruit waste and cheese whey. BMC Biotechnol. 2019, 19, 1–10. [Google Scholar] [CrossRef]

- Marchetti, R.; Vasmara, C. Co-digestion of Deproteinized Dairy Waste With Pig Slurry: Effect of Recipe and Initial pH on Biogas and Volatile Fatty Acid Production. Bioenergy Res. 2020, 13, 643–658. [Google Scholar] [CrossRef]

- Iglesias-Iglesias, R.; Kennes, C.; Veiga, M.C. Valorization of sewage sludge in co-digestion with cheese whey to produce volatile fatty acids. Waste Manag. 2020, 118, 541–551. [Google Scholar] [CrossRef]

- Parawira, W. Anaerobic Treatment of Agricultural Residues and Wastewater Application of High-Rate Reactors. Ph.D. Thesis, Department of Biotechnology, Lund University, Lund, Sweden, 2004. [Google Scholar]

- Fernandes, T.V.; Keesman, K.J.; Zeeman, G.; van Lier, J.B. Effect of ammonia on the anaerobic hydrolysis of cellulose and tributyrin. Biomass Bioenergy 2014, 47, 316–323. [Google Scholar] [CrossRef]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Lu, X.; Jin, W.; Xue, S.; Wang, X. Effects of waste sources on performance of anaerobic co-digestion of complex organic wastes: Taking food waste as an example OPEN. Sci. Rep. 2017, 7, 15702. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Comino, E.; Riggio, V.A.; Rosso, M. Biogas production by anaerobic co-digestion of cattle slurry and cheese whey. Bioresour. Technol. 2012, 114, 46–53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flores-Mendoza, A.P.; Hernández-García, H.; Cocotle-Ronzón, Y.; Hernandez-Martinez, E. Methanogenesis of raw cheese whey: pH and substrate–inoculum ratio evaluation at mesophyll temperature range. J. Chem. Technol. Biotechnol. 2020, 95, 1946–1952. [Google Scholar] [CrossRef]

- Nkoa, R. Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: A review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar] [CrossRef] [Green Version]

- Parra-Orobio, B.A.; Rotavisky-Sinisterra, M.P.; Pérez-Vidal, A.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P. Physicochemical, microbiological characterization and phytotoxicity of digestates produced on single-stage and two-stage anaerobic digestion of food waste. Sustain. Environ. Res. 2021, 31, 1–10. [Google Scholar] [CrossRef]

- de Lemos Chernicharo, C.A. Anaerobic Reactors; IWA: London, UK, 2007; Volume 6, ISBN 9781843391647. [Google Scholar]

- Mata-Alvarez, J. Biomethanization of the Organic Fraction of Municipal Solid Wasteso Title; IWA: London, UK, 2002; ISBN 9781900222143. [Google Scholar]

- Nayono, S. Anerobic Digestion of Organic Solid Waste for Energy Production. Ph.D. Thesis, Universitat Fridericiana zu Karlsruhe, Karlsruhe, Germany, 2009. [Google Scholar]

- Pagliano, G.; Ventorino, V.; Panico, A.; Romano, I.; Pirozzi, F.; Pepe, O. Anaerobic Process for Bioenergy Recovery from Dairy Waste: Meta-Analysis and Enumeration of Microbial Community Related to Intermediates Production Anaerobic Dairy Waste Process for Bioenergy. Front. Microbiol. 2019, 3, 3229. [Google Scholar] [CrossRef] [PubMed]

- Diamantis, V.I.; Kapagiannidis, A.G.; Ntougias, S.; Tataki, V.; Melidis, P.; Aivasidis, A. Two-stage CSTR-UASB digestion enables superior and alkali addition-free cheese whey treatment. Biochem. Eng. J. 2014, 84, 45–52. [Google Scholar] [CrossRef]

- Yang, Y.; Tada, C.; Miah, M.S.; Tsukahara, K.; Yagishita, T.; Sawayama, S. Influence of bed materials on methanogenic characteristics and immobilized microbes in anaerobic digester. Mater. Sci. Eng. C 2004, 24, 413–419. [Google Scholar] [CrossRef]

- Rico, C.; Muñoz, N.; Fernández, J.; Rico, J.L. High-load anaerobic co-digestion of cheese whey and liquid fraction of dairy manure in a one-stage UASB process: Limits in co-substrates ratio and organic loading rate. Chem. Eng. J. 2015, 262, 794–802. [Google Scholar] [CrossRef]

- Lovato, G.; Ratusznei, S.M.; Rodrigues, J.A.D.; Zaiat, M. Co-digestion of Whey with Glycerin in an AnSBBR for Biomethane Production. Appl. Biochem. Biotechnol. 2016, 178, 126–143. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Sánchez, C.; González-González, A.; Cuadros-Salcedo, F.; Cuadros-Blázquez, F. Using low-cost porous materials to increase biogas production: A case study in Extremadura (Spain). J. Clean. Prod. 2018, 198, 1165–1172. [Google Scholar] [CrossRef]

- Erdirencelebi, D. Treatment of high-fat-containing dairy wastewater in a sequential UASBR system: Influence of recycle. J. Chem. Technol. Biotechnol. 2011, 86, 525–533. [Google Scholar] [CrossRef]

- Jin, C.; Sun, S.; Yang, D.; Sheng, W.; Ma, Y.; He, W.; Li, G. Anaerobic digestion: An alternative resource treatment option for food waste in China. Sci. Total Environ. 2021, 779, 146397. [Google Scholar] [CrossRef] [PubMed]

- Begum, S.; Anupoju, G.R.; Sridhar, S.; Bhargava, S.K.; Jegatheesan, V.; Eshtiaghi, N. Evaluation of single and two stage anaerobic digestion of landfill leachate: Effect of pH and initial organic loading rate on volatile fatty acid (VFA) and biogas production. Bioresour. Technol. 2018, 251, 364–373. [Google Scholar] [CrossRef] [PubMed]

- Negri, C.; Ricci, M.; Zilio, M.; D’Imporzano, G.; Qiao, W.; Dong, R.; Adani, F. Anaerobic digestion of food waste for bio-energy production in China and Southeast Asia: A review. Renew. Sustain. Energy Rev. 2020, 133, 110138. [Google Scholar] [CrossRef]

- Wang, S.; Chandrasekhara Rao, N.; Qiu, R.; Moletta, R. Performance and kinetic evaluation of anaerobic moving bed biofilm reactor for treating milk permeate from dairy industry. Bioresour. Technol. 2009, 100, 5641–5647. [Google Scholar] [CrossRef]

- Moguel-Castañeda, J.G.; González-Salomón, M.; Hernández-Garciá, H.; Morales-Zarate, E.; Puebla, H.; Hernandez-Martinez, E. Effect of organic loading rate on anaerobic digestion of raw cheese whey: Experimental evaluation and mathematical modeling. Int. J. Chem. React. Eng. 2020, 18. [Google Scholar] [CrossRef]

- Calero, R.; Iglesias-Iglesias, R.; Kennes, C.; Veiga, M.C. Organic loading rate effect on the acidogenesis of cheese whey: A comparison between UASB and SBR reactors. Environ. Technol. 2018, 39, 3046–3054. [Google Scholar] [CrossRef] [PubMed]

- Cremonez, P.A.; Teleken, J.G.; Weiser Meier, T.R.; Alves, H.J. Two-Stage anaerobic digestion in agroindustrial waste treatment: A review. J. Environ. Manag. 2021, 281, 111854. [Google Scholar] [CrossRef]

- Chen, Y.; Xiao, K.; Jiang, X.; Shen, N.; Zeng, R.J.; Zhou, Y. Long solid retention time (SRT) has minor role in promoting methane production in a 65 °C single-stage anaerobic sludge digester. Bioresour. Technol. 2018, 247, 724–729. [Google Scholar] [CrossRef]

- Kothari, R.; Pandey, A.K.; Kumar, S.; Tyagi, V.V.; Tyagi, S.K. Different aspects of dry anaerobic digestion for bio-energy: An overview. Renew. Sustain. Energy Rev. 2014, 39, 174–195. [Google Scholar] [CrossRef]

- da Silva, L.F.M. Special Issue: 2nd International Conference on Materials Design and Applications 2018 (MDA 2018). Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 257. [Google Scholar] [CrossRef]

- Kılkış, Ş.; Kılkış, B. Integrated circular economy and education model to address aspects of an energy-water-food nexus in a dairy facility and local contexts. J. Clean. Prod. 2017, 167, 1084–1098. [Google Scholar] [CrossRef]

- Rosa, F. Waste Generated by Food Industry and Reuse in A Circular Economy Approach: The Whey Processing. Concepts Dairy Vet. Sci. 2018, 2, 171–173. [Google Scholar] [CrossRef]

- Komilis, D.; Barrena, R.; Lora, R.; Vogiatzi, V.; Sánchez, A.; Font, X. A state of the art literature review on anaerobic digestion of food waste: Influential operating parameters on methane yield. Rev. Environ. Sci. Bio/Technol. 2017, 16, 347–360. [Google Scholar] [CrossRef] [Green Version]

- Parra-Orobio, B.A.; Angulo-Mosquera, L.S.; Loaiza-Gualtero, J.S.; Torres-López, W.A.; Torres-Lozada, P. Inoculum mixture optimization as strategy for to improve the anaerobic digestion of food waste for the methane production. J. Environ. Chem. Eng. 2018, 6, 1529–1535. [Google Scholar] [CrossRef]

| ID | Equation |

|---|---|

| A | “Anaerobic digestion” AND “Cheese whey” AND Methane |

| B | “Anaerobic digestion” AND “Cheese whey” AND Inoculum OR Inoculum |

| C | “Anaerobic digestion” AND “Cheese whey” AND Stages |

| D | “Anaerobic digestion” AND “Cheese whey” AND “Anaerobic Co-digestion” OR “Anaerobic codigestion” |

| E | “Anaerobic digestion” AND “Cheese whey” AND Pretreatment |

| F | “Anaerobic digestion” AND “Cheese whey” AND Digestate |

| G | “Anaerobic digestion” AND “Cheese whey” AND "Climate change” |

| H | “Cheese whey” AND “Anaerobic co-digestion” OR “Anaerobic codigestion” AND Methane |

| I | “Anaerobic digestion” AND “Cheese whey” AND "Circular economy” |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casallas-Ojeda, M.; Torres-Guevara, L.E.; Caicedo-Concha, D.M.; Gómez, M.F. Opportunities for Waste to Energy in the Milk Production Industry: Perspectives for the Circular Economy. Sustainability 2021, 13, 12892. https://doi.org/10.3390/su132212892

Casallas-Ojeda M, Torres-Guevara LE, Caicedo-Concha DM, Gómez MF. Opportunities for Waste to Energy in the Milk Production Industry: Perspectives for the Circular Economy. Sustainability. 2021; 13(22):12892. https://doi.org/10.3390/su132212892

Chicago/Turabian StyleCasallas-Ojeda, Miguel, Luz Elba Torres-Guevara, Diana M. Caicedo-Concha, and María F. Gómez. 2021. "Opportunities for Waste to Energy in the Milk Production Industry: Perspectives for the Circular Economy" Sustainability 13, no. 22: 12892. https://doi.org/10.3390/su132212892

APA StyleCasallas-Ojeda, M., Torres-Guevara, L. E., Caicedo-Concha, D. M., & Gómez, M. F. (2021). Opportunities for Waste to Energy in the Milk Production Industry: Perspectives for the Circular Economy. Sustainability, 13(22), 12892. https://doi.org/10.3390/su132212892