Life Cycle Assessment and Economic Energy Efficiency of a Solar Thermal Installation in a Family House

Abstract

:1. Introduction

2. Materials and Methods

2.1. Input Data for the Simulation

2.2. T*SOL Software Characteristic

2.3. Output Data for the Annual Simulation

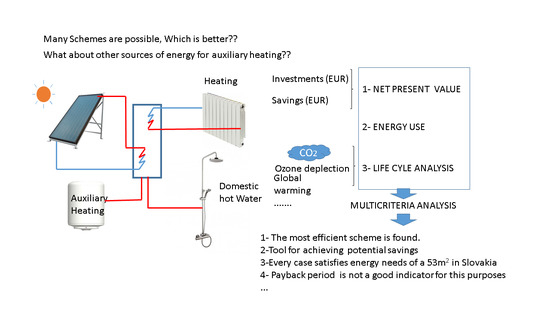

- Energy delivered by collectors (kWh). The software shows the energy produced by the solar thermal installation. It also divides this energy into solar energy increase to DHW (kWh) and heating (kWh).

- Auxiliary heating energy (kWh). This value showed that our installation cannot offer the total energy demanded by our building. This energy can be achieved by different sources such as gas boilers, heat pumps, wood pellet boilers, and many others. In this work, the method is described, and practitioners can incorporate any other energy sources.

2.4. Life Cycle Cost of ST Installation

2.5. Life Cycle Assessment

2.6. Multicriteria Analysis

2.7. Calculation Process

3. Case Study

3.1. Input Data for the Simulation

3.2. Cases Simulation

3.3. Economic Data

- Five solar collectors = 2128.8 € (this cost applies to all cases), type Thermosolar Žiar TS 300 flat plate collector, gross surface 2.03 m2, active solar surface 1.78 m2, gross collector area 10.15 m2, active collector area 8.9 m2, orientation 180°, inclination 45°, and azimuth angles 0°;

- Gas boiler = 1169 € (cases I, II, III, and IV), nominal output 15 kW;

- Solar preheating tank 200 L = 401.41 € (cases I, V, and VI), volume 200 L, height 1.8 m, insulation thickness 100 mm, effective thermal conductivity 0.065 W/(mK), and losses 2.31 kWh/day;

- Buffer tank 500 L = 906 € (cases I, II, V, VI, VII, and VIII), volume 500 L, height 2.93 m, insulation thickness 45 mm, effective thermal conductivity 0.03 W/(mK), and losses 3.46 kWh/day;

- DHW standby tank 120 L = 376 € (cases I, V, and VI), volume 120 L, height 1.8 m, insulation thickness 100 mm, effective thermal conductivity 0.065 W/(mK), and losses 1.95 kWh/day;

- Dual coil indirect water tank 300 L = 1944.76 € (cases II, IV, VII, VIII, XI, and XII), volume 300 L, height 1.8 m, insulation thickness 100 mm, effective thermal conductivity 0.065 W/(mK), and losses 3.23 kWh/day;

- Collector loop heat exchanger = 100 € (cases IV, XI, and XII), maximum heat transfer rate 4.45 kW;

- Combination tank = 3956.09 € (cases III, IX, and X), volume 1000 L, height 2 m, insulation thickness 100 mm, effective thermal conductivity 0.065 W/(mK), and losses 4.75 kWh/day;

- Heat pump = 14,744.0 € (cases V, VII, IX, and XI), nominal output 14 kW;

- Woodfire boiler = 852.0 € (cases VI, VIII, X, and XII), nominal output 14 kW.

4. Results

4.1. The Energy Required for Every Alternative

4.2. The Energy Required for Heating

4.3. Domestic Hot Water

4.4. Emissions and Impact on the Environment

4.5. Economic Savings of the Alternatives

4.6. Life Cycle Cost of the Solar Thermal Installations

4.7. Influence of the Discount Rate

4.8. Life Cycle Assessment Calculation

4.9. Multi-Criteria Decision Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AP | acidification potential |

| CDA | Concordance Discordance Analysis |

| DHW | Domestic hot water |

| EC | Energy Criteria Analysis |

| EP | eutrophication potential |

| EU | European Union |

| GWP | global warming potential |

| LCA | Life cycle assessment |

| LCC | Life Cycle Cost |

| MCA | Multi-criteria analysis |

| MCA7 | Software for performing MCA |

| NHW | non-hazard waste |

| NPV | Net present value |

| PBP | Pay Back Period |

| POCP | photochemical ozone creation potential |

| OneClickLCA | Software for performing LCA |

| ODP | ozone depletion potential |

| ST | Solar thermal |

| T*SOL | Software for ST calculations |

References

- Yearbook, G.E.S. Total Energy Consumption 2019; Enerdata Intelligence + Consulting: Grenoble, France, 2020. [Google Scholar]

- IEA. World Energy Outlook 2019; IEA: París, France, 2019. [Google Scholar]

- Alexandratos, N.; Bruinsma, J. World Agriculture towards 2030/2050: The 2012 Revision; Global Perspective Studies Unit Food and Agriculture Organization of the United Nations: Rome, Italy, 2012.

- Jamali, S.; Nemati, A.; Mohammadkhani, F.; Yari, M. Thermal and economic assessment of a solar chimney cooled semi-transparent photovoltaic (STPV) power plant in different climates. Sol. Energy 2019, 185, 480–493. [Google Scholar] [CrossRef]

- EC. Communication from the Commission to the European Parliament, The European Council, The European Economic and Social Committee, The Committee of the Regions and the European Investment Bank. A Clean Planet for All a European Strategic Long-Term Vision for; EC: Brussels, Belgium, 2018. [Google Scholar]

- Bottero, M.; Dell’Anna, F.; Morgese, V. Evaluating the Transition towards Post-Carbon Cities: A Literature Review. Sustainability 2021, 13, 567. [Google Scholar] [CrossRef]

- Bottero, M.; Caprioli, C.; Cotella, G.; Santangelo, M. Sustainable Cities: A Reflection on Potentialities and Limits based on Existing Eco-Districts in Europe. Sustainability 2019, 11, 5794. [Google Scholar] [CrossRef] [Green Version]

- Peng, J.; Lu, L.; Yang, H. Review on life cycle assessment of energy payback and greenhouse gas emission of solar photovoltaic systems. Renew. Sustain. Energy Rev. 2013, 19, 255–274. [Google Scholar] [CrossRef]

- Perino, M.; Serra, V. Switching from static to adaptable and dynamic building envelopes: A paradigm shift for the energy efficiency in buildings. J. Facade Des. Eng. 2015, 3, 143–163. [Google Scholar] [CrossRef] [Green Version]

- Sozer, H. Improving energy efficiency through the design of the building envelope. Build. Environ. 2010, 45, 2581–2593. [Google Scholar] [CrossRef]

- Omrany, H.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Raahemifar, K.; Tookey, J. Application of passive wall systems for improving the energy efficiency in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 62, 1252–1269. [Google Scholar] [CrossRef]

- Burman, E.; Mumovic, D.; Kimpian, J. Towards measurement and verification of energy performance under the framework of the European directive for energy performance of buildings. Energy 2014, 77, 153–163. [Google Scholar] [CrossRef] [Green Version]

- Fabrizio, E.; Seguro, F.; Filippi, M. Integrated HVAC and DHW production systems for Zero Energy Buildings. Renew. Sustain. Energy Rev. 2014, 40, 515–541. [Google Scholar] [CrossRef]

- European Commission Directive 2010/31/UE. Energy Performance of Building Directive Recast; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- Henning, H.-M.; Döll, J. Solar systems for heating and cooling of buildings. Energy Procedia 2012, 30, 633–653. [Google Scholar] [CrossRef]

- Bouhal, T.; Fertahi, S.; Agrouaz, Y.; El Rhafiki, T.; Kousksou, T.; Zeraouli, Y.; Jamil, A. Technical assessment, economic viability and investment risk analysis of solar heating/cooling systems in residential buildings in Morocco. Sol. Energy 2018, 170, 1043–1062. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M.; Stornelli, V. Solar photovoltaic panels combined with energy storage in a residential building: An economic analysis. Sustainability 2018, 10, 3117. [Google Scholar] [CrossRef] [Green Version]

- Tyagi, V.V.; Kaushik, S.C.; Tyagi, S.K. Advancement in solar photovoltaic/thermal (PV/T) hybrid collector technology. Renew. Sustain. Energy Rev. 2012. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. A comprehensive review of thermal energy storage. Sustainability 2018, 10, 191. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Kelman, A.; Daly, A.; Borrelli, F. Predictive control for energy efficient buildings with thermal storage: Modeling, stimulation, and experiments. IEEE Control Syst. 2012, 32, 44–64. [Google Scholar] [CrossRef]

- Khatib, T.; Mohamed, A.; Sopian, K. Optimization of a PV/wind micro-grid for rural housing electrification using a hybrid iterative/genetic algorithm: Case study of Kuala Terengganu, Malaysia. Energy Build. 2012. [Google Scholar] [CrossRef]

- Ishugah, T.F.; Li, Y.; Wang, R.Z.; Kiplagat, J.K. Advances in wind energy resource exploitation in urban environment: A review. Renew. Sustain. Energy Rev. 2014, 37, 613–626. [Google Scholar] [CrossRef]

- De Rosa, M.; Bianco, V.; Scarpa, F.; Tagliafico, L.A. Heating and cooling building energy demand evaluation; a simplified model and a modified degree days approach. Appl. Energy 2014, 128, 217–229. [Google Scholar] [CrossRef]

- Zhao, H.; Magoulès, F. A review on the prediction of building energy consumption. Renew. Sustain. Energy Rev. 2012, 16, 3586–3592. [Google Scholar] [CrossRef]

- Asdrubali, F.; Buratti, C.; Cotana, F.; Baldinelli, G.; Goretti, M.; Moretti, E.; Baldassarri, C.; Belloni, E.; Bianchi, F.; Rotili, A.; et al. Evaluation of green buildings’ overall performance through in situ monitoring and simulations. Energies 2013, 6, 6525–6547. [Google Scholar] [CrossRef] [Green Version]

- Bernardo, L.R.; Davidsson, H.; Andersson, E. Retrofitted solar domestic hot water systems for Swedish single-family houses—Evaluation of a prototype and life-cycle cost analysis. Energies 2016, 9, 953. [Google Scholar] [CrossRef] [Green Version]

- Buker, M.S.; Riffat, S.B. Building integrated solar thermal collectors—A review. Renew. Sustain. Energy Rev. 2015, 51, 327–346. [Google Scholar] [CrossRef]

- Pranesh, V.; Velraj, R.; Christopher, S.; Kumaresan, V. A 50 year review of basic and applied research in compound parabolic concentrating solar thermal collector for domestic and industrial applications. Sol. Energy 2019, 187, 293–340. [Google Scholar] [CrossRef]

- Qiu, Y.; He, Y.-L.; Li, P.; Du, B.-C. A comprehensive model for analysis of real-time optical performance of a solar power tower with a multi-tube cavity receiver. Appl. Energy 2017, 185, 589–603. [Google Scholar] [CrossRef] [Green Version]

- Košičan, J.; Pardo, M.Á.; Vilčeková, S. A Multicriteria Methodology to Select the Best Installation of Solar Thermal Power in a Family House. Energies 2020, 13, 1047. [Google Scholar] [CrossRef] [Green Version]

- Imteaz, M.A.; Ahsan, A. Solar panels: Real efficiencies, potential productions and payback periods for major Australian cities. Sustain. Energy Technol. Assess. 2018, 25, 119–125. [Google Scholar] [CrossRef]

- Attia, S.; Eleftheriou, P.; Xeni, F.; Morlot, R.; Ménézo, C.; Kostopoulos, V.; Betsi, M.; Kalaitzoglou, I.; Pagliano, L.; Cellura, M.; et al. Overview and future challenges of nearly zero energy buildings (nZEB) design in Southern Europe. Energy Build. 2017, 155, 439–458. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Energy and financial analysis of a solar driven thermoelectric generator. J. Clean. Prod. 2020, 2020, 121534. [Google Scholar] [CrossRef]

- Lamnatou, C.; Chemisana, D.; Mateus, R.; Almeida, M.G.; Silva, S.M. Review and perspectives on Life Cycle Analysis of solar technologies with emphasis on building-integrated solar thermal systems. Renew. Energy 2015, 75. [Google Scholar] [CrossRef]

- Ramírez-Villegas, R.; Eriksson, O.; Olofsson, T. Life cycle assessment of building renovation measures–trade-off between building materials and energy. Energies 2019, 12, 344. [Google Scholar] [CrossRef] [Green Version]

- Rønning, A.; Brekke, A. Life cycle assessment (LCA) of the building sector: Strengths and weaknesses. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Woodhead Publishing: Ostfold, Norway, 2013. [Google Scholar]

- Dekkiche, H.; Taileb, A. The Importance of Integrating LCA into the LEED Rating System. Procedia Eng. 2016, 145, 844–851. [Google Scholar] [CrossRef] [Green Version]

- Gagliano, A.; Aneli, S.; Nocera, F. Analysis of the performance of a building solar thermal facade (BSTF) for domestic hot water production. Renew. Energy 2019, 142, 511–526. [Google Scholar] [CrossRef]

- Arnaoutakis, N.; Souliotis, M.; Papaefthimiou, S. Comparative experimental Life Cycle Assessment of two commercial solar thermal devices for domestic applications. Renew. Energy 2017, 111, 187–200. [Google Scholar] [CrossRef]

- Hang, Y.; Qu, M.; Zhao, F. Economic and environmental life cycle analysis of solar hot water systems in the United States. Energy Build. 2012, 45. [Google Scholar] [CrossRef]

- Arabzadeh, V.; Jokisalo, J.; Kosonen, R. A cost-optimal solar thermal system for apartment buildings with district heating in a cold climate. Int. J. Sustain. Energy 2019, 38. [Google Scholar] [CrossRef]

- Comodi, G.; Bevilacqua, M.; Caresana, F.; Paciarotti, C.; Pelagalli, L.; Venella, P. Life cycle assessment and energy-CO2-economic payback analyses of renewable domestic hot water systems with unglazed and glazed solar thermal panels. Appl. Energy 2016, 164, 944–955. [Google Scholar] [CrossRef]

- Kumar, L.; Hasanuzzaman, M.; Rahim, N.A. Global advancement of solar thermal energy technologies for industrial process heat and its future prospects: A review. Energy Convers. Manag. 2019, 195, 885–908. [Google Scholar] [CrossRef]

- Morciano, M.; Fasano, M.; Secreto, M.; Jamolov, U.; Chiavazzo, E.; Asinari, P. Installation of a Concentrated Solar Power System for the Thermal Needs of Buildings or Industrial Processes. Energy Procedia 2016, 101, 956–963. [Google Scholar] [CrossRef] [Green Version]

- Chambers, T.; Raush, J.; Russo, B. Installation and Operation of Parabolic Trough Organic Rankine Cycle Solar Thermal Power Plant in South Louisiana. Energy Procedia 2014, 49, 1107–1116. [Google Scholar] [CrossRef] [Green Version]

- Lozano-Medina, A.; Manzano, L.; Marcos, J.D.; Blanco-Marigorta, A.M. Design of a concentrating solar thermal collector installation for a hotel complex in Gran Canaria. Energy 2019, 183, 803–811. [Google Scholar] [CrossRef]

- Ferreira, A.C.; Silva, A.; Teixeira, J.C.; Teixeira, S. Multi-Objective Optimization of Solar Thermal Systems Applied to Portuguese Dwellings. Energies 2020, 13, 6739. [Google Scholar] [CrossRef]

- Araújo, A.; Silva, R.; Pereira, V. Solar thermal modeling for rapid estimation of auxiliary energy requirements in domestic hot water production: On-off versus proportional flow rate control. Sol. Energy 2019, 177, 68–79. [Google Scholar] [CrossRef]

- Xu, B.; Li, P.; Chan, C.; Tumilowicz, E. General volume sizing strategy for thermal storage system using phase change material for concentrated solar thermal power plant. Appl. Energy 2015, 140, 256–268. [Google Scholar] [CrossRef] [Green Version]

- Shamir, U.; Howard, C.D.D. An analytic approach to scheduling pipe replacement. J.-Am. Water Work. Assoc. 1979, 71, 248–258. [Google Scholar] [CrossRef]

- Valentin Software, I. T*SOL ® Basic Version 5.0. Design and Simulation of Thermal Solar Systems; User Manual; Valentin Software, Inc.: Temecula, CA, USA, 2012; Volume 104. [Google Scholar]

- Pardo, M.Á.; Fernández, H.; Jodar-Abellan, A. Converting a Water Pressurized Network in a Small Town into a Solar Power Water System. Energies 2020, 13, 4013. [Google Scholar] [CrossRef]

- Bruce-Hyrkäs, T.; Pasanen, P.; Castro, R. Overview of Whole Building Life-Cycle Assessment for Green Building Certification and Ecodesign through Industry Surveys and Interviews. Procedia CIRP 2018, 69, 178–183. [Google Scholar] [CrossRef]

- Petrovic, B.; Myhren, J.A.; Zhang, X.; Wallhagen, M.; Eriksson, O. Life cycle assessment of a wooden single-family house in Sweden. Appl. Energy 2019, 251, 113253. [Google Scholar] [CrossRef]

- Pardo, M.A.; Manzano, J.; Valdés-Abellán, J.; Cobacho, R. Standalone direct pumping photovoltaic system or energy storage in batteries for supplying irrigation networks. Cost analysis. Sci. Total Environ. 2019. [Google Scholar] [CrossRef] [Green Version]

- Kleiner, Y.; Adams, B.J.; Rogers, J.S. Water distribution network renewal planning. J. Comput. Civ. Eng. 2001, 15, 15–26. [Google Scholar] [CrossRef] [Green Version]

- Ardente, F.; Beccali, G.; Cellura, M.; Brano, V. Lo Life cycle assessment of a solar thermal collector. Renew. Energy 2005, 30, 1031–1054. [Google Scholar] [CrossRef]

- Rubio, L.M.; Brito Filho, J.P.; Henriquez, J.R. Performance of a PV/T Solar Collector in a Tropical Monsoon Climate City in Brazil. IEEE Lat. Am. Trans. 2018, 16. [Google Scholar] [CrossRef]

- Geneletti, D. Multi-Criteria Analysis. LIAISE Toolbox. Available online: http://www.liaise-kit.eu/ia-method/multi-criteria-analysis (accessed on 19 February 2021).

- Keeney, R.L.; Raiffa, H.; Meyer, R.F. Decisions with Multiple Objectives: Preferences and Value Trade-Offs; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Hu, Y.C.; Chen, C.J. A PROMETHEE-based classification method using concordance and discordance relations and its application to bankruptcy prediction. Inf. Sci. 2011, 181, 4959–4968. [Google Scholar] [CrossRef]

- Magrassi, F.; Rocco, E.; Barberis, S.; Gallo, M.; Del Borghi, A. Hybrid solar power system versus photovoltaic plant: A comparative analysis through a life cycle approach. Renew. Energy 2019, 130, 290–304. [Google Scholar] [CrossRef]

- Murugesan, R. Energy Use Efficiency in Dryland Agriculture; Kalpaz Publications: Delhi, Indica, 2010; ISBN 8178357992. [Google Scholar]

- Pardo, M.Á.; Cobacho, R.; Bañón, L. Standalone Photovoltaic Direct Pumping in Urban Water Pressurized Networks with Energy Storage in Tanks or Batteries. Sustainability 2020, 12, 738. [Google Scholar] [CrossRef] [Green Version]

- Milousi, M.; Souliotis, M.; Arampatzis, G.; Papaefthimiou, S. Evaluating the Environmental Performance of Solar Energy Systems Through a Combined Life Cycle Assessment and Cost Analysis. Sustainability 2019, 11, 2539. [Google Scholar] [CrossRef] [Green Version]

- Passer, A.; Kreiner, H.; Maydl, P. Assessment of the environmental performance of buildings: A critical evaluation of the influence of technical building equipment on residential buildings. Int. J. Life Cycle Assess. 2012, 17, 1116–1130. [Google Scholar] [CrossRef]

| Building Location | Thermal Installation | ||

|---|---|---|---|

| Location | Košice, Slovakia | ||

| Latitude | 48.7° | Active solar surface | 1.78 m2 |

| Longitude | −21.3° | Gross collector area | 2.03 m2 |

| Overall global irradiation (tilt angle 45°) | 1144.4 kWh/m2 | Orientation | 180 °C |

| Diffuse radiation | 53.90% | Lowest outside temperature | −13 °C |

| Average outside temperature | 9.8 °C | Azimuth angles | 0° |

| Equipment | Case I | Case II | Case III | Case IV | Lifespan |

| Solar collector TS 300 5x | 2128.8 | 2128.8 | 2128.8 | 2128.8 | 30 |

| Solar Preheating tank 200 L | 401.4 | - | - | - | 20 |

| DHW standby tank 120 L | 376.0 | - | - | 15 | |

| Gas Boiler 15 kW | 1169.0 | 1169.0 | 1169.0 | 1169.0 | 15 |

| Combination tank | - | - | 3956.1 | - | 15 |

| Dual coil indirect water tank 300 L | - | 1944.8 | - | 1944.8 | 25 |

| Space-heating buffer tank 500 L | 906.0 | 906.0 | - | 906.0 | 15 |

| Collector loop heat exchanger | - | - | 100.0 | 30 | |

| Total Investment | 4981.2 | 6148.6 | 7253.9 | 6248.6 | |

| Equipment | Case V | Case VI | Case VII | Case VIII | Lifespan |

| Solar collector TS 300 5x | 2128.8 | 2128.8 | 2128.8 | 2128.8 | 30 |

| Solar Preheating tank 200 L | 401.4 | 401.4 | - | - | 20 |

| DHW standby tank 120 L | 376.0 | 376.0 | - | - | 15 |

| Heat pump- 14 kW | 14,744.0 | - | 14,744.0 | - | 15 |

| Wood fire boiler-14 kW | - | 852.0 | - | 852.0 | 15 |

| Combination tank | - | - | - | - | 25 |

| Dual coil indirect water tank 120 L | - | - | 1944.8 | 1944.8 | 15 |

| Space-heating buffer tank 500 L | 906.0 | 906.0 | - | 906.0 | 30 |

| Collector loop heat exchanger | - | - | - | - | 30 |

| Total Investment | 18,556.2 | 4664.2 | 18,817.6 | 5831.6 | |

| Equipment | Case IX | Case X | Case XI | Case XII | Lifespan |

| Solar collector TS 300 5x | 2128.8 | 2128.8 | 2128.8 | 2128.8 | 30 |

| DHW standby tank 120 L | - | - | - | - | 20 |

| Heat pump- 14 kW | 14,744.0 | - | 14,744.0 | - | 15 |

| Wood fire boiler-14 kW | - | 852.0 | - | 852.0 | 15 |

| Combination tank | 3956.09 | 3956.09 | - | - | 15 |

| Dual coil indirect water tank 120 L | - | - | 1944.8 | 1944.8 | 25 |

| Space-heating buffer tank 500 L | - | - | 906.0 | 906.0 | 15 |

| Collector loop heat exchanger | - | - | 100.0 | 100.0 | 30 |

| Total Investment | 20,828.89 | 6936.89 | 19,823.6 | 5931.6 | 30 |

| Gas Boiler | Heat Pump | Wood Pellet Boiler | |||

|---|---|---|---|---|---|

| Case I | 8970.7 | Case V | 8969.9 | Case VI | 8970.8 |

| Case II | 8911.9 | Case VII | 8970.8 | Case VIII | 8910.2 |

| Case III | 8934.1 | Case IX | 8931.5 | Case X | 8930.2 |

| Case IV | 8947.5 | Case XI | 8942.2 | Case XII | 8943.7 |

| Heating | Domestic Hot Water | |||

|---|---|---|---|---|

| Cases | Software | Real-Time | Software | Real-Time |

| ST heat pump | 8969.90 | 1131.02 | 2040.65 | 768.50 |

| ST wood-fired boiler | 8943.70 | 4547.40 | 2040.65 | 725.57 |

| ST gas boiler | 8970.70 | 3467.79 | 2040.65 | 792.35 |

| Heat Pump | CO2 [kg] | El. (kWh) | Wood-Fired | Pellets [kg] | CO2 [kg] | Gas Boiler | CO2 [kg] | N.Gas [kg] |

|---|---|---|---|---|---|---|---|---|

| Case V | 254.06 | 381.5 | Case VI | 579.7 | 179.7 | Case I | 711.29 | 336.4 |

| Case VII | 247.24 | 371.24 | Case VIII | 563.6 | 174.7 | Case II | 684.79 | 323.8 |

| Case IX | 324.78 | 487.7 | Case X | 734.3 | 227.6 | Case III | 853.08 | 403.4 |

| Case XI | 246.29 | 369.8 | Case XII | 560.8 | 173.8 | Case IV | 681.55 | 322.3 |

| Case I | Case II | Case III | Case IV |

| 159.14 | 159.81 | 159.56 | 159.41 |

| Case V | Case VI | Case VII | Case VIII |

| 247.47 | 230.73 | 247.56 | 230.94 |

| Case IX | Case X | Case XI | Case XII |

| 247.53 | 230.87 | 230.87 | 247.51 |

| Case I | Case II | Case III | Case IV |

| 37,496.36 | 35,884.69 | 33,628.54 | 35,671.05 |

| Case V | Case VI | Case VII | Case VIII |

| 49,519.68 | 58,207.72 | 49,063.36 | 56,205.22 |

| Case IX | Case X | Case XI | Case XII |

| 45,551.76 | 54,261.96 | 47,371.21 | 61,262.56 |

| Case | GWP kg CO2eq | AP kg SO2eq | EP kg (PO4)3−eq | ODP kg CFC11eq | POCP kg C2H4eq | NHW kg |

|---|---|---|---|---|---|---|

| I | 10,549.77 | 48.39 | 17.83 | 0.00253 | 3.68 | 1876.17 |

| II | 14,339.08 | 63.34 | 19.27 | 0.0033 | 3.80 | 1247.27 |

| III | 24,869.33 | 109.32 | 29.09 | 0.0052 | 5.29 | 1284.77 |

| IV | 21,190.66 | 92.92 | 34.97 | 0.0037 | 4.67 | 5282.93 |

| V | 17,592.63 | 89.27 | 22.2 | 0.00398 | 5.33 | 1833.69 |

| VI | 14,611.98 | 74.39 | 21.11 | 0.0029 | 9.11 | 6178.25 |

| VII | 21,180.22 | 103.07 | 23.47 | 0.00468 | 5.39 | 1197.44 |

| VIII | 18,401.30 | 89.34 | 22.55 | 0.0036 | 9.23 | 5549.34 |

| IX | 34,000.20 | 162.11 | 35.26 | 0.00698 | 7.51 | 1318.23 |

| X | 28,931.55 | 135.32 | 32.37 | 0.0056 | 10.72 | 5586.85 |

| XI | 28,003.48 | 132.49 | 39.14 | 0.00508 | 6.26 | 5232.08 |

| XII | 25,252.87 | 118.92 | 38.25 | 0.0041 | 10.10 | 9585.00 |

| Ranking | Priority | Score | Ranking | Priority | Score |

|---|---|---|---|---|---|

| 1 | Case VI | 4.4814 | 7 | Case XI | 10.3488 |

| 2 | Case IX | 5.3568 | 8 | Case I | 11.2578 |

| 3 | Case XII | 5.5442 | 9 | Case IV | 12.1477 |

| 4 | Case V | 7.5302 | 10 | Case X | 12.4270 |

| 5 | Case VIII | 7.5302 | 11 | Case III | 13.9121 |

| 6 | Case VII | 9.8262 | 12 | Case II | 16.9924 |

| Case I | Case II | Case III | Case IV |

| 2.68 | 3.31 | 3.94 | 3.38 |

| Case V | Case VI | Case VII | Case VIII |

| 6.68 | 1.71 | 6.77 | 2.15 |

| Case IX | Case X | Case XI | Case XII |

| 7.56 | 2.57 | 7.16 | 2.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Košičan, J.; Pardo Picazo, M.Á.; Vilčeková, S.; Košičanová, D. Life Cycle Assessment and Economic Energy Efficiency of a Solar Thermal Installation in a Family House. Sustainability 2021, 13, 2305. https://doi.org/10.3390/su13042305

Košičan J, Pardo Picazo MÁ, Vilčeková S, Košičanová D. Life Cycle Assessment and Economic Energy Efficiency of a Solar Thermal Installation in a Family House. Sustainability. 2021; 13(4):2305. https://doi.org/10.3390/su13042305

Chicago/Turabian StyleKošičan, Jaroslav, Miguel Ángel Pardo Picazo, Silvia Vilčeková, and Danica Košičanová. 2021. "Life Cycle Assessment and Economic Energy Efficiency of a Solar Thermal Installation in a Family House" Sustainability 13, no. 4: 2305. https://doi.org/10.3390/su13042305

APA StyleKošičan, J., Pardo Picazo, M. Á., Vilčeková, S., & Košičanová, D. (2021). Life Cycle Assessment and Economic Energy Efficiency of a Solar Thermal Installation in a Family House. Sustainability, 13(4), 2305. https://doi.org/10.3390/su13042305