Circular Economy and Internet of Things: Mapping Science of Case Studies in Manufacturing Industry

Abstract

:1. Introduction

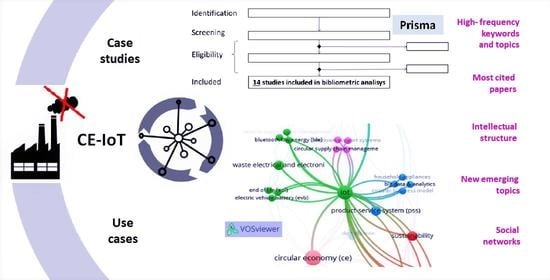

- What are the high frequency of keywords and relevant topics associated with the IoT and CE relationship?

- What are the most cited papers among the relevant collection?

- What main references or intellectual structures do the researchers adopt to develop their research concerning the IoT and CE relationship?

- What are the emerging themes regarding the IoT and CE relationship?

- What is the social structure of the field of study about the IoT and CE relationship?

2. Circular Economy and Internet of Things Concepts

3. Research Methodology

3.1. Define the Research Questions and Choose the Appropriate Bibliometric Methods

3.2. PRISMA Process: Select the Database That Contains Bibliometric Data, Filter the Core Document Set, and Export the Data from the Selected Database

3.2.1. Identification Phase

3.2.2. Screening Phase

3.2.3. Eligibility Phase

3.2.4. Inclusion Phase

3.3. Select the Bibliometric Software to Be Employed for Analysis and Decide which Visualization Method Should Be Used on the Results

4. Results

4.1. Co-Occurrence Analysis: High-Frequency of Keywords and Relevant Topics Associated with “IoT and CE”

4.1.1. Co-Occurrence of Keywords’ Analysis

4.1.2. Terms Map Analysis

4.2. Citation Analysis of Documents: The Most Cited Papers from the Relevant Collection

4.3. Co-Citation Analysis: The Intellectual Structure of the “IoT and CE”

- Cluster one:

- ∘

- Bakker, C.; Wang, F.; Huisman, J.; Den Hollander, M. Products that go round: exploring product life extension through design. Journal of Cleaner Production, 69, 10–16, (2014). Doi 10.1016/J.Jclepro.2014.01.028.

- ∘

- Lieder, M.; Rashid, A. Towards circular economy implementation: a comprehensive review in context of manufacturing industry. Journal of Cleaner Production, 115, 36–51, (2016). Doi 10.1016/J.Jclepro.2015.12.042.

- Cluster two:

- ∘

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The global e-waste monitor 2017: Quantities, flows and resources. United Nations University, International Telecommunication Union, and International Solid Waste Association, (2017).

- Cluster three:

- ∘

- Alvarez, R.; Ruiz-Puente, C. Development of the tool symbiosis to support the transition towards a circular economy based on industrial symbiosis strategies. Waste and Biomass Valorization, 8(5), 1521–1530, (2017). Doi 10.1007/S12649-016-9748-1.

- Cluster four:

- ∘

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? Journal of Cleaner Production, 143, 757–768, (2017). Doi 10.1016/J.Jclepro.2016.12.048.

4.4. Bibliographic Coupling: New Emerging Themes from the Relevant Collection

- Cluster one:

- ∘

- Garrido-Hidalgo et al. [38]: propose an end-to-end solution for Reverse Supply Chain Management (R-SCM) based on cooperation between different IoT communication standards, enabling cloud-based inventory monitoring of WEEE through embedded sensors.

- ∘

- Kerdlap et al. [44]: examine industry technologies and research across the six themes (design for zero waste, smart waste audit and reduction planning, smart waste collection, high-value mixed waste processing, collaborative platform for industrial symbiosis, and waste to resource conversion and recycling) to determine how the technologies can support ZWM. Regarding the smart waste collection systems, the use of IoT technologies should be applied to ZWM overall so that “waste generators, collectors, and converters can be integrated on a single system that shares data to facilitate greater waste to resource exchanges” (p. 17).

- Cluster two:

- ∘

- Bressanelli et al. [35]: develop a conceptual framework, based on the literature and a case study to implement a usage-focused servitized business model focused on the Internet of Things (IoT), Big Data, and Analytics, and identifies eight specific functionalities enabled by such technologies.

- ∘

- Turner et al. [47]: explore the viability of a re-distributed business model for manufacturers employing new manufacturing technologies such as additive manufacturing or three-dimensional (3D) printing, as part of a sustainable and circular production and consumption system. The authors emphasized the importance of the “ways in which the different functions representing supply, production, distribution, and use can communicate with each other through the transformation of materials into products, service offerings, and data, providing a guide for the implementation of re-distributed manufacturing processes into a consumer goods operation” (p. 16).

4.5. Co-Authorship Analysis: Social Structure of the Field

- Figure 2 → Appendix A. Co-occurrence analysis;

- Figure 4 → Appendix B. “Terms map” based on text data;

- Figure 9 → Appendix C. Cited references;

- Figure 10 → Appendix D. Emerging fields;

- → Appendix E. Network visualization of co-authorship analysis;

- → Appendix F. Social structure.

5. Discussion

6. Conclusions

6.1. Contributions to Theory

6.2. Managerial Contributions

6.3. Research Limitations and Suggestions for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Co-Occurrence Analysis

| Cluster 1 (Red) | Cluster 2 (Dark Green) | Cluster 3 (Dark Blue) | Cluster 4 (Yellow) | Cluster 5 (Purple) | Cluster 6 (Blue) |

|---|---|---|---|---|---|

| 5g Constrained application protocol (coap) Devices profile for web services (dpws) IIoT Industrial Industrial cloud Lightweight interactions Machine to machine (m2m) MQ telemetry transport (mqtt) Sustainability | Bluetooth low energy (ble) Electric vehicle battery (evb) End of life (eol) IoT Lorawan Reverse supply chain (rsc) Reverse supply chain management (r-scm) Waste electrical and electronic equipment (weee) | Big data and analytics Circular business model Digitalization Household appliances Predictive maintenance Product-service system (pss) Servitization Smart lighting | 3d-cad Bill of materials CO2 emission Global supply chain Life cycle inventory database Recycling Sharing data | Decision-making support Early design phase Modular design Product architecture Supply chain management Upgrade design | 3d printing Business model Circular production Industry 4.0 Re-distributed manufacturing |

| Cluster 7 (orange) | Cluster 8 (brown) | Cluster 9 (pink) | Cluster 10 (rose) | Cluster 11 (green) | |

| Data-driven Demand response Energy-intensive industries Particle swarm optimization Sustainable intelligent manufacturing | Data-driven models Machine learning Mathematical modelling Process resilience Waste valorisation | Circular supply chain management Decision support systems Semantic technology Zero waste | Circular economy (ce) Cost optimization Reverse logistics Value flow analysis | Industrial ecology Industrial symbiosis Sustainable manufacturing Waste management |

Appendix B. “Terms Map” Based on Text Data

| Cluster 1 (Red) | Cluster 2 (Green) | Cluster 3 (Blue) | Cluster 4 (Yellow) |

|---|---|---|---|

| Analysis Capability End-of-life (eol) Internet of Things (IoT) IoT technology Management Predictive maintenance Stakeholder Tracking Waste electrical and electronic equipment (weee) | Appropriate supplier Cost Efficiency Enterprise Factory Procurement stage Recycling Reduction Reuse | Data Energy Manufacturer Manufacturing Process resilience Waste valorization | Business Product usage Residual value Resource Resource efficiency Time |

Appendix C. Cited References

| Cluster 1 (Red) | Cluster 2 (Green) | Cluster 3 (Blue) | Cluster 4 (Yellow) |

|---|---|---|---|

| Bakker C, 2014, J Clean Prod, V69, P10, Doi 10.1016/J.Jclepro.2014.01.028 Ellen Macarthur Foundation, 2016, Int Ass Unl Circ Ec Ghisellini P, 2016, J Clean Prod, V114, P11, Doi 10.1016/J.Jclepro.2015.09.007 Govindan K, 2015, Eur J Oper Res, V240, P603, Doi 10.1016/J.Ejor.2014.07.012 Kirchherr J, 2017, Resour Conserv Recy, V127, P221, Doi 10.1016/J.Resconrec.2017.09.005 Lieder M, 2016, J Clean Prod, V115, P36, Doi 10.1016/J.Jclepro.2015.12.042 Linder M, 2017, Bus Strateg Environ, V26, P182, Doi 10.1002/Bse.1906 Murray A, 2017, J Bus Ethics, V140, P369, Doi 10.1007/S10551-015-2693-2 Pagoropoulos A, 2017, Proc Cirp, V64, P19, Doi 10.1016/J.Procir.2017.02.047 Pialot O, 2017, J Clean Prod, V141, P538, Doi 10.1016/J.Jclepro.2016.08.161 Rymaszewska A, 2017, Int J Prod Econ, V192, P92, Doi 10.1016/J.Ijpe.2017.02.016 Tukker A, 2015, J Clean Prod, V97, P76, Doi 10.1016/J.Jclepro.2013.11.049 Tukker A., 2004, Business Strategy En, Doi [10.1002/Bse.414, Doi 10.1002/Bse.414] Yin R.K., 2009, Case Study Res Desig | Balde C.P., 2017, Global E Waste Monit Dekker R., 2013, Reverse Logistics Qu Garrido-Hidalgo C, 2018, Ieee Access, V6, P28417, Doi 10.1109/Access.2018.2836677 Genovese A, 2017, Omega-Int J Manage S, V66, P344, Doi 10.1016/J.Omega.2015.05.015 Gu F, 2017, Waste Manage, V68, P434, Doi 10.1016/J.Wasman.2017.07.037 Gunasekaran A, 2004, Eur J Oper Res, V159, P269, Doi 10.1016/J.Ejor.2003.08.016 Islam Mt, 2018, Resour Conserv Recy, V137, P48, Doi 10.1016/J.Resconrec.2018.05.026 Jerbia R, 2018, Comput Ind Eng, V118, P23, Doi 10.1016/J.Cie.2018.02.011 Roda-Sanchez L, 2018, J Sensors, V2018, Doi 10.1155/2018/6272793 Srinivasan R, 2018, Prod Oper Manag, V27, P1849, Doi 10.1111/Poms.12746 Tibben-Lembke R.S., 2002, Supply Chain Manag, V7, P271, Doi 10.1108/13598540210447719 Zhong Ry, 2017, Engineering, V3, P616, Doi 10.1016/J.Eng.2017.05.015 | Alvarez R, 2017, Waste Biomass Valori, V8, P1521, Doi 10.1007/S12649-016-9748-1 Escrig Ej, 2019, Food Control, V104, P358, Doi 10.1016/J.Foodcont.2019.05.013 Fisher O, 2018, J Manuf Syst, V47, P53, Doi 10.1016/J.Jmsy.2018.03.005 Gani R, 2004, Comput Chem Eng, V28, P2441, Doi 10.1016/J.Compchemeng.2004.08.010 Qin Sj, 2014, Aiche J, V60, P3092, Doi 10.1002/Aic.14523 Sadati N, 2018, Expert Syst Appl, V93, P456, Doi 10.1016/J.Eswa.2017.10.028 Simeone A, 2018, Sensors-Basel, V18, Doi 10.3390/S18113742 | Geissdoerfer M, 2017, J Clean Prod, V143, P757, Doi 10.1016/J.Jclepro.2016.12.048 Jabbour Abld, 2018, Ann Oper Res, V270, P273, Doi 10.1007/S10479-018-2772-8 Okorie O, 2018, Energies, V11, Doi 10.3390/En11113009 Stock T, 2016, Proc Cirp, V40, P536, Doi 10.1016/J.Procir.2016.01.129 |

Appendix D. Emerging Fields

Appendix E. Network Visualization of Co-Authorship Analysis

Appendix F. Social structure

References

- Okorie, O.; Salonitis, K.; Charnley, F.; Moreno, M.; Turner, C.; Tiwari, A. Digitisation and the Circular Economy: A review of current research and future trends. Energies 2018, 11, 3009. [Google Scholar] [CrossRef] [Green Version]

- Alcayaga, A.; Wiener, M.; Hansen, E.G. Towards a framework of smart-circular systems: An integrative literature review. J. Clean. Prod. 2019, 221, 622–634. [Google Scholar] [CrossRef]

- MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Nižetić, S.; Šolić, P.; González-De-Artaza, D.L.-D.-I.; Patrono, L. Internet of Things (IoT): Opportunities, issues and challenges towards a smart and sustainable future. J. Clean. Prod. 2020, 274, 122877. [Google Scholar] [CrossRef]

- Nobre, G.C.; Tavares, E. Scientific literature analysis on Big Data and Internet of Things applications on Circular Economy: A bibliometric study. Scientometrics 2017, 111, 463–492. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2019, 58, 1662–1687. [Google Scholar] [CrossRef] [Green Version]

- Zupic, I.; Čater, T. Bibliometric methods in management and organization. Organ. Res. Methods 2014, 18, 429–472. [Google Scholar] [CrossRef]

- Drisko, J.W.; Maschi, T. Content Analysis; Oxford University Press: New York, NY, USA, 2016. [Google Scholar]

- Nobre, G.C.; Tavares, E. Assessing the role of big data and the Internet of Things on the transition to Circular Economy: Part I: An extension of the resolve framework proposal through a literature review. Johns. Matthey Technol. Rev. 2020, 64, 19–31. [Google Scholar] [CrossRef]

- Velvizhi, G.; Shanthakumar, S.; Das, B.; Pugazhendhi, A.; Priya, T.S.; Ashok, B.; Nanthagopal, K.; Vignesh, R.; Karthick, C. Biodegradable and non-biodegradable fraction of municipal solid waste for multifaceted applications through a closed loop integrated refinery platform: Paving a path towards circular economy. Sci. Total Environ. 2020, 731, 138049. [Google Scholar] [CrossRef]

- Marino, A.; Pariso, P. Comparing European countries’ performances in the transition towards the Circular Economy. Sci. Total Environ. 2020, 729, 138142. [Google Scholar] [CrossRef] [PubMed]

- Demestichas, K.; Daskalakis, E. Information and communication technology solutions for the Circular Economy. Sustain. J. Rec. 2020, 12, 7272. [Google Scholar] [CrossRef]

- De Jesus, A.; Antunes, P.; Santos, R.; Mendonça, S. Eco-innovation in the transition to a Circular Economy: An analytical literature review. J. Clean. Prod. 2018, 172, 2999–3018. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Rosa, P. Recycling of end-of-life vehicles: Assessing trends and performances in Europe. Technol. Forecast. Soc. Chang. 2020, 152, 119887. [Google Scholar] [CrossRef]

- Miorandi, D.; Sicari, S.; De Pellegrini, F.; Chlamtac, I. Internet of Things: Vision, applications and research challenges. Ad Hoc Netw. 2012, 10, 1497–1516. [Google Scholar] [CrossRef] [Green Version]

- Da Xu, L.; He, W.; Li, S. Internet of Things in industries: A survey. IEEE Trans. Ind. Inf. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Hassan, R.; Qamar, F.; Hasan, M.K.; Aman, A.H.M.; Ahmed, A.S. Internet of Things and its applications: A comprehensive survey. Symmetry 2020, 12, 1674. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of Things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742. [Google Scholar] [CrossRef] [Green Version]

- Brous, P.; Janssen, M.; Herder, P. The dual effects of the Internet of Things (IoT): A systematic review of the benefits and risks of IoT adoption by organizations. Int. J. Inf. Manag. 2020, 51, 101952. [Google Scholar] [CrossRef]

- Askoxylakis, I. A framework for pairing circular economy and the Internet of Things. In Proceedings of the 2018 IEEE International Conference on Communications (ICC), Kansas City, MO, USA, 20–24 May 2018; pp. 1–6. [Google Scholar]

- Ramadoss, T.S.; Alam, H.; Seeram, R. Artificial Intelligence and Internet of Things enabled Circular economy. Int. J. Eng. Sci. 2018, 7, 55–63. [Google Scholar] [CrossRef]

- Reuter, M.A. Digitalizing the Circular Economy: Circular Economy engineering defined by the metallurgical Internet of Things. Met. Mater. Trans. A 2016, 47, 3194–3220. [Google Scholar] [CrossRef]

- García-Muiña, F.E.; Medina-Salgado, M.S.; Ferrari, A.M.; Cucchi, M. Sustainability transition in Industry 4.0 and Smart Manufacturing with the triple-layered business model canvas. Sustainability 2020, 12, 2364. [Google Scholar] [CrossRef] [Green Version]

- González-Sánchez, R.; Settembre-Blundo, D.; Ferrari, A.M.; García-Muiña, F.E. Main dimensions in the building of the Circular Supply chain: A literature review. Sustain. J. Rec. 2020, 12, 2459. [Google Scholar] [CrossRef] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; for the PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. BMJ 2009, 339, b2535. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Liu, W. A tale of two databases: The use of Web of Science and Scopus in academic papers. Scientometrics 2020, 123, 321–335. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, M.; Fleury, A.; Lopes, A.P. An overview of the literature on technology roadmapping (TRM): Contributions and trends. Technol. Forecast. Soc. Chang. 2013, 80, 1418–1437. [Google Scholar] [CrossRef]

- Martín-Martín, A.; Thelwall, M.; Orduna-Malea, E.; López-Cózar, E.D. Google Scholar, Microsoft Academic, Scopus, Dimensions, Web of Science, and OpenCitation’ COCI: A multidisciplinary comparison of coverage via citations. Scientometrics 2021, 126, 871–906. [Google Scholar] [CrossRef]

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Mongeon, P.; Paul-Hus, A. The journal coverage of Web of Science and Scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Bown, M.; Sutton, A. Quality control in systematic reviews and meta-analyses. Eur. J. Vasc. Endovasc. Surg. 2010, 40, 669–677. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Krefting, L. Rigor in qualitative research: The assessment of trustworthiness. Am. J. Occup. Ther. 1991, 45, 214–222. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luis, E.C.; Celma, D. Circular Economy. A review and bibliometric analysis. Sustain. J. Rec. 2020, 12, 6381. [Google Scholar] [CrossRef]

- Meline, T. Selecting studies for systemic review: Inclusion and exclusion criteria. Contemp. Issues Commun. Sci. Disord. CICSD 2006, 33, 21–27. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring how usage-focused business models enable circular economy through digital technologies. Sustain. J. Rec. 2018, 10, 639. [Google Scholar] [CrossRef] [Green Version]

- Fisher, O.J.; Watson, N.J.; Escrig, J.E.; Gomes, R.L. Intelligent resource use to deliver waste valorisation and process resilience in manufacturing environments: Moving towards sustainable process manufacturing. Johns. Matthey Technol. Rev. 2020, 64, 93–99. [Google Scholar] [CrossRef]

- Fisher, O.J.; Watson, N.J.; Escrig, J.E.; Witt, R.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Considerations, challenges and opportunities when developing data-driven models for process manufacturing systems. Comput. Chem. Eng. 2020, 140, 106881. [Google Scholar] [CrossRef]

- Garrido-Hidalgo, C.; Olivares, T.; Ramirez, F.J.; Roda-Sanchez, L. An end-to-end Internet of Things solution for reverse supply chain management in Industry 4.0. Comput. Ind. 2019, 112, 103127. [Google Scholar] [CrossRef]

- Garrido-Hidalgo, C.; Ramirez, F.J.; Olivares, T.; Roda-Sanchez, L. The adoption of internet of things in a circular supply chain framework for the recovery of WEEE: The case of lithium-ion electric vehicle battery packs. Waste Manag. 2020, 103, 32–44. [Google Scholar] [CrossRef] [PubMed]

- Hatzivasilis, G.; Fysarakis, K.; Soultatos, O.; Askoxylakis, I.; Papaefstathiou, I.; Demetriou, G. The Industrial Internet of Things as an enabler for a Circular Economy Hy-LP: A novel IIoT protocol, evaluated on a wind parks SDN/NFV-enabled 5G industrial network. Comput. Commun. 2018, 119, 127–137. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Balkenende, R. Opportunities and challenges in IoT-enabled circular business model implementation–A case study. Resour. Conserv. Recycl. 2021, 162, 11. [Google Scholar] [CrossRef]

- Inoue, M.; Yamada, S.; Miyajima, S.; Ishii, K.; Hasebe, R.; Aoyama, K.; Yamada, T.; Bracke, S. A modular design strategy considering sustainability and supplier selection. J. Adv. Mech. Des. Syst. Manuf. 2020, 14, JAMDSM0023. [Google Scholar] [CrossRef] [Green Version]

- Irie, H.; Yamada, T. Decision support model for economical material carbon recovery and reduction by connecting supplier and disassembly part selections. J. Adv. Mech. Des. Syst. Manuf. 2020, 14, JAMDSM0024. [Google Scholar] [CrossRef] [Green Version]

- Kerdlap, P.; Low, J.S.C.; Ramakrishna, S. Zero waste manufacturing: A framework and review of technology, research, and implementation barriers for enabling a circular economy transition in Singapore. Resour. Conserv. Recycl. 2019, 151, 104438. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Liu, Y.; Yang, H.; Lv, J.; Ren, S. Data-driven sustainable intelligent manufacturing based on demand response for energy-intensive industries. J. Clean. Prod. 2020, 274, 123155. [Google Scholar] [CrossRef]

- Mboli, J.S.; Thakker, D.; Mishra, J.L. An Internet of Things-enabled decision support system for circular economy business model. Softw. Pr. Exp. 2020, 16. [Google Scholar] [CrossRef]

- Turner, C.J.; Moreno, M.; Mondini, L.; Salonitis, K.; Charnley, F.; Tiwari, A.; Hutabarat, W. Sustainable production in a Circular Economy: A business model for re-distributed manufacturing. Sustainability 2019, 11, 4291. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Cai, Y.; Xiao, Y.; Chen, X.; Zeng, H. The optimization of reverse logistics cost based on value flow analysis–a case study on automobile recycling company in China. J. Intell. Fuzzy Syst. 2018, 34, 807–818. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- van Eck, N.J.; Waltman, L. Text Mining and Visualization Using VOSviewer. ISSI Newsletter. 2011, 7(3), pp. 50–54, (paper, preprint) (arXiv:1109.2058). Available online: https://www.vosviewer.com/text-mining-and-visualization-using-vosviewer (accessed on 15 December 2020).

- van Eck, N.J.; Waltman, L. VOSviewer Manual. 2020. Available online: https://www.vosviewer.com/getting-started#vosviewer-manual (accessed on 8 December 2020).

- Zhang, J.; Yu, Q.; Zheng, F.; Long, C.; Lu, Z.; Duan, Z. Comparing keywords plus of WOS and author keywords: A case study of patient adherence research. J. Assoc. Inf. Sci. Technol. 2016, 67, 967–972. [Google Scholar] [CrossRef]

- van Eck, N.; Waltman, L. Visualizing bibliometric networks. In Measuring Scholarly Impact: Methods and Practice; Ding, Y., Rousseau, R., Wolfram, D., Eds.; Springer International Publishing: Berlin, Germany, 2014; pp. 285–320. [Google Scholar]

- Bergh, J.C.V.D. Six policy perspectives on the future of a semi-circular economy. Resour. Conserv. Recycl. 2020, 160, 104898. [Google Scholar] [CrossRef]

- De Man, R.; Friege, H. Circular Economy: European policy on shaky ground. Waste Manag. Res. 2016, 34, 93–95. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A review and typology of circular economy business model patterns. J. Ind. Ecol. 2018, 23, 36–61. [Google Scholar] [CrossRef] [Green Version]

- Oghazi, P.; Mostaghel, R. Circular business model challenges and lessons learned—An industrial perspective. Sustain. J. Rec. 2018, 10, 739. [Google Scholar] [CrossRef] [Green Version]

- MacArthur Foundation. Intelligent Assets: Unlocking the Circular Economy Potential; Ellen MacArthur Foundation: Cowes, UK, 2016; Available online: https://www.ellenmacarthurfoundation.org/publications/intelligent-assets (accessed on 2 March 2021).

| Secondary Research Questions | Bibliometric Methods | Definitions |

|---|---|---|

| What are the high frequency of keywords and relevant topics associated with the Internet of Things (IoT) and circular economy (CE) relationship? | Co-occurrence analysis | Constructing a similarity measure by the words of the documents, while other bibliometric techniques associate documents indirectly through citations or co-authorships. The words of the documents that frequently co-occur mean that there is a connection among them; therefore, the concepts behind those words are closely related. This analysis is employed to build a conceptual structure of a field, whose output is a network of themes and their relations. |

| What are the most cited papers among the relevant collection? | Citation analysis | Finding the documents, authors, and journals that are prominent in a certain research field through citation rates; meaning that, for example, if a paper is heavily cited, it is supposed to be relevant for the researchers’ area of study. |

| What main references or intellectual structure do the researchers adopt to develop their research concerning the IoT and CE relationship? | Co-citation analysis | Connecting documents, authors, or journals based on mutual appearances in reference register to establish measures of similarity. The assumption is that if two items are cited together, their content is potentially related, which means that experts cite publications that they consider valuable for the subject under study. This is most used to filter the important works or authors to the field. |

| What are the emerging themes regarding the IoT and CE relationship? | Bibliographic coupling | Employs the number of references shared by two documents as a measure of the similarity between them, which means that the connection of the documents is measured by the overlapping bibliographies. This method should be applied for mapping research fronts and emerging fields, where citation data do not exist. The bibliographic coupling identifies a research front better than that of a co-citation analysis, which is better to map older papers. |

| What is the social structure of the field of study about “IoT and CE” relationship? | Co-authorship analysis | Examines collaboration on the level of authors, institutions, and countries when co-publish a paper. Reflects stronger social networks than other measures. |

| Author (Year) | Study Objective | Case Focus |

|---|---|---|

| Bressanelli, G.; Adrodegari, F.; Perona, M.; et al. [35] | Develops a conceptual framework based on the literature and a case study to implement a usage-focused servitized business model employing Internet of Things (IoT), big data, and analytics. Identifies eight specific functionalities enabled by such technologies. | Servitized business model; retails household appliances company (washing machines, dishwashers, and tumble dryers). |

| Fisher, O.J.; Watson, E.; et al. [36] | Explores how data-driven modelling may facilitate and advance CE principles within process manufacturing systems, specifically waste valorisation and process resilience. | Data-driven models; case studies of two manufacturing process: (a) minimising resource consumption of industrial cleaning processes; (b) transforming wastewater treatment plants (WWTPs) into manufacturing centres. |

| Fisher, O.J.; Watson, E.; et al. [37] | Explores how data-driven models can be utilised to characterise process streams and support the implementation of the circular economy principles, process resilience, and waste valorisation. The considerations and challenges faced when developing data-driven models for manufacturing systems. | Data-driven models; food and drink industry and waste management industry. |

| Garrido-Hidalgo, C.; Olivares, T.; Ramirez, J.; et al. [38] | Proposes an end-to-end solution for reverse supply chain management (R-SCM) based on cooperation between different IoT communication standards, enabling cloud-based inventory monitoring of waste electrical and electronic equipment (WEEE) through embedded sensors. | Recovery of WEEE from computer-based components; implementation of an end-to-end system, addressing the deployment of IoT devices and sensors, carrying out a set of experimental tests focused on wireless communications to evaluate its performance; network configuration adopted overcomes the near real-time challenge and provides sufficient coverage to interconnect industrial areas such as warehouses or shop floors; its integration with a cloud-based inventory-management platform. |

| Garrido-Hidalgo, C.; Ramirez, J.; Olivares, T.; et al. [39] | Proposes the circular supply chain (CSC) framework for end-of-life (EoL) management aimed at satisfying the information infrastructure requirements in a particular scenario for the recovery of electric vehicle battery (EVB) packs. Heterogeneous IoT network deployment is proposed in pursuit of a digital CSC information infrastructure. | Disassembly and recovery of the Audi A6 Lithium-ion plug-in electric battery pack. |

| Hatzivasilis, G.; Fysarakis, K.; Soultatos, O.; et al. [40] | Proposes the Hy-LP—a novel hybrid protocol and development framework for Industrial IoT (IIoT) systems. Hy-LP enables the seamless communication of IIoT sensors and actuators, within and across domains, also facilitating the integration of the Industrial Cloud. The applicability of the proposed solutions is validated in the context of a real industrial setting, analyzing the network characteristics and performance requirements of an actual, operating wind park. | Hy-LP was applied on operating wind park, as use case of industrial networks. |

| Ingemarsdotter, E.; Jamsin, E.; Balkenende, R. [41] | Elucidate reasons for the apparent mismatch between the “theoretical opportunities” of IoT for CE as described in literature, and current implementation in practice. Identify opportunities for using IoT to support circular strategies in this specific case. | LED lighting; IoT can support servitized business models; improve tracking and record keeping of in-use and post-use products; enable conditions monitoring and predictive maintenance; improve estimations of remaining lifetime of used products; and inform design decisions to improve durability of products. |

| Inoue, M.; Yamada, S.; Miyajima, S.; et al. [42] | Proposes a modular design and a strategic evaluation method based on the viewpoint of supply chain management considering sustainability and supplier selection simultaneously. The proposed method evaluates the designed modular strategy from the perspectives of cost, environmental load in production and transportation, quality, and procurement lead time. | Modularization of three laptop components: the CPU, motherboard, and memory; indicatores evaluate the efficiencies of the candidate suppliers (perspectives of cost, environmental load in production and transportation, quality, and procurement lead time); compiling and assembling laptop components. |

| Irie, H.; Yamada, T. [43] | Proposes a decision support model for economical carbon recovery by connecting supplier and disassembly part selections on procurement and EOL stages. | Decision support model for economical material-based carbon recovery by connecting supplier and disassembly part selections; use case: vacuum cleaner. A bill of materials (BOM) is prepared using an Asian supplier selection with the 3D-CAD model and life cycle inventory (LCI) database. Disassembled parts of the EOL assembly products from the BOM data are selected for either recycling or disposal using 0–1 integer programming with ε constraint method. |

| Kerdlap, P.; Low, J.S.C.; Ramakrishna, S. [44] | A systematic literature review is used to examine industry technologies and research across the six themes to determine how the technologies can support zero waste manufacturing-ZWM; six themes of design for zero waste, smart waste audit and reduction planning, smart waste collection, high-value mixed waste processing, collaborative platform for industrial symbiosis, and waste to resource conversion and recycling. The research reveals that a variety of mature waste measurement, collection, and conversion technologies can be integrated through Internet-of-Things applications and a collaborative platform for industrial symbiosis to support Singapore and other countries in developing a ZWM ecosystem. | Technical limitations of implementing ZWM technologies in dense urban settings; the case study is Singapore. |

| Ma, S.; Zhang, Y.; Liu, Y.; et al. [45] | Propose a framework of data-driven sustainable intelligent/smart manufacturing based on demand response for energy-intensive industries. The technological architecture was designed to implement the proposed framework, and multilevel demand response models were developed based on machine, shop-floor, and factory to save energy cost. | Energy-intensive industries; energy utilization problems; the application is an analysis of the ball mills in a slurry shop-floor; a cooperative ceramic manufacturing company to demonstrate the proposed framework and models. |

| Mboli, J.S.; Thakker, D.; Mishra, J.L. [46] | Proposes an IoT-enabled decision support system (DSS) for CE business model that effectively allows tracking, monitoring, and analysing products in real time with the focus on residual value. The business model is implemented using an ontological model. This model is complemented by a semantic decision support system. | IoT-enabled decision support system (DSS) and the ontological model for CE business model to track, monitor, and analysis products in real time with the focus on residual value; use case: coffee machine. |

| Turner, C.; Moreno, M.; Mondini, L.; et al. [47] | Business models for re-distributed manufacture (RdM) are developed using an IDEF (Icam DEFinition for Function Modelling) description to serve as a guide for the implementation of the RdM concept in the consumer goods industry. Explores the viability of a re-distributed business model for manufacturers employing new manufacturing technologies such as additive manufacturing or three-dimensional (3D) printing, as part of a sustainable and circular production and consumption system. | Business models for re-distributed manufacture (RdM) are developed to data captured from, and communicated among, supply, production, distribution and use; use case: shoe manufacturing industry; ShoeLab project. |

| Zhou, Z.; Cai, Y.; Xiao, Y.; et al. [48] | Proposes value flow analysis of circular economy into the cost accounting, analysis and optimization of enterprise reverse logistics; take into account the external costs (secondary pollution and environmental benefits of recycling) in the reverse logistics cost accounting. | Cost optimization management; automobile recycling company. |

| Authors | WoS Categories | Research Areas |

|---|---|---|

| Fisher, OJ; Watson, NJ; Escrig, JE; Gomes, RL [36] | Chemistry, Physical | Chemistry |

| Zhou, ZF; Cai, YF; Xiao, YX; Chen, XH; Zeng, HX [48] | Computer Science, Artificial Intelligence | Computer Science |

| Hatzivasilis, G; Fysarakis, K; Soultatos, O; Askoxylakis, I; Papaefstathiou, I; Demetriou, G [40] | Computer Science, Information Systems; Engineering, Electrical & Electronic; Telecommunications | Computer Science; Engineering; Telecommunications |

| Garrido-Hidalgo, C; Olivares, T; Ramirez, FJ; Roda-Sanchez, L [38] | Computer Science, Interdisciplinary Applications | Computer Science |

| Fisher, OJ; Watson, NJ; Escrig, JE; Witt, R; Porcu, L; Bacon, D; Rigley, M; Gomes, RL [37] | Computer Science, Interdisciplinary Applications; Engineering, Chemical | Computer Science; Engineering |

| Mboli, JS; Thakker, D; Mishra, JL [46] | Computer Science, Software Engineering | Computer Science |

| Kerdlap, P; Low, JSC; Ramakrishna, S [44] | Engineering, Environmental; Environmental Sciences | Engineering; Environmental Sciences and Ecology |

| Garrido-Hidalgo, C; Ramirez, FJ; Olivares, T; Roda-Sanchez, L [39] | Engineering, Environmental; Environmental Sciences | Engineering; Environmental Sciences and Ecology |

| Ingemarsdotter, E; Jamsin, E; Balkenende, R [41] | Engineering, Environmental; Environmental Sciences | Engineering; Environmental Sciences and Ecology |

| Inoue, M; Yamada, S; Miyajima, S; Ishii, K; Hasebe, R; Aoyama, K; Yamada, T; Bracke, S [42] | Engineering, Manufacturing; Engineering, Mechanical | Engineering |

| Irie, H; Yamada, T [43] | Engineering, Manufacturing; Engineering, Mechanical | Engineering |

| Ma, SY; Zhang, YF; Liu, Y; Yang, HD; Lv, JX; Ren, S [45] | Green and Sustainable Science and Technology; Engineering, Environmental; Environmental Sciences | Science and Technology—Other Topics; Engineering; Environmental Sciences and Ecology |

| Bressanelli, G; Adrodegari, F; Perona, M; Saccani, N [35] | Green and Sustainable Science and Technology; Environmental Sciences; Environmental Studies | Science and Technology—Other Topics; Environmental Sciences and Ecology |

| Turner, C; Moreno, M; Mondini, L; Salonitis, K; Charnley, F; Tiwari, A; Hutabarat, W [47] | Green & Sustainable Science & Technology; Environmental Sciences; Environmental Studies | Science & Technology—Other Topics; Environmental Sciences and Ecology |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cavalieri, A.; Reis, J.; Amorim, M. Circular Economy and Internet of Things: Mapping Science of Case Studies in Manufacturing Industry. Sustainability 2021, 13, 3299. https://doi.org/10.3390/su13063299

Cavalieri A, Reis J, Amorim M. Circular Economy and Internet of Things: Mapping Science of Case Studies in Manufacturing Industry. Sustainability. 2021; 13(6):3299. https://doi.org/10.3390/su13063299

Chicago/Turabian StyleCavalieri, Adriane, João Reis, and Marlene Amorim. 2021. "Circular Economy and Internet of Things: Mapping Science of Case Studies in Manufacturing Industry" Sustainability 13, no. 6: 3299. https://doi.org/10.3390/su13063299

APA StyleCavalieri, A., Reis, J., & Amorim, M. (2021). Circular Economy and Internet of Things: Mapping Science of Case Studies in Manufacturing Industry. Sustainability, 13(6), 3299. https://doi.org/10.3390/su13063299