Population Dynamics of Methanogenic Archea in Co-Digestion Systems Operating Different Industrial Residues for Biogas Production

Abstract

:1. Introduction

2. Materials and Methods

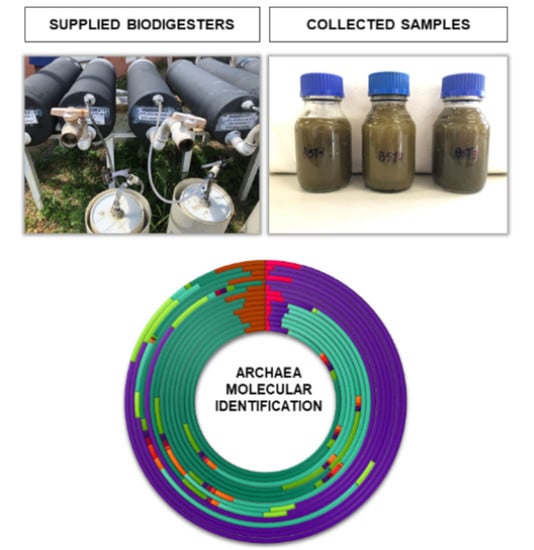

2.1. Pilot-Scale Biodigester

2.2. Substrates

2.3. Experimental Design for the Analysis of Archaea Dynamics

2.4. Analytical Techniques

2.5. Collection and Conservation of Samples

2.6. Sample Selection for Molecular Microbiology Analysis

2.7. DNA Extraction

2.8. Metagenomic Analysis—Sequencing and Bioinformatics

2.9. Statistical Analysis

3. Results and Discussion

3.1. Archaea Acclimatization

3.2. Physicochemical Analysis of Effluents from the Anaerobic Co-Digestion Phase

3.3. Archaea Identification during Anaerobic Co-Digestion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Babu, S.; Rathore, S.S.; Singh, R.; Kumar, S.; Singh, V.K.; Yadav, S.K.; Yadav, V.; Raj, R.; Yadav, D.; Shekhawat, K.; et al. Exploring agricultural waste biomass for energy, food and feed production and pollution mitigation: A review. Bioresour. Technol. 2022, 360, 127566. [Google Scholar] [CrossRef] [PubMed]

- de Vrieze, J.; Christiaens, M.E.; Verstraete, W. The microbiome as engineering tool: Manufacturing and trading between microorganisms. New Biotechnol. 2017, 39, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Latha, K.; Velraj, R.; Shanmugam, P.; Sivanesan, S. Mixing strategies of high solids anaerobic co-digestion using food waste with sewage sludge for enhanced biogas production. J. Clean. Prod. 2019, 210, 388–400. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.S.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Wang, S.; Xu, C.; Song, L.; Zhang, J. Anaerobic Digestion of Food Waste and Its Microbial Consortia: A Historical Review and Future Perspectives. Int. J. Environ. Res. Public Health 2022, 19, 9519. [Google Scholar] [CrossRef]

- Kunz, A.; Steinmetz, R.L.R.; do Amaral, A.C. Fundamentos da digestão anaeróbia, purificação do biogás, uso e tratamento do digestato. In O Processo da Biodigestão; do Amaral, A.C., Steinmetz, R.L.R., Kunz, A., Eds.; Embrapa Suínos e Aves: Santa Catarina, Brazil, 2019; pp. 13–26. [Google Scholar] [CrossRef]

- Rui, J.; Li, J.; Zhang, S.; Yan, X.; Wang, Y.; Li, X. The core populations and co-occurrence patterns of prokaryotic communities in household biogas digesters. Biotechnol. Biofuels 2015, 8, 158. [Google Scholar] [CrossRef]

- Nguyen, L.N.; Nguyen, A.Q.; Nghiem, L.D. Microbial Community in Anaerobic Digestion System: Progression in Microbial Ecology. In Water and Wastewater Treatment Technologies; Bui, X.T., Chiemchaisri, C., Fujioka, T., Varjani, S., Eds.; Springer: Singapore, 2019; pp. 331–335. [Google Scholar] [CrossRef]

- Vendruscolo, E.C.G.; Mesa, D.; Rissi, D.V.; Meyer, B.H.; Pedrosa, F.O.; Souza, E.M.; Cruz, L.M. Microbial communities network analysis of anaerobic reactors fed with bovine and swine slurry. Sci. Total Environ. 2020, 742, 140314. [Google Scholar] [CrossRef]

- Kumar, S.; Krishnani, K.K.; Bhushan, B.; Brahmane, M.P. Metagenomics: Retrospect and prospects in high throughput age. Biotechnol. Res. Int. 2015, 2015, 121735. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Harrison, J.P.; Chronopoulou, P.-M.; Salone, I.; Jilbert, T.; Koho, K.A. 16S and 18S rRNA Gene Metabarcoding Provide Congruent Information on the Responses of Sediment Communities to Eutrophication. Front. Mar. Sci. 2021, 8, 708716. [Google Scholar] [CrossRef]

- Assis, T.I.; Gonçalves, R.F. Valorization of food waste by anaerobic digestion: A bibliometric and systematic review focusing on optimization. J. Environ. Manag. 2022, 320, 115763. [Google Scholar] [CrossRef]

- Xu, R.; Zhang, K.; Liu, P.; Khan, A.; Xiong, J.; Tian, F.; Li, X. A critical review on the interaction of substrate nutrient balance and microbial community structure and function in anaerobic co-digestion. Bioresour. Technol. 2018, 247, 1119–1127. [Google Scholar] [CrossRef] [PubMed]

- Szaja, A.; Montusiewicz, A. Enhancing the co-digestion efficiency of sewage sludge and cheese whey using brewery spent grain as an additional substrate. Bioresour. Technol. 2019, 291, 121863. [Google Scholar] [CrossRef] [PubMed]

- Asunis, F.; De Gioannis, G.; Dessì, P.; Isipato, M.; Lens, P.N.L.; Muntoni, A.; Polettini, A.; Pomi, R.; Rossi, A.; Spiga, D. The dairy biorefinery: Integrating treatment processes for cheese whey valorisation. J. Environ. Manag. 2020, 276, 111240. [Google Scholar] [CrossRef] [PubMed]

- Carota, E.; Crognale, S.; D’Annibale, A.; Gallo, A.M.; Stazi, S.R.; Petruccioli, M. A sustainable use of Ricotta Cheese Whey for microbial biodiesel production. Sci. Total Environ. 2017, 584–585, 554–560. [Google Scholar] [CrossRef]

- Fillaudeau, L.; Blanpain-Avet, P.; Daufin, G. Water, wastewater and waste management in brewing industries. J. Clean. Prod. 2006, 14, 463–471. [Google Scholar] [CrossRef]

- Lu, M.; Chen, S.; Babanova, S.; Phadke, S.; Salvacion, M.; Mirhosseini, A.; Chan, S.; Carpenter, K.; Cortese, R.; Bretschger, O. Long-term performance of a 20-L continuous flow microbial fuel cell for treatment of brewery wastewater. J. Power Sources 2017, 356, 274–287. [Google Scholar] [CrossRef]

- Maintinguer, S.I.; Lazaro, C.Z.; Pachiega, R.; Varesche, M.B.A.; Sequinel, R.; de Oliveira, J.E. Hydrogen bioproduction with Enterobacter sp. isolated from brewery wastewater. Int. J. Hydrogen Energy 2017, 42, 152–160. [Google Scholar] [CrossRef]

- Xia, Y.; Massé, D.I.; McAllister, T.A.; Kong, Y.; Seviour, R.; Beaulieu, C. Identity and diversity of archaeal communities during anaerobic co-digestion of chicken feathers and other animal wastes. Bioresour. Technol. 2012, 110, 111–119. [Google Scholar] [CrossRef]

- Batstone, D.J.; Karakashev, D.; Batstone, D.J.; Trably, E.; Angelidaki, I. Acetate oxidation is the dominant methanogenic pathway of acetate in the absence of Methanosaetaceae. Appl. Environ. Microbiol. 2014, 72, 5138–5141. [Google Scholar] [CrossRef]

- Henard, C.A.; Smith, H.K.; Guarnieri, M.T. Phosphoketolase overexpression increases biomass and lipid yield from methane in an obligate methanotrophic biocatalyst. Metab. Eng. 2017, 41, 152–158. [Google Scholar] [CrossRef]

- Resende, J.A.; Godon, J.J.; Bonnafous, A.; Arcuri, P.B.; Silva, V.L.; Otenio, M.H.; Diniz, C.G. Seasonal variation on microbial community and methane production during anaerobic digestion of cattle manure in Brazil. Microb. Ecol. 2016, 71, 735–746. [Google Scholar] [CrossRef] [PubMed]

- da Silva, G.H.; Barros, N.O.; Santana, L.A.R.; Carneiro, J.D.C.; Otenio, M.H. Shifts of acidogenic bacterial group and biogas production by adding two industrial residues in anaerobic co-digestion with cattle manure. J. Environ. Sci. Health Part A 2021, 56, 1503–1511. [Google Scholar] [CrossRef] [PubMed]

- de Mendonça, H.V.; Ometto, J.P.H.B.; Otenio, M.H.; dos Reis, A.J.D.; Marques, I.P.R. Bioenergy recovery from cattle wastewater in an UASB-AF hybrid reactor. Water Sci. Technol. 2017, 76, 2268–2279. [Google Scholar] [CrossRef] [PubMed]

- APHA. 4500-N NITROGEN. In Standard Methods For the Examination of Water and Wastewater; Lipps, W.C., Baxter, T.E., Braun-Howland, E., Eds.; APHA Press: Washington, DC, USA, 2018. [Google Scholar] [CrossRef]

- Collins, C.H.; Braga, G.L.; Bonato, P.S. Introdução a Métodos Cromatográficos, 7th ed.; Unicamp: São Paulo, Brazil, 1997. [Google Scholar]

- Yu, Z.; Morrison, M. Improved extraction of PCR-quality community DNA from digesta and fecal samples. Biotechniques 2004, 36, 808–812. [Google Scholar] [CrossRef]

- Stevenson, D.M.; Weimer, P.J. Dominance of Prevotella and low abundance of classical ruminal bacterial species in the bovine rumen revealed by relative quantification real-time PCR. Appl. Microbiol. Biotechnol. 2007, 75, 165–174. [Google Scholar] [CrossRef]

- Turner, S.; Pryer, K.M.; Miao, V.P.W.; Palmer, J.D. Investigating deep phylogenetic relationships among cyanobacteria and plastids by small subunit rRNA sequence analysis. J. Eukaryot. Microbiol. 1999, 46, 327–338. [Google Scholar] [CrossRef]

- Caporaso, J.G.; Lauber, C.L.; Walters, W.A.; Berg-Lyons, D.; Huntley, J.; Fierer, N.; Owens, S.M.; Betley, J.; Fraser, L.; Bauer, M.; et al. Ultra-high-throughput microbial community analysis on the Illumina HiSeq and MiSeq platforms. ISME J. 2012, 6, 1621–1624. [Google Scholar] [CrossRef] [Green Version]

- Bolyen, E.; Rideout, J.R.; Dillon, M.R.; Bokulich, N.A.; Abnet, C.C.; Al-Ghalith, G.A.; Alexander, H.; Alm, E.J.; Arumugam, M.; Asnicar, F.; et al. Reproducible, interactive, scalable and extensible microbiome data science using QIIME 2. Nat. Biotechnol. 2019, 37, 852–857. [Google Scholar] [CrossRef]

- Glöckner, F.O.; Yilmaz, P.; Quast, C.; Gerken, J.; Beccati, A.; Ciuprina, A.; Bruns, G.; Yarza, P.; Peplies, J.; Westram, R.; et al. 25 years of serving the community with ribosomal RNA gene reference databases and tools. J. Biotechnol. 2017, 261, 169–176. [Google Scholar] [CrossRef]

- Leahy, S.C.; Kelly, W.J.; Ronimus, R.S.; Wedlock, N.; Altermann, E.; Attwood, G.T. Genome sequencing of rumen bacteria and archaea and its application to methane mitigation strategies. Animal 2013, 7, 235–243. [Google Scholar] [CrossRef]

- Henderson, G.; Cox, F.; Ganesh, S.; Jonker, A.; Young, W.; Janssen, P.H. Rumen microbial community composition varies with diet and host, but a core microbiome is found across a wide geographical range. Sci. Rep. 2015, 5, 14567. [Google Scholar] [CrossRef] [PubMed]

- Danielsson, R.; Dicksved, J.; Sun, L.; Gonda, H.; Müller, B.; Schnürer, A.; Bertilsson, J. Methane production in dairy cows correlates with rumen methanogenic and bacterial community structure. Front. Microbiol. 2017, 8, 226. [Google Scholar] [CrossRef] [PubMed]

- Senés-Guerrero, C.; Colón-Contreras, F.A.; Reynoso-Lobo, J.F.; Tinoco-Pérez, B.; Siller-Cepeda, J.H.; Pacheco, A. Biogas-producing microbial composition of an anaerobic digester and associated bovine residues. Microbiol. Open 2019, 8, e00854. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.; Lü, F.; Mazéas, L.; Desmond-Le Quéméner, E.; Madigou, C.; Guenne, A.; Shaocd, L.; Bouchez, T.; He, P. Stable isotope probing of acetate fed anaerobic batch incubations shows a partial resistance of acetoclastic methanogenesis catalyzed by Methanosarcina to sudden increase of ammonia level. Water Res. 2015, 69, 90–99. [Google Scholar] [CrossRef] [PubMed]

- Venkiteshwaran, K.; Milferstedt, K.; Hamelin, J.; Fujimoto, M.; Johnson, M.; Zitomer, D.H. Correlating methane production to microbiota in anaerobic digesters fed synthetic wastewater. Water Res. 2017, 110, 161–169. [Google Scholar] [CrossRef]

- Li, X.; Guo, S.; Peng, Y.; He, Y.; Wang, S.; Li, L.; Zhao, M. Anaerobic digestion using ultrasound as pretreatment approach: Changes in waste activated sludge, anaerobic digestion performances and digestive microbial populations. Biochem. Eng. J. 2018, 139, 139–145. [Google Scholar] [CrossRef]

- Wang, Q.; Guo, H.; Wang, H.; Urynowicz, M.A.; Hu, A.; Yu, C.P.; Fallgren, P.; Jin, S.; Zheng, H.; Zeng, R.J. Enhanced production of secondary biogenic coalbed natural gas from a subbituminous coal treated by hydrogen peroxide and its geochemical and microbiological analyses. Fuel 2019, 236, 1345–1355. [Google Scholar] [CrossRef]

- Yıldırım, E.; Ince, O.; Aydin, S.; Ince, B. Improvement of biogas potential of anaerobic digesters using rumen fungi. Renew. Energy 2017, 109, 346–353. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Kheirrouz, M.; Farabi-Asl, H.; Yousefi, H.; Hajinezhad, A. Biogas production potential from livestock manure in Iran. Renew. Sustain. Energy Rev. 2015, 50, 748–754. [Google Scholar] [CrossRef]

- Enitan, A.M.; Kumari, S.; Swalaha, F.M.; Adeyemo, J.; Ramdhani, N.; Bux, F. Kinetic modelling and characterization of microbial community present in a full-scale UASB reactor treating brewery effluent. Microb. Ecol. 2014, 67, 358–368. [Google Scholar] [CrossRef]

- Chen, H.; Chang, S.; Guo, Q.; Hong, Y.; Wu, P. Brewery wastewater treatment using an anaerobic membrane bioreactor. Biochem. Eng. J. 2016, 105, 321–331. [Google Scholar] [CrossRef]

- Comino, E.; Riggio, V.A.; Rosso, M. Biogas production by anaerobic co-digestion of cattle slurry and cheese whey. Bioresour. Technol. 2012, 114, 46–53. [Google Scholar] [CrossRef] [PubMed]

- Carlini, M.; Castellucci, S.; Moneti, M. Biogas production from poultry manure and cheese whey wastewater under mesophilic conditions in batch reactor. Energy Procedia 2015, 82, 811–818. [Google Scholar] [CrossRef]

- Imeni, S.M.; Pelaz, L.; Corchado-Lopo, C.; Busquets, A.M.; Ponsá, S.; Colón, J. Techno-economic assessment of anaerobic co-digestion of livestock manure and cheese whey (Cow, Goat & Sheep) at small to medium dairy farms. Bioresour. Technol. 2019, 291, 121872. [Google Scholar] [CrossRef]

- Lemmer, A.; Merkle, W.; Baer, K.; Graf, F. Effects of high-pressure anaerobic digestion up to 30 bar on pH-value, production kinetics and specific methane yield. Energy 2017, 138, 659–667. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, S.; Kafle, G.K. Importance of “weak-base” poplar wastes to process performance and methane yield in solid-state anaerobic digestion. J. Environ. Manag. 2017, 193, 423–429. [Google Scholar] [CrossRef]

- Zhou, H.; Li, H.; Wang, F. Anaerobic digestion of different organic wastes for biogas production and its operational control performed by the modified ADM1. J. Environ. Sci. Health Part A 2012, 47, 84–92. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, Y.; Wang, L.; Quan, X. Potential for direct interspecies electron transfer in an electric-anaerobic system to increase methane production from sludge digestion. Sci. Rep. 2015, 5, 11094. [Google Scholar] [CrossRef]

- Ferraro, A.; Dottorini, G.; Massini, G.; Mazzurco Miritana, V.; Signorini, A.; Lembo, G.; Fabbricino, M. Combined bioaugmentation with anaerobic ruminal fungi and fermentative bacteria to enhance biogas production from wheat straw and mushroom spent straw. Bioresour. Technol. 2018, 260, 364–373. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, A.; Zhuang, G.; Zhuang, X. The acetotrophic pathway dominates methane production in Zoige alpine wetland coexisting with hydrogenotrophic pathway. Sci. Rep. 2019, 9, 9141. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, C. Anaerobic codigestion of pretreated wheat straw with cattle manure and analysis of the microbial community. Bioresour. Technol. 2015, 186, 128–135. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; He, Q. Persistence of Methanosaeta populations in anaerobic digestion during process instability. J. Ind. Microbiol. 2015, 42, 1129–1137. [Google Scholar] [CrossRef] [PubMed]

- Saha, S.; Jeon, B.H.; Kurade, M.B.; Govindwar, S.P.; Chatterjee, P.K.; Oh, S.E.; Roh, H.S.; Lee, S.S. Interspecies microbial nexus facilitated methanation of polysaccharidic wastes. Bioresour. Technol. 2019, 289, 121638. [Google Scholar] [CrossRef]

- Chen, S.; Cheng, H.; Liu, J.; Hazen, T.C.; Huang, V.; He, Q. Unexpected competitiveness of Methanosaeta populations at elevated acetate concentrations in methanogenic treatment of animal wastewater. Appl. Microbiol. Biotechnol. 2017, 101, 1729–1738. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.; Zhang, K.; Liang, J.; Gao, W.; Du, L. Methanogenic community during the anaerobic digestion of different substrates and organic loading rates. Microbiol. Open 2019, 8, e00709. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Angelidaki, I. Ammonia inhibition on hydrogen enriched anaerobic digestion of manure under mesophilic and thermophilic conditions. Water Res. 2016, 105, 314–319. [Google Scholar] [CrossRef]

- Bayrakdar, A.; Sürmeli, R.Ö.; Calli, B. Dry anaerobic digestion of chicken manure coupled with membrane separation of ammonia. Bioresour. Technol. 2017, 244, 816–823. [Google Scholar] [CrossRef]

- Molaey, R.; Bayrakdar, A.; Sürmeli, R.Ö.; Çalli, B. Influence of trace element supplementation on anaerobic digestion of chicken manure: Linking process stability to methanogenic population dynamics. J. Clean. Prod. 2018, 181, 794–800. [Google Scholar] [CrossRef]

- Esquivel-Elizondo, S.; Parameswaran, P.; Delgado, A.G.; Maldonado, J.; Rittmann, B.E.; Krajmalnik-Brown, R. Archaea and bacteria acclimate to high total ammonia in a methanogenic reactor treating swine waste. Archaea 2016, 2016, 4089684. [Google Scholar] [CrossRef]

- Reilly, M.; Dinsdale, R.; Guwy, A. The impact of inocula carryover and inoculum dilution on the methane yields in batch methane potential tests. Bioresour. Technol. 2016, 208, 134–139. [Google Scholar] [CrossRef]

- Moset, V.; Fontaine, D.; Møller, H.B. Co-digestion of cattle manure and grass harvested with different technologies. Effect on methane yield, digestate composition and energy balance. Energy 2017, 141, 451–460. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, R.; Liu, F.; Yong, X.; Wu, X.; Zheng, T.; Jiang, M.; Jia, H. Biogas production and microbial community shift through neutral pH control during the anaerobic digestion of pig manure. Bioresour. Technol. 2016, 217, 44–49. [Google Scholar] [CrossRef] [PubMed]

- Dhungana, B.; Lohani, S.P.; Marsolek, M. Anaerobic Co-Digestion of Food Waste with Livestock Manure at Ambient Temperature: A Biogas Based Circular Economy and Sustainable Development Goals. Sustainability 2022, 14, 3307. [Google Scholar] [CrossRef]

| Biodigester | Substrate Characterization | Physicochemical Characteristics | |

|---|---|---|---|

| pH | Ammoniacal Nitrogen (mg/L NH3-N) | ||

| BM | 100% BM (Control) | 6.20 | 134.67 |

| RSB20 | 20% RSB + 80% BM | 5.98 | 81.22 |

| RSB40 | 40% RSB + 60% BM | 5.89 | 145.04 |

| RSB80 | 80% RSB + 20% BM | 5.48 | 121.83 |

| RCW20 | 20% RCW + 80% BM | 6.09 | 133.44 |

| RCW40 | 40% RCW + 60% BM | 6.08 | 98.63 |

| RCW80 | 80% RCW + 20% BM | 6.01 | 98.63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Motta, I.G.B.; Santana, L.A.R.; Pereira, H.P.; de Paula, V.R.; Martins, M.F.; da Costa Carneiro, J.; Otenio, M.H. Population Dynamics of Methanogenic Archea in Co-Digestion Systems Operating Different Industrial Residues for Biogas Production. Sustainability 2022, 14, 11536. https://doi.org/10.3390/su141811536

da Motta IGB, Santana LAR, Pereira HP, de Paula VR, Martins MF, da Costa Carneiro J, Otenio MH. Population Dynamics of Methanogenic Archea in Co-Digestion Systems Operating Different Industrial Residues for Biogas Production. Sustainability. 2022; 14(18):11536. https://doi.org/10.3390/su141811536

Chicago/Turabian Styleda Motta, Isabela Gomes Barreto, Larice Aparecida Rezende Santana, Hyago Passe Pereira, Vanessa Romário de Paula, Marta Fonseca Martins, Jailton da Costa Carneiro, and Marcelo Henrique Otenio. 2022. "Population Dynamics of Methanogenic Archea in Co-Digestion Systems Operating Different Industrial Residues for Biogas Production" Sustainability 14, no. 18: 11536. https://doi.org/10.3390/su141811536

APA Styleda Motta, I. G. B., Santana, L. A. R., Pereira, H. P., de Paula, V. R., Martins, M. F., da Costa Carneiro, J., & Otenio, M. H. (2022). Population Dynamics of Methanogenic Archea in Co-Digestion Systems Operating Different Industrial Residues for Biogas Production. Sustainability, 14(18), 11536. https://doi.org/10.3390/su141811536