Evaluating the Accuracy of Contour Ridgeline Positioning for Soil Conservation in the Northeast Black Soil Region of China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

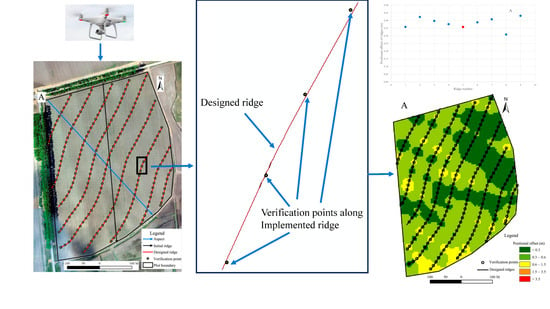

2.2. Design and Implementation of Contour Ridging

2.3. Data Collection

2.4. Data Analysis

3. Results

3.1. Slope Gradient along Contour Ridgelines

3.2. Elevation Variation along Contour Ridgelines

3.3. Statistical Analysis of Verification Point Positional Offsets

3.4. Spatial Distribution of Verification Point Positional Offsets

3.5. Positional Offsets of Ridgelines

4. Discussion

4.1. Soil and Water Conservation Effects of Contour Ridging

4.2. Positional Offset of Contour Ridging Ridgelines

4.3. Impact on the Baseline Setup of Contour Ridging

4.4. Recommendations for Navigation-Based Ridging

4.5. Implications for Future Works

5. Conclusions

- (1)

- Designing contour ridgelines using ArcMap can effectively estimate the effect of implemented contour ridging. The average measured slope gradient along ridgelines (0.5~0.6°) closely matches the designed value (0.6°), representing a 50% to 70% reduction compared to the original slope gradient along traditional downslope ridging. Regarding elevation changes along the ridgelines, most of the measured ridgelines were consistent with the designed baseline, being higher in the middle and lower on both sides, which shortened the length of overland flow on the slope;

- (2)

- At the field scale, the average positional offset between the contour ridgelines designed using ArcMap and the implemented ridgelines is less than a single ridge width (1.3 m wide). The median offset is only one-third of a single ridge width. Additionally, the error contributed by the movement of the ridging machinery may be larger than the error of the baseline setup;

- (3)

- The larger the distance from the baseline, the larger the positional offset between the measured and designed ridgelines. Besides, the positional offset between the measured and designed ridgelines is notably larger at the turning points. Therefore, the turns should be made as smooth as possible when designing ridgelines. During ridging, reducing the speed at these turns is recommended to minimize errors and maintain the accuracy of the ridging path.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Zhang, C.; Yao, X.; Yun, W.; Ma, J.; Gao, L.; Li, P. Scenario simulation of the tradeoff between ecological land and farmland in black soil region of Northeast China. Land Use Policy 2022, 114, 105991. [Google Scholar] [CrossRef]

- Gong, H.; Meng, D.; Li, X.; Zhu, F. Soil degradation and food security coupled with global climate change in northeastern China. Chin. Geogr. Sci. 2013, 23, 562–573. [Google Scholar] [CrossRef]

- Zhang, P. Revitalizing old industrial base of Northeast China: Process, policy and challenge. Chin. Geogr. Sci. 2008, 18, 109–118. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, B.; Wang, X.; Gao, X.; Liu, G. Erosion effect on the productivity of black soil in Northeast China. Sci. China Ser. D Earth Sci. 2009, 52, 1005–1021. [Google Scholar] [CrossRef]

- Sui, Y.; Liu, X.; Jin, J.; Zhang, S.; Zhang, X.; Herbert, S.J.; Ding, G. Differentiating the early impacts of topsoil removal and soil amendments on crop performance/productivity of corn and soybean in eroded farmland of Chinese Mollisols. Field Crops Res. 2009, 111, 276–283. [Google Scholar] [CrossRef]

- Li, H.; Cruse, R.M.; Liu, X.; Zhang, X. Effects of topography and land use change on gully development in typical Mollisol region of Northeast China. Chin. Geogr. Sci. 2016, 26, 779–788. [Google Scholar] [CrossRef]

- Zhang, S.; Han, X.; Cruse, R.M.; Zhang, X.; Hu, W.; Yan, Y.; Guo, M. Morphological characteristics and influencing factors of permanent gully and its contribution to regional soil loss based on a field investigation of 393 km2 in Mollisols region of northeast China. CATENA 2022, 217, 106467. [Google Scholar] [CrossRef]

- Liu, X.B.; Zhang, X.Y.; Wang, Y.X.; Sui, Y.Y.; Zhang, S.L.; Herbert, S.J.; Ding, G. Soil degradation: A problem threatening the sustainable development of agriculture in Northeast China. Plant Soil Environ. 2010, 56, 87–97. [Google Scholar] [CrossRef]

- Fan, H.; Hou, Y.; Xu, X.; Mi, C.; Shi, H. Composite Factors during Snowmelt Erosion of Farmland in Black Soil Region of Northeast China: Temperature, Snowmelt Runoff, Thaw Depths and Contour Ridge Culture. Water 2023, 15, 2918. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, F.; Zhang, X.J.; Wilson, G.V.; Qin, C.; He, C.; Liu, G.; Zhang, J. Discrimination of soil losses between ridge and furrow in longitudinal ridge-tillage under simulated upslope inflow and rainfall. Soil Tillage Res. 2020, 198, 104541. [Google Scholar] [CrossRef]

- Xin, Y.; Liu, G.; Xie, Y.; Gao, Y.; Liu, B.; Shen, B. Effects of soil conservation practices on soil losses from slope farmland in northeastern China using runoff plot data. CATENA 2019, 174, 417–424. [Google Scholar] [CrossRef]

- Gathagu, J.N.A.A.; Mourad, K.A.; Sang, J.J.W. Effectiveness of contour farming and filter strips on ecosystem services. Water 2018, 10, 1312. [Google Scholar] [CrossRef]

- Geng, R.; Yin, P.; Sharpley, A.N. A coupled model system to optimize the best management practices for nonpoint source pollution control. J. Clean. Prod. 2019, 220, 581–592. [Google Scholar] [CrossRef]

- Jia, L.; Zhao, W.; Zhai, R.; An, Y.; Pereira, P. Quantifying the effects of contour tillage in controlling water erosion in China: A meta-analysis. CATENA 2020, 195, 104829. [Google Scholar] [CrossRef]

- Saggau, P.; Kuhwald, M.; Duttmann, R. Effects of contour farming and tillage practices on soil erosion processes in a hummocky watershed. A model-based case study highlighting the role of tramline tracks. CATENA 2023, 228, 107126. [Google Scholar] [CrossRef]

- Wei, W.; Chen, D.; Wang, L.; Daryanto, S.; Chen, L.; Yu, Y.; Lu, Y.; Sun, G.; Feng, T. Global synthesis of the classifications, distributions, benefits and issues of terracing. Earth-Sci. Rev. 2016, 159, 388–403. [Google Scholar] [CrossRef]

- Morgan, R.P.C. Soil Erosion and Conservation; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Yu, P.; Yang, T.; Zhang, Z.; Zhou, X.; Qi, Z.; Yin, Z.; Li, A. Soil and water conservation effects of different tillage measures on phaeozems sloping farmland in northeast China. Land Degrad. Dev. 2024, 35, 1716–1733. [Google Scholar] [CrossRef]

- Farahani, S.; Fard, F.; Asoodar, M. Effects of contour farming on runoff and soil erosion reduction: A review study. Elixir Agric. 2016, 101, 44089–44093. [Google Scholar]

- Laflen, J.M.; Highfill, R.E.; Amemiya, M.; Mutchler, C.K. Structures and Methods for Controlling Water Erosion. In Soil Erosion and Crop Productivity; John Wiley & Sons: Hoboken, NJ, USA, 1985; pp. 431–442. [Google Scholar]

- Chen, X.; Liang, Z.; Zhang, Z.; Zhang, L. Effects of Soil and Water Conservation Measures on Runoff and Sediment Yield in Red Soil Slope Farmland under Natural Rainfall. Sustainability 2020, 12, 3417. [Google Scholar] [CrossRef]

- Scholand, D.; Schmalz, B. Deriving the Main Cultivation Direction from Open Remote Sensing Data to Determine the Support Practice Measure Contouring. Land 2021, 10, 1279. [Google Scholar] [CrossRef]

- Thompson, A.; Sudduth, K. Terracing and Contour Farming. In Precision Conservation: Geospatial Techniques for Agricultural and Natural Resources Conservation; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 151–163. [Google Scholar]

- Guo, W.J.; Maas, S. Terrace Layout Design Utilizing Geographic Information System and Automated Guidance System. Appl. Eng. Agric. 2012, 28, 31–38. [Google Scholar] [CrossRef]

- Guo, W. Application of Geographic Information System and Automated Guidance System in Optimizing Contour and Terrace Farming. Agriculture 2018, 8, 142. [Google Scholar] [CrossRef]

- Pineux, N.; Lisein, J.; Swerts, G.; Bielders, C.L.; Lejeune, P.; Colinet, G.; Degré, A. Can DEM time series produced by UAV be used to quantify diffuse erosion in an agricultural watershed? Geomorphology 2017, 280, 122–136. [Google Scholar] [CrossRef]

- Kou, P.; Xu, Q.; Yunus, A.P.; Ju, Y.; Guo, C.; Wang, C.; Zhao, K. Multi-temporal UAV data for assessing rapid rill erosion in typical gully heads on the largest tableland of the Loess Plateau, China. Bull. Eng. Geol. Environ. 2020, 79, 1861–1877. [Google Scholar] [CrossRef]

- Wang, R.; Sun, H.; Yang, J.; Zhang, S.; Fu, H.; Wang, N.; Liu, Q. Quantitative Evaluation of Gully Erosion Using Multitemporal UAV Data in the Southern Black Soil Region of Northeast China: A Case Study. Remote Sens. 2022, 14, 1479. [Google Scholar] [CrossRef]

- Shi, Z.H.; Cai, C.F.; Ding, S.W.; Wang, T.W.; Chow, T.L. Soil conservation planning at the small watershed level using RUSLE with GIS: A case study in the Three Gorge Area of China. CATENA 2004, 55, 33–48. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, L.; Liu, X.; Zhang, X.; Fu, S.; Dai, L. Soil nutrient variance by slope position in a Mollisol farmland area of Northeast China. Chin. Geogr. Sci. 2016, 26, 508–517. [Google Scholar] [CrossRef]

- GB 51018-2014; Code for Design of Soil and Water Conservation Engineering. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2014.

- Panagos, P.; Borrelli, P.; Meusburger, K.; van der Zanden, E.H.; Poesen, J.; Alewell, C. Modelling the effect of support practices (P-factor) on the reduction of soil erosion by water at European scale. Environ. Sci. Policy 2015, 51, 23–34. [Google Scholar] [CrossRef]

- Ricci, G.F.; Jeong, J.; De Girolamo, A.M.; Gentile, F. Effectiveness and feasibility of different management practices to reduce soil erosion in an agricultural watershed. Land Use Policy 2020, 90, 104306. [Google Scholar] [CrossRef]

- Li, S.; Xie, Y.; Liu, G.; Wang, J.; Lin, H.; Xin, Y.; Zhai, J. Water Use Efficiency of Soybean under Water Stress in Different Eroded Soils. Water 2020, 12, 373. [Google Scholar] [CrossRef]

- Tiwari, A.K.; Risse, L.M.; Nearing, M.A. Evaluation of WEPP and its comparison with USLE and RUSLE. Trans. ASAE 2000, 43, 1129–1135. [Google Scholar] [CrossRef]

- Dai, T.; Wang, L.; Li, T.; Qiu, P.; Wang, J. Study on the Characteristics of Soil Erosion in the Black Soil Area of Northeast China under Natural Rainfall Conditions: The Case of Sunjiagou Small Watershed. Sustainability 2022, 14, 8284. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, W.; Wang, D.; Wu, Z.; Shang, P. Spatial Pattern of Soil Erosion in Relation to Land Use Change in a Rolling Hilly Region of Northeast China. Land 2022, 11, 1253. [Google Scholar] [CrossRef]

- Duan, X.; Xie, Y.; Liu, B.; Liu, G.; Feng, Y.; Gao, X. Soil loss tolerance in the black soil region of Northeast China. J. Geogr. Sci. 2012, 22, 737–751. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Y.; Rong, L.; Duan, X.; Zhang, R.; Li, Y.; Guan, J. Effect of soil erosion depth on crop yield based on topsoil removal method: A meta-analysis. Agron. Sustain. Dev. 2021, 41, 63. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, K.; Zhang, Z.; Qiu, Q. Identifying soil redistribution patterns by magnetic susceptibility on the black soil farmland in Northeast China. CATENA 2015, 129, 103–111. [Google Scholar] [CrossRef]

- Drenjanac, D.; Tomic, S.; Agüera, J.; Perez-Ruiz, M. Wi-Fi and Satellite-Based Location Techniques for Intelligent Agricultural Machinery Controlled by a Human Operator. Sensors 2014, 14, 19767–19784. [Google Scholar] [CrossRef]

- Mousazadeh, H. A technical review on navigation systems of agricultural autonomous off-road vehicles. J. Terramech. 2013, 50, 211–232. [Google Scholar] [CrossRef]

- Shalal, N.; Low, T.; McCarthy, C.; Hancock, N.H. A Review of autonomous navigation systems in agricultural environments. In Proceedings of the SEAg 2013: Innovative Agricultural Technologies for a Sustainable Future, Barton, Australia, 22–25 September 2013. [Google Scholar]

- Qiangwen, F.; Liu, Y.; Liu, Z.; Li, S.; Guan, B. High-accuracy SINS/LDV Integration for Long-distance Land Navigation. IEEE/ASME Trans. Mechatron. 2018, 23, 2952–2962. [Google Scholar]

- Corno, M.; Panzani, G.; Roselli, F.; Giorelli, M.; Azzolini, D.; Savaresi, S. An LPV Approach to Autonomous Vehicle Path Tracking in the Presence of Steering Actuation Nonlinearities. IEEE Trans. Control Syst. Technol. 2020, 29, 1766–1774. [Google Scholar] [CrossRef]

- Li, R.; Zheng, S.; Wang, E.; Chen, J.; Feng, S.; Wang, D.; Dai, L. Advances in BeiDou Navigation Satellite System (BDS) and satellite navigation augmentation technologies. Satell. Navig. 2020, 1, 12. [Google Scholar] [CrossRef]

- Yun, C.; Kim, H.-J.; Jeon, C.-W.; Gang, M.; Lee, W.S.; Han, J.G. Stereovision-based ridge-furrow detection and tracking for auto-guided cultivator. Comput. Electron. Agric. 2021, 191, 106490. [Google Scholar] [CrossRef]

- Radocaj, D.; Plaščak, I.; Heffer, G.; Jurišić, M. A Low-Cost Global Navigation Satellite System Positioning Accuracy Assessment Method for Agricultural Machinery. Appl. Sci. 2022, 12, 693. [Google Scholar] [CrossRef]

| Plot | Area (hm2) | Natural Slope Gradient (°) | Aspect | Initial Ridge Orientation (High to Low in Elevation) | Slope Gradient along Downslope Ridge (°) |

|---|---|---|---|---|---|

| A | 17.3 | 2.5 | southeast | south→ north | 1.3 |

| B | 19.8 | 3 | south | north→ south | 2.6 |

| C | 20.2 | 3 | west | east→ west | 2.7 |

| Plot | Mean ± Standard Deviation (°) | Minimum (°) | Maximum (°) | Observations |

|---|---|---|---|---|

| A | 0.54 ± 0.11 | 0.40 | 0.69 | 9 |

| B | 0.62 ± 0.09 | 0.54 | 0.80 | 8 |

| C | 0.54 ± 0.07 | 0.44 | 0.64 | 8 |

| Plot | Mean ± Standard Deviation (m) | Median (m) | Minimum (m) | Maximum (m) | Observations |

|---|---|---|---|---|---|

| A | 0.38 ± 0.27 a | 0.32 | 0.00 | 1.45 | 233 |

| B | 1.47 ± 2.78 a | 0.43 | 0.00 | 16.69 | 204 |

| C | 0.52 ± 0.64 b | 0.31 | 0.00 | 3.61 | 118 |

| B-Corrected | 0.58 ± 0.65 a | 0.37 | 0.00 | 3.49 | 180 |

| Location | Downslope Ridging | Contour Ridging | Decrease Ratio (%) |

|---|---|---|---|

| A | 0.52 | 0.22 | 58 |

| B | 0.87 | 0.21 | 76 |

| C | 0.90 | 0.18 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhao, W.; Wang, J.; Geng, X.; Song, C. Evaluating the Accuracy of Contour Ridgeline Positioning for Soil Conservation in the Northeast Black Soil Region of China. Sustainability 2024, 16, 3106. https://doi.org/10.3390/su16083106

Li H, Zhao W, Wang J, Geng X, Song C. Evaluating the Accuracy of Contour Ridgeline Positioning for Soil Conservation in the Northeast Black Soil Region of China. Sustainability. 2024; 16(8):3106. https://doi.org/10.3390/su16083106

Chicago/Turabian StyleLi, Hao, Wenjing Zhao, Jing Wang, Xiaozhe Geng, and Chunyu Song. 2024. "Evaluating the Accuracy of Contour Ridgeline Positioning for Soil Conservation in the Northeast Black Soil Region of China" Sustainability 16, no. 8: 3106. https://doi.org/10.3390/su16083106

APA StyleLi, H., Zhao, W., Wang, J., Geng, X., & Song, C. (2024). Evaluating the Accuracy of Contour Ridgeline Positioning for Soil Conservation in the Northeast Black Soil Region of China. Sustainability, 16(8), 3106. https://doi.org/10.3390/su16083106