Study of the Raveling Resistance of Porous Asphalt Pavements Used in Sustainable Drainage Systems Affected by Hydrocarbon Spills

Abstract

:1. Introduction

2. Materials and Methods

| Properties | Unit | Standard | Binder | ||

|---|---|---|---|---|---|

| CBB | PMBB | FRBB | |||

| Original Penetration (o.p) 25 °C; 100 g; 5 s | 0.1 mm | EN 1426 | 60–70 | 45–80 | 35–50 |

| Retained Penetration | % of o.p | EN 1426 | >50 | >60 | >65 |

| Softening Point (Ring and Ball) | °C | EN 1427 | 46–54 | >60 | >85 |

| Softening Point Variation | °C | EN 1427 | <9 | <10 | <5 |

| Difference in Penetration | 0.1 mm | EN 13399 | - | <9 | <5 |

| Difference in Softening Temperature | °C | EN 13399 | - | <5 | <5 |

| Fraas Breaking Point | °C | EN 12593 | <−8 | <−12 | <−13 |

| Solubility in Toluene | % | EN 12592 | >99 | >95 | |

| Elastic Recovery at 25 °C | % | EN 13398 | - | >50 | >15 |

| Relative Density (25 °C/25 °C) | - | EN 3848 | - | >1.025 | |

| Mass Variation | % | EN 12607-1 | <0.5 | <1 | <0.3 |

| Sieve | 20 mm | 12.5 mm | 8 mm | 4 mm | 2 mm | 0.5 mm | 0.063 mm |

|---|---|---|---|---|---|---|---|

| % passing | 100 | 85 | 50 | 14 | 9 | 5 | 3 |

2.1. The Semi-Immersion Test

2.2. The Dripping and Runoff Test

| HYDROCARBON BANDS | COMPOSITION | ||||||

|---|---|---|---|---|---|---|---|

| Band | Area | Area (%) | Aliphatic (% in Weight) | Aromatic (% in Weight) | Compound | Area | Area (%) |

| C5-C6 | 237,608 | 0.71 | 0.71 | 0.00 | Benzene | 1154 | 0.00 |

| C6-C8 | 273,796 | 0.82 | 0.62 | 0.19 | Toluene | 64,953 | 0.19 |

| C8-C10 | 590,169 | 1.76 | 0.03 | 1.73 | Ethyl-Benzene | 34,932 | 0.10 |

| C10-C12 | 166,720 | 0.50 | 0.03 | 0.47 | Xylene | 19,984 | 0.60 |

| C12-C16 | 201,756 | 0.60 | 0.26 | 0.35 | Octane | 6777 | 0.02 |

| C16-C21 | 1,191,096 | 3.55 | 2.16 | 1.40 | Nonane | 3801 | 0.01 |

| C21-C35 | 5,783,999 | 17.26 | 15.98 | 1.27 | Decane | 6446 | 0.02 |

| >C35 | 25,069,548 | 74.80 | - | - | Undecane | 3517 | 0.01 |

| Hydrocarbon Spill Test | Binder Type | Treatment | Number of Samples (Ni) |

|---|---|---|---|

| Semi-Immersion test | CBB, PMBB, FRBB | Gasoline: 1356 mg | 4 * |

| + Distilled water: 800 mL | |||

| Diesel: 1356 mg + Distilled water: 800 mL | 4 * | ||

| Used motor oil: 1356 mg+ Distilled water: 800 mL | 4 * | ||

| Distilled water: 800 mL | 4 * | ||

| No treatment | 4 * | ||

| Dripping and Runoff test | CBB | Used motor oil: 271 mg, 814 mg, 1356 mg | 12 ** |

| + Distilled water: 800 mL | |||

| Distilled water: 800 mL | 12 | ||

| No treatment | 12 | ||

| PMBB | Used motor oil: 814 mg, 1356 mg, 1898 mg | 12 ** | |

| + Distilled water: 800 mL | |||

| Distilled water: 800 mL | 12 | ||

| No treatment | 12 | ||

| FRBB | Used motor oil: 1356 mg, 1898 mg, 2441 mg | 12 ** | |

| + Distilled water: 800 mL | |||

| Distilled water: 800 mL | 12 | ||

| No treatment | 12 |

3. Results and Discussion

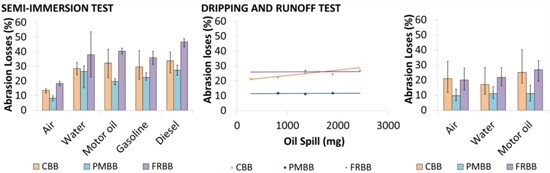

3.1. Semi-Immersion Test

3.2. Dripping and Runoff Test

- -

- Air conditioned samples at 20 °C;

- -

- Air conditioned samples at 20 °C with 800 mL of distilled water;

- -

- Air conditioned samples at 20 °C with 1356 mg of used motor oil and 800 mL of distilled water.

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dolz, J.; Gómez, M. Problems of stormwater drainage in urban areas and about the hydraulic study of collector networks. Dren. Urbano 1994, 1, 55–66. (In Spanish) [Google Scholar]

- Castro-Fresno, D.; Andrés-Valeri, V.C.A.; Sañudo-Fontaneda, L.A.; Rodríguez-Hernández, J. Sustainable Drainage Practices in Spain, Specifically Focused on Pervious Pavements. Water 2013, 5, 67–93. [Google Scholar] [CrossRef]

- Bayon, J.R.; Jato-Espino, D.; Blanco-Fernandez, E.; Castro-Fresno, D. Behaviour of geotextiles designed for pervious pavements as a support for biofilm development. Geotext. Geomembr. 2015, 43, 139–147. [Google Scholar] [CrossRef]

- Barrett, M.E.; Zuber, R.D.; Collins, E.R.; Malina, J.F.; Charbeneau, R.J.; Ward, G.H. A review and Evaluation of the Literature Pertaining to the Quality and Control of Pollution from Highway Runoff and Construction; Report No. CRWR 239; Centre for Research in Water Resources: Austin, TX, USA, 1993. [Google Scholar]

- Hagos, E.T. The Effect of Aging on Binder Properties of Porous Asphalt Concrete. Ph.D Thesis, The Delft University of Technology, Delft, The Netherlands, 2008. [Google Scholar]

- Giuliani, F.; Merusi, F.; Filippi, S.; Biondi, D.; Finocchiaro, M.L.; Polacco, G. Effects of polymer modification on the fuel resistance of asphalt binders. Fuel 2009, 88, 1539–1546. [Google Scholar] [CrossRef]

- Páez Dueñas, A. New fuel-resistant bitumens. In Proceedings of the Jornada Técnica: Panorámica Actual de las Mezclas Bituminosas, Madrid, Spain, 21 June 2005. (In Spanish)

- McBee, W.C.; Sullivan, T.A. Improved Resistance of Surfur-Asphalt Paving Formulations to Attack by Fuels. Ind. Eng. Chem. Prod. Res. Dev. 1977, 16, 93–95. [Google Scholar] [CrossRef]

- Shoenberger, J.E. Performance of Fuel-Resistant Sealers for Asphalt Concrete Pavements. J. Mater. Civ. Eng. 1994, 6, 137–149. [Google Scholar] [CrossRef]

- Corun, R.; Rooijen, R.C.; de Bondt, A.H. Performance Evaluation of Jet Fuel Resistant Polymer-Modified Asphalt for Airport Pavements. In Proceedings of the Airfield and Highway Pavement Specialty Conference, Atlanta, GA, USA, 30 April–3 May 2006; pp. 425–436.

- Merusi, F.; Polacco, G.; Nicoletti, A.; Giuliani, F. Kerosene resistance of asphalt binders modified with crumb rubber: Solubility and rheological aspects. Mater. Struct. 2010, 43, 1271–1281. [Google Scholar] [CrossRef]

- Prowell, B.D.; Watson, D.E.; Hurley, G.C.; Brown, E.R. Evaluation of stone matrix asphalt (SMA) for airfield pavements. In Proceedings of the 2010 FAA Worldwide Airport Technology Transfer Conference, Atlantic City, NJ, USA, 20–22 April 2010.

- Khalid, H.A.; Walsh, C.M.; Pérez Jiménez, F.E.; Miró Recasens, J.R. Rheological and mechanical characterization of aged and unaged porous asphalt binders. Proc. Inst. Civ. Eng. Transp. 1998, 129, 240–246. [Google Scholar] [CrossRef]

- Molenaar, A.A.A.; Hagos, E.T.; van de Ven, M.F.C. Effects of aging on the mechanical characteristics of bituminous binders in PAC. J. Mater. Civ. Eng. 2010, 22, 779–787. [Google Scholar] [CrossRef]

- Praticò, F.G.; Ammendola, R.; Moro, A. Influence of mix parameters on fuel resistance of porous and dense—Graded HMAs. Adv. Charact. Pavement Soil Eng. Mater. 2007, 2, 1105–1114. [Google Scholar]

- Praticò, F.G.; Ammendola, R.; Moro, A. Fuel resistance of HMAs: Theory and experiments. Int. J. Pavement Res. Technol. 2008, 1, 100–106. [Google Scholar]

- CEN. EN 12697-43. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 43: Resistance to Fuel; CEN (European Committee for Standardization): Bruxelles, Belgium, 2006. [Google Scholar]

- Calzada Pérez, M.A. Development and Normalization of the Abrasion Loss Test Applied to the Characterization, Dosing and Control of Bituminous Mixes with Open Gradation. Ph.D. Thesis, The University of Cantabria, Santander, Spain, 1984. [Google Scholar]

- Spanish Government. PG-3: Technical Recommendations in Roads and Bridges; Spanish Ministry of Public Works: Madrid, Spain, 2007. (In Spanish) [Google Scholar]

- AENOR. NLT-168/90: Bulk Density and Void Ratio in Compacted Bituminous Mixes; AENOR: Madrid, Spain, 1990. (In Spanish) [Google Scholar]

- Bond, P.C.; Newman, A.P.; Pratt, C.J. A Review of Stormwater Quantity and Quality Performance of Permeable Pavements in the UK. In Proceedings of the 8th International Conference on Urban Storm Drainage, Sydney, Australia, 30 August–3 September 1999.

- Pratt, C.J.; Newman, A.P.; Bond, P.C. Mineral Oil Bio-degradation within a Permeable Pavement. Water Sci. Technol. 1999, 39, 103–109. [Google Scholar] [CrossRef]

- Coupe, S.J.; Smith, H.G.; Newman, A.P.; Puehmeier, T. Biodegradation and Microbial Diversity within Permeable Pavements. Eur. J. Protistol. 2003, 39, 495–498. [Google Scholar] [CrossRef]

- CEN. EN 12697-17. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 17: Particle Loss of Porous Asphalt Specimen; CEN (European Committee for Standardization): Bruxelles, Belgium, 2007. [Google Scholar]

- Alvarez, A.E.; Martin, A.E.; Estakhri, C.K.; Button, J.W.; Glover, C.J.; Jung, S.H. Synthesis of Current Practice on the Design, Construction and Maintenance of Porous Friction Courses; Report No FHWA/TX-06/0-5262-1; Texas Transportation Institute, The Texas A&M University System: College Station, TX, USA, 2006. [Google Scholar]

- Sañudo-Fontaneda, L.; Andrés-Valeri, V.C.A.; Rodríguez-Hernández, J.; Castro-Fresno, D. Field study of infiltration capacity reduction of porous mixture surfaces. Water 2013, 6, 661–669. [Google Scholar] [CrossRef]

- Rodriguez-Hernandez, J.; Fernández-Barrera, A.; Andrés-Valeri, V.; Vega-Zamanillo, A.; Castro-Fresno, D. Closure to “Relationship between Urban Runoff Pollutant and Catchment Characteristics” by Jorge Rodriguez-Hernandez, Andrés, H. Fernández-Barrera, Valerio, C.A. Andrés-Valeri, Angel Vega-Zamanillo, and Daniel Castro-Fresno. J. Irrig. Drain Eng. 2015. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez-Hernandez, J.; Andrés-Valeri, V.C.; Calzada-Pérez, M.A.; Vega-Zamanillo, Á.; Castro-Fresno, D. Study of the Raveling Resistance of Porous Asphalt Pavements Used in Sustainable Drainage Systems Affected by Hydrocarbon Spills. Sustainability 2015, 7, 16226-16236. https://doi.org/10.3390/su71215812

Rodriguez-Hernandez J, Andrés-Valeri VC, Calzada-Pérez MA, Vega-Zamanillo Á, Castro-Fresno D. Study of the Raveling Resistance of Porous Asphalt Pavements Used in Sustainable Drainage Systems Affected by Hydrocarbon Spills. Sustainability. 2015; 7(12):16226-16236. https://doi.org/10.3390/su71215812

Chicago/Turabian StyleRodriguez-Hernandez, Jorge, Valerio C. Andrés-Valeri, Miguel A. Calzada-Pérez, Ángel Vega-Zamanillo, and Daniel Castro-Fresno. 2015. "Study of the Raveling Resistance of Porous Asphalt Pavements Used in Sustainable Drainage Systems Affected by Hydrocarbon Spills" Sustainability 7, no. 12: 16226-16236. https://doi.org/10.3390/su71215812

APA StyleRodriguez-Hernandez, J., Andrés-Valeri, V. C., Calzada-Pérez, M. A., Vega-Zamanillo, Á., & Castro-Fresno, D. (2015). Study of the Raveling Resistance of Porous Asphalt Pavements Used in Sustainable Drainage Systems Affected by Hydrocarbon Spills. Sustainability, 7(12), 16226-16236. https://doi.org/10.3390/su71215812