The Optimization of Cyclic Links of Live Pig-Industry Chain Based on Circular Economics

Abstract

:1. Introduction

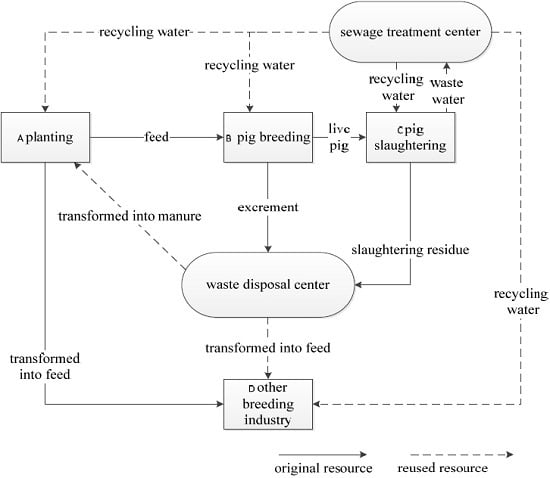

2. Circular Economic System for Live Pig Industry

3. Cyclic Model for Live Pig-Industry Chain

3.1. Problem Description

3.2. Symbol Description

| Planting capacity (The unit is kg.) | |

| Production capacity of pig-breeding industry. (The unit is kg.) | |

| Production capacity of pig-slaughtering industry. (The unit is kg.) | |

| Capacities of other related breeding industries. (The unit is kg.) | |

| Water demand of agricultural products in planting industry. (The unit is liter per kg.) | |

| Water demand of pig-breeding units. (The unit is liter per kg.) | |

| Water demand of pig-slaughtering units. (The unit is liter per kg.) | |

| Water demand of other related breeding units. (The unit is liter per kg.) | |

| Feed demand of pig-breeding units, that is, the pig-breeding coefficient after planted products become feed. (The unit is kg.) | |

| Feed demand of other breeding units, that is, the other breeding coefficient after planted products become feed. (The unit is kg.) | |

| Pig demand of slaughtering units to produce pork products. (The unit is kg.) | |

| Manure demand of planting units to produce agricultural products, that is, the input/output coefficient of waste manure to planting industry. (The unit is kg.) | |

| Feed demand of other breeding units, that is, the breeding coefficient of other breeding industries after the waste becomes feed. (The unit is kg.) | |

| Pig-slaughter capacity needed to meet the market demands. (The unit is kg.) | |

| Average amount of excrement produced by pig-breeding units. (The unit is kg.) | |

| Average amount of wastewater produced by pig-slaughtering units. (The unit is liter.) | |

| Average amount of waste produced by pig-slaughtering units. (The unit is kg.) | |

| Conversion rate of wastewater treated to become reclaimed water. | |

| Conversion rate of waste treated to become manure. | |

| Conversion rate of waste treated to become feed. | |

| Wastewater-treatment capacity. (The unit is liter.) | |

| Waste-disposal capacity. (The unit is kg.) | |

| Construction cost of wastewater-treatment unit capacity. (The unit is yuan per liter.) | |

| Construction cost of waste-disposal unit capacity. (The unit is yuan per kg.) | |

| Rated target utilization rate of wastewater-treatment capacity. | |

| Rated target utilization rate of waste-disposal capacity. | |

| Use amount of circulating water in planting industry. (The unit is liter.) | |

| Use amount of circulating water in pig-breeding industry. (The unit is liter.) | |

| Use amount of circulating water in pig-slaughtering industry. (The unit is liter.) | |

| Use amount of circulating water in other livestock-breeding industries. (The unit is liter.) | |

| Use amount of recycling manure in planting industry. (The unit is kg.) | |

| Use amount of recycling feed in other breeding industries. (The unit is kg.) | |

| Market demand for agricultural products. The random variables and distribution function can be determined by the empirical distribution of historical data. | |

| Market demand for pig-slaughtering products. The random variables and distribution function can be determined by the empirical distribution of historical data. | |

| Market demand for other breeding industries. The random variables and distribution function can be determined by the empirical distribution of historical data. |

3.3. Model Construction

3.4. Model Solution

- (1)

- Construct the uncertainty function as follows:

- (2)

- Generate input and output data for the uncertainty function. Generate the input and output data, of which the input data are produced as below: Randomly generate in accordance with the uniform distribution in . Then, randomly generate in accordance with the uniform distribution in . Similarly, randomly generate in accordance with the uniform distribution in , and finally, calculate . The corresponding output data are the expectations for the resource-utilization rate. Generate random samples according to market-demand distribution; then, calculate the corresponding uncertain function values of these samples. Finally, average the values according to the number of samples to obtain the output data of the input data under the group.

- (3)

- Use the input and output data to train the neural network to approximate . Utilize the input and output data to train the neural network.

- (4)

- Randomly generate the initial population of the genetic algorithm in the inner layer. Randomly generate sub-chromosomes to form the initial population according to step (2), and use the trained neural network to test its feasibility.

- (5)

- Crossover and mutation operation of inner-layer genetic algorithm. Conduct cross-operation and mutation operation on dub-chromosomes, generate new chromosomes, and use the trained neural network to test its feasibility.

- (6)

- Calculate the target value of the genetic algorithm in the inner layer. Calculate the corresponding objective value of each sub-chromosome, and calculate the fitness of each sub-chromosome according to the objective value.

- (7)

- Roulette selection of sub-chromosome for inner-layer optimization and iteration. Select the sub-chromosomes with roulette. Repeat (5)–(6) until the pre-set optimal number of cycles is reached.

- (8)

- Output the optimal solution of the inner genetic algorithm. Obtain the corresponding sub-chromosome of the optimal objective values.

4. Case Analysis

4.1. Case Design

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| a1 | 1/150 | g | 1.25 | p1 | 0.95 |

| a2 | 127/1,200,000 | α | 217/12,000 | p2 | 0.95 |

| a3 | 1/625 | β1 | 1/200 | p3 | 0.90 |

| a4 | 1/180 | β2 | 1/5 | p4 | 0.90 |

| b | 2.5 | γ1 | 0.80 | ξ1 | N(8000,128) |

| c | 3 | γ2 | 0.90 | ξ2 | N(96000,500) |

| d | 25/24 | γ3 | 0.56 | ξ3 | N(6000,138) |

| e | 1/1500 | η1 | 0.95 | ||

| f | 2.2 | η2 | 0.90 |

4.2. Results

| Variable | Value | Variable | Value |

|---|---|---|---|

| 591.73 m3 | 23,155.90 kg | ||

| 186.34 m3 | 71.12 m3 | ||

| 207.25 m3 | 45.33 m3 | ||

| 83.62 kg | 9639.10 kg |

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhu, D.; Zhu, Y. Deepen Theoretical Studies of Circular Economy under the Background of Eco-Civilization. Bull. Chin. Acad. Sci. 2013, 2, 207–218. (In Chinese) [Google Scholar]

- Boulding, K.E. The Economies of the Coming spaceship Earth. In Environmental Quality in a Growing Eeonomy; Jarrett, H., Ed.; Resources for the Future, Johns HoPkins University Press: Baltimore, MD, USA, 1966. [Google Scholar]

- Mathews, J.A.; Tang, Y.M.; Tan, H. China’s Move to a Circular Economy as a Development Strategy. Asian Bus. Manag. 2011, 10, 463–484. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A Review of the Circular Economy in China: Moving from Rhetoric to Implementation? J. Clean. Product. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- The State Council of China. Notice of Issuing the Recycle Economy Development Strategy & Immediate Plan of Action by the State Council of China; The State Council of China: Beijing, China, 2013. [Google Scholar]

- Green, K.W., Jr.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Ying, J.; Zhou, L. Study on green supply chain mangement based on circular economy. Phys. Procedia 2012, 25, 1682–1688. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K. Environmental Supply Chain Cooperation and Its Effect on the Circular Economy Practice Performance Relationship Among Chinese Manufacturers. J. Ind. Ecol. 2011, 15, 405–419. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Topp, E.; Scott, A.; Lapen, D.R.; Lyautey, E.; Duriez, P. Livestock Waste Treatment Systems for Reducing Environmental Exposure to Hazardous Enteric Pathogens: Some Considerations. Bioresour. Echnol. 2009, 100, 5395–5398. [Google Scholar] [CrossRef] [PubMed]

- Fu, X. Circular treatment and utilization of wastes from breeding. Beijing Agric. 2011, 134–135. (In Chinese) [Google Scholar]

- Dasheng, L.; Davis, J.; Wang, L. Industrialisation and the Sustainability of China’s Agriculture. Econ. Plan. 1998, 31, 213–230. [Google Scholar] [CrossRef]

- Mao, L. The development mode of circular economy for the husbandry industry. Feed Expo. 2009, 48–50. (In Chinese) [Google Scholar]

- Zhang, O.; Li, W. A study on the circular economic mode for a sustainable development of husbandry in Anhui Province. Ecol. Econ. 2010, 56–58. (In Chinese) [Google Scholar]

- Tan, D. Developing agricultural products logistics in China from the perspective of green supply chain. Int. J. Bus. Manag. 2012, 7, 106–112. [Google Scholar] [CrossRef]

- East, I.J.; Davis, J.; Sergeant, E.S.G.; Garner, M.G. Structure, dynamics and movement patterns of the Australian pig industry. Aust. Vet. J. 2014, 92, 52–57. [Google Scholar] [CrossRef] [PubMed]

- Coleman, G.J.; McGregor, M.; Hemsworth, P.H.; Boyce, J.; Dowline, S. The relationship between beliefs, attitudes and observed behaviours of abattoir personnel in the pig industry. Appl. Anim. Behav. Sci. 2003, 82, 189–200. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Rouch, K.E.; Dillon, O.W.; Holloway, L.E.; Hall, A. Design for sustainability (DFS): New challenges in developing and implementing a curriculum for next generation design and manufacturing engineers. Int. J. Eng. Educ. 2007, 23, 1053–1064. [Google Scholar]

- Bonneau, M.; Klauke, T.N.; Gonzàlez, J.; Rydhmer, L.; Ilari-Antoine, E.; Dourmad, J.Y.; de Greef, K.; Houwers, H.W.; Cinar, M.U.; Fàbrega, E.; et al. Evaluation of the sustainability of contrasted pig farming systems: Integrated evaluation. Animal 2014, 8, 2058–2068. [Google Scholar] [CrossRef] [PubMed]

- Jarrett, H. Environmental Quality in a Growing Economy; The Johns Hopkins University Press: Baltimore, MD, USA, 1966. [Google Scholar]

- Yang, W. The Research of Agricultural Development of Cyclic Economy in Ningxia Province. Ph.D. Thesis, Northwest Sci-Tech University of Agriculture and Forestry, Xi’an, China, 2008. [Google Scholar]

- Gan, L. Environmental pollution of massive livestock nad poultry breeding and prevention measures. Stud. Farming Mach. 2006, 22–24. (In Chinese) [Google Scholar]

- Mc Donough, W.; Braungart, M. A world of abundance. Interfaces 2000, 30, 55–65. [Google Scholar] [CrossRef]

- He, J.; Zheng, J. Study on the recycling and utilization of excrement of livestock and poultry. Jiangsu Agric. Sci. 2011, 487–488. (In Chinese) [Google Scholar]

- Wang, J.; Chen, R. The industrialization strategy of ecological agriculture and sustainable urban/rural development in China. Environ. Sustain. Dev. 2007, 92, 46–48. (In Chinese) [Google Scholar]

- Teira-Esmatges, M.R.; Flotats, X. A method for livestock waste management planning in NE Spain. Waste Manag. 2003, 23, 917–932. [Google Scholar] [CrossRef]

- Zinflou, A.; Gagne, C.; Gravel, M. GISMOO: A new hybrid genetic/immune strategy for multiple-objective optimization. Comput. Oper. Res. 2012, 39, 1951–1968. [Google Scholar] [CrossRef]

- Wang, F.; Lai, X.; Shi, N. A multi-objective optimization for green supply chain network design. Decis. Support Syst. 2011, 51, 262–269. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Razmi, J. Environmental supply chain network design using multi-objective fuzzy mathematical programming. Appl. Math. Model. 2012, 36, 3433–3446. [Google Scholar] [CrossRef]

- Pinto-Varela, T.; Barbosa-Póvoa, A.P.F.D.; Novais, A.Q. Bi-objective optimization approach to the design and planning of supply chains: Economic versus environmental performances. Comput. Chem. Eng. 2011, 35, 1454–1468. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Torabi, S.A. A possibilistic programming approach for closed-loop supply chain network design under uncertainty. Fuzzy Sets Syst. 2010, 161, 2668–2683. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Rabbani, M.; Torabi, S.A. A robust optimization approach to closed-loop supply chain network design under uncertainty. Appl. Math. Model. 2011, 35, 637–649. [Google Scholar] [CrossRef]

- Kenne, J.P.; Dejax, P.; Gharbi, A. Production planning of a hybrid manufacturing–remanufacturing system under uncertainty within a closed-loop supply chain. Int. J. Prod. Econ. 2012, 135, 81–93. [Google Scholar] [CrossRef]

- Chankong, V.; Cooper, W.W. Chance-constrained programming. Manag. Sci. 1969, 6, 73–79. [Google Scholar]

- Liu, B. Theory and Practice of Uncertain Programming; Physica-Verlag: Heidelberg, Germany, 2015. [Google Scholar]

- Jaszkiewicz, A. Genetic local search for multi-objective combinatory optimization. Eur. J. Oper. Res. 2002, 137, 50–71. [Google Scholar] [CrossRef]

- Liu, B.; Chen, X.W. Uncertain multi-objective programming and uncertain goal programming. J. Uncertain. Anal. Appl. 2015, 3, 10. [Google Scholar] [CrossRef]

- Javadi, A.A.; Farmani, R.; Tan, T.P. A hybrid Genetic Algorithm, Advanced Engineering. Informatics 2005, 19, 255–262. [Google Scholar]

- Faramarzi, A.; Alani, A.M.; Harireche, O. A Hybrid Approach to Design Materials with Negative Linear Compressibility. Comput. Mater. Sci. 2013, 79, 971–976. [Google Scholar] [CrossRef]

- Faramarzi, A.; Alani, A.M.; Javadi, A.A. An EPR-based self-learning approach to material modelling. Comput. Struct. 2014, 137, 63–71. [Google Scholar] [CrossRef]

- Yao, K.; Chen, X.W. A numerical method for solving uncertain differential equations. J. Intell. Fuzzy Syst. 2013, 25, 825–832. [Google Scholar]

- He, K.-L.; Peng, T. Green Supply Chain Management Model and Its Implementation Strategy for Pig Industry—A Case of Pig Industry in Chongqing City. Res. Agric. Mod. 2011, 32, 440–444. [Google Scholar]

- Wang, Z.; Liu, M.; Feng, Z.; Hua, L.; Xie, J.; Shao, G. A New Model of Recycling Agricultural Production. Agric. Sci. Technol. 2013, 14, 466–469, 537. [Google Scholar]

- Wang, Z.; Liu, Z.; Yang, T.; Fu, Q.; Ji, D. Engineering examples of high concentration livestock wastewater recycling system. J. Anhui Agric. Sci. 2013, 41, 6297–6299. [Google Scholar]

- Kůrková, V. Kolmogorov’s theorem and multilayer neural networks. Neural Netw. 1992, 5, 501–506. [Google Scholar] [CrossRef]

- Venkataraman, P. Applied Optimization with MATLAB Programming; Wiley Publishing: Hoboken, NJ, USA, 2009. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Xiao, X. The Optimization of Cyclic Links of Live Pig-Industry Chain Based on Circular Economics. Sustainability 2016, 8, 26. https://doi.org/10.3390/su8010026

Liu X, Xiao X. The Optimization of Cyclic Links of Live Pig-Industry Chain Based on Circular Economics. Sustainability. 2016; 8(1):26. https://doi.org/10.3390/su8010026

Chicago/Turabian StyleLiu, Xing, and Xu Xiao. 2016. "The Optimization of Cyclic Links of Live Pig-Industry Chain Based on Circular Economics" Sustainability 8, no. 1: 26. https://doi.org/10.3390/su8010026

APA StyleLiu, X., & Xiao, X. (2016). The Optimization of Cyclic Links of Live Pig-Industry Chain Based on Circular Economics. Sustainability, 8(1), 26. https://doi.org/10.3390/su8010026