Designing Sustainable Cold Chains for Long-Range Food Distribution: Energy-Effective Corridors on the Silk Road Belt

Abstract

:1. Introduction

2. Literature Review

3. A Cold Chain Design-Support Model

3.1. Environmental Sustainability Assessment in Cold Chains

3.2. Cold Chain Network Configuration

- the Growers that supply raw food ready for transformation (i.e., crops, orchards, farms);

- the Processing/Packaging nodes, which represent the plants where the raw products are transformed and packed, making them ready for distribution;

- the Storage/Consolidation nodes are where products are conserved, stored, and consolidated before and during distribution. Given the short shelf lives of perishable products, they pause in the distribution pipeline as briefly as possible, although they it is still necessary to balance the offer and demand mismatch or to perform multi-modal transport;

- the Demand nodes, where the food products meet the consumers. These include grocery shops, retail depots, wholesalers, or canteens. These nodes are usually located within high-density populated areas.

- The quantity of each product that must be harvested/processed/packaged/stored at each node;

- The proper transportation mode to adopt for each connection, route, and stage of the cold chain;

- The temperature set-point for each vehicle and at each storage node, given the products stored and the external expected climatic conditions;

- The production, processing, and delivery schedule for each product in order to meet the demand from the retailers.

- These results need to be interpreted in view of the planning horizon and the considered granularity of the periods (e.g., a day).

3.3. Energy Consumption Calculation

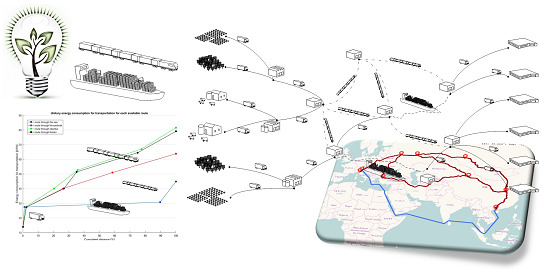

- the energy to move products throughout the logistic network. This depends on the traveling distance, on the transportation mode, and the type of the vehicle. Transport inter-modality is allowed in the model. The considered flows are illustrated in Figure 1;

- the energy to maintain vehicles and warehouses at the chosen temperature set-point. The closer the set-point is to the external temperature, the lower the energy consumption for refrigeration will be. However, the temperature set-point should respect the safe temperature range of the food products to avoid spoilage and quality decay;

- the energy required by crops and farms to process and package the products and to handle the products at the storage nodes (which is often negligible);

- the energy associated with food losses, which occur when a product’s quality decay is below the acceptance threshold. The quality decay of a product depends on the amount of time spent in the cold chain and the experienced environmental stresses (e.g., temperature rise). The minimum level of quality accepted at each stage determines the resulting flow of losses (i.e., those products that expire and are not accepted).

3.4. Model Formulation

| Index sets | |

| i = 1, …, I | Set of products |

| q = 1, …, qmax | Set of quality levels |

| k = 1, …, K | Set of temperatures |

| l = 1, …, L | Set of growers |

| p = 1, …, P | Set of packaging nodes |

| d = 1, …, D | Set of storage nodes |

| s = 1, …, S | Set of retailer nodes |

| m = 1, …, M | Set of vehicles and transportation modes |

| t = 1, …, T | Set of periods |

| Cluster of packaging, storage, and demand nodes | |

| Cluster of packaging and storage nodes | |

| Input parameters | |

| demandi,s,t | Demand of product i by the retailer s at period t, (units). |

| cci,l,t | Harvest of crop i from grower l at period t, (units). |

| pci,p,t | Packaging capacity of product i by packaging node p at period t, [units]. |

| dcpd | Storage capacity at packaging node p and storage node d, (units). |

| Transport capacity of transport mode m, (kg/vehicle). | |

| weighti | Weight of handling unit of product i, |

| cei,l | Energy needed to crop one unit of product i by grower l, |

| pei,p | Energy required by packaging node p to process one handling unit of product i, |

| storageei,pd | Energy required to store one handling unit of product i at packaging node p and storage node d, |

| Energy required by transport mode m, | |

| qmini,pds | Minimum quality level accepted for product i at packaging node p, storage node d, and retailer s. |

| wei | Energy losses for product i decay (i.e., waste), |

| coolemlpk,m,l,p | Energy requirements to set the transport mode m at temperature k to move from the grower l to the packaging node p, . |

| coolempdk,m,p,d | Energy requirements to set the transport mode m at temperature k to move from the packaging node p to the storage node d, . |

| coolemddk,m,d,d′ | Energy requirements to set the transport mode m at temperature k to move from the storage node d to the storage node d′, . |

| coolemdsk,m,d,s | Energy requirements to set the transport mode m at temperature k to move from the storage node d to the retailer s, . |

| coolepdk,pd | Energy requirements to set the facility temperature at k for both the packaging node p and the storage node d, |

| timelpm,l,p | Lead time to move products from the grower l to the packaging node p with the transportation mode m, |

| timepdm,p,d | Lead time to move products from the packaging node p to the storage node d with the transportation mode m, |

| timeddm,d,d′ | Lead time to move products from the storage node d to the storage node d′ with the transportation mode m, |

| timedsm,d,s | Lead time to move products from the storage node d to the retailer s with the transportation mode m, |

| distlpl,p | Travelling distance from the grower l to the packaging node p, . |

| distpdp,d | Routing distance from the packaging node p to the storage node d, . |

| distddd,d′ | Routing distance from the storage node d to the storage node d′, . |

| distdsd,s | Routing distance from the storage node d to the retailer s, . |

| varqpdi,k,pd | Degradation of the quality level of product i stored at packaging node p or storage node d at temperature k. |

| varqmlpi,k,m,l,p | Degradation of the quality level of product i transported by the transport mode m from the grower l to the packaging node p at temperature k. |

| varqmpdi,k,m,p,d | Degradation of the quality level of product i transported by the transport mode m from the packaging node p to the storage node d at temperature k. |

| varqmddi,k,m,d,d | Degradation of the quality level of product i transported by the transport mode m from the storage node d to the storage node d′ at temperature k |

| varqmdsi,k,m,d,s | Degradation of the quality level of product i transported by the transport mode m from the storage node d to the retailer s at temperature k. |

| Decision variables | |

| inventoryi,q,k,pd,t | Stock of product i stored within packaging node p or storage node d at temperature k and quality level q at period t, (units). |

| transportlpk,m,l,p,t | Number of transport vehicles m at temperature k used to move products from the grower l to the packaging node p at period t, (units). |

| transportpdk,m,p,d,t | Number of transport vehicles m at temperature k used to move products from the packaging node p to the storage node d at period t, (vehicles). |

| Number of transport vehicles m at temperature k used to move products from the storage node d to the storage node d′ at period t, (vehicles). | |

| transportdsk,m,d,s,t | Number of transport vehicles m at temperature k used to move products from the storage node d to the retailer s at period t, (vehicles). |

| xlpi,q,k,m,l,p,t | Flow of product i transported by vehicles m from the grower l to the packaging node p at quality q and temperature k at period t, . |

| xpdi,q,k,m,p,d,t | Flow of product i transported by vehicles m from the packaging node p to the storage node d at quality q and temperature k at period t, . |

| Flow of product i transported by vehicles m from the storage node d to the storage node d′ at quality q and temperature k at period t, . | |

| xdsi,q,k,m,d,s,t | Flow of product i transported by vehicles m from the storage node d to the retailer s at quality q and temperature k at period t, . |

| wastei,pds,t | Flow of expired/decayed product i at period t at any supply chain node, (units) |

4. A Case of Long-Ray Cold Chain Design: The New Silk Road Belt

4.1. Energy Parameters Formulation

4.2. Shelf Life Formulation

4.3. Results

- The selected grower/farmer (respectively for apples and milk) is able to satisfy completely the order from the retailer;

- The processing/packaging node is able to process all the incoming products;

- The capacity constraint at the storage nodes is relaxed.

4.4. Discussion

- The energy consumption of the vehicles used to travel along the route;

- The total distance traveled and the travel time, including the fixed setup time of multi-modal transport;

- The need for refrigeration power along the routes.

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Soussana, J.F. Research priorities for sustainable agro-food systems and life cycle assessment. J. Clean. Prod. 2014, 73, 19–23. [Google Scholar] [CrossRef]

- Manzini, R.; Accorsi, R.; Gamberi, M.; Regattieri, A.; Savino, M.M. Logistics and supply chain management: Issues and challenges for modern production systems. In Handbook of Transportation; Taylor & Francis, Routledge Book: New York, NY, USA, 2016; pp. 334–344. [Google Scholar] [CrossRef]

- Accorsi, R.; Manzini, R.; Pini, C. How logistics decisions affect the environmental sustainability of modern food supply chains. A case study from an Italian large scale-retailer. In Sustainability Challenges in the Agrofood Sector; Bhat, R., Ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2017; pp. 179–200. [Google Scholar] [CrossRef]

- Fitzgerald, W.B.; Howitt, O.J. A.; Smith, I.J.; Hume, A. Energy use of integral refrigerated containers in maritime transportation. Energy Policy 2015, 39, 1885–1896. [Google Scholar] [CrossRef]

- Coulomb, D. Refrigeration and cold chain serving the global food industry and creating a better future: Two key IIR challenges for improved health and environment. Trends Food Sci. Technol. 2008, 19, 413–417. [Google Scholar] [CrossRef]

- Bagheri, F.; Fayazbakhsh, M.A.; Bahrami, M. Real-time performance evaluation and potential GHG reduction in refrigerated trailers. Int. J. Refrig. 2017, 73, 24–38. [Google Scholar] [CrossRef]

- Tassou, S.A.; Ge, Y.T. Food transport refrigeration—Approaches to reduce energy consumption and environmental impacts of road transport. Appl. Thermal Eng. 2009, 29, 1467–1477. [Google Scholar] [CrossRef]

- Glouannec, P.; Michel, B.; Delamarre, G.; Grohens, Y. Experimental and numerical study of heat transfer across insulation wall of a refrigerated integral panel van. Appl. Thermal Eng. 2014, 73, 194–202. [Google Scholar] [CrossRef] [Green Version]

- Ahumada, O.; Villalobos, R. Application of planning models in the agro-food supply chain: A review. Eur. J. Oper. Res. 2009, 195, 1–20. [Google Scholar] [CrossRef]

- Accorsi, R.; Manzini, R.; Mora, C.; Cascini, A.; Penazzi, S.; Pini, C.; Pilati, F. Life cycle modelling for sustainable food supply chain. In Proceedings of the 22nd International Conference on Production Research (ICPR 2013), Iguazù Falls, Brazil, 28 July–1 August 2013. [Google Scholar]

- James, S.J.; James, C.; Evans, J.A. Modelling of food transportation systems—A review. Int. J. Refrig. 2006, 29, 947–957. [Google Scholar] [CrossRef]

- Strotmann, C.; Göbel, C.; Friedrich, S.; Kreyenschmidt, J.; Ritter, G.; Teitscheid, P. A Participatory Approach to Minimizing Food Waste in the Food Industry—A Manual for Managers. Sustainability 2017, 9, 66. [Google Scholar] [CrossRef]

- Valli, E.; Manzini, R.; Accorsi, R.; Bortolini, M.; Gamberi, M.; Bendini, A.; Lercker, G.; Gallina Toschi, T. Quality at destination: Simulating shipment of three bottled edible oils from Italy to Taiwan. Rivista Italiana delle Sostanze Grasse 2013, 90, 163–169. [Google Scholar]

- Manzini, R. A top-down approach and a decision support system for the design and management of logistic networks. Transp. Res. Part E 2012, 48, 1185–1204. [Google Scholar] [CrossRef]

- Georgiadis, P.; Vlachos, D.; Iakovou, E. A system dynamics modeling framework for the strategic supply chain management of food chains. J. Food Eng. 2005, 70, 351–364. [Google Scholar] [CrossRef]

- Mangina, E.; Vlachos, I.P. The changing role of information technology in food and beverage logistics management: Beverage network optimisation using intelligent agent technology. J. Food Eng. 2005, 70, 403–420. [Google Scholar] [CrossRef]

- Manzini, R.; Accorsi, R.; Bortolini, M. Operational planning models for distribution networks. Int. J. Prod. Res. 2014, 52, 89–116. [Google Scholar] [CrossRef]

- Handayati, Y.; Simatupang, T.M.; Perdana, T. Agri-food supply chain coordination: The state-of-the-art and recent developments. Logist. Res. 2015, 8, 5. [Google Scholar] [CrossRef]

- Akkerman, R.; Farahani, P.; Grunow, M. Quality, safety and sustainability in food distribution: A review of quantitative operations management. OR Spectr. 2010, 32, 863–904. [Google Scholar] [CrossRef]

- Borodin, V.; Bourtembourg, J.; Hnaien, F.; Labadie, N. Handling uncertainty in agricultural supply chain management: A state of the art. Eur. J. Oper. Res. 2016, 254, 348–359. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; Meuwissen, M.P.M.; Van der Vorst, J.G.A.J. A Review on Quantitative Models for Sustainable Food Logistics Management. Int. J. Food Syst. Dyn. 2012, 3, 136–155. [Google Scholar] [CrossRef]

- Bosona, T.G.; Gebresenbet, G. Cluster building and logistics network integration of local food supply chain. Biosyst. Eng. 2011, 108, 293–302. [Google Scholar] [CrossRef]

- Amorim, P.; Almada-Lobo, B. The impact of food perishability issues in the vehicle routing problem. Comput. Ind. Eng. 2014, 67, 223–233. [Google Scholar] [CrossRef]

- Song, B.D.; Ko, Y.D. A vehicle routing problem of both refrigerated- and general-type vehicles for perishable food products delivery. J. Food Eng. 2016, 169, 61–71. [Google Scholar] [CrossRef]

- Wang, S.; Tao, F.; Shi, Y.; Wen, H. Optimization of Vehicle Routing Problem with Time Windows for Cold Chain Logistics Based on Carbon Tax. Sustainability 2017, 9, 694. [Google Scholar] [CrossRef]

- Pipatprapa, A.; Huang, H.-H.; Huang, C.-H. A Novel Environmental Performance Evaluation of Thailand’s Food Industry Using Structural Equation Modeling and Fuzzy Analytic Hierarchy Techniques. Sustainability 2016, 8, 246. [Google Scholar] [CrossRef]

- Validi, S.; Bhattacharya, A.; Byrne, P.J. A case analysis of a sustainable food supply chain distribution system—A multi-objective approach. Int. J. Prod. Econ. 2014, 152, 71–87. [Google Scholar] [CrossRef]

- Yang, S.; Xiao, Y.; Zheng, Y.; Liu, Y. The Green Supply Chain Design and Marketing Strategy for Perishable Food Based on Temperature Control. Sustainability 2017, 9, 1511. [Google Scholar] [CrossRef]

- Accorsi, R.; Cholette, S.; Manzini, R.; Pini, C.; Penazzi, S. The land-network problem: Ecosystem carbon balance in planning sustainable agro-food supply chains. J. Clean. Prod. 2016, 112, 158–171. [Google Scholar] [CrossRef]

- Savino, M.M.; Manzini, R.; Mazza, A. Environmental and economic assessment of fresh fruit supply chain through value chain analysis. A case study in chestnuts industry. Prod. Plan. Control 2015, 26, 1–18. [Google Scholar] [CrossRef]

- Gwanpua, S.G.; Verboven, P.; Leducq, D.; Brown, T.; Verlinden, B.E.; Bekele, E.; Aregawi, W.; Evans, J.; Foster, A.; Duret, S.; et al. The FRISBEE tool, a software for optimising the trade-off between food quality, energy use, and global warming impact of cold chains. J. Food Eng. 2015, 148, 2–12. [Google Scholar] [CrossRef]

- Vanek, F.; Sun, Y. Transportation versus perishability in life cycle energy consumption: A case study of the temperature-controlled food product supply chain. Transp. Res. Part D 2008, 13, 383–391. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Fresh food sustainable distribution: Cost, delivery time and carbon footprint three-objective optimization. J. Food Eng. 2016, 174, 56–67. [Google Scholar] [CrossRef]

- Rong, A.; Akkerman, R.; Grunow, M. An optimization approach for managing fresh food quality throughout the supply chain. Int. J. Prod. Econ. 2011, 131, 421–429. [Google Scholar] [CrossRef]

- De Keizer, M.; Akkerman, R.; Grunow, M.; Bloemhof, J.M.; Haijema, R.; van der Vorst, J.G. A.J. Logistics network design for perishable products with heterogeneous quality decay. Eur. J. Oper. Res. 2017, 262, 535–549. [Google Scholar] [CrossRef]

- Saif, A.; Elhedhli, S. Cold supply chain design with environmental considerations: A simulation-optimization approach. Eur. J. Oper. Res. 2016, 251, 274–287. [Google Scholar] [CrossRef]

- Accorsi, R.; Gallo, A.; Manzini, R. A climate driven decision-support model for the distribution of perishable products. J. Clean. Prod. 2017, 165, 917–929. [Google Scholar] [CrossRef]

- Accorsi, R.; Manzini, R.; Gallo, A.; Regattieri, A.; Mora, C. Energy balance in sustainable food supply chain processes. In Proceeding of the 3rd International Workshop on Food Supply Chain (IWFSC 2014), San Francisco, CA, USA, 4–7 November 2014. [Google Scholar]

- Conforti, P.; Giampietro, M. Fossil energy use in agriculture: An international comparison. Agric. Ecosyst. Environ. 1997, 65, 231–243. [Google Scholar] [CrossRef]

- Church, N. Why Our Food Is So Dependent on Oil. Energy Bulletin. 1 April 2005. Available online: http://www.energybulletin.net/5045.html (accessed on 7 December 2016).

- Xi, J. Promote Friendship between Our People and Work Together to Build a Bright Future. Speech by H.E. Xi Jinping, President of the People’s Republic of China, Nazarbayev University, Astana; 7 September 2013. Available online: http://www.fmprc.gov.cn/ce/cebel/eng/zxxx/t1078088.html (accessed on 7 April 2017).

- McBride, J. Building the New Silk Road. The New Geopolitics of China, India, and Pakistan. 2015. Available online: https://www.cfr.org/backgrounder/building-new-silk-road (accessed on 7 April 2017).

- Hansen, V. The Silk Road: A New History; Oxford University Press: Oxford, UK, 2012. [Google Scholar]

- Wang, J.-Q.; Li, Y.-B. Coordination Degree Evaluation of Multiple Transport Modes of Comprehensive Transport Corridors in the Silk Road Economic Belt. In Proceedings of the 16th COTA International Conference of Transportation Professionals, Shanghai, China, 6–9 July 2016. [Google Scholar] [CrossRef]

- Xie, Y.; Fan, S. Multi-city sustainable regional urban growth simulation—MSRUGS: A case study along the mid-section of Silk Road of China. Stoch. Environ. Res. Risk Assess. 2014, 28, 829–841. [Google Scholar] [CrossRef]

- Xu, L.-J.; Fan, X.-C.; Wang, W.Q.; Xu, L.; Duan, Y.-L.; Shi, R.-J. Renewable and sustainable energy of Xinjiang and development strategy of node areas in the “Silk Road Economic Belt”. Renew. Sustain. Energy Rev. 2017, 79, 274–285. [Google Scholar] [CrossRef]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D. Fundamentals of Heat and Mass Transfer, 7th ed.; Wiley: Hoboken, NJ, USA, 2011; ISBN 10 0470501979. [Google Scholar]

- Stoecker, W.F. Industrial Refrigeration Handbook; McGraw-Hill Book Co.: New York, NY, USA, 1998. [Google Scholar]

- Connors, K.A.; Amidon, G.L.; Stella, J.V. Chemical Stability of Pharmaceuticals, 2nd ed.; Wiley: New York, NY, USA, 1986. [Google Scholar]

- Accorsi, R.; Manzini, R.; Ferrari, E. A comparison of shipping containers from technical, economic and environmental perspectives. Transp. Res. Part D 2014, 26, 52–59. [Google Scholar] [CrossRef]

- Accorsi, R.; Ferrari, E.; Gamberi, M.; Manzini, R.; Regattieri, A. A closed-loop traceability system to improve logistics decisions in food supply chains. A case study on dairy products. In Advances in Food Traceability Techniques and Technologies: Improving Quality throughout the Food Chain; Montserrat Espiñeira, M., Santaclara, F.J., Eds.; Woodhead Publishing, Elsevier: Cambridge, UK, 2016; pp. 337–351. [Google Scholar] [CrossRef]

- Accorsi, R.; Manzini, R.; Pini, C.; Penazzi, S. On the design of closed-loop networks for product life cycle management: Economic, environmental and geography considerations. J. Trans. Geogr. 2015, 48, 121–134. [Google Scholar] [CrossRef]

- Accorsi, R.; Bortolini, M.; Baruffaldi, G.; Pilati, F.; Ferrari, E. Internet-of-things paradigm in food supply chains control and management. Procedia Manuf. 2017, 11, 889–895. [Google Scholar] [CrossRef]

- Ayyad, Z.; Valli, E.; Bendini, A.; Accorsi, R.; Manzini, R.; Bortolini, M.; Gamberi, M.; Gallina Toschi, T. Simulating international shipments of vegetable oils: Focus on quality changes. Ital. J. Food Sci. 2017, 29, 38–49. [Google Scholar] [CrossRef]

- Manzini, R.; Accorsi, R.; Ayyad, Z.; Bendini, A.; Bortolini, M.; Gamberi, M.; Valli, E.; Gallina Toschi, T. Sustainability and quality in the food supply chain. A case study of shipment of edible oils. Br. Food J. 2014, 116, 2069–2090. [Google Scholar] [CrossRef]

| Logistics Network | Food Products | |||||

|---|---|---|---|---|---|---|

| Node | Country | Type | Average Temp. (°C) | Product | Weight (g/Unit) | Energy Content (kWh/Unit) |

| Vignola | Italy | Grower-Farmer | 26 | Ice cream | 125 | 0.30073 |

| Valsamoggia | Italy | Packaging node | 26 | Apple | 155 | 0.09423 |

| Beihai | China | Storage node | 25 | |||

| Ürümqi | China | Storage node | 27 | |||

| Venice | Italy | Storage node | 25 | |||

| Kazan | Russia | Storage node | 22 | |||

| Moscow | Russia | Storage node | 20 | |||

| Novosibirsk | Russia | Storage node | 20 | |||

| Istanbul | Turkey | Storage node | 27 | |||

| Zhengzhou | China | Retailer | 28 | |||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallo, A.; Accorsi, R.; Baruffaldi, G.; Manzini, R. Designing Sustainable Cold Chains for Long-Range Food Distribution: Energy-Effective Corridors on the Silk Road Belt. Sustainability 2017, 9, 2044. https://doi.org/10.3390/su9112044

Gallo A, Accorsi R, Baruffaldi G, Manzini R. Designing Sustainable Cold Chains for Long-Range Food Distribution: Energy-Effective Corridors on the Silk Road Belt. Sustainability. 2017; 9(11):2044. https://doi.org/10.3390/su9112044

Chicago/Turabian StyleGallo, Andrea, Riccardo Accorsi, Giulia Baruffaldi, and Riccardo Manzini. 2017. "Designing Sustainable Cold Chains for Long-Range Food Distribution: Energy-Effective Corridors on the Silk Road Belt" Sustainability 9, no. 11: 2044. https://doi.org/10.3390/su9112044

APA StyleGallo, A., Accorsi, R., Baruffaldi, G., & Manzini, R. (2017). Designing Sustainable Cold Chains for Long-Range Food Distribution: Energy-Effective Corridors on the Silk Road Belt. Sustainability, 9(11), 2044. https://doi.org/10.3390/su9112044