Ultrasonic Proximal Sensing of Pasture Biomass

Abstract

:1. Introduction

2. The Ultrasonic Pasture Meter Equation

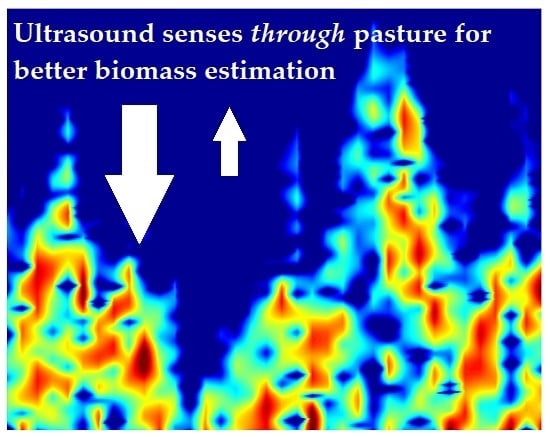

2.1. Signal Generation and Reception

2.2. Sensor Arrays and Beam-forming

3. Calibration in the Laboratory

3.1. Sensitivity

3.2. Beam Pattern

4. Acoustic Scattering from Pasture

4.1. Theoretical Considerations

4.2. Field Experiment Setup

4.3. Ultrasonic Profiles

4.4. Reflecting Objects

4.5. Multiple Scattering

5. Relationship between Biomass and Back-scattered Ultrasonic Power

5.1. Biomass and Reflectance

5.2. Height Variation within the Pasture Layer

5.3. Field Calibration Methodology

5.4. Relationship to Other Methods

6. Field Results

6.1. Biomass Versus Sward Height

6.2. Biomass Estimation Using the Reflectivity Profile

6.3. Model Resilience

7. Discussion and Conclusions

8. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Allen, V.G.; Batello, C.; Berretta, E.J.; Hodgson, J.; Kothmann, M.; Li, X.; McIvor, J.; Milne, J.; Morris, C.; Peeters, A. An international terminology for grazing lands and grazing animals. Grass Forage Sci. 2011, 66, 2–28. [Google Scholar] [CrossRef]

- Beukes, P.; McCarthy, S.; Wims, C.; Gregorini, P.; Romera, A. Regular estimates of herbage mass can improve profitability of pasture-based dairy systems. Anim. Prod. Sci. 2019, 59, 359–367. [Google Scholar] [CrossRef]

- Gebremedhin, A.; Badenhorst, P.; Wang, J.; Spangenberg, G.; Smith, K. Prospects for measurement of dry matter yield in forage breeding programs using sensor technologies. Agronomy 2019, 9, 65. [Google Scholar] [CrossRef]

- Earle, D.; McGowan, A. Evaluation and calibration of an automated rising plate meter for estimating dry matter yield of pasture. Austr. J. Experim. Agric. 1979, 19, 337–343. [Google Scholar] [CrossRef]

- Nakagami, K.; Itano, S. Improving pooled calibration of a rising-plate meter for estimating herbage mass over a season in cool-season grass pasture. Grass Forage Sci. 2014, 69, 717–723. [Google Scholar] [CrossRef]

- Angelone, A.; Toledo, J.M.; Burns, J.C. Herbage measurement insitu by electronics.1. The multiple-probe-type capacitance meter: a brief review. Grass Forage Sci. 1980, 35, 25–33. [Google Scholar] [CrossRef]

- Serrano, J.M.; Peça, J.O.; Marques da Silva, J.; Shahidian, S. Calibration of a capacitance probe for measurement and mapping of dry matter yield in Mediterranean pastures. Precis. Agric. 2011, 12, 860–875. [Google Scholar] [CrossRef]

- Murphy, W.; Silman, J.; Barreto, A.M. A comparison of quadrat, capacitance meter, HFRO sward stick, and rising plate for estimating herbage mass in a smooth-stalked, meadow grass-dominant white clover sward. Grass Forage Sci. 1995, 50, 452–455. [Google Scholar] [CrossRef]

- Clarke, D.; Litherland, A.; Mata, G.; Burling-Claridge, R. Pasture monitoring from space. In Proceedings of the South Island Dairy Event (SIDE) Conference, Lincoln, UK, 24–29 June 2009; pp. 26–28. [Google Scholar]

- Hunt, C.L.; Jones, C.S.; Hickey, M.; Hatier, J.H.B. Estimation in the field of individual perennial ryegrass plant position and dry matter production using a custom-made high-throughput image analysis tool. Crop Sci. 2015, 55, 2910–2917. [Google Scholar] [CrossRef]

- L´opez-D´ıaz, J.; Roca-Fern´andez, A.; Gonz´alezRodr´ıguez, A. Measuring herbage mass by non-destructive methods: A review. J. Agric. Sci. Technol. JAST 2011, 1, 303–314. [Google Scholar]

- Chao, Z.; Liu, N.; Zhang, P.; Ying, T.; Song, K. Estimation methods developing with remote sensing information for energy crop biomass: A comparative review. Biomass Bioenergy 2019, 122, 414–425. [Google Scholar] [CrossRef]

- Xue, J.; Su, B. Significant remote sensing vegetation indices: A review of developments and applications. J. Sens. 2017, 1–17. [Google Scholar] [CrossRef]

- Genever, L. Developing Grazing Systems for Beef Producers: A review of grassland tools. ADAS UK Ltd. 2016. Available online: http://beefandlamb.ahdb.org.uk/wp-content/uploads/2017/11/20160222_Grass-from-beef_tool-review_V4.pdf (accessed on 22 October 2019).

- Andersson, K.; Trotter, M.; Robson, A.; Schneider, D.; Frizell, L.; Saint, A.; Lamb, D.; Blore, C. Estimating pasture biomass with active optical sensors. Adv. Anim. Biosci. 2017, 8, 754–757. [Google Scholar] [CrossRef]

- Hanna, M.; Steyn-Ross, D.; Steyn-Ross, M. Estimating biomass for New Zealand pasture using optical remote sensing techniques. Geocart. Int. 1999, 14, 89–94. [Google Scholar] [CrossRef]

- Gu, Y.; Wylie, B.K.; Howard, D.M.; Phuyal, K.P.; Ji, L. NDVI saturation adjustment: A new approach for improving cropland performance estimates in the Greater Platte River Basin, USA. Ecol. Indic. 2013, 30, 1–6. [Google Scholar] [CrossRef]

- Wachendorf, M.; Fricke, T.; Möckel, T. Remote sensing as a tool to assess botanical composition, structure, quantity and quality of temperate grasslands. Grass Forage Sci. 2018, 73, 1–14. [Google Scholar] [CrossRef]

- Cao, Z.; Cheng, T.; Ma, X.; Tian, Y.; Zhu, Y.; Yao, X.; Chen, Q.; Liu, S.; Guo, Z.; Zhen, Q.; et al. A new three-band spectral index for mitigating the saturation in the estimation of leaf area index in wheat. Int. J. Remote Sens. 2017, 38, 3865–3885. [Google Scholar] [CrossRef]

- Serrano, J.; Shahidian, S.; Marques da Silva, J. Calibration of Grassmaster II to estimate green and dry matter yield in Mediterranean pastures: Effect of pasture moisture content. Crop Pasture Sci. 2016, 67, 780–791. [Google Scholar] [CrossRef]

- Serrano, J.M.; Shahidian, S.; Da Silva, J.R.M. Monitoring pasture variability: optical OptRxR crop sensor versus Grassmaster II capacitance probe. Environ. Monit. Assess. 2016, 188, 117. [Google Scholar] [CrossRef]

- Schulze-Brüninghoff, D.; Hensgen, F.; Wachendorf, M.; Astor, T. Methods for LiDAR-based estimation of extensive grassland biomass. Comput. Electron. Agric. 2019, 156, 693–699. [Google Scholar] [CrossRef]

- Pasqualotto, N.; Delegido, J.; Van Wittenberghe, S.; Rinaldi, M.; Moreno, J. Multi-Crop Green LAI Estimation with a New Simple Sentinel-2 LAI Index (SeLI). Sensors 2019, 19, 904. [Google Scholar] [CrossRef]

- Atzberger, C.; Darvishzadeh, R.; Immitzer, M.; Schlerf, M.; Skidmore, A.; le Maire, G. Comparative analysis of different retrieval methods for mapping grassland leaf area index using airborne imaging spectroscopy. Int. J. Appl. Earth Observ. Geoinf. 2015, 43, 19–31. [Google Scholar] [CrossRef] [Green Version]

- Berger, K.; Atzberger, C.; Danner, M.; D’Urso, G.; Mauser, W.; Vuolo, F.; Hank, T. Evaluation of the PROSAIL model capabilities for future hyperspectral model environments: a review study. Remote Sens. 2018, 10, 85. [Google Scholar] [CrossRef]

- Barthram, G. Experimental Techniques: The HFRO Sward Stick; Technical report; The Hill Farming Research Organization: Midlothian, UK, 1985. [Google Scholar]

- Hutchings, N.; Phillips, A.; Dobson, R. An ultrasonic rangefinder for measuring the undisturbed surface height of continuously grazed grass swards. Grass Forage Sci. 1990, 45, 119–127. [Google Scholar] [CrossRef]

- Hutchings, N. Spatial heterogeneity and other sources of variance in sward height as measured by the sonic and HFRO sward sticks. Grass Forage Sci. 1991, 46, 277–282. [Google Scholar] [CrossRef]

- Hutchings, N. Factors affecting sonic sward stick measurements: the effect of different leaf characteristics and the area of sward sampled. Grass Forage Sci. 1992, 47, 153–160. [Google Scholar] [CrossRef]

- Fricke, T.; Richter, F.; Wachendorf, M. Assessment of forage mass from grassland swards by height measurement using an ultrasonic sensor. Comput. Electron. Agric. 2011, 79, 142–152. [Google Scholar] [CrossRef]

- Zhou, Z.; Parsons, D. Estimation of yield and height of legume-grass swards with remote sensing in northern Sweden. In Sustainable Meat and Milk Production from Grasslands. In Proceedings of the 27th General Meeting of the European Grassland Federation, Cork, Ireland, 17–21 June 2018; Teagasc, Animal & Grassland Research and Innovation Centre: Fermoy, Ireland, 2018; pp. 920–922. [Google Scholar]

- King, W.; Rennie, G.; Dalley, D.; Dynes, R.; Upsdell, M. Pasture mass estimation by the C-Dax pasture meter: regional calibrations for New Zealand. In Proceedings of the 4th Australasian Dairy Science Symposium 2010: Meeting the Challenges for Pasture-based Dairying, Christchurch, New Zealand, 31 August–2 September 2010; 31, pp. 223–238. [Google Scholar]

- Benseman, M. Assessment of Standing Herbage Dry Matter Using A Range Imaging System. PhD Thesis, University of Waikato, Hamilton, New Zealand, 2013. [Google Scholar]

- Barmeier, G.; Mistele, B.; Schmidhalter, U. Referencing laser and ultrasonic height measurements of barley cultivars by using a herbometre as standard. Crop Pasture Sci. 2016, 67, 1215–1222. [Google Scholar] [CrossRef]

- Lee, J.M.; Matthew, C.; Thom, E.R.; Chapman, D.F. Perennial ryegrass breeding in New Zealand: A dairy industry perspective. Crop Pasture Sci. 2012, 63, 107–127. [Google Scholar] [CrossRef]

- Fehmi, J.S.; Stevens, J.M. A plate meter inadequately estimated herbage mass in a semi-arid grassland. Grass Forage Sci. 2009, 64, 322–327. [Google Scholar] [CrossRef]

- Fricke, T.; Wachendorf, M. Combining ultrasonic sward height and spectral signatures to assess the biomass of legume–grass swards. Comput. Electron. Agric. 2013, 99, 236–247. [Google Scholar] [CrossRef]

- Safari, H.; Fricke, T.; Wachendorf, M. Determination of fibre and protein content in heterogeneous pastures using field spectroscopy and ultrasonic sward height measurements. Comput. Electron. Agric. 2016, 123, 256–263. [Google Scholar] [CrossRef]

- Safari, H. Combined Use of Spectral Signatures and Ultrasonic Sward Height for the Assessment of Biomass and Quality Parameters in Heterogeneous Pastures. Ph.D. Thesis, Department of Grassland Science and Renewable Plant Resources, University of Kassel, Witzenhausen, Germany, 2017. [Google Scholar]

- Möckel, T.; Safari, H.; Reddersen, B.; Fricke, T.; Wachendorf, M. Fusion of ultrasonic and spectral sensor data for improving the estimation of biomass in grasslands with heterogeneous sward structure. Remote Sens. 2017, 9, 98. [Google Scholar] [CrossRef]

- Möckel, T.; Fricke, T.; Wachendorf, M. Multitemporal estimation of forage biomass in heterogeneous pastures using static and mobile ultrasonic and hyperspectral measurements. In Sustainable Meat and Milk Production from Grasslands. In Proceedings of the 27th General Meeting of the European Grassland Federation, Cork, Ireland, 17–21 June 2018; Teagasc, Animal & Grassland Research and Innovation Centre: Fermoy, Ireland, 2018; pp. 813–815. [Google Scholar]

- Scotford, I.M.; Miller, P.C.H. Combination of spectral reflectance and ultrasonic sensing to monitor the growth of winter wheat. Biosyst. Eng. 2004, 87, 27–38. [Google Scholar] [CrossRef]

- Enterprises, N. Pasture reader. Available online: http:// pasturereader.com.au/ (accessed on 22 October 2019).

- Barrett, B.A.; Faville, M.J.; Nichols, S.N.; Simpson, W.R.; Bryan, G.T.; Conner, A.J. Breaking through the feed barrier: Options for improving forage genetics. Anim. Prod. Sci. 2015, 55, 883–892. [Google Scholar] [CrossRef]

- Bradley, S.; Legg, M. Systems, Apparatus and Methods for Vegetation Measurement; No. 753949; Gallagher Group Limited: Hamilton, New Zealand, 2019. [Google Scholar]

- Bradley, S.; Legg, M. Vegetation Measurement Apparatus, Systems, and Methods; No. 2019201425; Gallagher Group Limited: Hamilton, New Zealand, 2019. [Google Scholar]

- Rossing, T. Springer Handbook of Acoustics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Marage, J.-P.; Mori, Y. Sonar and Underwater Acoustics; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Ainslie, M.A. Principles of Sonar Performance Modelling; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Hodges, R.P. Underwater Acoustics: Analysis, Design and Performance of Sonar; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Jackson, J.C.; Summan, R.; Dobie, G.I.; Whiteley, S.M.; Pierce, S.G.; Hayward, G. Time-of-flight measurement techniques for airborne ultrasonic ranging. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 343–355. [Google Scholar] [CrossRef]

- Ayton, L.J. Acoustic scattering by a finite rigid plate with a poroelastic extension. J. Fluid Mech. 2016, 791, 414–438. [Google Scholar] [CrossRef] [Green Version]

- Merry, K.; Bettinger, P. Smartphone GPS accuracy study in an urban environment. PLoS ONE 2019, 14, e0219890. [Google Scholar] [CrossRef]

- Högbom, J.A. Aperture synthesis with a non-regular distribution of interferometer baselines. Astron. Astrophys. Suppl. 1974, 15, 417. [Google Scholar]

| srx V Pa−1 | Nrx | Grx | stx V Pa−1 | Ntx | Vtx V | Vref V | D m | Rref m | R m |

|---|---|---|---|---|---|---|---|---|---|

| 0.0126 | 21 | 100 | 0.0075 | 29 | 0.5 | 3 | 0.06 | 0.15 | 0.78 |

| Transect | Biomass Samples | Passes at 5 km/h | Passes at 10 km/h | Passes at 15 km/h | Passes at 20 km/h | Total Passes | Length [m] |

|---|---|---|---|---|---|---|---|

| 1 | 20 | 4 | 4 | 1 | 3 | 12 | 20 |

| 2 | 20 | 1 | 1 | 2 | 4 | 10 | |

| 3 | 20 | 2 | 6 | 3 | 3 | 14 | 10 |

| Transect | 5 km/h | 10 km/h | 15 km/h | 20 km/h | |

|---|---|---|---|---|---|

| Profiles per pass | 1 | 63 | 63 | 63 | 63 |

| 2&3 | 144 | 72 | 48 | 36 | |

| Profiles per biomass sample | 1 | 3 | 3 | 3 | 2 |

| 2&3 | 7.1 | 3.6 | 2.4 | 1.8 |

| Model | Regression Equation | Number N of Regressors |

|---|---|---|

| 1 | B = B0 + μρH | 1 |

| 2 | B = c0R0 + c1R1 | 2 |

| 3 | B = c0H + c1R1 | 2 |

| 4 | B = c0H + c1R1 + c2R2 | 3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Legg, M.; Bradley, S. Ultrasonic Proximal Sensing of Pasture Biomass. Remote Sens. 2019, 11, 2459. https://doi.org/10.3390/rs11202459

Legg M, Bradley S. Ultrasonic Proximal Sensing of Pasture Biomass. Remote Sensing. 2019; 11(20):2459. https://doi.org/10.3390/rs11202459

Chicago/Turabian StyleLegg, Mathew, and Stuart Bradley. 2019. "Ultrasonic Proximal Sensing of Pasture Biomass" Remote Sensing 11, no. 20: 2459. https://doi.org/10.3390/rs11202459

APA StyleLegg, M., & Bradley, S. (2019). Ultrasonic Proximal Sensing of Pasture Biomass. Remote Sensing, 11(20), 2459. https://doi.org/10.3390/rs11202459