Evolution of Si Crystallographic Planes-Etching of Square and Circle Patterns in 25 wt % TMAH

Abstract

:1. Introduction

2. Experimental Setup

3. Discussion and Results

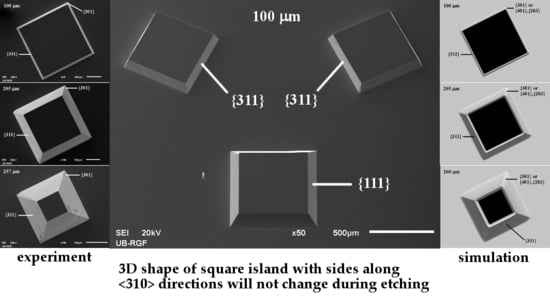

3.1. Square Islands in the Masking Layer with Sides Along <n10> Crystallographic Directions

3.2. Square Apertures in the Masking Layer with Sides Along <n10> Crystallographic Cirections

3.3. Circle Island and Aperture in the Masking Layer

3.4. Etch Rates of Exposed Planes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lindroos, V.; Tilli, М.; Lehto, А.; Motooka, T. Handbook of Silicon Based MEMS Materials and Technologies; William Andrew: Norwich, NY, USA, 2010. [Google Scholar]

- Frühauf, Ј. Shape and Functional Elements of the Bulk Silicon Microtechnique; Springer: Berlin, Germany, 2005. [Google Scholar]

- Shikida, М.; Sato, K.; Tokoro, K.; Uchikawa, D. Differences in anisotropic etching properties of KOH and TMAH solutions. Sens. Actuators A 2000, 80, 179–188. [Google Scholar] [CrossRef]

- Sato, K.; Shikida, M.; Yamashiro, T.; Asaumi, K.; Iriye, Y.; Yamamoto, M. Anisotropic etching rates of single-crystal silicon for TMAH water solution as a function of crystallographic orientation. Sens. Actuators A 1999, 73, 131–137. [Google Scholar] [CrossRef]

- Resnik, D.; Vrtacnik, D.; Aljancic, U.; Amon, S. Wet etching of silicon structures bounded by (311) sidewalls. Microelectron. Eng. 2000, 51–52, 555–566. [Google Scholar] [CrossRef]

- Resnik, D.; Vrtacnik, D.; Amon, S. Morphological study of {311} crystal planes anisotropically etched in (100) silicon: Role of etchants and etching parameters. J. Micromech. Microeng. 2000, 10, 430–439. [Google Scholar] [CrossRef]

- Yang, H.; Bao, M.; Shen, S.; Li, X.; Zhang, D.; Wu, G. A novel technique for measuring etch rate distribution of Si. Sens. Actuators A 2000, 79, 136–140. [Google Scholar] [CrossRef]

- Landsberger, L.M.; Naseh, S.; Kahrizi, M.; Paranjape, M. On Hillocks Generated During Anisotropic Etching of Si in TMAH. J. Microelectromech. Syst. 1996, 5, 106–116. [Google Scholar] [CrossRef]

- Zubel, I.; Barycka, I.; Kotowska, K.; Kramkowska, M. Silicon anisotropic etching in alkaline solution IV: The effect of organic and inorganic agents on silicon anisotropic etching process. Sens. Actuators A 2001, 87, 163–171. [Google Scholar] [CrossRef]

- Trieu, H.K.; Mokwa, W. A generalized model describing corner undercutting by the experimental analysis of TMAH/IPA. J. Micromech. Microeng. 1998, 8, 80–83. [Google Scholar] [CrossRef]

- Sarro, P.M.; Brida, D.; Vlist, W.V.D.; Brida, S. Effect of surfactant on surface quality of silicon microstructures etched in saturated TMAHW solutions. Sens. Actuators A 2000, 85, 340–345. [Google Scholar] [CrossRef]

- Smiljanić, M.M.; Jović, V.; Lazić, Ž. Maskless convex corner compensation technique on a (1 0 0) silicon substrate in a 25 wt. % TMAH water solution. J. Micromech. Microeng. 2012, 22, 115011. [Google Scholar] [CrossRef]

- Smiljanic, M.M.; Radjenović, B.; Radmilović-Radjenović, M.; Lazić, Ž.; Jović, V. Simulation and experimental study of maskless convex corner compensation in TMAH water solution. J. Micromech. Microeng. 2014, 24, 115003. [Google Scholar] [CrossRef]

- Mukhiya, R.; Bagolini, A.; Margesin, B.; Zen, M.; Kal, S. <100> bar corner compensation for CMOS compatible anisotropic TMAH etching. J. Micromech. Microeng. 2006, 16, 2458–2462. [Google Scholar] [CrossRef]

- Bagolini, A.; Faes, A.; Decarli, M. Influence of Etching Potential on Convex Corner Anisotropic Etching in TMAH Solution. J. Microelectromech. Syst. 2010, 19, 1254–1259. [Google Scholar] [CrossRef]

- Mukhiya, R.; Bagolini, A.; Bhattacharyya, T.K.; Lorenzelli, L.; Zen, M. Experimental study and analysis of corner compensation structures for CMOS compatible bulk micromachining using 25 wt % TMAH. Microelectron. J. 2011, 42, 127–134. [Google Scholar] [CrossRef]

- Merlos, A.; Acero, M.C.; Bao, M.H.; Bausells, J.; Esteve, J. A study of the undercutting characteristics in the TMAH-IPA system. J. Micromech. Microeng. 1992, 2, 181–183. [Google Scholar] [CrossRef]

- Merlos, A.; Acero, M.C.; Bao, M.H.; Bausells, J.; Esteve, J. TMAH/IPA anisotropic etching characteristics. Sens. Actuators A 1993, 37–38, 737–743. [Google Scholar] [CrossRef]

- Pal, P.; Sato, K.; Shikida, M.; Gosalvez, M.A. Study of corner compensating structures and fabrication of various shape of MEMS structures in pure and surfactant added TMAH. Sens. Actuators A 2009, 154, 192–203. [Google Scholar] [CrossRef]

- Pal, P.; Sato, K.; Chandra, S. Fabrication techniques of convex corners in a (100)-silicon wafer using bulk micromachining: A review. J. Micromech. Microeng. 2007, 17, R111–R133. [Google Scholar] [CrossRef]

- Powell, O.; Harrison, H.B. Anisotropic etching of {100} and {110} planes in (100) silicon. J. Micromech. Microeng. 2001, 11, 217–220. [Google Scholar] [CrossRef]

- Pal, P.; Sato, K. A comprehensive review on convex and concave corners in silicon bulk micromachining based on anisotropic wet chemical etching. Micro Nano Syst. Lett. 2015, 3, 1–42. [Google Scholar] [CrossRef]

- Pal, P.; Sato, K.; Gosalvez, M.A.; Shikida, M. Study of rounded concave and sharp edge convex corners undercutting in CMOS compatible anisotropic etchants. J Micromech. Microeng. 2007, 17, 2299–2307. [Google Scholar] [CrossRef]

- Pal, P.; Haldar, S.; Singh, S.S.; Ashok, A.; Yan, X.; Sato, K. A detailed investigation and explanation to the appearance of different undercut profiles in KOH and TMAH. J Micromech. Microeng. 2014, 24, 095026. [Google Scholar] [CrossRef]

- Zubel, I.; Kramkowska, M. Development of etch hilloks on different Si (hkl) planes in silicon anisotropic etching. Surf. Sci. 2008, 602, 1712–1721. [Google Scholar] [CrossRef]

- Barycka, I.; Zubel, I. Silicon anisotroping etching in KOH-isopropanol etchant. Sens. Actuators A 1995, 48, 229–238. [Google Scholar] [CrossRef]

- Zubel, I.; Barycka, I. Silicon anisotropic etching in alkaline solutions I. The geometric description of figures developed under etching Si (100) in various solutions. Sens. Actuators A 1998, 70, 250–259. [Google Scholar] [CrossRef]

- Zubel, I. The influence of atomic configuration of (hkl) planes on adsorption processes associated with anisotropic etching of silicon. Sens. Actuators A 2001, 94, 76–86. [Google Scholar] [CrossRef]

- Zubel, I. Silicon anisotropic etching in alkaline solutions III. On the possibility of spatial structures forming in the course of Si (100) anisotropic etching in KOH and KOH+IPA solutions. Sens. Actuators A 2000, 84, 116–125. [Google Scholar] [CrossRef]

- Gosalvez, M.A.; Nieminen, R.; Kilpinen, P.; Haimi, E.; Lindroos, V.K. Anisotropic wet chemical etching of crystalline silicon: Atomistic Monte-Carlo simulations and experiments. Appl. Surf. Sci. 2001, 178, 7–26. [Google Scholar] [CrossRef]

- Puers, B.; Sansen, W. Compensation structures for convex corner micromachining in silicon. Sens. Actuators A 1990, 21–23, 1036–1041. [Google Scholar] [CrossRef]

- Monterio, T.S.; Kastytis, P.; Goncalves, L.M.; Minas, G.; Cardoso, S. Dynamic Wet Etching of Silicon through Isopropanol Alcohol Evaporation. Micromachines 2015, 10, 1534–1545. [Google Scholar] [CrossRef]

- Osher, S.; Sethian, J.A. Fronts Propagating with Curvature Dependent Speed: Algorithms Based on Hamilton-Jacobi Formulations. J. Comp. Phys. 1988, 79, 12–49. [Google Scholar] [CrossRef]

- Radjenović, B.; Lee, J.K.; Radmilović-Radjenović, M. Sparse field level set method for non-convex Hamiltonians in 3D plasma etching profile simulations. Comput. Phys. Commun. 2006, 174, 127–132. [Google Scholar] [CrossRef]

- Radjenović, B.; Radmilović-Radjenović, M.; Mitrić, M. Non-convex Hamiltonians in 3D level set simulations of the wet etching of silicon. Appl. Phys. Lett. 2006, 89, 213102. [Google Scholar] [CrossRef]

- Radjenović, B.; Radmilović-Radjenović, M. 3D simulations of the profile evolution during anisotropic wet etching of silicon. Thin Solid Films 2009, 517, 4233–4237. [Google Scholar] [CrossRef]

- Radjenović, B.; Radmilović-Radjenović, M.; Mitrić, M. Level Set Approach to Anisotropic Wet Etching of Silicon. Sensors 2010, 10, 4950–4967. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Montoliu, C.; Ferrando, N.; Gosalvez, M.A.; Cerda, J.; Colom, R.J. Level set implementation for the simulation of anisotropic etching: Application to complex MEMS micromachining. J. Micromech. Microeng. 2013, 23, 075017. [Google Scholar] [CrossRef]

- Montoliu, C.; Ferrando, N.; Gosalvez, M.A.; Cerda, J.; Colom, R.J. Implementation and evaluation of the Level Set method—Towards efficient and accurate simulation of wet etching for microengineering applications. Comput. Phys. Commun. 2013, 184, 2299–2309. [Google Scholar] [CrossRef]

- Yu, J.C.; Zhou, Z.F.; Su, J.L.; Xia, C.F.; Zhang, X.W.; Wu, Z.Z.; Huang, Q.A. Three-Dimensional Simulation of DRIE Process Based on the Narrow Band Level Set and Monte Carlo Method. Micromachines 2018, 2, 74. [Google Scholar] [CrossRef]

- Available online: http://www.paraview.org (accessed on 26 January 2019).

- Shikida, M.; Nanbara, K.; Koizumi, T.; Sasaki, H.; Odagaki, M.; Sato, K.; Ando, M.; Furuta, S.; Asaumi, K. A model explaining mask-corner undercut phenomena in anisotropic silicon etching: A saddle point in the etching-rate diagram. Sens. Actuators A 2002, 97–98, 758–763. [Google Scholar] [CrossRef]

- Hubbard, T.J. MEMS Design-Geometry of Silicon Micromachining. Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 1994. [Google Scholar]

| Plane {n11} | γn11 theo (°) | Etch Rate rn11 input (µm/min) | γn11 exp (°) | Etch Rate rn11 exp (µm/min) | γn11 sim (°) | Etch Rate rn11 sim (µm/min) |

|---|---|---|---|---|---|---|

| {111} | 54.7 | 0.02 | 54.2 | 0.02 | 54.7 | 0.03 |

| {211} | 65.9 | 0.87 | 66.7 | 0.87 | 65.3 | 0.81 |

| {311} | 72.5 | 0.93 | 74.2 | 0.93 | 69.8 | 0.88 |

| {411} | 76.4 | 0.82 | 78.7 | 0.85 | 76.9 | 0.79 |

| {511} | 78.9 | 0.75 | 80.9 | 0.81 | 79.4 | 0.74 |

| {611} | 80.7 | 0.71 | 81 | 0.73 | 80.8 | 0.70 |

| {711} | 82 | 0.67 | 83.1 | 0.69 | 82.1 | 0.66 |

| {811} | 82.9 | 0.65 | 83.1 | 0.66 | 82.9 | 0.64 |

| {911} | 83.7 | 0.63 | 84.1 | 0.63 | 83.8 | 0.62 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smiljanić, M.M.; Lazić, Ž.; Radjenović, B.; Radmilović-Radjenović, M.; Jović, V. Evolution of Si Crystallographic Planes-Etching of Square and Circle Patterns in 25 wt % TMAH. Micromachines 2019, 10, 102. https://doi.org/10.3390/mi10020102

Smiljanić MM, Lazić Ž, Radjenović B, Radmilović-Radjenović M, Jović V. Evolution of Si Crystallographic Planes-Etching of Square and Circle Patterns in 25 wt % TMAH. Micromachines. 2019; 10(2):102. https://doi.org/10.3390/mi10020102

Chicago/Turabian StyleSmiljanić, Milče M., Žarko Lazić, Branislav Radjenović, Marija Radmilović-Radjenović, and Vesna Jović. 2019. "Evolution of Si Crystallographic Planes-Etching of Square and Circle Patterns in 25 wt % TMAH" Micromachines 10, no. 2: 102. https://doi.org/10.3390/mi10020102

APA StyleSmiljanić, M. M., Lazić, Ž., Radjenović, B., Radmilović-Radjenović, M., & Jović, V. (2019). Evolution of Si Crystallographic Planes-Etching of Square and Circle Patterns in 25 wt % TMAH. Micromachines, 10(2), 102. https://doi.org/10.3390/mi10020102