Technical Model of Micro Electrical Discharge Machining (EDM) Milling Suitable for Bottom Grooved Micromixer Design Optimization

Abstract

:1. Introduction

2. Materials and Methods

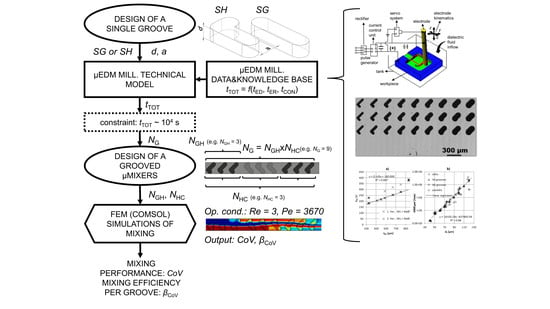

2.1. Investigation Workflow

2.2. BGM Geometry and Mixing Simulation Tool

2.3. Micro EDM Milling

- op1: dressing of the electrode using on the machine integrated wire dressing unit. Time needed for this operation is denoted as tED and is a function of:tED = f(dE(geometry, gap(regime)), electrode working length(, regime));

- op2: actual erosion time tER = f(dE, regime, strategy, MRR, volume of geometry);

- op3: time for electrode wear control tCON = f (depth of the geometry, ).

2.3.1. Dressing of the Tool Electrode

2.3.2. Material Removal Rate and Erosion Time

- pockets: length of 310 µm, d = 100 µm, dE = 40–120 µm, 2 passes with 40% overlap, 2 repetitions (Figure 4d);

- SH slots: d = 40, 120 µm, dE = 40, 70, 100 µm, 1 repetition;

2.3.3. Electrode Wear Control

2.4. Implementation of the Technical Model

2.5. Simulated BGM Designs

3. Results and Discussion

3.1. Micro EDM Milling DKB Construction

- based on the premise rG == a/2 single electrode slotting strategy is selected;

- volume to be removed is calculated as:

- electrode diameter is calculated as: dE = a - 2∙lGAP = 82 µm;

- electrode working length (Equation (6)): lWL = f(h,d) = 290 µm;

- time of electrode dressing (Equation (4)): tED = f(lWL = 290 µm) = 202 s;

- material removal rate (Equation (5)): MRR = f(dE = 82 µm) = 9.3 × 105 µm3/min;

- erosion time: tER = VW/MRR = 51 s;

- control time (Equation (7)): tCON = f (d = 40 µm) = 90 s;

- one SG groove machining time: t1groove = tED + tER + tCON = 343 s;

3.2. Micromixer Design for Micro EDM Milling

3.3. Simulation Runs of Technical Model

3.4. General Applicability of the Technical Model

4. Conclusions

- When machining narrow slots (a < 60 µm) optimization of MRR is crucial for reduction of feature machining time.

- At machining wider (a > 60 µm) and deeper (d > 40 µm) slots reducing electrode control and dressing time is sensible optimization strategy.

- For lower aspect ratio slots (d/a < 0.6) electrode dressing time contributes dominantly to feature machining time.

- Narrow groove corner roundings should be avoided if possible, despite applying a 2-electrode strategy, due to corresponding very low MRR(dE2).

- Predicted future implementations of concurrent electrode wear estimations could eliminate electrode wear control time and thus, significantly shorten feature machining time. In the case of grooves applied in this investigation from 19% up to 40%.

- Investigated BGM designs are readily applicable in metal substrates, thus demonstrating the capabilities of micro EDM milling technology, which in terms of obtainable feature aspect ratios surpasses soft lithography methods.

- The best BGM configuration in terms of mixing performance (CoV and βCoV) was SGM configuration with groove dimension of a = 88 µm and d = 70 µm, representing a favourable groove geometry.

- SG micromixers with round groove corners achieve better mixing performance. In SH micromixers smaller corner roundings (i.e. sharper corners) perform better.

- More half-cycles for fixed number of grooves improves mixing performance of SH micromixers.

- SGM design is more suitable than SHM for micro EDM milling and gives better mixing performance.

- Lower mixing performances of SHMs may be attributed to reduced effectiveness of the shorter arm due to groove corner roundings which are inherently connected with micro EDM milling technology.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alting, L.; Kimura, F.; Hansen, H.N.; Bissacco, G. Micro engineering. CIRP Ann. Manuf. Technol. 2003, 52, 635–657. [Google Scholar] [CrossRef]

- Masuzawa, T. State of the art of micromachining. CIRP Ann. Manuf. Technol. 2000, 49, 473–488. [Google Scholar] [CrossRef]

- Hessel, V.; Lowe, H.; Muller, A.; Kolb, G. Chemical Micro Process Engineering: Processing and Plants, 1st ed.; Wiley-VCH: Weinheim, Germany, 2005; ISBN 978-3-527-30998-6. [Google Scholar]

- Cvjetko, M.; Žnidaršič-Plazl, P. Ionic Liquids within Microfluidic Devices. In Ionic Liquids: Theory, Properties, New Approaches; InTech: London, UK, 2011. [Google Scholar]

- Stroock, A.D.; Dertinger, S.K.W.; Ajdari, A.; Mezic, I.; Stone, H.A.; Whitesides, G.M. Chaotic Mixer for Microchannels. Science 2002, 295, 647–651. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lynn, N.S.; Dandy, D.S. Geometrical optimization of helical flow in grooved micromixers. Lab Chip 2007, 7, 580–587. [Google Scholar] [CrossRef]

- Yang, J.T.; Huang, K.J.; Lin, Y.C. Geometric effects on fluid mixing in passive grooved micromixers. Lab Chip 2005, 5, 1140–1147. [Google Scholar] [CrossRef]

- Aubin, J.; Fletcher, D.F.; Xuereb, C. Design of micromixers using CFD modelling. Chem. Eng. Sci. 2005, 60, 2503–2516. [Google Scholar] [CrossRef] [Green Version]

- Ansari, M.A.; Kim, K.-Y. Application of the Radial Basis Neural Network to Optimization of a Micromixer. Chem. Eng. Technol. 2007, 30, 962–966. [Google Scholar] [CrossRef]

- Williams, M.S.; Longmuir, K.J.; Yager, P. A practical guide to the staggered herringbone mixer. Lab Chip 2008, 8, 1121. [Google Scholar] [CrossRef] [Green Version]

- Cortes-Quiroz, C.A.; Zangeneh, M.; Goto, A. On multi-objective optimization of geometry of staggered herringbone micromixer. Microfluid. Nanofluidics 2009, 7, 29–43. [Google Scholar] [CrossRef]

- Hossain, S.; Husain, A.; Kim, K.Y. Optimization of micromixer with staggered herringbone grooves on top and bottom walls. Eng. Appl. Comput. Fluid Mech. 2011, 5, 506–516. [Google Scholar] [CrossRef] [Green Version]

- Yoshimura, M.; Shimoyama, K.; Misaka, T.; Obayashi, S. Optimization of passive grooved micromixers based on genetic algorithm and graph theory. Microfluid. Nanofluidics 2019, 23, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Rhoades, T.; Kothapalli, C.R.; Fodor, P.S. Mixing Optimization in Grooved Serpentine Microchannels. Micromachines 2020, 11, 61. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ianovska, M.A.; Mulder, P.P.M.F.A.; Verpoorte, E. Development of small-volume, microfluidic chaotic mixers for future application in two-dimensional liquid chromatography. RSC Adv. 2017, 7, 9090–9099. [Google Scholar] [CrossRef] [Green Version]

- Sitar, A.; Golobic, I. Heat transfer enhancement of self-rewetting aqueous n-butanol solutions boiling in microchannels. Int. J. Heat Mass Transf. 2015, 81, 198–206. [Google Scholar] [CrossRef]

- Marschewski, J.; Brechbühler, R.; Jung, S.; Ruch, P.; Michel, B.; Poulikakos, D. Significant heat transfer enhancement in microchannels with herringbone-inspired microstructures. Int. J. Heat Mass Transf. 2016, 95, 755–764. [Google Scholar] [CrossRef]

- Hahn, R.; Wagner, S.; Schmitz, A.; Reichl, H. Development of a planar micro fuel cell with thin film and micro patterning technologies. J. Power Sources 2004, 131, 73–78. [Google Scholar] [CrossRef]

- Brousseau, E.B.; Dimov, S.S.; Pham, D.T. Some recent advances in multi-material micro- and nano-manufacturing. Int. J. Adv. Manuf. Technol. 2010, 47, 161–180. [Google Scholar] [CrossRef]

- Hung, J.C.; Yang, T.C.; Li, K.C. Studies on the fabrication of metallic bipolar plates—Using micro electrical discharge machining milling. J. Power Sources 2011, 196, 2070–2074. [Google Scholar] [CrossRef]

- Hessel, V.; Hardt, S.; Löwe, H.; Schönfeld, F. Laminar mixing in different interdigital micromixers: I. Experimental characterization. AIChE J. 2003, 49, 566–577. [Google Scholar] [CrossRef]

- Pennemann, H.; Watts, P.; Haswell, S.J.; Hessel, V.; Löwe, H. Benchmarking of Microreactor Applications. Org. Process Res. Dev. 2004, 8, 422–439. [Google Scholar] [CrossRef]

- Liu, K.; Lauwers, B.; Reynaerts, D. Process capabilities of Micro-EDM and its applications. Int. J. Adv. Manuf. Technol. 2010, 47, 11–19. [Google Scholar] [CrossRef] [Green Version]

- Kunieda, M.; Lauwers, B.; Rajurkar, K.P.; Schumacher, B.M. Advancing EDM through fundamental insight into the process. CIRP Ann. Manuf. Technol. 2005, 54, 64–87. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Kozak, J.; Rajurkar, K.P. Modelling and simulation of micro EDM process. CIRP Ann. Manuf. Technol. 2003, 52, 143–146. [Google Scholar] [CrossRef]

- Jeong, Y.H.; Min, B.-K. Geometry prediction of EDM-drilled holes and tool electrode shapes of micro-EDM process using simulation. Int. J. Mach. Tools Manuf. 2007, 47, 1817–1826. [Google Scholar] [CrossRef]

- Heo, S.; Jeong, Y.H.; Min, B.-K.; Lee, S.J. Virtual EDM simulator: Three-dimensional geometric simulation of micro-EDM milling processes. Int. J. Mach. Tools Manuf. 2009, 49, 1029–1034. [Google Scholar] [CrossRef]

- Surleraux, A.; Pernot, J.-P.; Elkaseer, A.; Bigot, S. Iterative surface warping to shape craters in micro-EDM simulation. Eng. Comput. 2016, 32, 517–531. [Google Scholar] [CrossRef] [Green Version]

- Hinduja, S.; Kunieda, M. Modelling of ECM and EDM processes. CIRP Ann. Manuf. Technol. 2013, 62, 775–797. [Google Scholar] [CrossRef]

- Lovatt, A.M.; Shercliff, H.R. Manufacturing process selection in engineering design. Part 1: The role of process selection. Mater. Des. 1998, 19, 205–215. [Google Scholar] [CrossRef]

- Lynn, N.S.; Bocková, M.; Adam, P.; Homola, J. Biosensor Enhancement Using Grooved Micromixers: Part II, Experimental Studies. Anal. Chem. 2015, 87, 5524–5530. [Google Scholar] [CrossRef]

- Lehmann, M.; Wallbank, A.M.; Dennis, K.A.; Wufsus, A.R.; Davis, K.M.; Rana, K.; Neeves, K.B. On-chip recalcification of citrated whole blood using a microfluidic herringbone mixer. Biomicrofluidics 2015, 9, 064106. [Google Scholar] [CrossRef] [Green Version]

- Žnidaršič Plazl, P.; Plazl, I. Modelling and experimental studies on lipase-catalyzed isoamyl acetate synthesis in a microreactor. Process Biochem. 2009, 44, 1115–1121. [Google Scholar] [CrossRef]

- Aubin, J.; Prat, L.; Xuereb, C.; Gourdon, C. Effect of microchannel aspect ratio on residence time distributions and the axial dispersion coefficient. Chem. Eng. Process. Process Intensif. 2009, 48, 554–559. [Google Scholar] [CrossRef] [Green Version]

- Valentinčič, J.; Sabotin, I.; Tristo, G.; Bissacco, G.; Bigot, S. Tooling and Microinjection Moulding of Bottom Grooved Micromixers. In Proceedings of the 10th International Conference on Multi-Material Micro Manufacture, San Sebastian, Spain, 10 October 2013. [Google Scholar]

- Sabotin, I.; Tristo, G.; Junkar, M.; Valentinčič, J. Two-step design protocol for patterned groove micromixers. Chem. Eng. Res. Des. 2013, 91, 778–788. [Google Scholar] [CrossRef]

- Okuducu, M.; Aral, M. Performance Analysis and Numerical Evaluation of Mixing in 3-D T-Shape Passive Micromixers. Micromachines 2018, 9, 210. [Google Scholar] [CrossRef] [Green Version]

- Kukuková, A.; Noël, B.; Kresta, S.M.; Aubin, J. Impact of sampling method and scale on the measurement of mixing and the coefficient of variance. AIChE J. 2008, 54, 3068–3083. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Masuzawa, T.; Fujino, M. Micro-EDM for three-dimensional cavities—Development of uniform wear method. CIRP Ann. Manuf. Technol. 1998, 47, 169–172. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Wong, Y.S.; Rahman, M. Profile error compensation in high precision 3D micro-EDM milling. Precis. Eng. 2013, 37, 399–407. [Google Scholar] [CrossRef]

- Li, J.Z.; Xiao, L.; Wang, H.; Yu, H.L.; Yu, Z.Y. Tool wear compensation in 3D micro EDM based on the scanned area. Precis. Eng. 2013, 37, 753–757. [Google Scholar] [CrossRef]

- Tong, H.; Zhang, L.; Li, Y. Algorithms and machining experiments to reduce depth errors in servo scanning 3D micro EDM. Precis. Eng. 2014, 38, 538–547. [Google Scholar] [CrossRef]

- Wang, J.; Qian, J.; Ferraris, E.; Reynaerts, D. In-situ process monitoring and adaptive control for precision micro-EDM cavity milling. Precis. Eng. 2017, 47, 261–275. [Google Scholar] [CrossRef]

- Bleys, P.; Kruth, J.P.; Lauwers, B. Sensing and compensation of tool wear in milling EDM. J. Mater. Process. Technol. 2004, 149, 139–146. [Google Scholar] [CrossRef]

- Tristo, G.; Balcon, M.; Carmignato, S.; Bissacco, G. Validation of on-machine microfeatures volume measurement using micro EDM milling tool electrode as touch probe. In Proceedings of the 13th International Conference of the European Society for Precision Engineering and Nanotechnology, Berlin, Germany, 27 May–31 May 2013; EUSPEN: Delft, The Netherlands, 2013. [Google Scholar]

- Tsai, Y.-Y.; Masuzawa, T. An index to evaluate the wear resistance of the electrode in micro-EDM. J. Mater. Process. Technol. 2004, 149, 304–309. [Google Scholar] [CrossRef]

- Bissacco, G.; Hansen, H.N.; Tristo, G.; Valentinčič, J. Feasibility of wear compensation in micro EDM milling based on discharge counting and discharge population characterization. CIRP Ann. Manuf. Technol. 2011, 60, 231–234. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, Z.; Yim, C.; Lin, M.; Cao, X. Evaluation of Floor-grooved Micromixers using Concentration-channel Length Profiles. Micromachines 2010, 1, 19–33. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.S.; Lee, S.W.; Kwon, T.H.; Lee, S.S. A barrier embedded chaotic micromixer. J. Micromech. Microeng. 2004, 14, 798–805. [Google Scholar] [CrossRef]

- Bissacco, G.; Tristo, G.; Hansen, H.N.; Valentincic, J. Reliability of electrode wear compensation based on material removal per discharge in micro EDM milling. CIRP Ann. Manuf. Technol. 2013, 62, 179–182. [Google Scholar] [CrossRef]

| Main Channel Cross-Section (µm) | Groove Inclination Angle | SH Groove Apex Asymmetry | Groove Width a (µm) | Groove Depth d (µm) | Groove Aspect Ratio | Ridge Length b (µm) | Radius of the Groove Corners rG (µm) |

|---|---|---|---|---|---|---|---|

| w × h = 200 × 50 | 45° | 1/3 × w | 48–106 | 40–75 | 0.38–0.85 | 70 | 25–53 |

| Parameters | dE = 40 µm | dE = 50–120 µm | dE = 183 µm |

|---|---|---|---|

| E (index) | 13 | 13 | 105 |

| (+,-) | - | - | - |

| tP (indeks) | 2 | 2 | 6 |

| fP (kHz) | 180 | 180 | 100 |

| iP (index) | 80 | 100 | 65 |

| u (V) | 77 | 90 | 100 |

| z1L (µm) | 0.7 | 0.7 | 0.7 |

| gain (index) | 100 | 100 | 80 |

| gi (index) | 74 | 74 | 80 |

| nCON | every 10 µm | every 10 µm | every 10 µm |

| No | Var. | a (µm) | d (µm) | rG (µm) | NGH | NHC | t1groove (s) | tGR (s) | tCH (s) | TTOT (s) | CoV | βCoV |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| #1 | SGM | 48 | 40 | a/2 | 12 | 1 | 478 | 5741 | 4069 | 9810 | 0.57 | 0.15 |

| #2 | SGM | 71 | 40 | a/2 | 15 | 1 | 357 | 5348 | 4587 | 9934 | 0.15 | 0.44 |

| #3 | SGM | 88 | 40 | a/2 | 15 | 1 | 342 | 5133 | 4784 | 9917 | 0.14 | 0.48 |

| #4 | SGM | 106 | 40 | a/2 | 15 | 1 | 335 | 5019 | 4981 | 10000 | 0.15 | 0.44 |

| #5 | SGM | 71 | 60 | a/2 | 13 | 1 | 437 | 5676 | 4376 | 10052 | 0.07 | 1.10 |

| #6 | SGM | 88 | 70 | a/2 | 12 | 1 | 474 | 5690 | 4429 | 10119 | 0.05 | 1.67 |

| #7 | SGM | 106 | 75 | a/2 | 12 | 1 | 467 | 5603 | 4587 | 10189 | 0.06 | 1.39 |

| #8 | SHM | 48 | 40 | a/2 | 2 | 6 | 477 | 5718 | 4209 | 9927 | 0.32 | 0.26 |

| #9 | SHM | 48 | 40 | a/2 | 3 | 4 | 477 | 5718 | 4139 | 9857 | 0.37 | 0.23 |

| #10 | SHM | 48 | 40 | a/2 | 4 | 3 | 477 | 5718 | 4104 | 9822 | 0.47 | 0.18 |

| #11 | SHM | 48 | 40 | a/2 | 6 | 2 | 477 | 5718 | 4069 | 9787 | 0.47 | 0.18 |

| #12 | SHM | 71 | 40 | a/2 | 3 | 5 | 355 | 5331 | 4692 | 10023 | 0.15 | 0.44 |

| #13 | SHM | 71 | 40 | a/2 | 5 | 3 | 355 | 5331 | 4622 | 9953 | 0.25 | 0.27 |

| #14 | SHM | 71 | 60 | a/2 | 3 | 4 | 435 | 5220 | 4341 | 9561 | 0.19 | 0.44 |

| #15 | SHM | 71 | 60 | a/2 | 6 | 2 | 435 | 5220 | 4271 | 9491 | 0.28 | 0.30 |

| #16 | SHM | 88 | 40 | 25 | 3 | 3 | 711 | 6395 | 4109 | 10503 | 0.52 | 0.21 |

| #17 | SHM | 88 | 40 | 25 | 2 | 5 | 711 | 7105 | 4297 | 11402 | 0.34 | 0.29 |

| #18 | SHM | 106 | 40 | 25 | 3 | 3 | 728 | 6548 | 4227 | 10774 | 0.54 | 0.21 |

| #19 | SHM | 106 | 40 | 25 | 2 | 5 | 728 | 7275 | 4429 | 11704 | 0.41 | 0.24 |

| #20 | SHM | 88 | 70 | 25 | 3 | 3 | 994 | 8948 | 4109 | 13056 | 0.25 | 0.44 |

| #21 | SHM | 88 | 70 | 25 | 2 | 5 | 994 | 9942 | 4297 | 14239 | 0.16 | 0.63 |

| #22 | SHM | 106 | 75 | 25 | 3 | 3 | 1043 | 9388 | 4227 | 13615 | 0.26 | 0.43 |

| #23 | SHM | 106 | 75 | 25 | 2 | 5 | 1043 | 10431 | 4429 | 14860 | 0.18 | 0.56 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabotin, I.; Tristo, G.; Valentinčič, J. Technical Model of Micro Electrical Discharge Machining (EDM) Milling Suitable for Bottom Grooved Micromixer Design Optimization. Micromachines 2020, 11, 594. https://doi.org/10.3390/mi11060594

Sabotin I, Tristo G, Valentinčič J. Technical Model of Micro Electrical Discharge Machining (EDM) Milling Suitable for Bottom Grooved Micromixer Design Optimization. Micromachines. 2020; 11(6):594. https://doi.org/10.3390/mi11060594

Chicago/Turabian StyleSabotin, Izidor, Gianluca Tristo, and Joško Valentinčič. 2020. "Technical Model of Micro Electrical Discharge Machining (EDM) Milling Suitable for Bottom Grooved Micromixer Design Optimization" Micromachines 11, no. 6: 594. https://doi.org/10.3390/mi11060594

APA StyleSabotin, I., Tristo, G., & Valentinčič, J. (2020). Technical Model of Micro Electrical Discharge Machining (EDM) Milling Suitable for Bottom Grooved Micromixer Design Optimization. Micromachines, 11(6), 594. https://doi.org/10.3390/mi11060594