Low Power Consumption 3D-Inverted Ridge Thermal Optical Switch of Graphene-Coated Polymer/Silica Hybrid Waveguide

Abstract

:1. Introduction

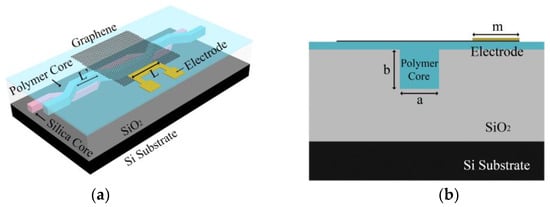

2. Device Design and Theoretical Analysis

3. Optimization and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Song, J.; Luo, X. Three-dimensional (3D) monolithically integrated photodetector and WDM receiver based on bulk silicon wafer. Opt. Express 2014, 22, 19546–19554. [Google Scholar] [CrossRef] [PubMed]

- Stone, A.; Jain, H. Direct laser-writing of ferroelectric single-crystal waveguide architectures in glass for 3D integrated optics. Sci. Rep. 2015, 5, 10391. [Google Scholar] [CrossRef] [PubMed]

- Forget, S.; Balembois, F. A new 3D multipass amplifier based on Nd:YAG or Nd:YVO4 crystals. Appl. Phys. B Lasers Opt. 2002, 75, 481–485. [Google Scholar] [CrossRef] [Green Version]

- Hurtado, A.; Henning, I.D. Bistability and nonlinear gain in 1.55 μ m vertical cavity semiconductor optical amplifiers: Theory and experiments. Appl. Phys. Lett. 2007, 91, 151106. [Google Scholar] [CrossRef]

- Woods, R.; Feldbacher, S. 3D optical waveguides produced by two photon photopolymerisation of a flexible silanol terminated polysiloxane containing acrylate functional groups. Opt. Mater. Express 2014, 4, 486–498. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Z.; Yang, J.; Xiao, H.; Ren, G.; Jiang, Y.; Zhao, T.; Nguyen, T.; Mitchell, A.; Yang, J.; et al. On-chip switchable and reconfigurable optical mode exchange device using cascaded three-waveguide-coupling switches. Opt. Express 2020, 28, 9552–9562. [Google Scholar] [CrossRef]

- Ohkoshi, S.; Takano, S. 90-degree optical switching of output second-harmonic light in chiral photomagnet. Nat. Photonics 2014, 8, 65–71. [Google Scholar]

- Vlasov, Y.; Green, W.M.J.; Xia, F. High-throughput silicon nanophotonic wavelength-insensitive switch for on-chip optical networks. Nat. Photonics 2008, 2, 242–246. [Google Scholar] [CrossRef]

- Popa, D.; Sun, Z. Graphene Q-switched, tunable fiber laser. Appl. Phys. Lett. 2011, 98, 073106. [Google Scholar] [CrossRef] [Green Version]

- Lancaster, D.G.; Gross, S.; Ebendorff-Heidepriem, H.; Withford, M.J.; Monro, T.M.; Jackson, S.D. Efficient 29 μm fluorozirconate glass waveguide chip laser. Opt. Lett. 2013, 38, 2588–2591. [Google Scholar] [CrossRef]

- Hadfield, R.H. Single-photon detectors for optical quantum information applications. Nat. Photonics 2009, 3, 696–705. [Google Scholar] [CrossRef]

- Han, Z.; Singh, V.; Kita, D.; Monmeyran, C.; Becla, P.; Su, P.; Li, J.; Huang, X.; Kimerling, L.C.; Hu, J.; et al. On-chip chalcogenide glass waveguide-integrated mid-infrared PbTe detectors. Appl. Phys. Lett. 2016, 109, 071111. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, Y. Design and Analysis of a Novel Graphene-Assisted Silica/Polymer Hybrid Waveguide with Thermal-Optical Phase Modulation Structure. IEEE Photonics J. 2019, 11, 1–10. [Google Scholar] [CrossRef]

- Bian, Y.; Zheng, Z.; Zhao, X.; Zhu, J.; Zhou, T. Symmetric hybrid surface plasmon polariton waveguides for 3D photonic integration. Opt. Express 2009, 17, 21320–21325. [Google Scholar] [CrossRef]

- Pandit, M.K.; Chan, H.P. The WDM performance of compact X-junction switches in polymer. Microw. Opt. Technol. Lett. 2001, 28, 423–426. [Google Scholar]

- Chan, H.P.; Chow, C.K. A wide-angle X-junction polymeric thermooptic digital switch with low crosstalk. IEEE Photonics Technol. Lett. 2003, 15, 1210–1212. [Google Scholar]

- Oh, M.; Lee, H. Asymmetric X-junction thermooptic switches based on fluorinated polymer waveguides. IEEE Photonics Technol. Lett. 1998, 10, 813–815. [Google Scholar]

- Song, Q.Q.; Chen, K.X. Low-power total internal reflection thermo-optic switch based on hybrid SiON-polymer X-junction waveguides. Appl. Opt. 2018, 57, 9809–9813. [Google Scholar] [PubMed]

- Xu, Q.; Jiang, M. Fast and low-power thermo-optic switch based on organic-inorganic hybrid strip-loaded waveguides. Opt. Lett. 2018, 43, 5102–5105. [Google Scholar]

- Yan, Y.; Zheng, C. Response-time improvement of a 2 × 2 thermo-optic switch with polymer/silica hybrid waveguide. Opt. Commun. 2012, 285, 3758–3762. [Google Scholar]

- Ansell, D.; Radko, I.P. Hybrid graphene plasmonic waveguide modulators. Nat. Commun. 2015, 6, 8846. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Cao, Y. A low-power consumption MZI thermal optical switch with a graphene-assisted heating layer and air trench. Rsc Adv. 2017, 7, 39922–39927. [Google Scholar] [CrossRef] [Green Version]

- Chang, Z.; Chiang, K.S. Ultra-broadband mode filters based on graphene-embedded waveguides. Opt. Lett. 2017, 42, 3868–3871. [Google Scholar] [CrossRef]

- Hao, T.; Chang, Z. Externally pumped low-loss graphene-based fiber Mach-Zehnder all-optical switches with mW switching powers. Opt. Express 2019, 27, 4216–4225. [Google Scholar] [CrossRef]

- Debnath, K.; Khokhar, A.Z. Low-Loss Slot Waveguides with Silicon (111) Surfaces Realized Using Anisotropic Wet Etching. Front. Mater. 2016, 3, 5. [Google Scholar] [CrossRef] [Green Version]

- Bazylenko, M.V.; Gross, M. Effect of reactive ion etching-generated sidewall roughness on propagation loss of buried-channel silica waveguides. Appl. Phys. Lett. 1996, 69, 2178–2180. [Google Scholar] [CrossRef]

- Zhang, C.; Subbaraman, H. Printed photonic elements: Nanoimprinting and beyond. J. Mater. Chem. C 2016, 4, 5133–5153. [Google Scholar] [CrossRef]

- Wan, L.; Zhu, N. All-polymeric planar waveguide devices based on a gas-assisted thermal imprinting technique. Microsyst. Technol. 2017, 23, 5271–5279. [Google Scholar] [CrossRef]

- Hiltunen, M.; Heinonen, E. Nanoimprint Fabrication of Slot Waveguides. IEEE Photonics J. 2013, 5, 2200808. [Google Scholar] [CrossRef]

- Hida, Y.; Hida, Y. Polymer waveguide thermooptic switch with low electric power consumption at 1.3 μm. IEEE Photonics Technol. Lett. 1993, 5, 782–784. [Google Scholar] [CrossRef]

- Chang, Z.; Chiang, K.S. Experimental verification of optical models of graphene with multimode slab waveguides. Opt. Lett. 2016, 41, 2129–2132. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Yi, Y.; Yang, Y.; Lin, B.; Lv, J.; Zhao, H.; Wang, F.; Zhang, D. Low Power Consumption 3D-Inverted Ridge Thermal Optical Switch of Graphene-Coated Polymer/Silica Hybrid Waveguide. Micromachines 2020, 11, 783. https://doi.org/10.3390/mi11080783

Cao Y, Yi Y, Yang Y, Lin B, Lv J, Zhao H, Wang F, Zhang D. Low Power Consumption 3D-Inverted Ridge Thermal Optical Switch of Graphene-Coated Polymer/Silica Hybrid Waveguide. Micromachines. 2020; 11(8):783. https://doi.org/10.3390/mi11080783

Chicago/Turabian StyleCao, Yue, Yunji Yi, Yue Yang, Baizhu Lin, Jiawen Lv, Haowen Zhao, Fei Wang, and Daming Zhang. 2020. "Low Power Consumption 3D-Inverted Ridge Thermal Optical Switch of Graphene-Coated Polymer/Silica Hybrid Waveguide" Micromachines 11, no. 8: 783. https://doi.org/10.3390/mi11080783

APA StyleCao, Y., Yi, Y., Yang, Y., Lin, B., Lv, J., Zhao, H., Wang, F., & Zhang, D. (2020). Low Power Consumption 3D-Inverted Ridge Thermal Optical Switch of Graphene-Coated Polymer/Silica Hybrid Waveguide. Micromachines, 11(8), 783. https://doi.org/10.3390/mi11080783