Nanoscale-Precision Removal of Copper in Integrated Circuits Based on a Hybrid Process of Plasma Oxidation and Femtosecond Laser Ablation

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. Laser Configuration

2.3. Characterization

3. Modeling Approach and Numerical Simulation

3.1. Model

3.2. Simulation

4. Results and Discussion

4.1. Simulation Results

4.2. Laser Ablation of Cu Films

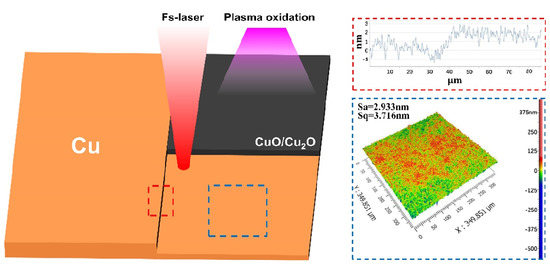

4.3. Oxidation-Laser Ablation

4.3.1. Surface Morphology and Composition

4.3.2. Removal Accuracy

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Huang, Y.; Xie, X.; Li, M.; Xu, M.; Long, J. Copper circuits fabricated on flexible polymer substrates by high-frequency femtosecond laser-induced selective local reduction of copper oxide nanoparticles. J. Opt. Express 2021, 19, 2573–2579. [Google Scholar]

- Lee, J.H.; Li, P.K.; Hung, H.W.; Chuang, W.; Song, J.M. Geometrical effects on ultrasonic al bump direct bonding for microsystem integration: Simulation and experiments. Micromachines 2021, 12, 750. [Google Scholar] [CrossRef]

- Sharma, S.; Kumar, M.; Rani, S.; Kumar, D.; Tripathi, C.C. Structural and electrical characterization of CoNiO monolayer as copper diffusion barrier in integrated circuits. Mater. Sci. Semicond. Process. 2016, 48, 1–8. [Google Scholar] [CrossRef]

- Ryu, C.H.; Joo, S.J.; Kim, H.S. Intense pulsed light sintering of Cu nano particles/micro particles-ink assisted with heating and vacuum holding of substrate for warpage free printed electronic circuit. Thin Solid Film. 2019, 675, 23–33. [Google Scholar] [CrossRef]

- Lee, C.J.; Kang, D.G.; Hwang, B.U.; Min, K.D.; Jung, S.B. Fabrication of an IPL-Sintered Cu Circuit and its Electrochemical Migration Behavior. J. Alloys Compd. 2021, 863, 158726. [Google Scholar] [CrossRef]

- Rakov, A.V.; De, S.; Koledintseva, M.Y.; Hinaga, S.; Drewniak, J.L.; Stanley, R.J. Quantification of Conductor Surface Roughness Profiles in Printed Circuit Boards. IEEE Trans. Electromagn. Compat. 2015, 57, 264–273. [Google Scholar] [CrossRef]

- Ghosh, G.; Sidpara, A.; Bandyopadhyay, P.P. Experimental and theoretical investigation into surface roughness and residual stress in magnetorheological finishing of OFHC copper. J. Mater. Process. Technol. 2020, 288, 116899. [Google Scholar] [CrossRef]

- Yao, C.; Wang, C.; Niu, X.; Wang, Y.; Tian, S.; Jiang, Z. The stability of a novel weakly alkaline slurry of copper interconnection CMP for GLSI. J. Semicond. 2018, 39, 026002. [Google Scholar] [CrossRef]

- Nik, F.E.; Matthiesen, I.; Herland, A.; Winkler, T.E. Low-cost PVD shadow masks with submillimeter resolution from laser-cut paper. Micromachines 2020, 11, 676. [Google Scholar]

- Xu, Q.; Chen, L.; Yang, F. Influence of slurry components on copper CMP performance in alkaline slurry. Microelectron. Eng. 2017, 183–184, 1–11. [Google Scholar] [CrossRef]

- Li, C.Y.; Zhang, D.H.; Lu, P.W.; Su, S.S. Metal-organic chemical vapor deposited copper interconnects for deep submicron integrated circuits. Thin Solid Film. 2005, 471, 270–272. [Google Scholar] [CrossRef]

- Seah, C.H.; You, G.Z.; Wang, S.R.; Li, C.Y.; Kumar, R. Impact of electroplated copper thickness on copper CMP and Cu/Coral™ BEOL integration. Microelectron. Eng. 2005, 81, 66–74. [Google Scholar] [CrossRef]

- Gutmann, R.J.; Steigerwald, J.M.; You, L.; Price, D.T.; Neirynck, J.; Duquette, D.J. Chemical-mechanical polishing of copper with oxide and polymer interlevel dielectrics. Thin Solid Film. 1995, 270, 596–600. [Google Scholar] [CrossRef]

- Ein-Eli, Y.; Starosvetsky, D. Review on copper chemical–mechanical polishing (CMP) and post-CMP cleaning in ultra large system integrated (ULSI)—An electrochemical perspective. Electrochim. Acta 2007, 52, 1825–1838. [Google Scholar] [CrossRef]

- Hong, J.; Niu, X.; Liu, Y.; He, Y.; Zhang, B.; Wang, J. Effect of a novel chelating agent on defect removal during post-CMP cleaning. Appl. Surf. Sci. 2016, 378, 239–244. [Google Scholar] [CrossRef]

- Song, M.G.; Lee, J.H.; Lee, Y.G.; Koo, J.H. Stabilization of gamma alumina slurry for chemical-mechanical polishing of copper. J. Colloid Interface Sci. 2006, 300, 603–611. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Wu, D.; Niu, L.; Pan, B.; Kang, R. Investigation on flatness and surface integrity of pure copper processed by electrochemical mechanical polishing. Procedia CIRP 2020, 95, 721–725. [Google Scholar] [CrossRef]

- Ryu, J.S.; Lim, E.T.; Choi, J.S. Dry etching of copper thin films in high density plasma of CH3COOH/Ar. Thin Solid Film. 2018, 672, 55–61. [Google Scholar] [CrossRef]

- Cha, M.H.; Lim, E.T.; Park, S.Y.; Ji, S.L.; Chung, C.W. Inductively coupled plasma reactive ion etching of copper thin films using ethylenediamine/butanol/Ar plasma. Vacuum 2020, 181, 109421. [Google Scholar] [CrossRef]

- Balachninait, O.; Tamulien, V.; Eias, L.; Aiaitis, V.V. Laser micromachining of steel and copper using femtosecond laser pulses in GHz burst mode. Results Phys. 2021, 8, 103847. [Google Scholar] [CrossRef]

- Butkut, A.; Jonuauskas, L. 3D manufacturing of glass microstructures using femtosecond laser. Micromachines 2021, 12, 499. [Google Scholar] [CrossRef] [PubMed]

- Kuchmizhak, A.A.; Pavlov, D.V.; Vitrik, O.B.; Kulchin, Y.N. Laser ablative fabrication of nanocrowns and nanojets on the cu supported film surface using femtosecond laser pulses. Appl. Surf. Sci. 2015, 357, 2378–2384. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.; Ki, H. Enhancing coupling efficiency in laser keyhole welding of copper using femtosecond laser surface modification. Opt. Laser Technol. 2021, 139, 106943. [Google Scholar] [CrossRef]

- Wang, Q.; Luo, S.; Chen, Z.; Qi, H.; Deng, J.; Hu, Z. Drilling of aluminum and copper films with femtosecond double-pulse laser. Opt. Laser Technol. 2016, 80, 116–124. [Google Scholar] [CrossRef]

- Wang, S.Y.; Ren, Y.; Cheng, C.W.; Chen, J.K.; Tzou, D.Y. Micromachining of copper by femtosecond laser pulses. Appl. Surf. Sci. 2013, 265, 302–308. [Google Scholar] [CrossRef]

- Murzin, S.P.; Liedl, G.; Pospichal, R. Coloration of a copper surface by nanostructuring with femtosecond laser pulses. Opt. Laser Technol. 2019, 119, 105574. [Google Scholar] [CrossRef]

- Sun, X.; Dong, Z.; Kong, D.; Hu, Y.; Duan, J.A. Switchable bubble wettability copper mesh for underwater gas collection ablated by spatial modulated femtosecond laser. Surf. Coat. Technol. 2021, 418, 127241. [Google Scholar] [CrossRef]

- Dong, Z.; Sun, X.; Kong, D.; Chu, D.; Duan, J.A. Spatial light modulated femtosecond laser ablated durable superhydrophobic copper mesh for oil-water separation and self-cleaning. Surf. Coat. Technol. 2020, 402, 126254. [Google Scholar] [CrossRef]

- Fraggelakis, F.; Mincuzzi, G.; Lopez, J.; Manek-Hönninger, I.; Kling, R. Texturing metal surface with MHz ultra-short laser pulses. Opt. Express 2017, 25, 18131–18139. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barret, P.H.; Palmer, M. High-Power and Femtosecond Lasers: Properties, Materials and Applications; Nova Science Publishers: Hauppauge, NY, USA, 2009. [Google Scholar]

- Abdelmalek, A.; Bedrane, Z.; Amara, E.-H.; Sotillo, B.; Bharadwaj, V.; Ramponi, R.; Eaton, S. Ablation of Copper Metal Films by Femtosecond Laser Multipulse Irradiation. Appl. Sci. 2018, 8, 1826. [Google Scholar] [CrossRef] [Green Version]

- Salapare, H.S.; Balbarona, J.A.; Clerc, L.; Bassoleil, P.; Zenerino, A.; Amigoni, S.; Guittard, F. Cupric Oxide Nanostructures from Plasma Surface Modification of Copper. Biomimetics 2019, 4, 42. [Google Scholar] [CrossRef] [Green Version]

- Kirfel, A.; Eichhorn, K. Accurate structure analysis with synchrotron radiation. The electron density in Al2O3 and Cu2O. Acta Crystallogr. Sect. A Found. Crystallogr. 1990, 46, 271–284. [Google Scholar] [CrossRef]

- Malerba, C.; Biccari, F.; Ricardo, C. Absorption coefficient of bulk and thin film Cu2O. Sol. Energy Mater. Sol. Cells 2011, 95, 2848. [Google Scholar] [CrossRef]

- Seo, C.; Ahn, D.; Kim, D. Removal of oxides from copper surface using femtosecond and nanosecond pulsed lasers. Appl. Surf. Sci. 2015, 349, 361–367. [Google Scholar] [CrossRef]

- Meyer, B.K.; Polity, A.; Reppin, D.; Becker, M.; Hering, P.; Kramm, B. Chapter Six—The Physics of Copper Oxide (Cu2O). In Science & Technology; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Daurelio, G.; Giorleo, G. Experimental techniques to cut and weld copper by laser-a review. Mater. Manuf. Process. 1991, 6, 577–603. [Google Scholar] [CrossRef]

- Lim, H.U.; Kang, J.; Guo, C.; Hwang, T.Y. Manipulation of multiple periodic surface structures on metals induced by femtosecond lasers. Appl. Surf. Sci. 2018, 454, 327–333. [Google Scholar] [CrossRef]

| Species | Density (g/cm3) | Reflectivity | Absorption Coefficient | Thermal Conductivity (W/(m·K)) | Evaporation Temperature (K) |

|---|---|---|---|---|---|

| Cu | 8.96 | 0.9 | 70.8 | 377 | 2835 |

| Cu2O | 6.09 | 0.21 | 1.1 | 7 | 2073 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wang, Y.; Zhang, S.; Wang, L.; Chen, S.; Zheng, H.; Zhang, C.; Liu, S.; Cheng, G.J.; Liu, F. Nanoscale-Precision Removal of Copper in Integrated Circuits Based on a Hybrid Process of Plasma Oxidation and Femtosecond Laser Ablation. Micromachines 2021, 12, 1188. https://doi.org/10.3390/mi12101188

Wang S, Wang Y, Zhang S, Wang L, Chen S, Zheng H, Zhang C, Liu S, Cheng GJ, Liu F. Nanoscale-Precision Removal of Copper in Integrated Circuits Based on a Hybrid Process of Plasma Oxidation and Femtosecond Laser Ablation. Micromachines. 2021; 12(10):1188. https://doi.org/10.3390/mi12101188

Chicago/Turabian StyleWang, Shuai, Yaoyu Wang, Shizhuo Zhang, Lingfeng Wang, Shuai Chen, Huai Zheng, Chen Zhang, Sheng Liu, Gary J. Cheng, and Feng Liu. 2021. "Nanoscale-Precision Removal of Copper in Integrated Circuits Based on a Hybrid Process of Plasma Oxidation and Femtosecond Laser Ablation" Micromachines 12, no. 10: 1188. https://doi.org/10.3390/mi12101188

APA StyleWang, S., Wang, Y., Zhang, S., Wang, L., Chen, S., Zheng, H., Zhang, C., Liu, S., Cheng, G. J., & Liu, F. (2021). Nanoscale-Precision Removal of Copper in Integrated Circuits Based on a Hybrid Process of Plasma Oxidation and Femtosecond Laser Ablation. Micromachines, 12(10), 1188. https://doi.org/10.3390/mi12101188