Wide-Angle Mini-Light-Emitting Diodes without Optical Lens for an Ultrathin Flexible Light Source

Abstract

:1. Introduction

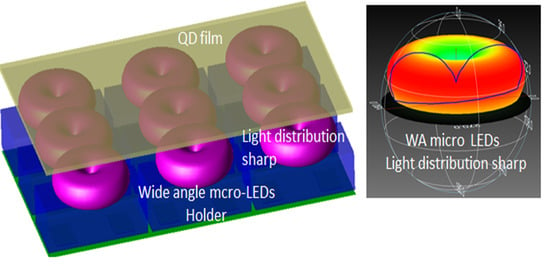

2. Fabrication of Packaged Wide-Angle Mini-LEDs

3. Fabrication of QD Film

4. Fabrication of Flexible Circuit Board Design for Wide-Angle Mini-LEDs

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, E.H.; Zhou, Y.Y.; Yang, X.B.; Liao, Z.F.; Zhao, W.R.; Deng, T.T.; Wang, L.Y.; Ma, Y.Y.; Ye, S.; Zhang, Q.Y. Highly efficient and stable narrow-band red phosphor Cs2SiF6:Mn4+ for high-power warm white LED applications. ACS Photonics 2017, 4, 2556–2565. [Google Scholar] [CrossRef]

- Zhou, Y.Y.; Ming, H.; Zhang, S.; Deng, T.T.; Song, E.H.; Zhang, Q.Y. Unveiling Mn4+ substitution in oxyfluoride phosphor Rb2MoO2F4:Mn4+ applied to wide-gamut fast-response backlight displays. Chem. Eng. J. 2021, 415, 128974. [Google Scholar] [CrossRef]

- Li, H.R.; Liang, Y.J.; Liu, S.Q.; Zhang, W.L.; Bi, Y.Y.; Gong, Y.M.; Chen, Y.J.; Lei, W. Highly efficient green-emitting phosphor Sr4Al14O25:Ce,Tb with low thermal quenching and wide color gamut upon UV-light excitation for backlighting display applications. J. Mater. Chem. C 2021, 9, 2569–2581. [Google Scholar] [CrossRef]

- Wang, X.C.; Bao, Z.; Chang, Y.C.; Liu, R.S. Perovskite quantum dots for application in high color gamut backlighting display of light-emitting diodes. ACS Energy Lett. 2020, 5, 3374–3396. [Google Scholar] [CrossRef]

- Ho, S.J.; Hsu, H.C.; Yeh, C.W.; Chen, H.S. Inkjet-printed salt-encapsulated quantum dot film for UV-based RGB color-converted micro-light emitting diode displays. ACS Appl. Mater. Interfaces 2020, 12, 33346–33351. [Google Scholar] [CrossRef]

- Liu, Z.J.; Lin, C.H.; Hyun, B.R.; Sher, C.W.; Lv, Z.J.; Luo, B.Q.; Jiang, F.L.; Wu, T.; Ho, C.H.; Kuo, H.C.; et al. Micro-light-emitting diodes with quantum dots in display technology. Light-Sci. Appl. 2020, 9, 83. [Google Scholar] [CrossRef]

- Yin, Y.M.; Hu, Z.P.; Ali, M.U.; Duan, M.; Gao, L.; Liu, M.; Peng, W.X.; Geng, J.; Pan, S.; Wu, Y.W.; et al. Full-color micro-LED display with CsPbBr3 perovskite and CdSe quantum dots as color conversion layers. Adv. Mater. Technol. 2020, 5, 2000251. [Google Scholar] [CrossRef]

- Chen, S.W.H.; Shen, C.C.; Wu, T.Z.; Liao, Z.Y.; Chen, L.F.; Zhou, J.R.; Lee, C.F.; Lin, C.H.; Lin, C.C.; Sher, C.W.; et al. Full-color monolithic hybrid quantum dot nanoring micro light-emitting diodes with improved efficiency using atomic layer deposition and nonradiative resonant energy transfer. Photonics Res. 2019, 7, 416–422. [Google Scholar] [CrossRef]

- Ye, Z.T.; Ruan, M.J.; Kuo, H.C. CSP-LEDs combined with light guide without reflective matrix for antiglare design. IEEE Access 2020, 8, 156718–156726. [Google Scholar] [CrossRef]

- Ye, Z.T.; Chang, C.; Juan, M.C.; Chen, K.J. Luminous intensity field optimization for antiglare LED desk lamp without second optical element. Appl. Sci. 2020, 10, 2607. [Google Scholar] [CrossRef]

- Ye, Z.T.; Chen, C.L.; Chen, L.C.; Tien, C.H.; Nguyen, H.T.; Wang, H.C. Hollow light guide module involving mini light-emitting diodes for asymmetric luminous planar illuminators. Energies 2019, 12, 2755. [Google Scholar] [CrossRef]

- Liu, H.; Li, S.Y.; Wang, B.; Wang, K.; Wu, R.Z.; Ekberg, C.; Volinsky, A.A. Multiscale recycling rare earth elements from real waste trichromatic phosphors containing glass. J. Clean Prod. 2019, 238, 117998. [Google Scholar] [CrossRef]

- Xia, Z.G.; Liu, Q.L. Progress in discovery and structural design of color conversion phosphors for LEDs. Prog. Mater. Sci. 2016, 84, 59–117. [Google Scholar] [CrossRef]

- Huang, Y.G.; Hsiang, E.L.; Deng, M.Y.; Wu, S.T. Mini-LED, Micro-LED and OLED displays: Present status and future perspectives. Light-Sci. Appl. 2020, 9, 105. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.H.; Kim, J.J. Origin and control of orientation of phosphorescent and TADF dyes for high-efficiency OLEDs. Adv. Mater. 2018, 30, 1705600. [Google Scholar] [CrossRef]

- Lin, H.; Yang, J.; Liu, Y.F.; Zeng, F.J.; Tang, X.S.; Yao, Z.Q.; Guan, H.L.; Xiong, Q.; Zhou, J.E.; Wu, D.F.; et al. Stable and efficient hybrid Ag-In-S/ZnS@SiO2-carbon quantum dots nanocomposites for white light-emitting diodes. Chem. Eng. J. 2020, 393, 124654. [Google Scholar] [CrossRef]

- Wang, Y.J.; Zhang, R.L.; Yue, Y.; Yan, S.S.; Zhang, L.Y.; Chen, D.P. Room temperature synthesis of CsPbX3 (X = Cl, Br, I) perovskite quantum dots by water-induced surface crystallization of glass. J. Alloys Compd. 2020, 818, 152872. [Google Scholar] [CrossRef]

- Zhang, H.; Su, Q.; Chen, S.M. Quantum-dot and organic hybrid tandem light-emitting diodes with multi-functionality of full-color-tunability and white-light-emission. Nat. Commun. 2020, 11, 2826. [Google Scholar] [CrossRef]

- Smith, M.J.; Lin, C.H.; Yu, S.T.; Tsukruk, V.V. Composite structures with emissive quantum dots for light enhancement. Adv. Opt. Mater. 2019, 7, 1801072. [Google Scholar] [CrossRef]

- Asad, M.; Li, Q.; Sachdev, M.; Wong, W.S. Thermal and optical properties of high-density GaN micro-LED arrays on flexible substrates. Nano Energy 2020, 73, 104724. [Google Scholar] [CrossRef]

- Zhang, H.; Rogers, J.A. Recent advances in flexible inorganic light emitting diodes: From materials design to integrated optoelectronic platforms. Adv. Opt. Mater. 2019, 7, 1800936. [Google Scholar] [CrossRef]

- Chen, L.C.; Tien, C.H.; Chen, D.F.; Ye, Z.T.; Kuo, H.C. High-uniformity planar mini-chip-scale packaged LEDs with quantum dot converter for white light source. Nanoscale Res. Lett. 2019, 14, 182. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.H.; Li, Y.F.; Su, X.L.; Feng, L.G.; Wang, S.; Ding, W.; Li, Q.; Zhang, Y.; Guo, M.F.; Yun, F.; et al. Super flexible GaN light emitting diodes using microscale pyramid arrays through laser lift-off and dual transfer. Opt. Express 2018, 26, 1817–1824. [Google Scholar] [CrossRef]

- Tian, P.F.; McKendry, J.J.D.; Gu, E.D.; Chen, Z.Z.; Sun, Y.J.; Zhang, G.Y.; Dawson, M.D.; Liu, R. Fabrication, characterization and applications of flexible vertical InGaN micro-light emitting diode arrays. Opt. Express 2016, 24, 699–707. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.H.; Verma, A.; Kang, C.Y.; Pai, Y.M.; Chen, T.Y.; Yang, J.J.; Sher, C.W.; Yang, Y.Z.; Lee, P.T.; Lin, C.C.; et al. Hybrid-type white LEDs based on inorganic halide perovskite QDs: Candidates for wide color gamut display backlights. Photonics Res. 2019, 7, 579–585. [Google Scholar] [CrossRef]

- Wang, H.C.; Lin, S.Y.; Tang, A.C.; Singh, B.P.; Tong, H.C.; Chen, C.Y.; Lee, Y.C.; Tsai, T.L.; Liu, R.S. Mesoporous silica particles integrated with all-inorganic CsPbBr3 perovskite quantum-dot nanocomposites (MP-PQDs) with high stability and wide color gamut used for backlight display. Angew. Chem. Int. Ed. 2016, 55, 7924–7929. [Google Scholar] [CrossRef]

- Jang, E.; Jun, S.; Jang, H.; Lim, J.; Kim, B.; Kim, Y. White-light-emitting diodes with quantum dot color converters for display backlights. Adv. Mater. 2010, 22, 3076–3080. [Google Scholar] [CrossRef]

- Guo, W.; Chen, N.; Lu, H.; Su, C.W.; Lin, Y.; Chen, G.; Lu, Y.; Zheng, L.L.; Peng, Z.B.; Kuo, H.C.; et al. The impact of luminous properties of red, green, and blue mini-LEDs on the color gamut. IEEE Trans. Electron. Devices 2019, 66, 2263–2268. [Google Scholar] [CrossRef]

- Hsiang, E.L.; Yang, Q.; He, Z.; Zou, J.; Wu, S.T. Halo effect in high-dynamic-range mini-LED backlit LCDs. Opt. Express 2020, 28, 36822–36837. [Google Scholar] [CrossRef]

- Song, S.J.; Kim, Y.I.; Bae, J.; Nam, H. Deep-learning-based pixel compensation algorithm for local dimming liquid crystal displays of quantum-dot backlights. Opt. Express 2019, 27, 15907–15917. [Google Scholar] [CrossRef]

- Chen, S.W.H.; Huang, Y.M.; Chang, Y.H.; Lin, Y.; Liou, F.J.; Hsu, Y.C.; Song, J.; Choi, J.; Chow, C.W.; Lin, C.C.; et al. High-bandwidth green semipolar (20–21) InGaN/GaN micro light-emitting diodes for visible light communication. ACS Photonics 2020, 7, 2228–2235. [Google Scholar] [CrossRef]

- Xuan, T.T.; Shi, S.C.; Wang, L.; Kuo, H.C.; Xie, R.J. Inkjet-printed quantum dot color conversion films for high-resolution and full-color micro light-emitting diode displays. J. Phys. Chem. Lett. 2020, 11, 5184–5191. [Google Scholar] [CrossRef] [PubMed]

- Gou, F.W.; Hsiang, E.L.; Tan, G.J.; Lan, Y.F.; Tsai, C.Y.; Wu, S.T. High performance color-converted micro-LED displays. J. Soc. Inf. Disp. 2019, 27, 199–206. [Google Scholar] [CrossRef]

- Mei, S.L.; Liu, X.Y.; Zhang, W.L.; Liu, R.; Zheng, L.R.; Guo, R.Q.; Tian, P.F. High-bandwidth white-light system combining a micro-LED with perovskite quantum dots for visible light communication. ACS Appl. Mater. Interfaces 2018, 10, 5641–5648. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.M.; Ryu, M.; Cha, J.H.J.; Kim, H.S.; Jeong, T.; Jang, J. Ten micrometer pixel, quantum dots color conversion layer for high resolution and full color active-matrix micro-LED display. J. Soc. Inf. Disp. 2019, 27, 347–353. [Google Scholar] [CrossRef]

- Gou, F.W.; Hsiang, E.L.; Tan, G.J.; Chou, P.T.; Li, Y.L.; Lan, Y.F.; Wu, S.O. Angular color shift of micro-LED displays. Opt. Express 2019, 27, A746–A757. [Google Scholar] [CrossRef]

- Li, X.X.; Hu, B.B.; Zhang, M.; Wang, X.; Chen, L.; Wang, A.Q.; Wang, Y.H.; Du, Z.L.; Jiang, L.; Liu, H. Continuous and controllable liquid transfer guided by a fibrous liquid bridge: Toward high-performance QLEDs. Adv. Mater. 2019, 31, 1904610. [Google Scholar] [CrossRef]

- Kang, H.L.; Kang, J.G.; Won, J.K.; Jung, S.M.; Kim, J.; Park, C.H.; Ju, B.K.; Kim, M.G.; Park, S.K. Spatial light patterning of full color quantum dot displays enabled by locally controlled surface tailoring. Adv. Opt. Mater. 2018, 6, 1701335. [Google Scholar] [CrossRef]

- Chen, S.W.H.; Huang, Y.M.; Singh, K.J.; Hsu, Y.C.; Liou, F.J.; Song, J.; Choi, J.; Lee, P.S.; Lin, C.C.; Chen, Z.; et al. Full-color micro-LED display with high color stability using semipolar (20-21) InGaN LEDs and quantum-dot photoresist. Photonics Res. 2020, 8, 630–636. [Google Scholar] [CrossRef]

- Chen, Q.Z.; Yan, Y.J.; Wu, X.M.; Wang, X.M.; Zhang, G.C.; Chen, J.W.; Chen, H.P.; Guo, T.L. Gate-tunable all-inorganic QLED with enhanced charge injection balance. J. Mater. Chem. C 2020, 8, 1280–1285. [Google Scholar] [CrossRef]

- He, L.R.; Fei, M.; Chen, J.; Tian, Y.F.; Jiang, Y.; Huang, Y.; Xu, K.; Hu, J.T.; Zhao, Z.; Zhang, Q.H.; et al. Graphitic C3N4 quantum dots for next-generation QLED displays. Mater. Today 2019, 22, 76–84. [Google Scholar] [CrossRef]

- Jang, H.J.; Lee, J.Y.; Kim, J.; Kwak, J.; Park, J.H. Progress of display performances: AR, VR, QLED, and OLED. J. Inf. Disp. 2020, 21, 1–9. [Google Scholar] [CrossRef]

- Zeng, H.B. QLED goes to be both bright and efficient. Sci. Bull. 2019, 64, 464–465. [Google Scholar] [CrossRef]

- Ye, Z.T.; Wu, H.C.; Kuo, H.C. First optical design for wide-angle micro-LED without second lens. In Proceedings of the Optical Design and Testing X 2020, Online, China, 11–16 October 2020. [Google Scholar]

- Ye, Z.T.; Cheng, Y.H.; Liu, K.H.; Yang, K.S. Mini-LEDs with Diffuse Reflection Cavity Arrays and Quantum Dot Film for Thin, Large-Area, High-Luminance Flat Light Source. Nanomaterials 2021, 11, 2395. [Google Scholar] [CrossRef] [PubMed]

| Item | Characteristics |

|---|---|

| Operational voltage (V) | 96.2 V |

| Operational current (A) | 0.015 A |

| Power consumption (W) | 1.44 W |

| Luminance (nits) | 10,322 nits |

| Uniformity (%) | 92% |

| NTSC coverage (%) | 104.2% |

| Bending Diameter (mm) | Operation Current (A) | Operation Voltage (V) | Luminance (nits) |

|---|---|---|---|

| Flat | 0.015 | 96.2 | 10,322 |

| 130 | 0.015 | 96.4 | 10,128 |

| 115 | 0.015 | 96.3 | 10,056 |

| 100 | 0.015 | 96.3 | 10,097 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.-L.; Chin, W.-C.; Tsai, C.-W.; Chiu, C.-C.; Tien, C.-H.; Ye, Z.-T.; Han, P. Wide-Angle Mini-Light-Emitting Diodes without Optical Lens for an Ultrathin Flexible Light Source. Micromachines 2022, 13, 1326. https://doi.org/10.3390/mi13081326

Chen Y-L, Chin W-C, Tsai C-W, Chiu C-C, Tien C-H, Ye Z-T, Han P. Wide-Angle Mini-Light-Emitting Diodes without Optical Lens for an Ultrathin Flexible Light Source. Micromachines. 2022; 13(8):1326. https://doi.org/10.3390/mi13081326

Chicago/Turabian StyleChen, Yen-Lung, Wen-Chung Chin, Chun-Wei Tsai, Chang-Che Chiu, Ching-Ho Tien, Zhi-Ting Ye, and Pin Han. 2022. "Wide-Angle Mini-Light-Emitting Diodes without Optical Lens for an Ultrathin Flexible Light Source" Micromachines 13, no. 8: 1326. https://doi.org/10.3390/mi13081326

APA StyleChen, Y. -L., Chin, W. -C., Tsai, C. -W., Chiu, C. -C., Tien, C. -H., Ye, Z. -T., & Han, P. (2022). Wide-Angle Mini-Light-Emitting Diodes without Optical Lens for an Ultrathin Flexible Light Source. Micromachines, 13(8), 1326. https://doi.org/10.3390/mi13081326