Miniaturized Rotary Actuators Using Shape Memory Alloy for Insect-Type MEMS Microrobot

Abstract

:1. Introduction

2. Materials and Methods

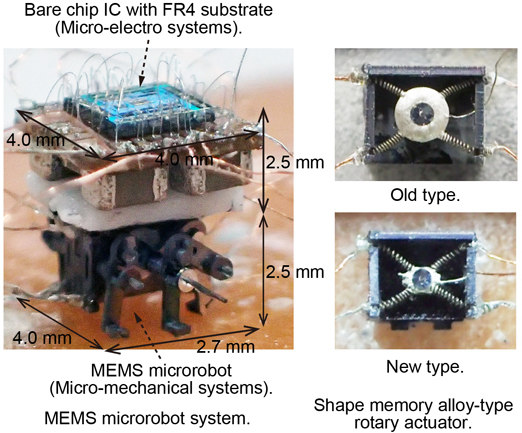

2.1. Micro-Mechanical System

2.1.1. Mechanical Components

2.1.2. Locomotion Mechanism Using Shape Memory Alloy-Type Rotary Actuator

2.2. Micro-Electro System

2.2.1. Electrical Components

2.2.2. Artificial Neural Networks

2.2.3. Current Mirror Circuit

2.2.4. Bare Chip IC of Artificial Neural Networks with Current Mirror Circuit

3. Results and Discussion

3.1. Locomotion of the MEMS Microrobot System

3.2. Heat Conduction of the Shape Memory Alloy-Type Rotary Actuator

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shibata, T.; Aoki, Y.; Otsuka, M.; Idogaki, T.; Hattori, T. Microwave Energy Transmission System for Microrobot. IEICE Trans. Electron. 1997, 80, 303–308. [Google Scholar]

- Takeda, M. Applications of MEMS to Industrial Inspection. In Proceedings of the 14th IEEE International Conference on IEEE MEMS Mechanical Systems, Interlaken, Switzerland, 25–25 January 2001; pp. 182–191.

- Habib, M.K.; Watanabe, K.; Izumi, K. Biomimetcs robots: From bio-inspiration to implementation. In Proceedings of the 33rd Annual Conference of the IEEE Industrial Electronics Society, Taipei, Taiwan, 5–8 November 2007; pp. 143–148.

- Habib, M.K. Biomimetcs: Innovations and Robotics. Int. J. Mechatron. Manuf. Syst. 2011, 4, 113–134. [Google Scholar]

- Hoover, M.A.; Steltz, E.; Fearing, S.R. RoACH: An autonomous 2.4 g crawling hexapod robot. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; pp. 26–33.

- Baisch, A.T.; Sreetharan, P.S.; Wood, R.J. Biologically-inspired locomotion of a 2 g hexapod robot. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 5360–5365.

- Rubenstein, M.; Ahler, C.; Nagpal, R. Kilobot: A Low Cost Scalable Robot System for Collective Behaviors. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, St Paul, MN, USA, 14–18 May 2012; pp. 3293–3298.

- Sabelhaus, P.A.; Mirsky, D.; Hill, L.M.; Martins, N.C.; Bergbreiter, S. TinyTeRP: A Tiny Terrestrial Robotic Platform with Modular Sensing. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 2600–2605.

- Tsuruta, K.; Mikuriya, Y.; Ishikawa, Y. Micro sensor developments in Japan. Sensor Rev. 1999, 19, 7–42. [Google Scholar] [CrossRef]

- Donald, B.R.; Levey, C.G.; McGray, C.D.; Paprotny, I.; Rus, D. An untethered, electrostatic, globally controllable MEMS micro-robot. J. Microelectromech. Syst. 2006, 15, 1–15. [Google Scholar] [CrossRef]

- Edqvist, E.; Snis, N.; Mohr, R.C.; Scholz, O.; Corradi, P.; Gao, J.; Diéguez, A.; Wyrsch, N.; Johansson, S. Evaluation of building technology for mass producible millimeter-sized robots using flexible printed circuit boards. J. Micromech. Microeng. 2009, 19, 075011. [Google Scholar] [CrossRef]

- Tang, W.C.; Nguyen, T.H.; Howe, R.T. Laterally driven poly silicon resonant microstructure. In Proceedings of the IEEE Conference on Micro Electro Mechanical Systems, Salt Lake City, UT, USA, 20–22 February 1989; pp. 53–59.

- Sniegowski, J.J.; Garcia, E.J. Surface-micromachined gear trains driven by an on-chip electrostatic microengine. IEEE Electron Device Lett. 1996, 17, 366–368. [Google Scholar] [CrossRef]

- Asada, N.; Matsuki, H.; Minami, K.; Esashi, M. Silicone micromachined two-dimensional galvano optical scanner. IEEE Trans. Magnet. 1994, 30, 4647–4649. [Google Scholar] [CrossRef]

- Suzuki, Y.; Tani, K.; Sakuhara, T. Development of a new type piezoelectric Micromotor. Sens. Actuators A Phys. 2000, 83, 244–248. [Google Scholar] [CrossRef]

- Surbled, P.; Clerc, C.; Pioufle, B.L.; Ataka, M.; Fujita, H. Effect of the composition and thermal annealing on the transformation temperature sputtered TiNi shape memory alloy thin films. Thin Solid Films 2001, 401, 52–59. [Google Scholar] [CrossRef]

- Matsuoka, K. Mechanism of Frequency and Pattern Control in the Neural Rhythm Generators. Biol. Cybernet. 1987, 56, 345–353. [Google Scholar] [CrossRef]

- Ikemoto, T.; Nagashino, H.; Kinouchi, Y.; Yoshinaga, T. Transitions in a Four Coupled Neural Oscillator Model. In Proceedings of the International Symposium on Nonlinear Theory and Its Applications, Hilton Hawaiian Village, HI, USA, 29 November–3 December 1997; pp. 561–564.

- Nakada, K.; Asai, T.; Amemiya, Y. An Analog CMOS Central Pattern Generator for Interlimb Coordination in Quadruped Locomotion. IEEE Trans. Neural Netw. 2003, 14, 1356–1365. [Google Scholar] [CrossRef] [PubMed]

- Okazaki, K.; Ogiwara, T.; Yang, D.; Sakata, K.; Saito, K.; Sekine, Y.; Uchikoba, F. Development of pulse control type MEMS micro robot with hardware neural network. Artif. Life Robot. 2011, 16, 229–233. [Google Scholar] [CrossRef]

- Saito, K.; Takato, M.; Sekine, Y.; Uchikoba, F. Biomimetics Micro Robot with Active Hardware Neural Networks Locomotion Control and Insect-Like Switching Behaviour. Int. J. Adv. Robot. Syst. 2012, 9, 1–6. [Google Scholar] [CrossRef]

- Kazuaki, M.; Shinpei, Y.; Hiroki, O.; Yuka, N.; Kei, I.; Masaki, T.; Yuki, O.; Yuki, I.; Tomohiro, H.; Yohei, A.; et al. Hexapod-Type SMA Driven MEMS Microrobot with Mounted Bare Chip Artificial Neural Networks IC. In Proceedings of the 19th International Symposium on Artificial Life and Robotics 2014, Beppu, Japan, 22–24 January 2014; pp. 401–405.

- Saito, K.; Maezumi, K.; Naito, Y.; Hidaka, T.; Iwata, K.; Okane, Y.; Oku, H.; Takato, M.; Uchikoba, F. Neural Networks Integrated Circuit for Biomimetics MEMS Microrobot. Robotics 2014, 3, 235–246. [Google Scholar]

- Bhardwaj, J.K.; Ashraf, H. Advanced silicon etching using high-density plasmas. Proc. SPIE 1995, 2639, 224–233. [Google Scholar]

- Saito, K.; Matsuda, A.; Saeki, K.; Uchikoba, F.; Sekine, Y. Synchronization of Coupled Pulse-Type Hardware Neuron Models for CPG Model; The Relevance of the Time Domain to Neural Network Models, Springer Series on Cognitive and Neural Systems; Springer: New York, NY, USA, 2011; pp. 117–133. [Google Scholar]

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saito, K.; Iwata, K.; Ishihara, Y.; Sugita, K.; Takato, M.; Uchikoba, F. Miniaturized Rotary Actuators Using Shape Memory Alloy for Insect-Type MEMS Microrobot. Micromachines 2016, 7, 58. https://doi.org/10.3390/mi7040058

Saito K, Iwata K, Ishihara Y, Sugita K, Takato M, Uchikoba F. Miniaturized Rotary Actuators Using Shape Memory Alloy for Insect-Type MEMS Microrobot. Micromachines. 2016; 7(4):58. https://doi.org/10.3390/mi7040058

Chicago/Turabian StyleSaito, Ken, Kei Iwata, Yuki Ishihara, Kazuki Sugita, Minami Takato, and Fumio Uchikoba. 2016. "Miniaturized Rotary Actuators Using Shape Memory Alloy for Insect-Type MEMS Microrobot" Micromachines 7, no. 4: 58. https://doi.org/10.3390/mi7040058

APA StyleSaito, K., Iwata, K., Ishihara, Y., Sugita, K., Takato, M., & Uchikoba, F. (2016). Miniaturized Rotary Actuators Using Shape Memory Alloy for Insect-Type MEMS Microrobot. Micromachines, 7(4), 58. https://doi.org/10.3390/mi7040058