Carbon Nanotube Paper-Based Electroanalytical Devices

Abstract

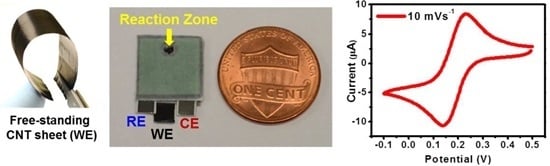

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation for Device Fabrication

2.3. Surface Morphology

2.4. Electrochemical Sensing Evaluation

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Martinez, A.W.; Phillips, S.T.; Butte, M.J.; Whitesides, G.M. Patterned paper as a platform for inexpensive, low-volume, portable bioassays. Angew. Chem. Int. Ed. 2007, 46, 1318–1320. [Google Scholar] [CrossRef] [PubMed]

- Klasner, S.A.; Price, A.K.; Hoeman, K.W.; Wilson, R.S.; Bell, K.J.; Culbertson, C.T. Paper-based microfluidic devices for analysis of clinically relevant analytes present in urine and saliva. Anal. Bioanal. Chem. 2010, 397, 1821–1829. [Google Scholar] [CrossRef] [PubMed]

- Songjaroen, T.; Dungchai, W.; Chailapakul, O.; Laiwattanapaisal, W. Novel, simple and low-cost alternative method for fabrication of paper-based microfluidics by wax dipping. Talanta 2011, 85, 2587–2593. [Google Scholar] [CrossRef] [PubMed]

- Koo, Y.; Sankar, J.; Yun, Y. High performance magnesium anode in paper-based microfluidic battery, powering on-chip fluorescence assay. Biomicrofluidics 2014, 8, 054104. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Thuo, M.M.; Liu, X. A microfluidic paper-based electrochemical biosensor array for multiplexed detection of metabolic biomarkers. Sci. Technol. Adv. Mater 2013, 14, 054402. [Google Scholar] [CrossRef]

- Noiphung, J.; Songjaroen, T.; Dungchai, W.; Henry, C.S.; Chailapakul, O.; Laiwattanapaisal, W. Electrochemical detection of glucose from whole blood using paper-based microfluidic devices. Anal. Chim. Acta 2013, 788, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Dungchai, W.; Chailapakul, O.; Henry, C.S. Electrocheical detection for paper-based microfluidics. Analy. Chem. 2009, 81, 5821–5826. [Google Scholar] [CrossRef] [PubMed]

- Renault, C.; Anderson, M.J.; Crooks, R.M. Electrochmicstry in hollow-channel paper anlaytical devices. J. Am. Chem. Soc. 2014, 136, 4616–4623. [Google Scholar] [CrossRef] [PubMed]

- Lan, W.-J.; Maxwell, E.J.; Parolo, C.; Bwambok, D.; Subramaniam, A.; Whitesides, G.M. Paper-based electroanalytical devices with an integrted, stable reference electrode. Lab Chip 2013, 13, 4103–4108. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Wang, S.; Ge, L.; Ge, S. A novel chemiluminescence paper microfluidic biosensor based on enzymatic reaction for uric acid determination. Biosens. Bioelectron. 2011, 26, 3284–3289. [Google Scholar] [CrossRef] [PubMed]

- Delaney, J.L.; Hogan, C.F.; Tian, J.; Shen, W. Electrogenerated chemiluminescence detection in paper-based microfluidic sensors. Anal. Chem. 2011, 83, 1300–1306. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Crooks, R.M. Three-dimensional paper microfluidic devices assembled using the principles of Origami. J. Am. Chem. Soc. 2011, 133, 17564–17566. [Google Scholar] [CrossRef] [PubMed]

- Nie, Z.; Nijhuis, C.A.; Gong, J.; Chen, X.; Kumachev, A.; Martinez, A.W.; Narovlyansky, M.; Whitesides, G.M. Electrochemical sensing in paper-based microfluidic devices. Lab Chip 2010, 10, 477–483. [Google Scholar] [CrossRef] [PubMed]

- Zang, D.; Ge, L.; Yan, M.; Song, X.; Yu, J. Electrochemical immunoassay on a 3D microfluidic paper-based device. Chem. Commun. 2012, 48, 4683–4685. [Google Scholar] [CrossRef] [PubMed]

- Ge, S.; Ge, L.; Yan, M.; Song, X.; Yu, J.; Huang, J. A disposable paper-based electrochemical sensor with an addressable electrode array for cancer screening. Chem. Commun. 2012, 48, 9397–9399. [Google Scholar] [CrossRef] [PubMed]

- Zang, D.; Yan, M.; Ge, S.; Ge, L.; Yu, J. A disposable simultaneous electrochemical sensor array based on a molecularly imprinted film at a NH2-graphene modified screen-printed electrode for determination of psychotropic drugs. Analyst 2013, 138, 2704–2711. [Google Scholar] [CrossRef] [PubMed]

- Adkins, J.; Boehle, K.; Henry, C. Electrochemical paper-based microfluidic devices. Electrophoresis 2015, 36, 1811–1824. [Google Scholar] [CrossRef] [PubMed]

- Dossi, N.; Toniolo, R.; Terzi, F.; Impellizzieri, F.; Bontempelli, G. Pencil leads doped with electrochemically deposited Ag and AgCl for drawing reference electrodes on paper-based electrochemical devices. Electrochim. Acta 2014, 146, 518–524. [Google Scholar] [CrossRef]

- Shitanda, I.; Yamaguchi, T.; Hoshi, Y.; Itagaki, M. Fully screen-printed paper-based electrode chip for glucose detection. Chem. Lett. 2013, 42, 1369–1370. [Google Scholar] [CrossRef]

- Gao, C.; Guo, Z.; Liu, J.H.; Huang, X.J. The new age of carbon nanotubes: An updated review of functionalized carbon nanotubes in electrochemical sensors. Nanoscale 2012, 4, 1948–1963. [Google Scholar] [CrossRef] [PubMed]

- Vashist, S.K.; Zheng, D.; Al-Rubeaan, K.; Luong, J.H.T.; Sheu, F.S. Advances in carbon nanotube based electrochemical sensors for bioanalytical applications. Biotechnol. Adv. 2011, 29, 169–188. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, C.B.; Peairs, M.J.; Venton, B.J. Review: Carbon nanotube based electrochemical sensors for biomolecules. Anal. Chim. Acta 2010, 662, 105–127. [Google Scholar] [CrossRef] [PubMed]

- Agüí, L.; Yáñez-Sedeño, P.; Pingarrón, J.M. Role of carbon nanotubes in electroanalytical chemistry: A review. Anal. Chim. Acta 2008, 622, 11–47. [Google Scholar] [CrossRef] [PubMed]

- Munaiah, Y.; Suresh, S.; Dheenadayalan, S.; Pillai, V.K.; Ragupathy, P. Comparative electrocatalytic performance of single-walled and multiwalled carbon nanotubes for Zinc Bromine redox flow batteries. J. Phys. Chem. C 2014, 118, 14795–14804. [Google Scholar] [CrossRef]

- Koo, Y.; Malik, R.; Alvarez, N.; White, L.; Shanov, V.N.; Schulz, M.; Collins, B.; Sankar, J.; Yun, Y. Aligned carbon nanotube/copper sheets: A new electrocatalyst for CO2 reduction to hydrocarbons. RSC Adv. 2014, 4, 16362–16367. [Google Scholar] [CrossRef]

- Wang, J. Carbon-nanotube based electrochemical biosensors: A review. Electroanalysis 2005, 17, 7–14. [Google Scholar] [CrossRef]

- Lawal, A.T. Synthesis and utilization of carbon nanotubes for fabrication of electrochemical biosensors. Mater. Res. Bull. 2016, 73, 308–350. [Google Scholar] [CrossRef]

- Li, F.; Peng, J.; Wang, J.; Tang, H.; Tan, L.; Xie, Q.; Yao, S. Carbon nanotube-based label-free electrochemical biosensor for sensitive detection of miRNA-24. Biosens. Bioelectron. 2014, 54, 158–164. [Google Scholar] [CrossRef] [PubMed]

- Pumera, M. Carbon Nanotube Biosensors Based on Electrochemical Detection. Carbon Nanotub. Methods Protoc. 2010, 625, 205–212. [Google Scholar]

- Jiang, L.C.; Zhang, W.D. A highly sensitive nonenzymatic glucose sensor based on CuO nanoparticles-modified carbon nanotube electrode. Biosens. Bioelectron. 2010, 25, 1402–1407. [Google Scholar] [CrossRef] [PubMed]

- Swamy, B.E.K.; Venton, B.J. Carbon nanotube-modified microelectrodes for simultaneous detection of dopamine and serotonin in vivo. Analyst 2007, 132, 876–884. [Google Scholar] [CrossRef] [PubMed]

- Villamizar, R.A.; Braun, J.; Gompf, B.; Dressel, M.; Rius, F.X. Morphological and electrical characteristics of biofunctionalized layers on carbon nanotubes. Biosens. Bioelectron. 2009, 25, 161–166. [Google Scholar] [CrossRef] [PubMed]

- Munge, B.S.; Krause, C.E.; Malhotra, R.; Patel, V.; Gutkind, J.S.; Rusling, J.F. Electrochemical immunosensors for interleukin-6. Comparison of carbon nanotube forest and gold nanoparticle platforms. Electrochem. Commun. 2009, 11, 1009–1012. [Google Scholar] [CrossRef] [PubMed]

- Tam, P.D.; Hieu, N.V.; Chien, N.D.; Le, A.T.; Tuan, M.A. DNA sensor development based on multi-wall carbon nanotubes for label-free influenza virus (type A) detection. J. Immunol. Methods 2009, 350, 118–124. [Google Scholar] [CrossRef] [PubMed]

- Dastagir, T.; Forzani, E.S.; Zhang, R.; Amlani, I.; Nagahara, L.A.; Tsui, R.; Tao, N. Electrical detection of hepatitis C virus RNA on single wall carbon nanotube-field effect transistors. Analyst 2007, 132, 738–740. [Google Scholar] [CrossRef] [PubMed]

- Niu, S.; Han, B.; Cao, W.; Zhang, S. Sensitive DNA biosensor improved by Lutolin copper(II) as indicator based on silver nanoparticles and carbon nanotubes modified electrode. Anal. Chim. Acta 2009, 651, 42–47. [Google Scholar] [CrossRef] [PubMed]

- Koo, Y.; Shanov, V.N.; Yarmolenko, S.; Schulz, M.; Sankar, J.; Yun, Y. Inverse-ordered fabrication of free-standing CNT sheets for supercatpcitor. Langmuir 2015, 31, 7616–7622. [Google Scholar] [CrossRef] [PubMed]

- Randles, J.E.B. A cathod ray polarogarph. Part II. The current-voltage curves. Trans. Faraday Soc. 1948, 44, 327–338. [Google Scholar] [CrossRef]

- Taurino, I.; Carrara, S.; Giorcelli, M.; Tagliaferro, A.; Micheli, G.D. Comparison of two different carbon nanotube-based surfaces with respect to potassium ferricyanide electrochemistry. Surf. Sci. 2012, 606, 156–160. [Google Scholar] [CrossRef]

- Banerjee, S.; Hemraj-Benny, T.; Wong, S.S. Covalent surface chemistry of single-walled carbon nanotubes. Adv. Mater. 2005, 17, 17–29. [Google Scholar] [CrossRef]

- Wang, Y.; Iqbal, Z.; Malhotra, S.V. Functionalization of carbon nanotubes with amines and enzymes. Chem. Phys. Lett. 2005, 402, 96–101. [Google Scholar] [CrossRef]

- Yun, Y.; Dong, Z.; Shanov, V.; Heineman, W.R.; Halsall, H.B.; Bhattacharya, A.; Conforti, L.; Narayan, R.K.; Ball, W.S.; Schulz, M.J. Nanotube electrodes and biosensors. Nano Today 2007, 2, 30–37. [Google Scholar] [CrossRef]

| Electrolyte | Layers | Rs (Ω) | CPEL (S·sn) | n1 | RL (Ω) | CPEDL (S·sn) | n2 | RCT (Ω) | ZW (S·s1/2) |

|---|---|---|---|---|---|---|---|---|---|

| 1X PBS | 100 | 67.6 | 1.7 × 10−5 | 6.7 × 10−1 | 3.1 × 103 | 8.9 × 10−7 | 9.4 × 10−1 | 1.7 × 105 | 1.4 × 10−7 |

| 200 | 65.02 | 6.7 × 10−5 | 8.0 × 10−1 | 3.1 × 103 | 8.1 × 10−6 | 8.8 × 10−1 | 3.7 × 103 | 4.0 × 10−7 | |

| 5 mM PF in 1X PBS | 100 | 69.15 | 3.0 × 10−5 | 6.8 × 10−1 | 4.2 × 103 | 1.7 × 10−6 | 1.0 × 100 | 1.3 × 103 | 3.9 × 10−5 |

| 200 | 62.12 | 4.2 × 103 | 8.1 × 10−1 | 9.9 × 102 | 1.5 × 10−5 | 8.1 × 10−1 | 4.2 × 103 | 6.6 × 10−5 |

| Device | v (mV/s) | Eps (mV) | Ipa (μA) | Ipc (μA) | Ipa/Ipc |

|---|---|---|---|---|---|

| 100-layered WE | 10 | 96 | 7.19 | 7.85 | 0.92 |

| 25 | 103 | 9.83 | 11.1 | 0.89 | |

| 50 | 108 | 12 | 13.1 | 0.92 | |

| 100 | 119 | 15 | 17.1 | 0.88 | |

| 200-layered WE | 10 | 95 | 10.7 | 10.7 | 1.00 |

| 25 | 98 | 15.6 | 16.8 | 0.93 | |

| 50 | 102 | 20.4 | 21.3 | 0.96 | |

| 100 | 111 | 26.5 | 29.4 | 0.90 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koo, Y.; Shanov, V.N.; Yun, Y. Carbon Nanotube Paper-Based Electroanalytical Devices. Micromachines 2016, 7, 72. https://doi.org/10.3390/mi7040072

Koo Y, Shanov VN, Yun Y. Carbon Nanotube Paper-Based Electroanalytical Devices. Micromachines. 2016; 7(4):72. https://doi.org/10.3390/mi7040072

Chicago/Turabian StyleKoo, Youngmi, Vesselin N. Shanov, and Yeoheung Yun. 2016. "Carbon Nanotube Paper-Based Electroanalytical Devices" Micromachines 7, no. 4: 72. https://doi.org/10.3390/mi7040072

APA StyleKoo, Y., Shanov, V. N., & Yun, Y. (2016). Carbon Nanotube Paper-Based Electroanalytical Devices. Micromachines, 7(4), 72. https://doi.org/10.3390/mi7040072